Reasons for repainting windows

Painting of plastic windows is carried out when renovating the interior, but sometimes painting of frames is necessary. This happens in the following cases:

- The plastic has turned gray;

- The coating has turned yellow;

- There are chips, scratches and other flaws on the surface of the material that cannot be removed in another way;

- The new design of the room requires the creation of a cover of a different color;

- Tired of the white paint, I want to change the color, having received an unusual design.

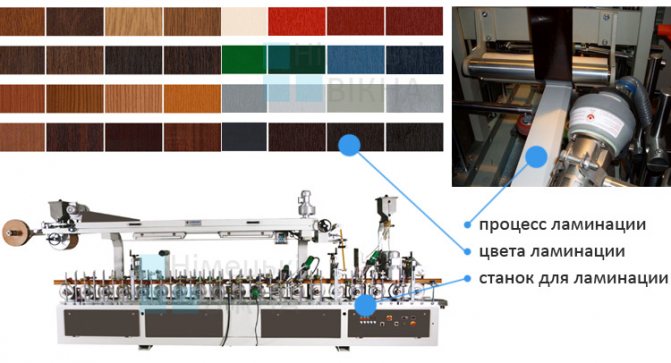

Coloring of PVC windows is not prohibited by manufacturers. The professional technique includes surface treatment with laminates. They help to obtain not only a stable color, but also protection of the material from ultraviolet radiation, moisture and other external factors. The composition is applied only with the help of specialized tools used only by specialists.

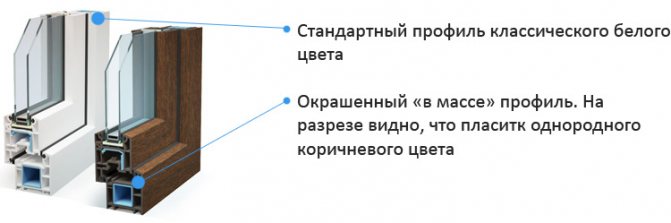

The coating can be sprayed with polyurethane paint. This is done to create brown frames that look like wood. A slightly different material is used here, different from standard PVC windows. Window frames can be painted at home by other means, which paint is suitable for PVC windows will be described below.

The professional technique includes surface treatment with laminates.

Reasons for painting window structures

PVC windows can be painted in any color that matches the interior design

During operation, defects appear on the surface of the profile - yellow spots, scratches and abrasions. The reason for negative changes is sunlight, low quality of polyvinyl chloride, the use of products with abrasive particles in the care.

Also, the need for painting arises when changing the architecture of the facade or interior of the room, the desire to make the apartment original, to give it an individual look with the help of bright accents.

Advantages and disadvantages

Among the advantages of painting windows, it can be noted that the resulting layer will close the existing defects, it can be easily washed after. It will be possible to carry out further correction of the coating quickly, it is enough just to touch up such a defect. The process is simple to perform, you can handle it yourself.

The paints presented for sale are harmless and can be safely used indoors. Usually the coating is done in one layer, this makes the consumption economical, the cost of painting will be inexpensive. The downside is the difficulty of painting areas next to the glass, although this moment is easily solved by gluing masking tape.

Usually the coating is done in one layer, this makes the consumption economical.

Painting the frame in several layers

After filling, the frame becomes smooth, which means that the paint will lie flat. In order for the coating to have a dense surface, a multilayer application is used. Painting is quite simple:

- the work surface is cleaned of dust and dirt so that fresh paint does not come in lumps;

- the composition is opened, mixed and filtered through a fine mesh.

Some masters apply paint from a can to the prepared coating, which is highly discouraged. Typically, various coating materials are sold very thick, and a thick film of paint and solvent forms on their surface. When applied, such a composition gives a thick layer that will drip and form thick accumulations of paint. Such a coating will not look aesthetically pleasing, and over time it will quickly crack.

It is not recommended to pour the entire jar into the dilution vessel. Add a little paint to get the consistency you want. You should not choose a solvent on your own, ask a consultant about which composition is recommended for this coating.

The first layer of paint is made liquid so that it penetrates into the structure of the array. Before applying a second coat to an already painted surface, the first must be completely dry. The third layer promotes adhesion to the wood. For two finishing layers, the composition is made thick to prevent drips. If droplets and accumulations of paint form, remove them with a cloth and solvent. Do not wait for the drips to dry, they quickly harden and spoil the look of the entire frame.

