Articles

All photos from the article

Recently, summer residents have been trying to build two and even three-story houses, since they save space on the site and at the same time are quite comfortable for living. One of their advantages is the ability to equip a wooden balcony with your own hands, which will provide housing with even more useful space. This article is devoted to this topic, in which we will take a closer look at the process of building a wooden balcony.

Wooden balcony

Pros and cons of a balcony

The absence of a balcony in a private house can cause the whole structure to be perceived as an unfinished building. It is a decoration of the facade and an ideal place for spending time outdoors... But this is a complex structure, for the construction of which a certain number of requirements are imposed, and the most important among them are: ensuring the integrity and unity of the entire structure.

Among the positive aspects are:

- A balcony is a great opportunity to give your home a unique, inimitable look. Beautiful, individual and unusual designs will decorate any private house and give it a complete look.

- A balcony extension is an additional area that can be used as a place for relaxation, entertainment or even a work space. If the balcony is installed above the terrace, then this will help to visually divide the house into two parts, which will visually increase the volume of the entire building.

- The balcony extension is an emergency exit during a fire.

- A balcony is not a cheap pleasure, but in some cases its installation can be profitable. Installation of a balcony in a country house, where there is a terrace or bay window, will help save on the roof: its role will be played by the base of this structure. The balcony also acts as a roof over the entrance to the house, which becomes a reliable weather protection.

But, despite the rather large number of positive aspects, there are negative factors:

- The presence of a balcony is the reason for heat loss. Very often this is due to the door installed on the balcony and thermal bridges inherent in the cantilever structure. As exceptions in this case, structures with autonomous supports can act, but their installation requires significant cash costs and significant space.

- The construction of this structure is notable for the complexity of the development of project documentation and installation work. Before the construction of such a facade structure, it is required to carry out a fairly large number of calculations related to the determination of the loads that it will experience on itself, and the installation process itself requires certain knowledge and skills in this construction area.

- Installation of a balcony requires considerable financial costs, so you need to be prepared for the fact that this pleasure will cost the owner of the house a lot.

- A thoughtless question about the placement of the balcony may become the reason that the structure will not be used for its intended purpose. This often happens when the balcony faces the road, or faces a neighbor's yard.That is why it is necessary, already at the stage of project approval, to carefully plan the overview visibility of the structure with the peculiarities of the environment and the nearby construction objects.

Types of balconies

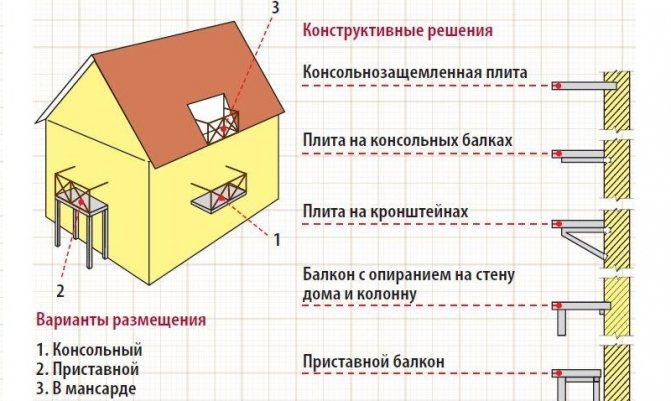

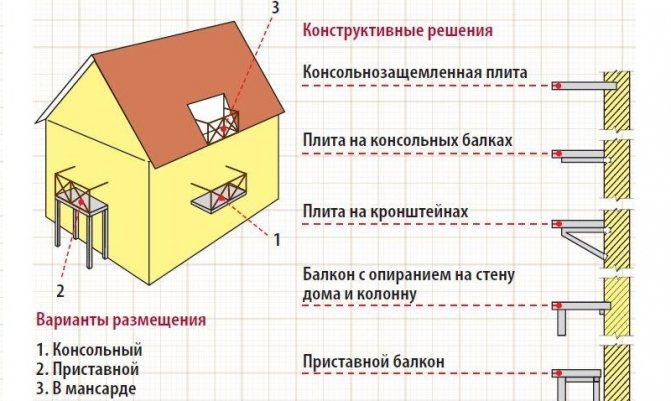

Wooden balconies differ in types depending on how the support is created. The methods described below are best known.

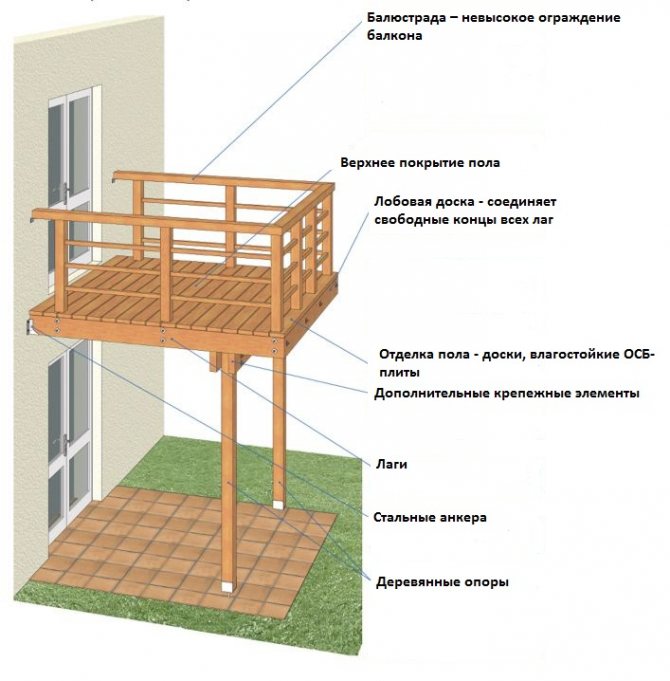

Attached option

The simplest and most modern way to build a sustainable balcony. The side supports securely hold the balcony base, and the front posts provide rigidity to the entire structure... There should be a free area under the base to make the foundation. In some cases, such a balcony can be a roof for a veranda or terrace.

