A distinctive feature of SKU-7L polyurethane is the fact that this elastomer is endowed with an increased level of wear resistance, reliability, it cannot be damaged by impacts and loads. At the same time, regardless of external factors, such as various temperature drops, this material perfectly retains its elastic properties. Therefore, our online store offers the manufacture of products from SKU-7L polyurethane to buy inexpensively.

Using such a prepolymer material in the production of gaskets and other seals, you can be quite calm about the fact that such products will not prematurely disable the equipment. With the help of this material, we manage to create various shaft coatings, regardless of their scope. At the same time, it is especially important to take into account that it is precisely due to its wear resistance that a material such as SKU-7L polyurethane is excellent for use in the lining of cyclones, hydrocyclones, as well as for creating other elements necessary in conditions requiring high strength of components.

The use of such polyurethane is excellent for all areas of application, which include:

- Food and chemical industry;

- For a complete set of lifting and transport mechanisms;

- For the creation of water treatment facilities and structures;

- For use in the pulp and paper and oil industries;

- In general mechanical engineering and automotive industry;

- For use in electronics and electrical engineering;

- Textile and mining industry;

- In conveyor and construction technologies.

Polyurethane (GOST): basic properties

Polyurethane (GOST-14896) has unique properties, including high strength and elasticity with significant resistance to abrasion and mechanical stress. Unlike rubber, the flame retardant elastomer is characterized by slow aging, which provides it with several tens of times longer service life. Because of this, it is often called "eternal rubber".

This polymer retains its original properties over a wide range of negative temperatures. For example, the irreversible deterioration of the elasticity of polyurethane GOST-14896 84 occurs below the mark of –18 + 2 / 20C, and the appearance of fragility - at –60 +/- 60C, depending on humidity. Products made from this elastomer are non-toxic and have a low glass transition threshold. At the same time, the bond of the elastomer with metals is several times stronger in comparison with a similar bond "rubber-metal".

Polyurethane sheet

Polyurethane sheet with a thickness of 2 mm to 150 mm with a maximum size of 2000x1500 mm.

It can be manufactured as:

- stamping plates in forging and stamping production;

- dielectric rugs;

- notched sheet for the shoe industry;

- floor covering to reduce vibration and sound insulation;

- lining sheets of tanks and pipelines;

- notched sheet is used as rugs of various colors at the entrance groups of doors to ensure the safety of people when walking on stairs, faced with granite, marble, tiles and other materials with a reduced coefficient of friction.

- manufacturing of parts for prosthetics.

The sheet is made of various hardness (conventional unit Shore A).

Polyurethane (GOST): advantages

- Low abrasive wear with low weight and density.

- A wide range of operating temperatures (from –70 0С to +150 0С) and operating pressure without permanent deformation (up to 100 MPa).

- Resistance to tearing and to dynamic loads is especially characteristic of polyurethane GOST-22704.

- Significant dielectric properties at high rates of absorption of mechanical stress, vibration and shaking.

- Chemical resistance with high elasticity.

Physical and mechanical properties of Polyurethane SKU-7L (TU 22.29.29-001-15762649-2017)

| The name of indicators | Indicators |

| Shore A hardness, conventional units | 75-92 |

| Permissible operating temperature, C ° | -30 … +80 |

| Short-term temperature rise, up to ° С | +100 |

| Elongation at break,%, not less | 500-580 |

| Relative residual deformation after rupture,% no more | 4-6 |

| Conditional stress at 100% elongation, MPa, not less | 38-48 |

| Wear resistance, mm | 48-57 |

| Specific gravity (density | 1,24 |

| Oil and petrol resistance | high |

| Hydrolytic resistance (in water) | low |

SKU-7L polyurethane is considered one of the most modern materials used in the construction of various elements. This is due to the fact that such material is endowed with fairly good technical characteristics, such as:

- Increased level of wear resistance;

- Permanent preservation of elastic properties;

- Not abrasion resistant;

- This is a fairly strong and solid material;

- Ability to withstand various high pressures;

- Not able to deform;

- Not affected by solvents and other chemicals;

- Does not lend itself to various temperature changes;

- Resistant to mold formation;

- Vibration resistant;

- Oil-, petrol-resistant;

- Retains elasticity even at low temperatures;

- Moisture resistant;

- Does not conduct electricity.

