Product design

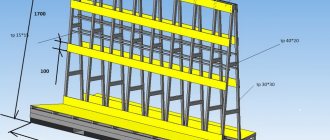

A sealed glass unit can be made by hand

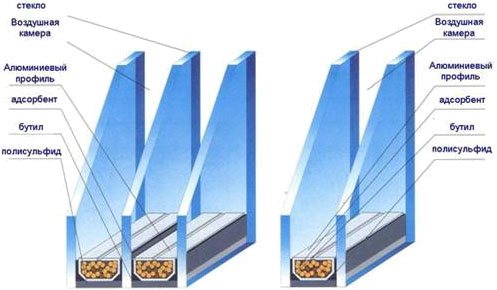

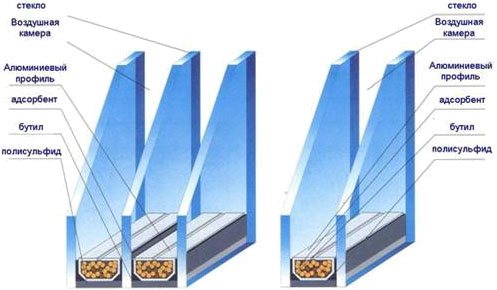

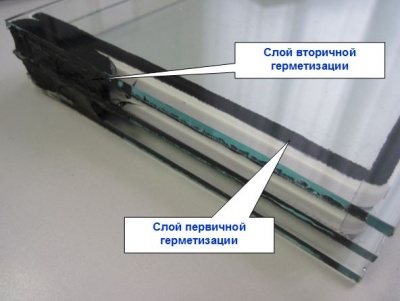

An installation of a sealed type, which consists of two or more glasses, is called a double-glazed unit. Inside, it is divided into chambers filled with air. The main component of the design is the distance frame. It prevents condensation from forming inside. During the manufacturing process, it is necessary to maintain the distance between the glasses.

The internal components are as follows:

- canvas;

- space;

- profile frame;

- molecular sieve - it is made of a material with drying properties, designed to protect against condensation;

- sealed components.

Double-glazed windows are divided into three types:

- single-chamber;

- two-chamber;

- three-chambered.

The difference between them lies in the amount of glass and density. The first option is rarely used for finishing residential premises. It has a low level of sound insulation and thermal conductivity. The only exception can be glazing of balconies and loggias. Their main advantage is their low weight, which facilitates the installation process.

Double-glazed windows are suitable for installation in residential premises. They consist of three glass panes and two air layers. They are characterized by high noise insulation.

Glass cutting

One of the main and most important procedures is glass cutting. Moreover, in this process, not only accuracy is important, but also the preservation of the structure of the material being cut, as well as ensuring smooth edges of the fault. The fact is that in the process of cutting, microcracks are formed on the glass, which have the ability to "self-heal" rather quickly. As a result of such a feature, if you hesitate, you can tolerate a marriage, therefore, with a high-quality cutting, the break should be performed immediately after the cut.

Today, this process is fully automated, so the manufacturers of insulating glass units have managed to improve the quality. Cutting is carried out on special CNC panel saws and special air cushions for glass sheets. In addition, to prevent chipping, the cutting line is immediately and automatically treated with a low viscosity lubricating fluid. Thanks to this, the process of "self-healing" of the glass is significantly slowed down, and it is possible to achieve perfectly even breaks without chips.

Required tools and materials

Components and materials for the manufacture of a glass unit

To start work on the manufacture of a double-glazed window at home on your own, you need to prepare:

- a sheet of paper with a pencil;

- hacksaw for metal;

- aluminum spacer;

- corners for connecting the frame;

- silicone gel;

- butyl tape, it can be replaced with transparent double-sided tape;

- sealant;

- painting knife;

- folding rule.

The frame, at the request of the owner, can be made of aluminum, wood or plastic profile.

Correct measurements

For the manufacture of a conventional double-glazed window, you need the height and width of the window.

Before you start making a double-glazed window at home, you need to correctly determine all the parameters. Their removal is carried out from the inside and outside. It is important that the depth of the opening is correctly determined. It is especially necessary to make measurements in a panel house. There are often cases when the opening is significantly skewed. This is due to the fact that slabs and blocks are used already in a cast form.

Most of the windows are fitted with ledges. In construction, they are called quarters.By standards, their length is 6.5 cm, 1/4 brick. A correctly measured window structure should be 1.5 cm higher than the bottom of the quarter so that a drain can be installed under the frame. The window extends no more than 1.5 cm beyond the upper quarters, and 4 cm beyond the side quarters.