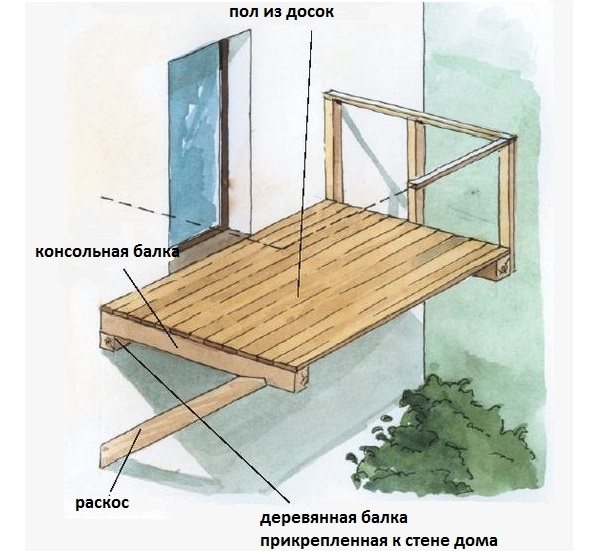

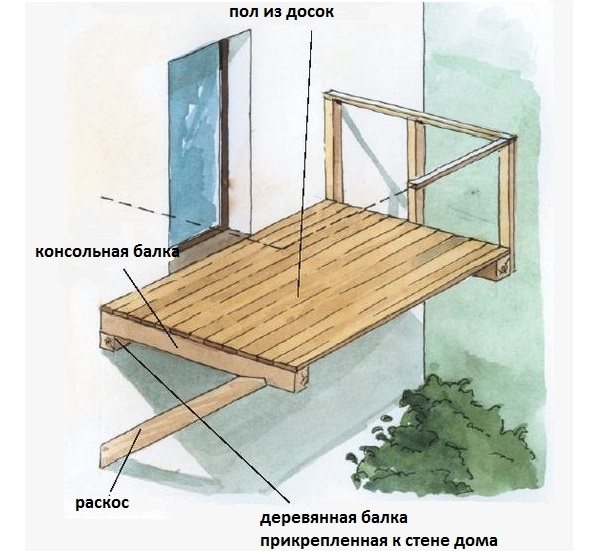

Console option

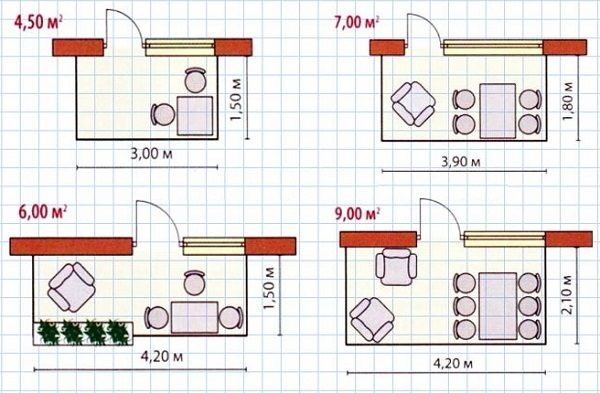

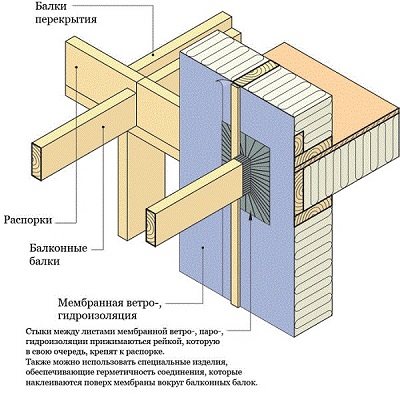

If it is impractical to build a balcony on supports, then the cantilever support method comes to the rescue. With this method, the base of the balcony rests on the extensions of the beams that create the interfloor overlap.

In addition, the base can be created by beams laid parallel or perpendicular to the floor beams. Such a base adorns the walls of the building, but there is a high risk of rotting from moisture ingress.

Open type design

Open balconies take a leading position in comparison with closed views. This the facade structure is used as a decorative element, therefore, great attention is paid to the choice of materials for finishing and its decoration. Forged metal fences, which are the main components of the decor, are widespread.

When installing a forged fence, the following points must be taken into account:

- the size of the fence should not exceed the size of the supporting plate and the opening of the balcony;

- when carrying out work to determine the permissible loads, it is necessary to take into account the fact that the installation of a metal fence is planned;

- the installation of the fence is possible only after the reinforced concrete slab has been completely restored and leveled: on its surface it is necessary to eliminate all chips and cracks.

Closed design

Glazing of the balcony structure allows you to increase the functionality of this space and use the balcony as widely as possible: as a room for relaxation, creativity, or even as a bedroom. And those who love home flowers can breed species that prefer a lot of sunlight here.

The glazed area is protected from bad weather, extraneous noise and annoying insects... For an unusual, aesthetic and original design of facade structures, various types of glazing can be used: panoramic, partial, stained glass.