The use of SKU-7L polyurethane, the characteristics of which make it possible to replace rubber, is an excellent solution to significantly improve production! Products made from such polyurethane have the property of resistance to impacts and various atmospheric changes. They are able to serve a long service life, without the slightest complaints about their quality. Due to such characteristics, which distinguish this material from rubber, it was most expedient to buy SKU-7L polyurethane from us inexpensively.

Polyurethanes (GOST): the use of major brands

- Polyurethane SKU PFL-100M is used for the manufacture of parts intended for operation under intense abrasive wear, including humid environments. Highly elastic polymer, characterized by a low degree of residual deformation during compression, is indispensable for the production of seals.

- Polyurethane GOST SKU-7L is used for the production of wear-resistant products operating under conditions of exposure to oils, fuel oil and other refined products. It is often used as a raw material for stamped parts.

- Polyurethanes designation according to GOST SKU-6 and "Vibratan-6060" with high hardness and elasticity is used for the manufacture of elastic parts of mining equipment. Also, these elastomers are widely demanded in the machine industry and shipbuilding.

- Polyurethane sheet "Vibratan-8000" with a range of operating temperatures from -60 0C to +120 0C is one of the most high-tech elastomers. It is used for the manufacture of shock-resistant assemblies for lifting equipment.

- Polyurethane sheet GOST-14896 84 is used for the production of cuffs and seals, as well as various general-purpose parts.

In addition to the above synthetic elastomers, there are many other types of material that are widely in demand in various industries, in production and in everyday life.

You can buy polyurethane products of various standards at. If necessary, our specialists will ensure the release of a batch of unique products with specific parameters.

Where is SKU-7L polyurethane used?

Such a reliable material as SKU-7L polyurethane, the price of which is the most optimal with us, is used in the manufacture of absolutely various parts that work for wear, as well as, as a covering material, regardless of the scope of application of the part to be coated.This elastomer is commonly used in both the metallurgical and chemical industries to create a reliable coating of guide and pull shafts. Among other things, it is also used to cover shafts and drums used in the cutting of glass products, paper and cardboard, as well as fiberglass.

Also, it is worth noting that this material has established itself as highly efficient in the manufacture of rollers used in conveyor lines. Massive tires made of SKU-7L polyurethane used for vehicles used inside the plant will be no less durable and reliable. At the same time, the use of such tires is excellent for working in refrigerated warehouses. And this, by no means the entire list, where the use of such material plays one of the most important roles.

This is due to the fact that all products made from such injection molded polyurethane are not subject to combustion. They belong to a group of materials that are considered difficult to burn. Moreover, this material can be considered safe for human health and life. It is absolutely non-toxic, incapable of exploding and igniting, and also, regardless of various factors, including natural, it remains in its usual, constant form. That is why the use of such polyurethane, in combination with metal products, is considered more effective than a combination of metal and rubber.

Polyurethanes are heterochain polymers, the macromolecule of which contains an unsubstituted and / or substituted urethane group —N (R) —C (O) O—, where R = H, alkyl, aryl or acyl. Polyurethane macromolecules can also contain simple and ester functional groups, urea, amide groups, and some other functional groups that determine the complex of properties of these polymers. Polyurethanes belong to synthetic elastomers and are widely used in industry due to a wide range of strength characteristics. They are used as substitutes for rubber in the manufacture of products operating in aggressive environments, under conditions of high alternating loads and temperatures. Operating temperature range - from -60 ° С to +80 ° С.

Polyurethane was first obtained in 1937 by Otto Georg Wilhelm, a chemist-technologist Bayer, well-known in Germany. In the same year, an industrial enterprise was organized for the production of polymer, but in small quantities. Like everything new, polyurethane has long won a place in the industrial market. And only in 1957 it began to be widely used in the construction industry, rural industry, food and other industries.