When painting the window frame, the brush is dipped into the vessel only half of the pile. This will protect the tool from the formation of surplus and permanent smudges. Coating begins on the side facing the street.

Note! It is best to work with several 3-4 sizes of brushes. To cover a large area - use a thick one, and for difficult areas a small one, a couple of centimeters wide. Window frames are painted with a flat brush, it creates a flat and even stroke

To keep the line straight, the brush is placed on top of the frame bar and released, allowing the brush to slide out under its own weight. Under the force of gravity, the tool draws an even, almost perfect line

The window frames are painted with a flat brush, it creates a flat and even stroke. To keep the line straight, the brush is placed on top of the frame bar and released, allowing the brush to slide out under its own weight. Under the force of gravity, the tool draws a straight, almost perfect line.

After the window is completely painted, you need to wait until the frame is completely dry. Only after the coating is completely dry, the protective tape is removed. It is worth remembering that paint should be removed from wooden windows before work.

Having familiarized yourself with the peculiarities of different coatings and the rules of application, you can paint the windows yourself without resorting to the help of specialists. When choosing a coloring composition, its characteristics should be correlated with the operating conditions of the coating.

What paints are suitable

Paint for plastic windows must have a number of properties that contribute to obtaining a high-quality result. The following necessary characteristics can be distinguished:

- Good environmental exposure. From the outside, various factors will affect the coating: sudden changes in temperature, rain, ultraviolet rays and more;

- The degree of viscosity, it is necessary to paint windows without the formation of smudges, the less fluid the paint is, the easier it will be to get an even coating;

- An ecological property, they must be safe for humans.

The best option for working at home is to use water-dispersion compounds with an acrylic base. They meet the above requirements.

They are sold only in white, therefore, to give the desired shade, you need to add a dye, it must be suitable for working with plastic. The packaging indicates - PVC coloring.

Acrylic-based paints stand out for their fade resistance, reliability and fast drying rate. They do not smell, so the work will be carried out safely.

The best option for working at home is to use water-dispersion compounds with an acrylic base.

What you need to know about paint

To paint a PVC profile, a special paint is required, which must be resistant to the influence of the atmospheric environment, namely:

- exposure to ultraviolet radiation;

- the presence of high humidity;

- sudden changes in temperature.

The choice of dyes for PVC is extremely large. The structure of paints contains various binding elements: vegetable oils, epoxy resins, and other components.However, acrylic paints based on polyacrylates and acrylic resins are most suitable for working with plastic windows.

Their advantage is as follows: they perfectly fit on a smooth plastic surface, and at the same time cover the original color of the product well. One layer of the composition is enough to qualitatively restore the surface. Only in case of significant defects, the application of a second layer is mandatory.

Drying time for acrylic paints is negligible. Another plus: they don't have a pungent odor. For homework, it is more correct to use a water-based paint (acrylic water-dispersion).

It's important to know! Water-dispersion paint is diluted with ordinary water, and this is a significant indicator when painting double-glazed windows. Paints containing alcohols, solvents, ethers have a negative effect on glass seals and can damage them.

As a rule, white paint is taken to prepare the coloring composition. It adds

pigment in a certain proportion to achieve the desired shade. Kohler should be appropriate. That is, intended for PVC surfaces.

What tools to use

The best option would be to spray the composition from a spray bottle. With it, it is easy to get uniform coloring, the process will be carried out quickly, and the paint and varnish material will not be unnecessarily consumed.

If there is no spray gun, then you can paint the windows with a brush with a width for the frame. There are paints in spray cans, you do not need to purchase a spray bottle for them, they also do a good job of spraying the substance evenly.

If you need to first remove the protective film, or the remnants of the sealant, then an ordinary spatula is chosen.

The best option would be to spray the composition from a spray bottle.

RAL color catalog for painting plastic windows

The RAL catalog, which has received worldwide recognition from domestic and foreign manufacturers, is constantly updated and supplemented. Each color has a unique number. In addition to the index, all shades are supplied with a picture with a description.

Experts offer you to choose any of more than 200 shades in the RAL catalog. A complete catalog of shades will be provided to you by the company's managers in the sales offices.

Window preparation

It is easier to paint plastic windows that have not yet been installed. In this position, the work will be more convenient. However, working with an installed window is also permissible. First, remove the protective film of the frame, remove all its particles.

After that, the entire plastic coating is washed to exclude any dirt residues. The next step will be to degrease the surface with special means, they must be suitable for plastic material.