Balconies can be made of concrete or wood.

Concrete balcony

Concrete is very often used as a base material for balconies due to its unique properties and extended service life.

This architectural structure has individual characteristics:

- The reliability of such a structure directly depends on the thickness of the wall of the house, since the supporting structures are recessed into the wall. In the event that the wall does not differ in increased strength, then it is necessary to install additional supports.

- The length of the balcony overhang should not be less than one meter.

- The foundation slab is inserted into the wall along its entire length if the residential building was built of bricks.

- The top level of the slab should be 5 to 8 cm below the planned level of the floor covering.

- The base of the structure must be waterproofed.

- The height of the parapet cannot be less than one meter.

Wooden balcony

A wooden balcony is somewhat inferior in reliability, but superior in decorative characteristics concrete.This is due to the fact that wood is a unique material, thanks to which you can easily and simply create an atmosphere of comfort, sophistication and splendor. The wood has a unique smell and excellent aesthetic properties.

Installation of a wooden facade structure has its own distinctive features to be considered:

- Installation requires the use of beams with a section of 10x20 centimeters.

- The depth of the beams in the facade is at least 25 centimeters.

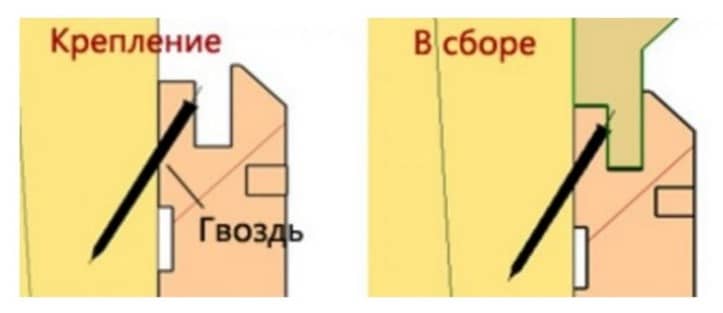

- The main fasteners are metal corners and bolts.

- The vertical and longitudinal racks fixed to the console have the following dimensions: 4 by 10 cm and 5 by 10 cm, respectively.

- After installing the boards, handrails are installed, the flooring is laid.

Wooden elements are subject to mandatory processing with oil paint, and handrails and grilles are additionally covered with a waterproof and resistant to low temperature varnish.

Step-by-step instructions for installing wooden frames

Specialized firms usually accept orders for the production of expensive binders with three-chamber double-glazed windows together with the installation. It is unrealistic to make such a structure at home. Therefore, it is rational to consider the installation of simple balcony glazing with wooden frames.

According to the installation methods, the installation of a binding with single, double glazing differs little, but it will save home financial resources (up to 20 - 30 percent of the cost of the window unit).

Tool and preparatory work

For installation operations you need a small set of tools:

- locksmith tools (hammer, screwdriver, wrenches or socket bits);

- meters (tape measure, metal ruler, construction square, level, plumb line, laser plane builder);

- rubber mallet;

- carpentry tools (for finishing, grinding, varnishing, polishing windows);

- power tools (wrench, pneumatic chisel, screwdriver, electric drill, "grinder");

- assembly guns for foam, plugging in dowels.

To glaze a balcony, a loggia with wood (if the loggia was glazed), you will need to dismantle the old box. To do this, unscrew the screws from the hinges of the doors, cut the box into pieces with a saw or a "grinder". Remove old fasteners. The railing is removed, a bar is installed in their place along the perimeter of the fence. Instead of a support bar, you can use a thick board protruding into the perimeter. It will serve as a window sill of the window block.

The process of dismantling the old structure in this video:

A strictly horizontal installation of the timber is mandatory, which is controlled according to the building level. The fence is sheathed with wooden, plastic panels. Only after installing the support bar, the dimensions of the box are removed for ordering or self-manufacturing of the window block.

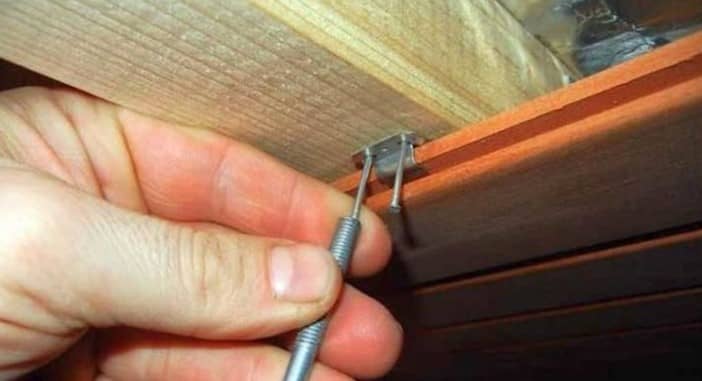

Mounting brackets or a corner are screwed to the finished frame, they begin to try on the box, which is necessary for marking the mountings in the balcony opening. To install the glazing of balconies with wooden frames, use a direct through fastening of the box with anchor bolts or fasteners with bent brackets, a solid corner.

Compliance with the vertical installation of the box is controlled by a plumb line or a laser plane builder. Since the support bar is already installed horizontally, double wooden (plastic) wedges are used to adjust the vertical, which are installed in the upper part of the box. On loggias, wedge adjustment is carried out on three sides of the box (on the sides and top).

For three-sided balcony glazing with wooden frames, adjustment wedges are driven between the frame and the base plate of the upper balcony. Having installed the box vertically (with a discrepancy of no more than 2 - 3 mm), the holes for the fasteners are marked.With the direct method of fastening, the box is drilled through and through (with a step of 300 - 700 mm), the points of placement of the anchor plates are marked through the holes with a pencil.

