Veneer is a natural wood sheet material. They are covered with fiberboard, MDF, an array of inexpensive wood species and other surfaces to give them a presentable appearance.

The name is of German origin and translates as "wood chips". It was in Germany in 1562 that a special saw was created by Georg Renner, which made it possible to obtain thin cuts of wood.

However, the history of veneer began long before this event. It is not known exactly where exactly thin wood sheets were invented and were first used for finishing. They were found during excavations of the villages of Ancient Egypt, Ancient Rome. Most likely, an acute shortage of wood prompted the idea of using it as economically as possible.

The first veneer factory was opened in Germany in 1843. Now this material is used very widely. This is not surprising, because it is natural, perfectly imitates solid wood, and products from it are cheaper than from solid wood.

What is veneer

The word veneer comes from the German - Spon, which means sliver, lining. Veneer is a natural natural material, which is a thin sheet made of natural wood of various species. Depending on the production method, veneer is called peeled veneer (made on special peeling machines), sliced or sawn veneer.

Veneer is a natural material that is a thin sheet made of natural wood of various species.

Rotary cut veneer (thickness 0.1 - 10 mm) is the most widespread, cheapest and most affordable type of veneer for the consumer. Manufactured on peeling machines. For the production of rotary cut veneer, mainly wood species such as alder, birch, pine, and oak are used. The technology of its manufacture is simple - rounded short logs - the blocks are cut in a spiral, forming thin shavings - veneer of a given thickness.

Sawed veneer (thickness from 1 to 10 mm), made on veneer saws or horizontal saw frames. It is made from coniferous wood: fir, cedar, spruce. This veneer is of a particularly high quality and can be used, in particular, for the production of violin decks and other stringed musical instruments. Sawed veneer is a rather expensive material, since during its manufacture a large amount of wood is spent on sawdust.

Veneering - gluing veneer on a stable base (tamburat panel, MDF, chipboard, plywood, etc.).

Sliced veneer (thickness from 0.2 to 5 mm) is made on veneer planing machines. Such veneer is produced mainly from valuable wood species with a beautiful texture. These are oak, beech, acacia, walnut, mahogany, Karelian birch, ash, elm, yew and others. For different wood species, a different planing direction is chosen, depending on the showiness of the natural wood pattern. The result is tangential, radial-tangential, tangential-butt and radial veneer.

Benefits of veneered panels

By veneering, they make wood-effect wall panels... They are obtained by gluing veneer to any material. It should be said that gluing can be performed on chipboard or MDF boards. Their main difference from solid wood products is that veneered panels are available in terms of price. This means that most consumers can purchase them.By ordering furniture or veneer panels, a person receives interior items that acquire a number of positive qualities.

For the interior of the room, decorated with veneer panels, the following advantages are characteristic:

- natural appearance and environmental safety of the material;

- high strength and long service life;

- beautiful texture and wonderful appearance;

- an opportunity to show your individuality and show your good taste.

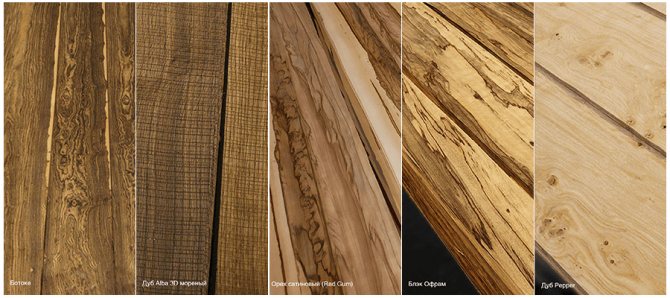

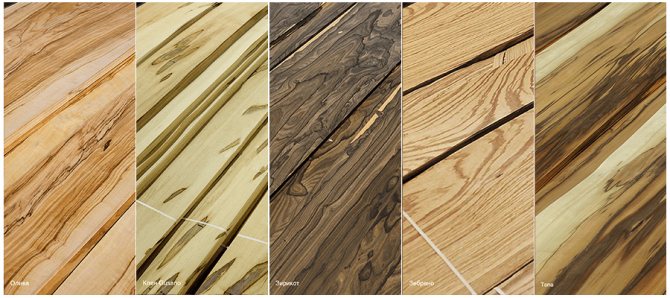

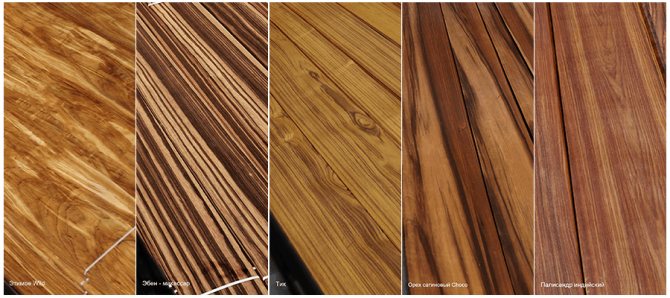

High quality veneered panels from the side are indistinguishable from products made of solid wood. On the market, these products are available from such tree species as oak, beech, mahogany. Along with them, panels are offered from rocks that are exotic in our country. These include:

- rosewood;

- chirigeiro.

Various types of varnish compositions used for finishing veneered panels. The formulations used can be of different shades:

- glossy;

- semi-matte;

- with different toning.

Veneer types

Manufacturers currently offer three types of veneer:

- natural;

- fine-line;

- multi-veneer.

Natural and artificial veneer

Natural veneer is a thin sheet that is removed from the solid wood by sawing, peeling, chipping or planing. This veneer is called natural because the unique texture of the wood is fully preserved during the production process.

Such material occupies an intermediate price position: it is cheaper than natural solid wood, but more expensive than chipboard. At the same time, natural veneer has such qualities as environmental friendliness, sophistication and uniqueness of the pattern.

Artificial veneer is a plastic film that in appearance imitates the structure and color of natural wood. Artificial veneer is widely used in decorating JSM surfaces.

Fine-line veneer

Fine-line veneer is a reconstructed veneer made using a special technology from natural wood with the ability to imitate various types of wood with certain sizes and different shades. Wood of fast-growing tree species is used as the main raw material in the manufacture of veneer using fine-line technology.

"Fine-line" veneer is produced from rotary cut veneer, by forming it into blocks, from which veneer of various colors, patterns and sizes is then obtained. The technology for manufacturing this type of veneer was developed in accordance with modern environmental requirements and the need to obtain a new texture.

Fine-line veneer does not repeat any of the existing types of wood and has a unique, clearly defined structure, pattern and color that meets modern trends in the production of slopes, arches, portals, doors, panels, furniture, etc.

Fine-line veneer reconstructed veneer made using a special technology from natural wood with the ability to imitate various types of wood

During production, wood goes through the following stages of processing:

- peeling: the logs are dissolved into a tape of a certain thickness, which is then cut into veneer sheets of a certain size;

- drying the obtained veneer sheets and sorting them by color;

- through staining: sorted veneer is immersed in a container with a dyeing solution;

- gluing and pressing: colored sheets are collected in bundles with the same fiber direction and sandwiched with a binder. The adhesive not only binds the veneer layers to each other, but also creates an additional decorative effect by adding dye. The created pack is pressed under high pressure;

- planing: from the resulting block, planed veneer sheets with a certain predetermined texture and structure are obtained.

Composition: 92 - 94% - natural wood, 7 - 8% binder (glue), 0.3 - 0.5% - dye.Advantages: the material has a uniform predetermined pattern and color, there are no defects typical for natural wood - knots, knots and cavities. Disadvantages: the material turns out to be brittle, as well as porous and requires a lot of glue when veneering.

Multi-veneer

Multi-veneer is a specially reconstructed natural wood veneer. This type of veneer can be called the most "decorative", because its appearance is often the least reminiscent of patterns of natural wood. The main color motifs of multi-veneer are geometric patterns, often combining different color shades. Products made from this type of veneer look modern and fit perfectly into any Art Nouveau interior.

The main advantages of veneered products are:

- environmental friendliness (natural natural material);

- impeccable appearance (rich assortment, the ability to remove defects inherent in solid wood);

- the duration of operation (products lined with veneer do not dry out, like products made of solid wood, they are not afraid of humidity and temperature).

Application

Veneer is used for the manufacture of plywood, matchsticks (see match), in the manufacture of furniture, drum shells, the top soundboard of acoustic and electric guitars, radio equipment cases, for example, radio equipment, for decorative work (inlays), as well as for the manufacture of delta wood and skateboards.

Disadvantages of veneered parts: uniform size. Veneered doors and furniture parts are made, as a rule, according to the same standard, in most cases there is no individual version. Possible problems with environmental friendliness, unscrupulous manufacturers can use poor-quality adhesives or varnishes.

In the XX century, veneer was widely used for the production of matchboxes, as well as for the manufacture of kurai.

In addition, the natural veneer coating is widely used in the field of car tuning, specifically, in the decoration of interior parts.

