Articles

All photos from the article

In this article, we will show you how to make wooden blinds with your own hands. Considering that the price of these fashionable accessories today is high, recommendations for their self-production will be of interest to many. But, before proceeding with the manufacture, we will consider what the blinds assembled from wood are, what types of them are on the market and what are the features of the application of these devices.

Louvered grilles for interior use

Construction and main characteristics of blinds with wood lamellas

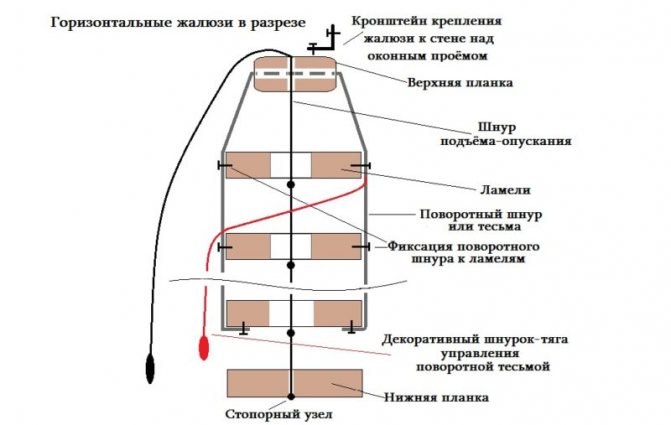

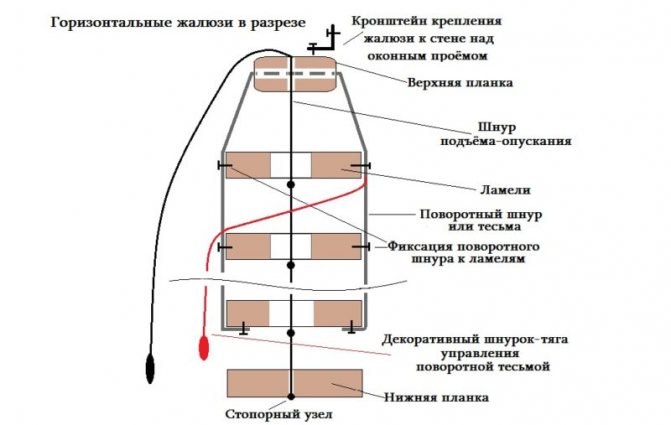

A device with a horizontal arrangement of lamellas can be divided into 3 groups of components:

- upper - upper cornice with a swivel mechanism (axle, flywheel);

- medium - a set of lamellas;

- lower - lower cornice.

These groups are interconnected by cords for lifting and lowering the blinds and synchronous rotation of the lamellas around their longitudinal axes.

One of the advantages of natural wood is the environmental friendliness of all its types, with the affordability of most of them. In addition, modern finishing technologies make it possible to imitate products from common types of wood for accessories made of valuable species.

Therefore, do-it-yourself wooden blinds are a widespread option for arranging window openings.

A bit of history ...

There is a legend that says that a Venetian jealous man invented the blinds to hide his wife from the sticky glances passing by men. Due to the lack of sunlight, the wife of a wealthy Venetian began to languish. The thought came to him - it was necessary to attach thin strips of wood, so the light began to enter the room, however, there was no way to see what was happening behind them.

Blinds have not lost their popularity to this day. Officially, the owner of the patent for the manufacture of blinds became John Hampton, on August 21, 1841. But the design patented at the time was only slightly similar to the blinds of our time.

Blinds - are slats (lamellas) horizontally or vertically placed on window openings, which are interconnected and are designed to protect from sunlight and from the intrusive glances of neighbors, and also carry a decorative function. Is this not a gazebo solution?

Lamellas (panels) are made of fabric, aluminum, plastic and wood. Wooden blinds on the windows of the gazebo will look especially harmonious, and the fact that they are made of environmentally friendly material is a huge plus. In operation, this type of blinds is convenient, and it is easy to install them.

⚠️The main advantages of wooden blinds are: durability and reliability.

Blinds are usually installed on the upper slopes, in window openings. sohow to make wood blinds with your own hands?

Self-production of wooden blinds

The work is preceded by the design part. Regardless of whether the lamellas will be located vertically or horizontally, it is necessary to decide on which side (left or right) the control cords of the device will be located - lifting and lowering and adjusting the angle of inclination of the lamellas. It depends on the location of the window opening on the wall, furniture arrangement, individual preferences of the owner (right-handed, left-handed), etc.

Horizontal lamella device

When self-manufacturing blinds, they most often give preference to just such a design, as the simplest in execution.