The frame must not touch the opening itself. A gap of at least 4 cm is left between them for pouring the polyurethane foam.

When measuring, it is necessary to take into account the place for pouring the polyurethane foam

You need to start measurements from the outside. Three centimeters are added to the width of the slope. The width of the PVC profile structure should be greater than the opening indicator and a quarter. During installation, the window itself rests on the slopes.

To determine the height of the product, you need to measure the distance from the edge of the upper quarter to the base. Subtract two centimeters from the resulting size. The result will be a place for the assembly seam.

If the window will be mounted with an ebb, the vertical measurement must be removed from another 4 to 6 centimeters. This distance will go to the base profile.

The technology of installing a wooden window into a brick or concrete building

Stage number 1. Analysis and preparation of the opening. The window opening must have a clear geometry. To do this, all faces are checked using a level. Surfaces are cleaned of debris, irregularities are removed.

Stage 2. Installation and fixing of the window block in the opening. The frame is fixed with dowels or self-tapping screws, but, in no case, nails or polyurethane foam. The distance between the fasteners is 70-80 cm.

Stage number 3. Sealing. A double-glazed window can lose its properties if there are gaps between the frame and the box, therefore, sealing with a sealant is a mandatory installation moment. A compression tape is used as a sealing agent.

Stage number 4. It is imperative to carry out measures aimed at the vapor barrier of the structure.

Stage number 5. Elimination of cracks and holes. The final step is foaming the holes. Polyurethane foam will help to avoid the ingress of cold air, dust. After hardening, the foam is cut off with an assembly knife. From the outside, in order to avoid the destruction of the foam during operation under the influence of natural factors, they are sealed with tape, mounted cashing or plastered.

Stage 6. Installation of the window sill. The board must be made of hardwood (oak, beech).

The user chooses the dimensions and design of the window sill. However, it is worth remembering that the window sill should not protrude more than 5-6 cm. If you want to expand the structure, then it must be strengthened.

Stage 7. Installation of platbands and ebbs. Platbands are designed to mask the seams and give the window an aesthetic appearance.

Ebb tides are mounted to drain moisture and condensation. They are usually made of steel or aluminum.

Features of making a double-glazed window with your own hands

To make a PVC frame with your own hands, you will need special equipment for the plastic joint

The window production process must start with the frame. To fix it, you need corners. It is recommended to purchase them together with the profile to fit the width. It is often a problem to get fasteners of the same size. If they are much smaller than the profile, purchase twice as much and install them in pairs.

As soon as the structure is assembled, silica gel is poured into the grooves. These are small granules that absorb moisture. The procedure is done as follows:

- put on a corner at one end, and pour granules into the hole, a quarter of the volume should remain empty;

- close the open edge with a corner;

- connect the parts already filled with desiccant.

Before starting the manufacture of a double-glazed window, you need to make measurements:

- take the finished frame, measure the height and width along the inner edge;

- subtract one centimeter from each parameter.

The next step is to start cutting the aluminum profile. Using a hacksaw for metal, you need to cut 2 pieces for the vertical posts and two for the horizontal strips.

All measurements and cuts must be as accurate as possible.

The glass must be degreased before making the bag.

The glass must be cut correctly, if there is no suitable tool at hand, it is best to contact a specialist. You can buy a ready-made part in size right away in the store. If the work is carried out on a large surface, you need to purchase a roller quick cutter.

The work process is as follows:

- Pre-prepare the table, it must be large and even.

- Cover with a thick cloth.

- Using a long ruler, cut out the glass to the desired size. They must be at least 4 mm thick.

- Prepare the surface as much as possible. It should be perfectly clean. To remove dirt, use window cleaners, soft sponges, alcohol and solvents. The edges of the glass must be degreased.

To prevent the glass unit from fogging up, granules are poured inside to absorb moisture

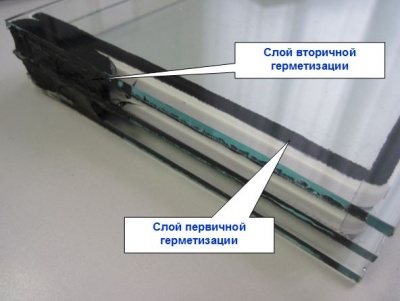

As soon as the frame and elements of the glass unit are ready, you can start assembling:

- The edge of the frame is glued with double-sided transparent tape.

- The protective layer is removed from the frame.

- A second glass is applied to it from above.

- The outer end is filled with polyurethane sealant; this must be done using a special spatula.

- Wait at least 12 hours, then remove any residual sealant and sand the surface.