Basic installation

Before installation, through fastenings in the upper base plate, side partitions of the loggias, the walls of the building, cut through the recesses for the installation of the anchor plates. The operation is easier to perform with a pneumatic chisel or electric chisel, and the manual method of knocking out concrete with a hammer and chisel is difficult. Anchor plates are bricked into the recesses in the cement mortar. Before installation, the window sashes are removed by unscrewing the hinges or knocking out the rods.

During installation, the following operations are performed:

- Reposition and orient the box.

- Attach the frame to the support rail of the parapet. For fastening, use long construction screws or self-tapping screws.

- When fastening with anchors, the bolts are tightened.

- When fastening with a corner or brackets, pins (self-tapping screws for concrete) or dowels are used. Time-consuming operations are facilitated by using electric screwdrivers, assembly guns.

- Remove the side and top mounting wedges.

- Seal the gaps with polyurethane foam. When glazing loggias with wooden frames, the gaps between the side concrete walls and the upper base plate are sealed. Three-sided balcony glazing will require sealing the assembly joints with the base plate and two walls of the house. Over the polyurethane foam, the gap is sealed with polymer compounds or PSUL tape.

- Swing doors are hung on the hinges.

- Double-glazed windows are inserted into the blind doors, the glass is fixed with glazing beads.

- Decorative strips are screwed on to mask the assembly seams.

After the installation is completed, the operations of grinding, varnishing, polishing the wooden elements of the window block are started.

How to make a balcony in wooden houses

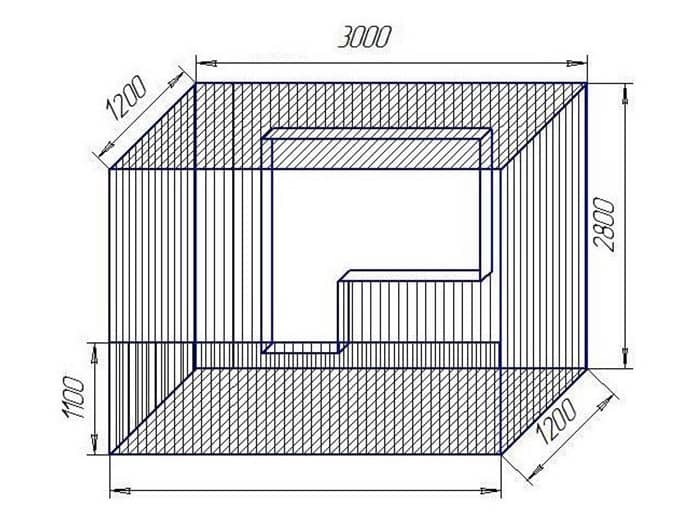

A balcony in a wooden house can be installed with your own hands. First of all, the owner of the house needs to decide on the type of future construction. Often, balconies are installed directly in the roof. If the owner wants to install a gable balcony, then this wish should be taken into account already at the stage of building the building, since it is necessary to make one of the fronts deeper, taking into account the planned width of the future facade structure.

The base plate must be covered with insulation, on top of which a layer of waterproofing is laid, after which a screed is made. At the final stage, a fence is installed, the material for which is selected according to the wishes of the customer: wood, metal, brick.

Design features

Any balcony, regardless of appearance, decor elements and size, it has three main structural elements:

- base plate;

- parapet or fence;

- visor (roof), windscreen.

The slab is the main structural element... It can be made of wood or reinforced concrete. The advantage of a wooden slab is its low weight, thanks to which the installation of this structure can be carried out on the facade of any house.

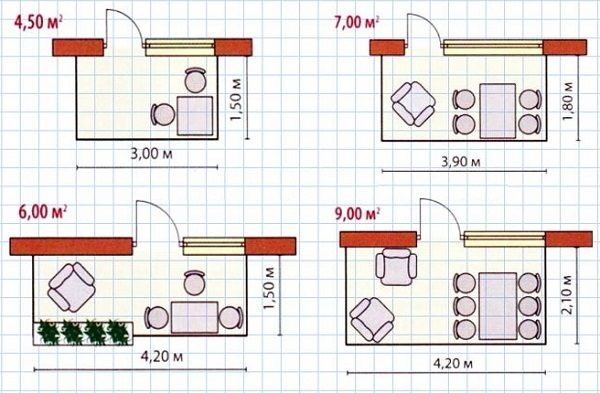

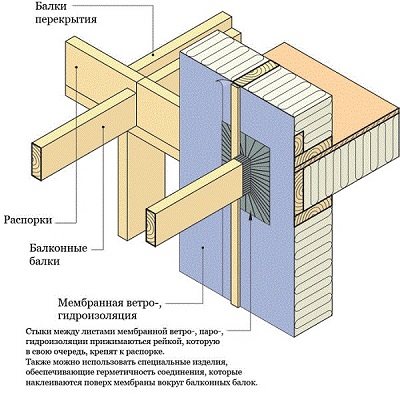

Construction placement options

Usually the balcony is located on the central part of the house and has a common roof with it. This location option is best suited for low-rise buildings. This arrangement allows you to equip the recreation area in the best possible way, protected from bad weather and scorching sun rays. Enough spacious space allows you to install folding or plastic furniture here: tables, chairs.

A small triangular balcony looks unusual and attractivelocated under the roof of the building. Such a room can be successfully used to organize a flower corner.