When the surface dries out, the handles are removed, near the section of the wall, the slopes are covered with masking tape, and they also do with the window area, which should not be stained. Moving on to priming the surface, brushes with synthetic fibers are used.

Rinse all plastic coverings to remove dirt residues.

Required tools and materials

Before using the spray gun, the glass must be glued

Application of paintwork materials with a spray gun is much more efficient and faster than working with a brush. The tool provides an even coating of the surface. Lint stripes remain on the windows when using a brush.

- brush with natural or artificial flat bristles;

- spray gun;

- sandpaper;

- masking tape;

- plastic spatula;

- personal protective equipment.

You also need to buy plastic wrap to protect the glass if the painting will be done with a spray gun. When preparing the substrate, you will need a PVC cleaner and a primer.

Painting the window

They start with tinting the paint, you should immediately prepare the composition for the entire amount of work, then it will be difficult to get an identical shade. Work from the outside can take place only at temperatures from +18 to +25 degrees. Otherwise, the paint layer will dry unevenly and the effect will be smeared.

You should immediately prepare the composition for the entire scope of work.

Ideal for work would be to use a spray bottle. It creates an even distribution of the coloring composition, eliminating smudges. The workflow will go quickly. In this case, paintwork will not be unnecessarily consumed.

On the spray gun, the pressure is regulated to 2 atmospheres, when the nozzle diameter is 1.6-1.8 mm. This will help to obtain the required layer thickness, it will be enough to apply the product in one layer.

The master must protect himself if he works with a spray bottle. Wear protective goggles and a respirator.

The sprayer creates an even distribution of the coloring composition, eliminating smudges.

If brushes are chosen for work, then they are used with villi made of natural material or synthetic. Apply two layers with brushes, each must dry before applying the next. It is possible to apply a second layer of clear varnish, which will make either a matte or glossy finish. It can also be applied from a spray gun.

If brushes are chosen for work, then they are used with villi made of natural material or synthetic.

Dyeing plastic at home

It is possible to cope with the painting of plastic materials on your own, this will largely save the budget. Turning to professionals is a very expensive business. To carry out the work at home yourself, you will need to take care of your own safety by preparing protective equipment, also prepare all the necessary tools (listed above), and perform all stages of the work. They will be discussed in detail later.

It is possible to cope with the painting of plastic materials on your own, this will largely save the budget.

Painting methods

The paint coat is available either in cans or in aerosols. Which option to choose depends on the size of the product and the experience of the person who will carry out the painting work.

- Spray cans are more appropriate for a small object of painting, it is not difficult to work with them, but before starting, you should try it by sprinkling a little paint on an unnecessary surface, this will help you understand how best to spray in order to get the desired result. In general, the aerosol method will give a good even coverage. This method does not allow mixing tones, and thus you will not be able to apply clear color boundaries.

- A can of a larger volume than a can, but storage in it is possible only for a short time. For this reason, it is more often used for a large amount of work. It should also be taken into account that working with a brush is much more difficult and requires skill. Otherwise, an ugly trace of bristles may remain on the product, and stains, the coating will be uneven and aesthetically unkempt.

The use of a spray gun can facilitate the process; a roller is rarely used. For a beginner, the spray method will be more suitable.

Preparing plastics for painting

As mentioned earlier, you should carefully prepare the product before starting work in order to get an excellent result. This stage includes the following steps:

- Get rid of the previous cladding, you can use sandpaper, solvent, construction hairdryer.

- Get rid of contamination.

- The product must be degreased using a solvent.

- Treat the product with an antistatic agent.

- If required, apply a putty.

- To ensure good adhesion, the surface is treated with no more than 180 sandpaper, after the completion of this stage, the object is again cleaned and dried.

- Degreasing is carried out again.

- Carry out priming work, if required.

- Rub and clean again.

The product must be degreased using a solvent.

Plastic dyeing technology

Having chosen the type of coloring agent, it is worth understanding the method of work. The article will discuss two technologies: painting with a brush, and application with an aerosol.

They work with a brush, making wide straight strokes, initially move the brush gently, then press harder, so the coating will become thinner, and the finishing stroke is also done softly to align. If everything is done correctly, then a one-time work with a brush is enough.

General recommendations:

- The brush should not be dipped whole, the tip is enough;

- You should strive to make the layer as thin as possible by pressing on the bristles;

- Maintain the slope of the working position of the hand

They work with a brush, making wide straight strokes, initially move the brush gently, then press harder.