The process is repeated on the other side. Craftsmen often use butyl tape instead of scotch tape. It adheres instantly, immediately after that the glass can be glued.

If the double-glazed window is two-chamber, you need to make two frames. The method is the same. As soon as both halves are ready, the glass is placed on the table, the film is removed from the profile end. The structure is treated with butyl.

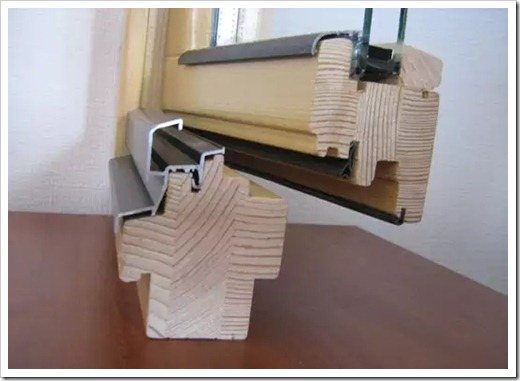

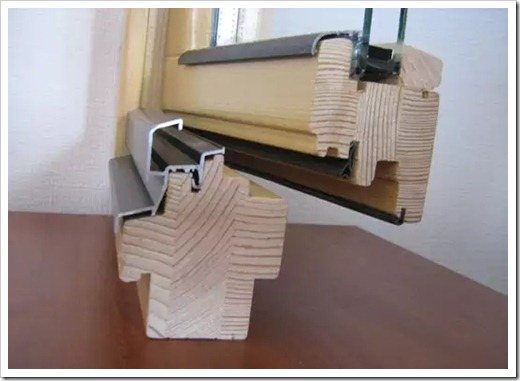

Wooden windows

Wooden frame for double-glazed windows

An insulating glass unit can also be made for a conventional window frame that is already installed. To work with wood, you will need to additionally prepare:

- double-sided mounting tape;

- plasticine or sealant;

- hardener;

- glass cleaner;

- catalyst.

You can make your own sealant. This will require:

- wiper;

- synthetic paint;

- methyl ethyl ketone peroxide, previously it is dissolved in dimethyl phthalate.

The amount of sealant depends on the size of the glass and the size of the mounting tape. To cover a square meter of glass with tape 1 mm thick, a liter of substance is required.

For cooking, you need to take a plastic volumetric dish, combine all the components, add a hardener. Mix everything thoroughly and leave for 20 minutes.

Working with glass does not differ from the process of manufacturing a structure in plastic windows. It should be perfectly clean.

After washing, dry the surface with a paper towel or newspaper.

Further it is necessary:

- Paste the glass around the perimeter with mounting tape, after removing a layer of film from it, small gaps of 2-3 mm are made at the corners.

- Attach the second piece, aligning the edges precisely.

- Squeeze the glasses so that the tape sticks.

- Pour the prepared substance between them.

- Remove the excess part of the mounting tape.

If bubbles appear inside, you need to remove them with a syringe. Finally, seal the structure around the perimeter, leave to dry for several hours. Insert the finished product into a wooden frame. There are two ways:

- Just like ordinary glass. To do this, you need to expand the grooves, put the bag and fill it with sealant around the edges.

- Stick it in as a spacer.

In the second case, the structure should be smaller in size than the opening.

Installation and adjustment

Installation of a double-glazed window into a wooden frame

For installation, the product is brought into the opening, placed on support blocks and aligned horizontally. Holes are drilled in the frame for driving anchor bolts into the wall. This is the most reliable method, but the most difficult one. Installation can also be carried out using anchor mounting plates, which are attached to the profile and then to the wall. This is a faster method, but when performing it, it must be borne in mind that the structure may sag or twist due to a strong wind load.

There are certain nuances in the placement of the window in the opening. If the wall of the house is made of brick or concrete, the frame deepens by 2/3 of the internal thickness of the opening. In case of additional finishing with foam plastic, the fastening must be done before the insulation layer. The process is carried out in the following sequence:

- Insert the frame along the level, fix it.

- Hang the shutters, adjust their work, check the mechanisms.

- At the end, the window is tightly closed, the gaps are sealed with polyurethane foam.

It is important to protect the material from direct sunlight as it degrades. After the foam dries, it remains to whitewash the slopes on both sides. The structure can only be opened a day after installation.

Making a double-glazed window at home is a simple process that anyone who is familiar with the nuances can easily handle.

Video

By making a do-it-yourself double-glazed window in a wooden frame or metal profile, you can save some money on repairs. In addition, this method gives you the opportunity to show your design skills - glass can not only be tinted, but also painted like a stained glass window.