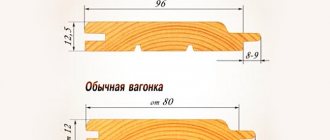

Thermowood lining

It is a natural material made from solid wood with stabilization at temperatures up to 230 °.After removing excess resin, the tree acquires moisture-repellent properties, resistance to biological destruction and a noble dark color. Even ordinary inexpensive pine after such processing looks like a valuable species.

Thermowood lining is used for finishing rooms with high humidity. Its service life is measured in tens of years, and for maintenance it is not necessary to carry out regular staining and varnishing.

What to give preference: roof or visor

The roof is not included in the list of mandatory components of the balcony, but it allows you to significantly expand its functionality. Instead of a roof, a visor can also be installed, which will also act as protection from bad weather and direct sunlight.

Roof requirements:

- The surface area of the roof should be slightly larger than the surface area of the base plate and balcony railing.

- The roof must be installed at a slope so that the accumulation of snow does not occur.

On a note! The roof can be pitched or gable. The first option is the simplest and most affordable, the second is ideal for corner balconies.

A special awning "Marquis" will help to give the balcony an unusual and stylish look.... This metal structure is covered with a special fabric, which allows it not only to act as a protective element, but also to emphasize the individual style of the entire structure.

Dome type canopies are less popular.... This is due to certain difficulties in its manufacture, but many owners of individual buildings prefer this particular method of decorating the facade structure.

The arched visor looks stylish and elegant, which is notable for its practicality and high functionality.

Important points

Balcony glazing with wooden frames has a number of advantages:

- When using natural wood for this, you can make the curtain structure a functional room that can be used at any time, regardless of climatic conditions.

- When carrying out soundproofing and insulation works, the balcony will become not only warm, but also completely protected from extraneous street sounds.

- If desired, you can organize an office for reading and work, a room for flowers, a room for receiving guests in the additional space that appears.

Where to order balcony glazing with wooden frames? This question worries many owners of city apartments, who have chosen just this way of protecting the premises from precipitation and extraneous noise. You can place an order in the workshops engaged in the production of wooden products, or go directly to a factory specializing in the production of wooden blocks.

Among the most affordable options are blocks of coniferous wood: pine, spruce. Depending on the type of wood, the cost of finished balcony blocks can increase several times. What do the professionals recommend? If wooden frames are chosen for glazing, the cladding of the inner walls of the loggia with natural clapboard will be a harmonious addition to the design being created. To increase the service life of this material, it can be covered with a protective varnish layer.

If in the last century the option of decorating a balcony with wooden frames was considered not the best investment of material resources, then in recent years many professional designers have used natural wood in their creative works.

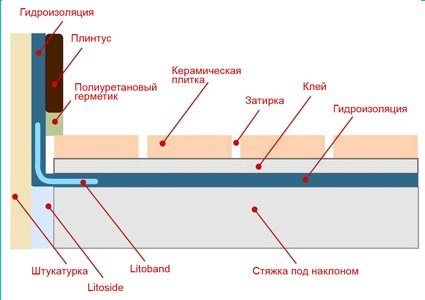

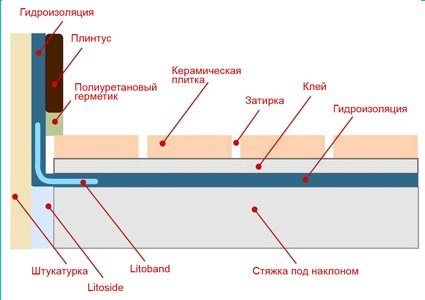

Balcony waterproofing

Hydraulic insulation must be carried out in any case... Water will be absorbed into the floor, as a result of which the slab may begin to collapse if the base is made of concrete or mold if the balcony structure is made of wood.

A balcony built in a wooden house needs hydraulic insulation more than its stone (concrete) counterparts... This is due to the fact that wood is susceptible to the destructive effect of atmospheric phenomena.

In addition, it is susceptible to biological contamination.... All of these factors lead to rapid destruction of the structure.