Spray operation process:

- They put the product on a flat surface, for example, on a chair, mark the part to be painted with paper tape, close the lying objects (with film, newspaper, paper);

- You must first shake the aerosol;

- There should be 20-30 centimeters to the subject;

- Spray paint smoothly in one layer, keeping the balloon straight;

- For complete staining, it is worth making two or three layers;

- Wait for the time indicated on the package between the application of layers until it dries;

- After completing the work, the tape is immediately removed.

Once dry, you can varnish the item to increase durability. Acting in the same way as when painting.

Spray paint smoothly in one layer, keeping the balloon straight.

Plastic paint is a great option to freshen up old items and give them new life. The presence of a wide variety of colors allows you to come up with various solutions for decoration. Before painting the plastic, they include all the imagination, they take the tools necessary for this process, as a result, you can perfectly decorate your home yourself.

Colored plastic windows: solution options

If it is decided to paint the window frame in a different color in an apartment building, then it must be borne in mind that in some architectural objects this may be prohibited. Therefore, this moment requires approval. From the inside, the owner can paint the frames in any color.

In order not to be mistaken in the selection of shades and successfully combine it with the general interior. You can use the RAL palette, which can be easily found on the Internet.

Manufacturers immediately release windows that look like wood. The price for them is higher than for ordinary white ones. But they look presentable.

A new trend has become the painting of windows in black, it looks luxurious. In this case, you can get a matte, glossy and metallic effect.

From the inside, the owner can paint the frames in any color.

Do-it-yourself painting of windows is a simple process. The main thing is to approach the choice of paint for a given purpose with special attention. Then it will not be difficult to get a high-quality and durable result. It is more convenient to work with the material using a spray gun, it will help to obtain uniform coloring and save time.

Criteria for the selection of CM for painting PVC windows

To paint plastic window structures, you need a composition that meets certain requirements:

- resistance to negative environmental factors: fluctuations in temperature, humidity, UV rays of the sun. It should be borne in mind that such influences are constant from the outside and only resistant paint will cope with them;

- uniformity of application of CM, without gaps and accumulation in one place. Such a coating is possible with the optimal viscosity of the CM;

- high drying speed is the key to the attractiveness of the coating. Dust, dirt particles will not have time to adhere to a new layer of dye;

- the absence of harmful, toxic components characterizes the paint as an environmentally friendly material.

Rating of the best window paints for 2021

Acrylic

Akvest - 18, Master, 1.2 kg

Semi-matt water-based paint intended for covering wooden windows. Stir thoroughly before use and, if necessary, dilute with water in a volume of no more than 5% of the total mass. It is applied exclusively on a clean surface in one or two layers. At the same time, the ambient temperature should not be lower than +5 degrees.

Application methods:

- brush;

- roller;

- spray.

Consumption directly depends on the type of base. On average, the indicator is 120 - 150 g / m2. It is advisable to apply a second layer, but not earlier than one hour later, if the room temperature is +20 degrees and the humidity is about 70%. The product is stored closed at temperatures above 0 degrees for no more than one year.

The average price is 280 rubles per unit.

Akvest - 18, Master, 1.2 kg

Advantages:

- ease of application;

- dries quickly;

- durable;

- budgetary cost;

- benign;

- does not contain toxic components;

- the ability to complete the repair in a short time.

Disadvantages:

- significant are not established.

Svyatozar - 31, semi-matt white

The Russian manufacturer produces high-quality paint with a semi-gloss degree of gloss. Packing - from 30 to 40 liters. The product is bright white for painting windows and other wooden facade elements. Can be tinted in pastel and bright colors. There is an opportunity to choose an individually colored paste "Svyatozar". Average consumption - 250 - 300 g / m2, provided that it is applied in two layers.

The product can be ordered online from an online store, or purchased at a specialized outlet. How much is? On average, 8224 rubles.

Svyatozar - 31, semi-matt white

Advantages:

- quality;

- reliable;

- durable;

- not afraid of water, mildew and mold;

- fit well on any surface.

Disadvantages:

- volume in the package.