First of all, they are determined with the place of installation of the device, so that the size of the manufactured components corresponds to the nuances of the location.

If the accessory is to be mounted on a metal-plastic window unit, it is necessary to choose the method of attachment to the binding.

Of no small importance is the choice of finishing the blinds - depending on the technology, the decoration can be performed both before the installation of the device, and after installation.

Layout and layout of components

When making an accessory for wall mounting, the vertical dimension of the blinds must be 10 cm greater than the height of the window opening, and the width of the device must be 20 cm greater than its horizontal dimension.

Important! The maximum length of the lamellas is limited to 2.0 m, since a larger size will be accompanied by deflection of the slats, problems in the functioning of the lifting and turning mechanisms, and the width is made from 4 to 12 cm - so that the details are visually commensurate with the dimensions of the window.

With the blinds open, adjacent lamellas should overlap each other by 8-10 mm, therefore, calculating the number of slats of the required length, the size of the future device vertically must be divided by the width of one plate, reduced by these 8-10 mm.

Horizontal wooden blinds in open and closed position

Preparation of components

For the manufacture of lamellas, ready-made wooden strips of the required length and width are purchased or ordered from a pre-selected type of wood. Linden has proven itself well in this capacity - a material not only possible for decoration, but also lightweight.

Important! There are many options for the decorative design of the planks, but one preliminary operation must be performed without fail - after the end of the mechanical and abrasive processing of the planks and cornices, a protective layer of nitro varnish must be applied to them, regardless of the type of wood.

Samples of produced wooden slats for the production of blinds

It is difficult to make slats and cornices only by description, so it is better to take a closer look at the model of blinds in advance, which you can use as a sample.

Industrial-made accessories, simple at first glance, have components in their design, which are very difficult to manufacture in a domestic environment. For example, a system of swivel cords is elements made by weaving a row of cells with a fixed pitch of transverse sections. When weaving this system by hand, it will not be possible to accurately withstand the step, and the slats in the blinds will not be parallel to each other. Therefore, it is better to use another execution technology - from a braid, which will be attached to the ends of the strips located at a given pitch.

Using the webbing as a swivel cord

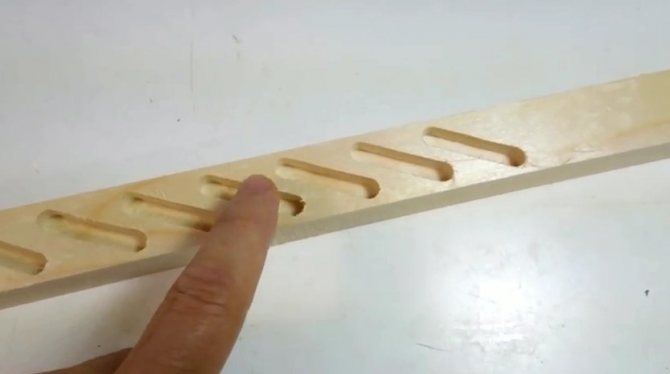

To assemble the blinds, it is necessary to pre-drill the slats, top and bottom strips.

On the lower cornice, a longitudinal axis is drawn and, stepping back 10-15 cm from both ends, one hole is made on each side - so that a cord can be threaded through them. On the front side of the cornice, the holes are countersunk - they are slightly widened in depth by 0.5 cm, in order to subsequently drown the cord knot.

On the upper cornice, the holes are made with the same distance from the edges, but in the perpendicular direction - from the front side to the back side, and the diameter should ensure free passage of the cord, taking into account the bend at the corners.

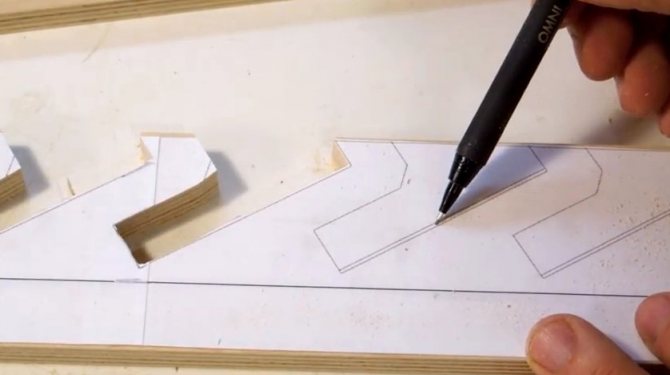

On lamellas of dots, applied in the same way, perpendiculars 1-3 cm long are laid on both sides of the axis (depending on the width of the slats). At the ends of the obtained segments (2-6 cm), holes are drilled with a diameter of 1 mm larger than the diameter of the cord.