Open balcony

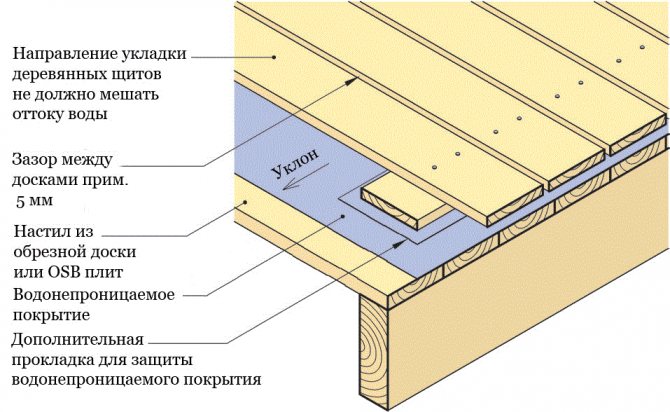

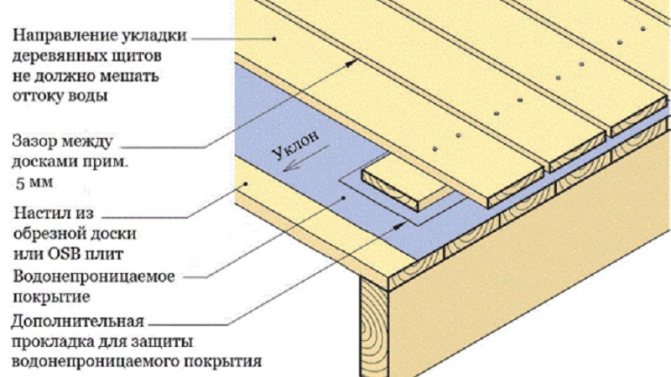

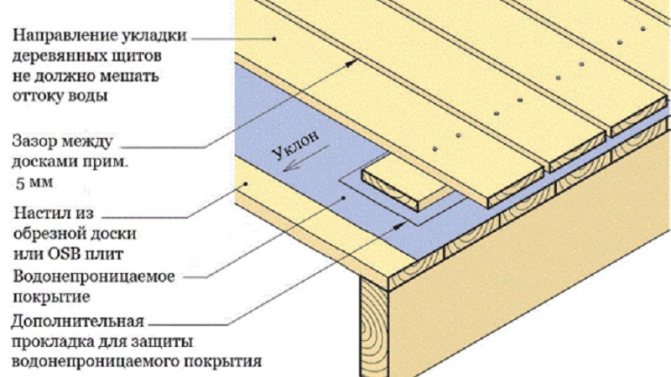

When performing hydraulic insulation of an open type structure, it is important to ensure its slope towards the street. This will help prevent excess moisture from accumulating on its surface. The slope of the base from the wall to the edge can be 40 mm. In addition, this solution avoids the destruction of the installed insulation.

The most important role is played by the waterproofing of the balcony in a wooden house... There are many materials available for its arrangement. This list includes roll materials, mastics, membranes, etc.

Important! The quality of the insulation depends a lot on when it is done. Of course, its quality will be higher if it is performed at the stage of its construction.

If it has already been built, then the most inexpensive way would be laying on top of a concrete screed, a liquid mixture, which includes liquid rubber. It is possible to use special sheets that can be laid as the base of the floor covering.

Waterproofing made on the basis of liquid rubber shows good results to protect the balcony structure from water. It is applied to the surface of the wood using a spray gun. But the use of this technology requires the use of specialized technological equipment, which is operated only by masters who perform work on hydraulic isolation.

Closed balcony

The methods of hydraulic isolation of a closed structure are not much different from those used to protect an open structure. The only thing to remember is that, in addition to the floor, on a closed structure, it is necessary to insulate the walls and ceiling.

Features of mounting PVC and MDF lining

In addition to wooden finishing boards, PVC or MDF panels are often used. They are more resistant to moisture, more varied in design.

PVC lining is obtained from polyvinyl chloride with subsequent decorative surface treatment. To make the plastic resistant to the sun, stabilizers are added to the raw material, and the outer side is covered with protective films.

MDF panels are made from wood waste by dry pressing. With this method, a natural glue, lignin, is released from the fibers of the tree. It combines the fine fraction into a solid structure. Additionally, synthetic resins are added to increase the moisture resistance of the material. Decorative processing is carried out by painting, laminating, veneering.

When installing a lining simulation, the same sequence of operations is maintained. The exception is finishing with paints or varnish, which artificial panels do not need.

Further care is also very simple. It consists in periodic wet cleaning of the surface. Care must be taken not to scratch the decorative trim.

Preparation for work

Preparatory work, first of all, includes the creation of a project with calculations... If the loads on the supporting structures are correctly calculated, then the balcony is not in danger of collapse.

The success of the construction largely depends on the quality of the project. When preparing it, first of all, they are determined with the location of the structure... The classic version is the location above the entrance to the house. In this case, the columns of the porch will hold the balcony base.

Experts recommend simplified preparation at the stage of preparation for construction calculate the load taking into account the strength factor and the weight of the following components:

- balcony designs;

- installed furniture;

- people leaving the balcony.

There are also other requirements for the correct choice of an extension design:

- for safety, there must be a fence with a height of at least 105 cm;

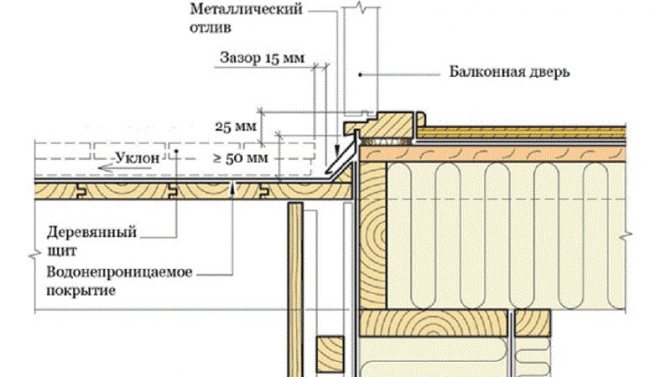

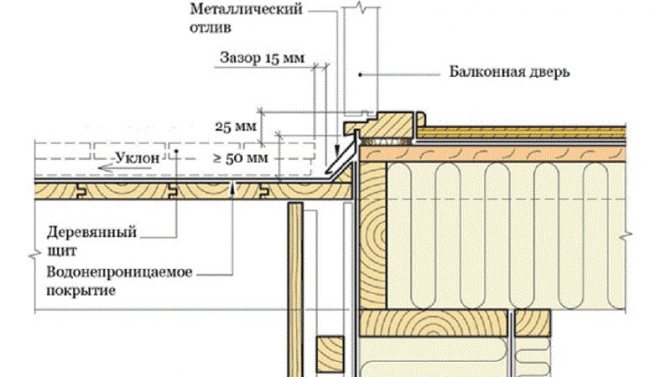

- the base of the balcony is mounted with a slope of up to two degrees, so that during precipitation, water flows out;

- the location of the balcony must correspond to the purpose. For decorative purposes, it is placed on the facade of the building, and for relaxation in quiet places;

- additional equipment of the canopy will protect the balcony well from precipitation and extend its operation time.