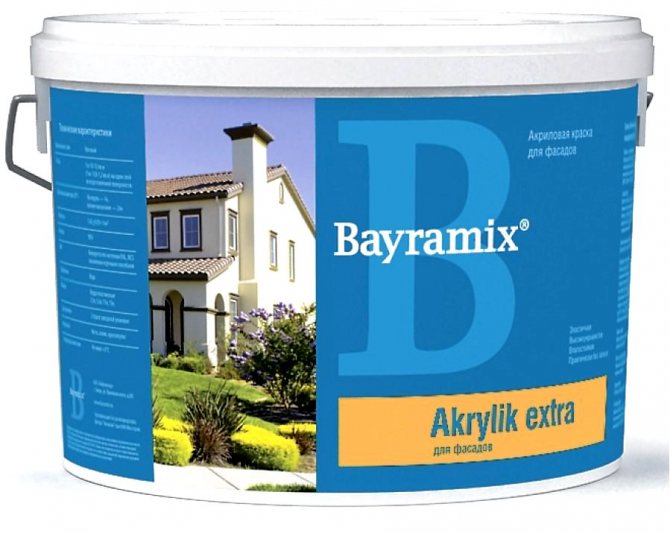

Akrylik Extra, 9 liters

Solid white matte composition of the universal plan on an acrylic base. The main quality is essential moisture resistance. Release form - cans with packing of 9, 2.7 and 0.9 liters. Tinting is provided. In addition to wood, it can be applied to any mineral base, including gypsum plaster, asbestos cement, fiberboard, chipboard, drywall, concrete, plywood.

It is applied on a clean and dry surface at a temperature of at least +5 degrees. If old coatings are present, then they are carefully removed, the defects are putty, then primed using Astar primer. Before applying the first layer, the composition can be diluted with water in a volume of no more than 10%, subsequent layers are applied without dilution. Application assistants include a roller, brush or spray.

Average consumption is 1 liter per 0.9 - 1 sq. M. It dries completely in a day if the room temperature is +24 degrees and above, and the relative humidity does not exceed 65%. After using the instruments, they are thoroughly washed and dried. The paint is stored in a cool and dry room at a positive temperature.

The product can be purchased at a price of 3850 for 9 liters.

Akrylik Extra, 9 liters

Advantages:

- vapor permeability;

- environmentally friendly;

- easy and high quality applied;

- moisture resistance;

- hiding power indicator;

- the film is smooth, without flaws;

- adhesion index;

- the smell is practically absent;

- can be washed with special products;

- subsequent disposal;

- shelf life.

Disadvantages:

- significant are not established.

Dali / 6 5 kg

The paint consists of an active antiseptic, titanium dioxide, water, filler, acrylic dispersions, special additives. For application, use a spray, roller or brush. Dilution with water is allowed. It is used at temperatures above +10 degrees. Apply at least two layers. Average consumption - 1 kg per 10 sq. M. (in one layer). It ceases to stick in an hour, you will have to wait five days until it dries completely.

Tintable in manual mode. The base is white.The service life is 6 years for external coating and 7 years for repairs inside the building. Tools are cleaned with warm water. It is used for painting wooden surfaces, as well as concrete, plywood, brick, plasterboard and others. There is no question of where to buy the product. It can be purchased at any specialty store at a price of 409 rubles.

Dali / 6 5 kg

Advantages:

- convenient packing;

- low consumption;

- durable;

- ease of use;

- applied to any type of surface;

- good value for money;

- recycling does not cause any problems.

Disadvantages:

- significant were not identified.

Zobel Deco - tec 5450 B Ral 6011, 1 l

The German manufacturer produces high quality products with a silky matte sheen. The color palette is impressive. You can choose a shade for every taste. It is supposed to be applied in two layers. Designed for exterior and interior decoration. Refers to a new generation product that meets modern European standards. Environmentally friendly product, which contains no organic solvent. Experts advise using paint not only for residential buildings, but also for playgrounds.

Significant hiding power makes it possible to make the coating opaque. Packaged in a metal container of 20, 5 and 1 liter. Apply by spray or brush. Each layer is dried for at least four hours.

The average cost of a product is 1233 rubles.

Zobel Deco - tec 5450 B Ral 6011, 1 l

Advantages:

- not afraid of ultraviolet rays;

- resistance to humid environment;

- resistance to temperature extremes;

- easy to use;

- application area;

- complete safety;

- ecological cleanliness;

- lack of smell;

- full compliance with European standards;

- structure;

- no volatile organic solvents.

Disadvantages:

- significant are absent.

Alkyd

Pinotex Ultra

High-strength protective impregnation, produced using AWB technology, has a long service life - up to 8 years. Does not lose its original properties under rain, snow, bright sunlight and severe frosts. Contains active additives against algae and mold. Easy to apply, quickly absorbed, forming a semi-glossy film.