Polyurethane (polyurethane, polyuretan) is a synthetic polymer material with unique properties and universal application. It is divided into several types. For starters, it is worth mentioning polyurethane foam, as it is often used in construction. It is highly water resistant, has low density, and is very easy to use. The production of foamed polyurethane is experiencing a real boom in recent years in Russia and the CIS countries. It is used to make thermal insulation, elements of upholstered furniture decor, such as columns, cornices, etc. Liquid polyurethane is also very popular in construction, most often it is used to create a polyurethane roof. Construction is the main industry for the use of PU products. By the way, you need to use special glue for polyurethane, and each type needs its own. Polyurethane sheet is more often used in the automotive and other industries. For the manufacture of medical products, as well as auto sealing rings, silent blocks and other sealing elements, polyurethane casting material is used.

Polyurethane sheets are a flat rectangular plate made of polymeric resilient elastic material. Supplied in various modifications. The quality is determined by TU 84-404-78 and other standards.

There are two types of polyurethane polymers: ester (AU) and ether (EU). Complex esters are very resistant to oils, fuels and solvents. But they are destroyed by hydrolysis. Conversely, ether urethanes are not prone to hydrolysis. However, their oil and fuel resistance are better than nitrile butadine and hydrogenated nitrile butadiene, which contain a low concentration of acrylate (18-22%). Both complex urethanes and ether urethanes have excellent wear resistance, high tensile strength and are highly elastic compared to any other type of elastomer.

Receiving and chemical structure

The developer of polyurethane is Otto Georg Wilhelm Bayer, a German chemist, one of the authors of the stepwise polymerization method. Industrial production of polyurethanes was imposed in Germany in the late 30s and early 40s of the last century. Since then, the technology for the production of these materials has taken a great leap forward in quality.

In terms of polymer chemistry, polyurethanes are synthetic heterochain polymers. Since its inception, many options for the composition of the polymer have been developed, but the common point is the presence in the composition of the so-called urethane groups

—N (H) —C (O) O—

Moreover, in place of hydrogen, the chain may include alkyls (CH3) or other groups.

In addition, other functional groups can be included in the composition of the material; it is also possible to create branched or even cross-linked polymers, which makes it possible to synthesize polyurethanes with a wide range of physical and mechanical properties.

Application

Polyurethane is widely used for the manufacture of sheet sealing materials, lip seals and O-rings, various bushings, rods, equipment parts and other construction materials, in the production of stuffing box packing, in the shoe industry and the production of workwear, for the manufacture of rollers and solid tires (for special equipment) as a material for lining and lining equipment and pipelines. Also, polyurethane is widely used in construction, both in the form of adhesives and a component of building mixtures, and in foamed form. The wider use of this material is hindered by the small temperature range of operation.

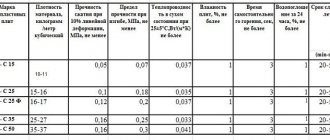

Composition brand:

Polyurethanes are a kind of link between rubbers and plastics.

The most important advantage of PU is their excellent wear resistance. In this key indicator, PU products are superior to those made from high-quality rubbers.

In addition, the best PU is characterized by a combination of high oil, gas and ozone resistance with excellent damping, thermophysical, electrical and elastic properties.

The possibilities of using materials in the automotive, mechanical engineering, cable, electrical and footwear industries are enormous and versatile.

Despite its relatively high cost, the use of PU is not only technically feasible, but also economically profitable, due to a significant increase in durability and an increase in the quality of products.

What is more economical?

Rubber, which is only 8 times cheaper, or polyurethane, which lasts hundreds of times longer?

We offer products from injection molded polyurethane for sheet-stamping production, manufactured in strict accordance with TU 84-404-78 grades SKU-PFL and SKU-7L in plates (sheets) and cylinders.

Properties of polyurethane. Extract from TU 84-404-78

| Name of characteristics | SKU-PFL | SKU-7L | LUR-90 (LUR-PT) | LUR-STLUR-SP | |

| Tensile strength (rupture), kg / cm2, not less: | TU 84-404-78 The actual | 300 450-500 | 300-350 350-450 | 200 400-450 | 250 400-450 |

| Elongation at break,%, not less: | TU 84-404-78 The actual | 300 350-400 | 370 550-650 | 300 400-450 | 600 650-750 |

| Shore hardness, A, conventional units: | 90-95 | 76 — 86 | 85-95 | 70-80 | |

| Tear resistance, kn / m, not less: | TU 84-404-78 The actual | 54 140-160 | 30 100-140 | 60 95-140 | 30 100-130 |

| Residual elongation (relative residual deformation),%, no more | TU 84-404-78 The actual | 10 3-5 | 4 2-4 | 15 2-4 | 10 0-2 |

| Conditional stress at 100% elongation, MPa, | TU 84-404-78 The actual | not norms | ruled | not less than 6 6,5-10,5 | no more than 4 2-4 |

* approx. LUR brands are created specifically for use in the aviation industry. LUR-SP is the old name of the LUR-ST brand, the LUR-PT brand is slightly different from the LUR-90 brand.