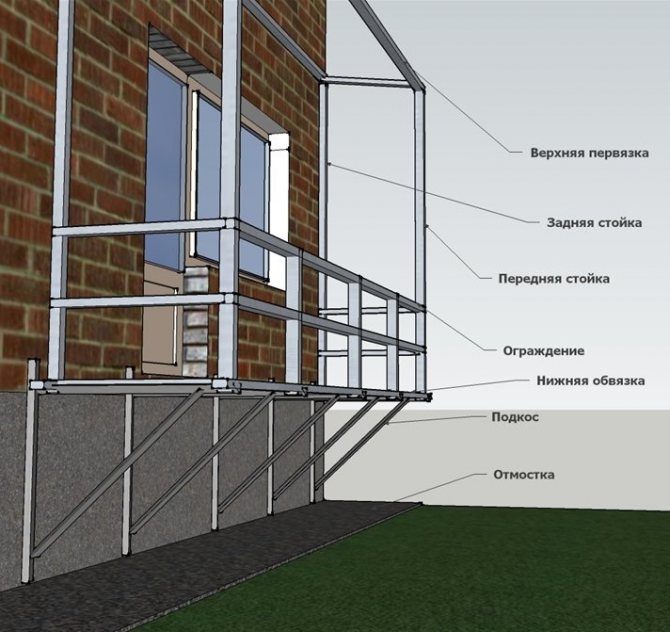

Constructing a cantilever balcony

Initially, the materials that are specified in the project are purchased, and the tool is being prepared. In addition, the project must have drawings with dimensions of parts. This will save materials and also make assembly easier.

Important! If the extension is carried out in a house under construction, then the protruding floor beams are a good basis for the construction of a wooden balcony. In a built house, the option with support on pillars would be optimal.

Before starting work, make sure that the location of the balcony door will not affect the strength of the load-bearing wall.

In the cantilever balcony, one of the options is used for mounting the base:

- pinching in the wall. Disadvantage: the width of the base is limited to one meter;

- support on cantilever beams. The dimensions of the base increase to one and a half meters.

Construction work is carried out in stages:

- markings are made on the wall according to the project;

- for the balcony beams, a wooden beam with dimensions of 200 x 100 mm is prepared. It is pretreated with antiseptic solutions;

- holes are cut in the wall with a depth of at least 250 mm and a step of up to 1 meter. The ends of the beams wrapped with waterproofing are sealed in them;

- the ends of the beams are connected by a transverse beam, which is then used to fasten the fence;

- to increase the load-bearing capacity of the balcony, wooden brackets are installed, which abut against the wall at an angle of 45 degrees. Brackets from the bottom of the beams are attached to the transverse beam;

- lathing for flooring from boards is laid on the cantilever beams; arrangement is in progress.

Important! Be sure to treat the wooden surface with protective compounds!

Construction of an attached balcony

As in the previous version, work begins with the procurement of materials and preparation of tools. Unlike cantilever structures, such structures are more complicated to install and require more financial costs.

Stages of construction of an attached base:

- according to the project, markings are applied on the wall and in the places where the pillars are installed;

- for supports, columns with a diameter of more than 140 mm are selected. They are treated with an antiseptic. The lower part of the pillars is covered with bitumen to the depth of installation in the ground;

- pits are dug or drilled. At their bottom, a sand pillow is laid;

- the pillars are poured with concrete. For a closed balcony, the height of the pillars must be higher than the height of the ceiling;

- under the door, a wall support is attached strictly horizontally along the entire length of the future balcony;

- at the level of the wall support, the posts are strapped with crossbeams;

- the pillars are connected to the wall support with a crate, which is necessary for the installation of wooden flooring; arrangement is in progress.

Obtaining permits

When you decide to make a balcony, contact your local redevelopment office. You should be consulted and given an explanation whether it is generally possible to carry out such work in your case.

Check out the situations in which it is not allowed to make a balcony at all:

- You live in a house that is an architectural monument;

- The apartment windows face the main street;

- The balcony requires partial destruction of the load-bearing wall;

- Communications are close to home (sometimes they can be moved, but you pay the costs);

- No permission from neighbors.

There are no other options for obtaining permission for a homemade balcony.Moreover, the wait for a decision can exceed 45 days, and there is no guarantee of a positive result. Since it is not easy to make a balcony on the first floor, such an idea did not gain wide popularity, but still.

If an extension on the ground floor is possible, and you have received permission, then keep in mind that the work must be carried out in strict accordance with the technical documentation.

Please note that even a few extra centimeters that you tried to win in the end can completely deprive you of your balcony. Moreover, you may even incur administrative penalties.

If you have received permission to build a balcony on the first floor, then consider yourself very lucky and start building immediately.

Arrangement of the balcony base

Data work requires special care, since the reliability, attractiveness and longevity of the balcony structure largely depend on them.

Connecting the balcony frame to the wall

Usually, the frame of the wooden balcony is made of wooden elements.

Firstly, wood has high thermal insulation qualities, and secondly, it goes well with various architectural styles.