No dilution is required. It is applied with a brush on a clean and dry surface, the first layer dries for 24 hours. You can buy nine ready-made colors or make 36 different shades. Stored in a cool dry place.

The average cost is 833 rubles per unit.

Pinotex Ultra

Advantages:

- long service life;

- ease of application;

- high-quality protection against UV radiation;

- the composition contains active additives against mold and algae;

- the presence of biocorrosion protection;

- can be washed with cleaning agents.

Disadvantages:

- significant were not identified.

Tikkurila Empire, 0.225 L

Used exclusively for interior work. She is covered with wooden surfaces of furniture, as well as plastic or wooden windows, metal radiators, wood fiber boards. Can be tinted according to the Tikkurila Siphonia catalog. It is applied on a dry base at an average air temperature of at least +5 degrees. Consumption parameters - 1 liter per 10 - 12 sq. M.

The average price is 393 rubles.

Tikkurila Empire, 0.225 L

Advantages:

- evenly applied;

- dries quickly;

- no smudges;

- there is practically no smell;

- tinting in 20,000 shades;

- the opportunity to bring to life the most daring design ideas;

- durable;

- the presence of a restrained gloss.

Disadvantages:

- significant are not established.

Teknos Futura 3, 9 l

Universal product for wood flooring. It can be used for both indoor and outdoor work. The main feature is impressive adhesion to glass, tiles, PVC - plastic, aluminum and galvanized. The paint does not allow mold to grow.Can be used in kindergartens, hospitals, food industries.

At a temperature of +23 degrees it dries up in two hours, it is advisable to apply the next layer after six hours. A spray, roller or brush is used. One liter is enough to paint 8 - 10 sq.m. surface.

The average price is 8031 rubles.

Teknos Futura 3, 9 l

Advantages:

- long service life;

- reliable;

- effective;

- high quality;

- economical.

Disadvantages:

- significant are absent.

Yaroslavl paints, 0.8 kg

A Russian-made product intended for painting wooden windows. White glossy enamel is sold by the manufacturer at a negotiated price, based on the volume of the order. Average consumption - 1 liter per 9 sq.m. Suitable for previously painted and primed surfaces.

Yaroslavl paints, 0.8 kg

Advantages:

- does not leave smudges even on a vertical surface;

- can be applied with a roller, spray or brush;

- does not lose its qualities for a long time;

- easy to apply;

- there are no toxic substances in the composition.

Disadvantages:

- there is an unpleasant odor, therefore ventilation of the premises is required.

Olecolor, 0.9 kg

High quality alkyd enamel is used for painting window frames made of wood. Produced by a Russian company that has proven itself on the positive side. There are no complaints about the quality of its products. Consumption of the composition - from 80 to 100 per 1 sq. M. The best option is two layers.

Price is negotiable.

Olecolor, 0.9 kg

Advantages:

- used for both internal and external work;

- insignificant consumption;

- ease of application;

- lasting shine;

- high whiteness;

- good elasticity and flow.

Disadvantages:

- there is a smell.

Alpina Fenster und Tur, 0.75 L

The German company produces high quality products at affordable prices for coating wooden surfaces. Recommended for chipboard, MDF, fiberboard and so on. Apply by spray, brush or roller. After three hours it does not stick to hands, after six hours it can be reapplied.

The average cost is 1038 rubles.

Alpina Fenster und Tur, 0.75 L

Advantages:

- high moisture resistance and weather resistance;

- high drying speed;

- resistant to mechanical damage;

- does not lose color fastness for a long time;

- excellent adhesion;

- washable with household chemicals and detergents.

Disadvantages:

- slight odor.

Brite Fensterlack, 075 l

The product is manufactured by a Russian company. It is very popular with specialists. Used for indoor and outdoor use. Base - alkyd-urethane, color - white. Belongs to the category of universal. Both wood and metal surfaces can be painted. Complete drying takes place after eight hours. Apply by roller, spray or brush.

The average price is 399 rubles.

Brite Fensterlack, 075 l

Advantages:

- well distributed over the surface;

- can be opened in one layer;

- does not form sags and smudges;

- forms an elastic film;

- not afraid of water and detergents.

Disadvantages:

- slight odor.