What is wood veneer

Those who think that veneer is something artificial, akin to plastic, are deeply mistaken. In fact, this material is the same natural wood, only processed using a special technology.

Veneer is wood sheets with a thickness of 0.1 mm to 12 mm, which are obtained by cutting the thinnest layers of wood from a tree trunk. Therefore, if a choice arises, what is better to use for finishing work with your own hands - veneer or PVC, give preference to the first one, since it is an absolutely natural material.

The scope of application of veneer is very wide - from the furniture industry and construction to automotive production. It is used to make matches, cabinet furniture, doors, floor coverings, wall panels, musical instruments, and even to tune the interiors of expensive cars.

Usually, veneer with the help of special glue and a press is glued onto MDF boards, from which various products are then made. This technological process can be easily reproduced in a home workshop, if you want to update some simple wooden surface with your own hands.

Where is it applied?

Decorating with this decorative material can be found quite often. The interior door leaf can be decorated with veneer in whole or in part. You can find canvases with artistic inserts.

Important! Decorative sheets are used in the assembly of cabinet furniture and kitchen sets. There are thick countertops, bar counters covered with veneer and varnish. It looks very impressive and expensive.

It is not uncommon to use MDF (pressed veneer inserts) in interior design, in car decoration. Cladding of window frames and window sills, musical instruments is allowed.

The main types of wood veneer and their characteristics

Veneer is classified according to the method of its manufacture:

- shelled;

- planed;

- sawn.

The thinnest veneer is obtained by peeling. The essence of this production process is to cut the thinnest piece of wood from a constantly rotating log. This type of veneer is the cheapest and in some qualities inferior to planed and sawn.

As a rule, such types of trees as aspen, pine, alder, birch, beech, oak are used for its production. This type of processing is used for the production of laminated plastics, plywood, laminated glued wood, MDF pasting, as well as for veneering of individual furniture elements.

The thinnest veneer is obtained by peeling

Sliced veneer is produced by slicing a wooden bar with special knives. It makes an ideal pasting for door and furniture facades, wall panels, since the production technology allows you to cut from a bar at different angles, experimenting with the pattern and texture of the wood. It is often used to decorate objects using the marquetry technique.

Sawn veneer is the thickest - from 1 to 12 mm. It is produced by sawing the processed log into thin planks. This is the oldest method of obtaining material known to craftsmen, but also the most expensive, as a result of its use remains a lot of waste. Veneer made in this way is often used for expensive furniture inlaying, as well as for creating bent joinery or furniture elements. It is best made from cedar, fir or spruce raw materials.

This type of veneer is of the highest quality among all that are produced, therefore, if you are doing repairs yourself and are looking for a suitable finishing material, then it would be quite advisable to use it in combination with MDF for cladding doors, creating wall panels or curved stairs. Just keep in mind that in this case, the repair will cost a little more than using planed or peeled material.

With the help of sawn veneer, you can update and restore rare furniture - in such a situation, pasting the product with sheets with wood patterns carefully selected to the original will help.

Wood veneer: general characteristics

Wood veneer is a thin cut of wood with a thickness of 0.5 to 3 mm, which is then glued to a base made of MDF, HPL and other materials. The veneer fully conveys the texture of the tree and has a unique pattern. They learned how to make veneer back in ancient Egypt, but the first sliced veneer was produced in America in 1800.

For the production of veneer, wood species such as birch, alder, beech, oak, linden, ash, larch, cedar and others are used.

Improvement of technologies allowed to reduce the thickness of veneer, as well as improve the quality of the material, so now manufacturers of furniture, doors and interior items can offer products that convey all the natural beauty of wood, but at the same time have an attractive price and do not require special care.

Benefits of using veneer:

- veneer products are lighter and cheaper than solid wood;

- veneer sheets have a unique inimitable texture;

- veneer is less susceptible to deformation;

- it is a natural and environmentally friendly material;

- veneer products have increased resistance to mechanical stress;

- veneer has good sound insulation properties.

Natural wood veneer

Natural veneer is a thin sheet that is removed from the solid wood by sawing, peeling, chipping or planing

Natural wood veneer, depending on the production technology, is divided into peeled, sawn or planed.Rotary cut veneer is produced mainly from hard wood on a special machine; such veneer is considered the cheapest and is mainly used for plywood production.

Sliced veneer is made only from hard wood, and it perfectly conveys the texture and pattern of wood of a particular species. Sawed veneer is obtained from softwood, and it is considered the most valuable, however, it has one drawback: a large loss of material during processing.