Polyurethane (PU):

Polyurethane elastomers are monolithic polyurethanes with a unique combination of properties - high strength, resistance to wear, shock resistance, retaining highly elastic properties in a wide temperature range (from -60 ° C to + 110 ° C). Polyurethane elastomers are used as a coating for pulling and guide shafts in the metallurgical and chemical industries, shafts and drums for cutting fiberglass, fiberglass, paper, cardboard. Polyurethane elastomer is used to make rollers for conveyor lines, massive tires for in-plant transport, including for work in warehouses - refrigerators, sieves in the mining and food industries, internal coatings of screens, cyclones and separators, including for the separation of abrasive slurries. Due to their increased wear resistance and reduced coefficient of friction, polyurethane elastomers are widely used for the manufacture of gaskets and seals for various purposes - static, reciprocating, rotating, working in pneumatic, hydraulic systems, or as simple scraper seals for flat surfaces and shafts. Application: punches and dies for metal stamping, dampers, buffers, coating of shafts for various purposes, lining of cyclones, hydrocyclones, manufacturing of products operating under conditions of increased wear. The aging resistance of polyurethane and elastomers is higher than that of natural and synthetic rubbers. The most common brands of polyurethane are SKU-7L and SKU-PFL. We offer polyurethane (various hardness) of the following brands: NITs PU 5, SKU-PFL, SKU-7L, LUR-ST. Polyurethane has high tear resistance, high wear resistance and high pressure capability along with high elasticity, oil resistance and heat resistance. Polyurethane can be machined in a variety of ways. Thanks to these qualities, the savings from the use of polyurethane (in comparison with other materials) are very significant. Studies have confirmed that in real conditions the resistance of polyurethane is several hundred times higher than that of rubber. For comparison: The density of rubber is 1.37; density of polyurethane 1.259.

Basic physical and mechanical indicators

| Properties | Polyurethane grade | ||

| SKU-7L | SKU-PFL | Adipren L-167 | |

| Modulus at 100% elongation, kgf / cm2 (MPa) | 40-90 (4-9) | 130-150 (13-15) | 127 (12,7) |

| Breaking strength kgf / cm2 (MPa) | 550-600 (55-60) | 400-500 (40-50) | 352 (35,2) |

| Relative extension, % | 450 -500 | 350-370 | 400 |

| Hardness according to TM-2 (Shore, A) | 76-86 | 92-95 | 95 |

| Tear resistance, kgf / cm2 (MPa) | 55-60 (5,5) | 100 (10) | 111,5 (11) |

| Number of cycles with repeated stretching | 5000 | 3000 | —- |

| Rebound elasticity,% | 25-30 | 40 | 40 |

| Residual compression deformation,% | 3-5 | 10-12 | — |

| Operating temperature range, ° С | -5..+100 | -40…+80 | -40…+80 |

| Short-term temperature rise to, ° С | +120 | +100 | +100 |

The main physical and mechanical properties of polyurethane "ELAST A-101T" TU 2224-001-45130869-03 analogue of the brand "SKU-7L" (TU 84-404-78)

| № | Indicator name | Unit change | "ELAST A-101T" |

| 1. | Breaking strength, not less | MPa | 30 |

| 2. | Elongation, not less | % | 370 |

| 3. | Residual elongation after rupture, no more | % | 4 |

| 4. | Tear resistance, not less | N / mm | 30 |

| 5. | Shore A hardness, | Unit | 76-86 |

| 6. | Oil and petrol resistance | — | High |

| 7. | Wear resistance | mm | 40 |

| 8. | Operating temperature | hail. FROM | — 30…….+ 80 |

| 9. | Water resistance | — | Satisfactory |