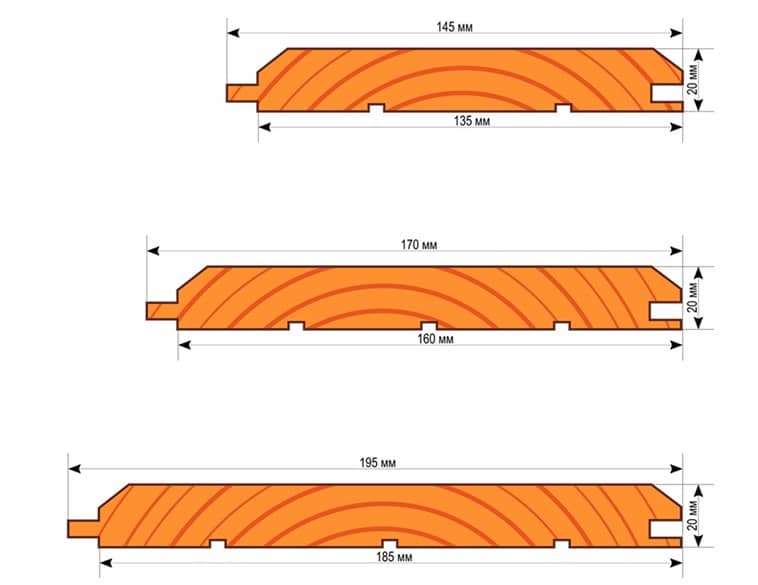

Usually the balcony frame is connected to the wall using barsmounted vertically on the wall at the ends of the balcony base. The height of the bars determines the dimensions of the fence. The wall is sheathed most often with clapboard.

Pine and larch lining looks good and is durable... If the frame of the balcony is large, then boards of a round profile (block house) are mounted. Such a wall has a pronounced log appearance.

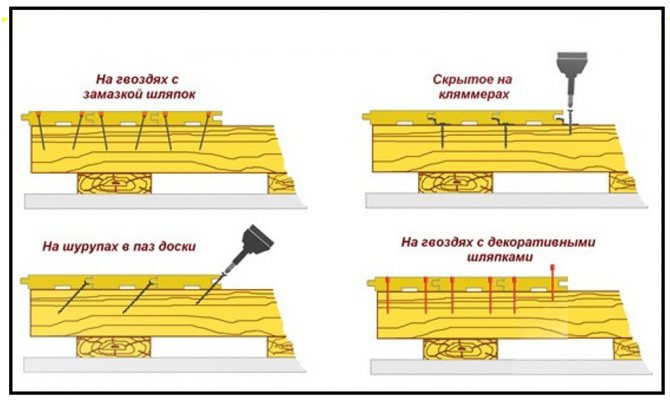

Floor laying

The floor is mounted on the prepared crate... 40mm planed boards are selected as the material. To prevent water from accumulating, they spread with a gap of up to 2 mm.

Terrace boards have worked well for flooring on the balcony.... They are durable, but easy to process. The corrugated surface of the boards is suitable for open balconies.

Installation of the fence

Good fencing is not only attractive, combined with the architectural style of the building, but also characterized by strength and reliability. Chiseled or carved balusters create an attractive look for a wooden balcony.

Railings are made from different materials:

- The wrought iron railings transform the balcony into a work of art. The number of possible options for ornaments is practically unlimited. These fences combine elegance with high strength.

- High safety and reliability are ensured by wooden railings. They are easy to manufacture and install. However, such railings have a short lifespan due to moisture decay.

There are certain the rules to be followed by the fences of wooden balconies:

- the height of the railing is not less than 1.0 m;

- the distance between the balusters is not more than 0.1 m;

- permissible horizontal load on the railing is not less than 100 kg / m;

- there should be no jags or roughness on the surface of the railing.

Note! When choosing a railing, it is necessary, first of all, to be guided by the safety of using the balcony.

Creating a canopy

Not every wooden balcony needs a canopy... It is equipped to create coziness and to protect the balcony from the destructive effects of natural conditions.

It is easy to construct a canopy as an extension of the roof slope. In this case, it is sufficient to have longer rafters.

The simplest design is strapping the upper part of the support pillars balcony base. After that, a crate is made, on which the roofing is laid.

There are polycarbonate awningsmounted on the wall. For a canopy, lightweight materials are suitable that can withstand snow and wind loads.

Processing of elements made of wood

A prerequisite for all wooden balconies is protection from insects and weather conditions.

Protection will be effective if it is carried out in a comprehensive manner.:

- applying primers;

- impregnation with antiseptics;

- coating with a fade-resistant varnish.

Special requirements for the processing of cladding material on open balconies without awnings... Therefore, before the start of installation work, the floorboards on the back side are covered with VISASOL antiseptic primer. It contains substances that prevent the formation of mold.

An elastic, hard and weather-resistant varnish is selected for the wooden railings.... The best option is alkyd-urethane varnish. He is not afraid of mechanical influences, temperature fluctuations, direct sunlight.

Note! It is necessary to process wooden fences with primer, impregnation and varnish from one manufacturer. Only then will full compatibility of all coatings be guaranteed.

Outside, it is necessary to cover the wooden balcony with paintmatching the color of the facade of the house.

disadvantages

However, nothing is perfect, and the tree also has some costs.

- despite all types of treatments, it is still a natural material, which means that it is influenced by weather conditions. Elite euro windows are less sensitive to precipitation and dryness, and less expensive frames, due to insufficient processing, can start to fail quite quickly.

- Even the highest quality windows need to be re-impregnated from time to time to increase their service life.

- The tree tends to age over time.

- If exposed to too hot air for a long time, the wooden frame may crack.