Oil based

Prestige MA - 15, 0.8 kg

A good option for painting wood and metal surfaces. Not afraid of heating up to 100 degrees. Complete drying time - 12 hours. The composition includes linseed oil based on vegetable oils of the highest grade, fillers, metallized pigments, various additives. The products are ready to use immediately after thorough mixing.

If thickening occurs, it can be diluted with white spirit or kerosene. The base is pre-cleaned from dirt and dust and degreased. For application, use a spray or brush. Stored unopened in a cool dry place. Do not allow interaction with fire, do not allow children to play.

The average price is 174 rubles.

Prestige MA - 15, 0.8 kg

Advantages:

- durable;

- reliable;

- attractive;

- inexpensive.

Disadvantages:

- after painting, the room must be ventilated.

Kazachka MA - 15, 1.9 kg

High quality drying oil was used in the manufacture of the product. It is recommended to apply in one or two coats. Consumption - from 160 to 200 g per 1 sq. M. White spirit or solvent is used as a solvent. The period of complete drying is a day. It is applied at temperatures from +5 to +35 degrees. The shelf life is one year from the date of manufacture.

The product can be purchased from the manufacturer at a price of 227 rubles per item.

Kazachka MA - 15, 1.9 kg

Advantages:

- weatherproof;

- not afraid of water;

- retains its original properties for a long time;

- excellent wear resistance;

- budget cost.

Disadvantages:

- afraid of high temperatures;

- does not have anti-corrosion properties.

Lakra MA - 15, 1.9 kg

The products are made on the basis of linseed oil. Ready to eat. Both wooden and metal surfaces can be opened. Requires preliminary preparation: the metal base is cleaned of rust and scale, old paint is removed from the wooden one, plastered, impregnated with drying oil. Stir thoroughly before use until a homogeneous mass is formed. If necessary, dilute with white spirit. Apply by spray, roller or brush.

Not afraid of dust after 12 hours, a day should pass before it dries completely. Store no more than a year and a half from the date of manufacture. Consumption - 1 kg per 5 or 10 square meters, depending on the quality of the surface. It is advisable to protect from direct sunlight, moisture, heat sources.

Average price - 227 rubles.

Lakra MA - 15, 1.9 kg

Advantages:

- easy to apply;

- leaves no smudges;

- does not lose brightness;

- acceptable cost.

Disadvantages:

- significant were not identified.

Tikkurila Teho

An excellent product for protecting window surfaces from snow and rain. Does not fade in direct sunlight, is not afraid of mold. The white base can be tinted with any shade. Gloss degree - semi-gloss. Consumption - 1 liter for 8 - 10 sq.m. It is worth using at a temperature of +5 degrees. Apply with a brush. Dries up in a day at a temperature of +23 degrees. Can be stored and transported at subzero temperatures, without loss of basic qualities. Started paint can be stored for a long time with the lid tightly closed.

The average cost is 1049 rubles per item.

Tikkurila Teho

Advantages:

- perfectly covers the surface;

- dries quickly;

- leaves no smudges;

- good wear resistance;

- intended for internal and external work;

- a huge selection of colors;

- dirt is washed off with cleaning agents.

Disadvantages:

- will not be stored for a long time with a loosely closed lid.

Tikkurila Valtti Color Extra

Mainly used for outdoor use, protecting wood from negative weathering. Gives windows an impeccable appearance, successfully protecting them from snow, rain, direct sunlight. Glossy shine lends a certain charm. You can make 40 different shades. Diluted with an alkyd solvent 2010. Dries up after 24 hours at a temperature of +24 degrees. Application by brush or spray is provided.

The average cost is 929 rubles.

Tikkurila Valtti Color Extra

Advantages:

- high-quality protection from snow and rain;

- tolerates UV radiation well;

- durable;

- convenient to use;

- variety of shades;

- a good combination of price and quality.

Disadvantages:

- significant are not established.

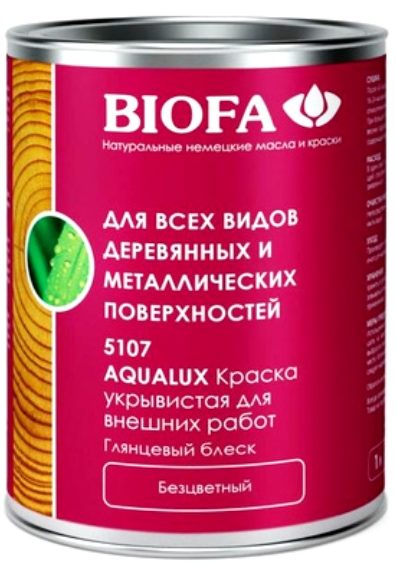

Biofa 5107 Aqualux

Paint with excellent hiding power for external work. It is applied by spray, brush or roller, giving the surface a semi-glossy shine. One liter is enough for 12 sq.m. in one layer, and 6 sq.m. in two layers. The base is colorless, tinting is carried out according to the catalog. Refers to the type of water-soluble. Dries up within 24 hours. When working with metal surfaces, there is a need for their pretreatment.