Then the holes are connected with the help of needle files and slots are obtained along which the cord should move freely.

Execution in the lamellas of the slots for the cord lifting and lowering

There is no need to tint the cut surface, but it is necessary to cover it with a colorless hydrophobic compound (nitrolac, wax and paraffin-containing mixtures).

Watching this video will give clarity to the description of the lamella manufacturing technology:

Assembly and installation

The assembly of the device starts from the bottom bar. Two pieces of cord are cut off with a length equal to the height of the window opening plus another 0.5 m. A knot is tied at one end of each segment, after which the cords are threaded with their free ends into the holes until they are locked by knots in the countersunk holes. Stopper knots will also be knitted on them with a step equal to the width of the lamellas minus 1 cm, on top of each of which the lamellae will be successively strung.

Two pieces of tape 2-5 cm wide and a length equal to twice the height of the window opening plus another 20-25 cm are cut off. One end of each piece is attached from below to the cornice with a stapler opposite the hole with a threaded cord. Then, with a simple pencil, risks are applied to the braid with a step that is also equal to the width of the lamellas minus 1 cm. In the places where the marks are applied, the braid is attached with a furniture stapler to the ribs of the slats - also opposite the cuts made.

Conditional layout diagram of controls on horizontal blinds

After the end of fixing the braid to all the slats on the front side of the blinds, the ribbon is threaded into the holes of the upper cornice and continues to be attached to the lamellas up to the lower cornice.

After the end of fixation, a decorative lace is sewn to the braid from the back of the blinds near the first top strip, the second end of which is brought out to the front side. By pulling this element, you can turn the planks to the desired angle.

Decorative cord for controlling the angle of rotation of the lamellas

Installation of blinds on the wall is not particularly difficult. Brackets are attached to the upper cornice with self-tapping screws, along which, on the base, using a bubble level, markings are made and holes are drilled for plastic snipe, after which the device is mounted on the project site.

Blinds with vertical slats

An accessory with this orientation of the lamellas is more difficult for independent execution, since it does not use the gravity force of the slats. It is difficult to manufacture and assemble a rotary mechanism of the required design in a domestic environment, while also providing a decent level of aesthetics.

Therefore, if you want to install an original accessory in an apartment, they usually act differently - they buy inexpensive blinds and replace the slats with them, setting high-class artistic performance strips.

Variants of execution of vertical blinds

Important! When choosing an accessory in order to replace the planks, it is necessary to purchase models with a margin of safety, since installing wooden planks instead of synthetic ones will increase the load on the structure.

From newspapers

Newspaper blinds look no less sophisticated, but their production requires more time and labor. However, this is more than offset by the long service life.

Newspaper tubes can be replaced with plastic, wooden rods, or cane straw.

For one meter-high window you will need:

- about 200 colored newspaper tubes;

- scissors;

- PVA glue;

- rope or twine from nylon;

- rings - 2 pcs.

- By the size of the window, tubes are harvested from unnecessary newspapers and magazines.

- They are painted in any color with paint.

- After complete drying, the parts are evenly laid out in a row, aligned on the sides.

- The rope is tied to the ring and they begin to sequentially tie each newspaper component with double-sided fixation.

- Now it remains to mount the lifting device.To do this, make a loop on the lower and upper crossbar and thread the twine on the back of the canvas. Attach the retainer.

Types and features

The first blinds were made in the United States in the eighteenth century, but they did not gain mass distribution until a hundred years later. The development of modern technologies allows manufacturers to produce products from cheaper materials - plastic, aluminum, fabrics, but they have not been able to displace the classic wooden samples, which never lose their relevance.

Blinds are classified into two main groups.

- Vertical models, which are similar to conventional curtains, but with more functionality, regulate the flow of sunlight by simply turning the slats. They add volume, creating the illusion of the height of the room. With the help of such blinds, you can close not only a window, but also a wall with a balcony door. Most often used in residential buildings.

- Horizontal - the construction with the "ladder" system limits the flow of light using a special device. Such models visually expand the space, look good in narrow rooms. They are most suitable for decorating offices, giving them elegance.

Blinds are attached to the ceiling, free space above the window or into the opening itself using brackets or double-sided tape. A lightweight wooden structure will hold firmly if the surface is degreased with acetone before attaching the tape. Installation outside the window opening will allow you to decorate a large area, radically changing the entire design. The width of the product should exceed the opening by ten centimeters, the height is optional, but not less than the height of the window. When making blinds to the floor, it is necessary to take into account all the protrusions of the heating devices. When mounted on sashes, the width is determined by the size of the glass plus three centimeters to cover the entire area.