Retailers offer products at a cost of 3080 rubles per unit.

Biofa 5107 Aqualux

Advantages:

- the presence of water and dirt-repellent qualities;

- completely safe;

- can be used in children's rooms;

- meets all European quality standards;

- high adhesion;

- excellent covering ability;

- permanent elasticity;

- not afraid of moisture and significant temperature changes;

- long service life;

- easy to use.

Disadvantages:

- with significant heat exposure, a slight yellowness may appear.

Is lamination an alternative to painting?

In addition to the actual paint and primer intended for plastic frames, the window can be pasted over with a special film - laminated. The film can be either plain or covered with patterns. In this case, before application, the surface is cleaned and covered with an adhesive composition. Alternatively, ultraviolet light can be used, which fuses the film to the window surface.

The method is attractive, but at the same time unsuitable for an ordinary person at home. The thing is that the lamination of windows is done at the factory using special equipment with rollers configured as needed. Manual application of the film in most cases will not do without defects. In addition, for this it is necessary to dismantle the fittings, and sometimes the glass unit, which is too laborious. So it's better to paint the window anyway.

How to paint a PVC window sill with your own hands

The first is to visually assess the evenness of the surface, identify chips, cracks, and other defects. Now you need to wash the surface, including the joints with window frames, dry well.

After preparation, the algorithm of actions is as follows:

- Cover the frames with masking tape so as not to stain them with paint. If possible, it is recommended to remove the sash by installing the window sill after drying. It is impossible to remove, seal with tape as high as possible, not forgetting to protect the glass. Protection is especially needed if an aerosol is used - a dispersed substance tends to settle on all surfaces.

- Clean the surface of the window sill from glue, grease, pieces of film. If the plane was previously painted, remove the decor with a special wash for PVC window sills.

- Treat the surface with a primer. The composition can also be selected for PVC surfaces. Impregnation is also useful - the price of the compositions is high, but the coatings provide excellent adhesion, besides, the paint then lays down much smoother.

Expert opinion Vladislav Ponomarev Design engineer, inventor

The primer must be applied after cleaning the surface from dirt. The window sill is treated with impregnation before applying a layer of paint, that is, after sealing the defects. If there are no defects, you can immediately process the washed and dried surface.

- Defects - chips, cracks, cover up with putty. Before sealing the area of chips and cracks, clean it with medium-sized emery. After the place of restoration, dry it, grind it with fine emery - the plane should be perfectly flat.

- Treat the dried leveled window sill with impregnation. Treat generously, but without leaving puddles of the composition. Be sure to dry the surface before painting.

Now it remains only to paint the window sill with the selected composition and dry it. It is best to let the paint dry naturally. For aerosols, the period is up to 4-5 hours, other mixtures dry up to 9 hours.

Loading ...

Water-based acrylic paints

This is a fairly popular paint for wooden windows. It has high technical characteristics, the price of the material makes it affordable for buyers. The main substance is acrylic resin diluted with plain water. The paint is odorless, well suited for wood products, does not emit harmful substances.

The positive properties include the economy of paint, the ability to dry quickly, the ability to form a plastic coating, due to which the paint layer is not disturbed by temperature extremes. If you use colors, you can get any desired shade. In the sun, the paint does not fade, does not lose color saturation. The material is not afraid of low temperatures, moisture, suitable for use both outdoors and indoors.

acrylic water-dispersion enamel for windows

Window frame paint can also contain other additives that increase its performance, for example, various antiseptics to combat fungi and mold. With the addition of certain components, the material can become a serious obstacle to fire.

When covering the frame with fire retardant, cover other window components with it; do not forget about the window sill, slopes, other structural elements, which also consist of wood and may be damaged in case of fire.

If the window includes metal elements, you cannot use paint designed for wood on them. For them, you should choose a similar one, but designed specifically for metal structures. For example, Polistil can be attributed to high-quality fire retardant paints.

Colors for acrylic paint