Reconstructed veneer "Fine-line" (fine-line)

It is worth mentioning separately the reconstructed veneer (FineLine), it is produced by pressing many thin layers of wood, including different species. The layers can be painted in different colors, this technology allows you to create unique patterns, as well as imitate valuable wood species.

The reconstructed veneer not only provides great design opportunities, but also allows it to not harm the environment, due to the fact that it is produced from fast-growing trees.

Advantages and disadvantages

Veneer has many advantages for which it is appreciated and chosen by consumers. It is worth mentioning the following advantages:

- Economical array replacement. If you buy products finished with natural veneer, then the visual difference is not immediately noticeable, but you can save a lot.

- Environmentally friendly material. Any veneer, even second-rate, consists of at least 75% wood, which allows it to be used in the manufacture of all kinds of interior items (as opposed to film).

- Various shades. A variety of colors and shades of material allows you to make a combination in work (for example, on doors or wardrobes);

- The coating gives additional strength to the structures.

This coating has few disadvantages. Basic: the detrimental effect of moisture on the material, when pressing it is difficult to apply a decorative sheet to the embossed base, that is, the veneered inserts will be of a simple form.

Wood veneer

First of all, you should understand what wood veneer is - this type of product is thin sheets of natural wood, which are used to decorate various elements, giving them a more attractive look. The plates are glued to the base, which is most often MDF, chipboard or cheaper types of wood, and this process is carried out on special equipment.

Wood veneer began to be produced in the 19th century, then a peeling and sawing machine was invented

On a production scale, wood veneer began to be produced in the 19th century, when Mark Isambard Brunel (Great Britain) received a patent in 1806 for the construction of a planer. Further, a peeling and sawing machine was invented, constantly improving the thickness, uniformity and speed of production of a strip from wood.

To date, the range of veneers has grown tremendously. As materials most often used beams of the highest quality such species as oak, beech, ash, maple, alder, pine, sycamore, walnut, wenge, cherry and many others.

What are the advantages of veneer:

- you can find a huge number of textures and colors, which allows you to give a particular product the desired effect. The same breed can be produced in dozens of variants, which differ in shades and features of the texture, because what the surface will look like depends on how the wooden blanks were cut;

- wood surfaces, especially if these are valuable species, have been associated with wealth and prosperity for several centuries, therefore this option fits perfectly into a variety of environments and interiors and is a universal solution that can make the atmosphere more comfortable;

- experienced craftsmen can trim structures of the most complex shapes with veneer; it is also often used for inlaying items in the old style. This type of product allows you to create luxurious products, while the costs will be ten times lower than when purchasing an array, the price of which is very high;

- if necessary, minor damage can be restored, which allows you to keep the products in excellent condition for a long period of time. Of course, areas curled up from moisture cannot be restored, but as for ordinary chips and scratches, they can be eliminated with your own hands.

As for the disadvantages of veneer, they are as follows:

- high-quality products cost quite a lot due to the fact that the best wood is used for their manufacture and the latest equipment is used, but still, in comparison with the solid wood, this is a very budget option;

- if you are going to work with the material on your own, then you should know that finishing curved elements causes the greatest problems, since wood can crack at bends, which is why materials of the highest quality are needed for such structures;

- with temperature and humidity changes, the veneer begins to crack and deform, therefore it should be used only in heated rooms with a stable microclimate.

What types of wood veneer are there

Sliced veneer

As for this product group, it has the following differences:

- sheets are made on special veneer planing equipment, which is characterized by high accuracy and cleanliness of processing;

- product thickness can vary from 0.2 to 5 millimeters, which is sufficient for most uses;

- this method of production is used when working with valuable species of wood, as it allows you to present their structure in the most favorable light. Most often, the work uses wood from oak, walnut, beech, Karelian birch, acacia, ash, yew and much more.

One simple rule should be remembered the thicker the veneer, the more reliable it is, therefore you should not save and purchase the thinnest options

Rotary cut veneer

The production of wood veneer using this technology has the following features:

- The production process is very simple: the logs are cut into pieces of small width, after which they are cut into a sheet of small thickness using a special knife. The quality of this option is noticeably lower than the first one, but the cost price is also lower, therefore it is the most popular;

- the following types of wood are most often used for work: pine, birch, alder and oak;

- the thickness of the finished elements can be from 0.1 to 10 millimeters, which allows you to choose the optimal solution for any type of work.

Sawn veneer

As for this type of product, the following can be noted regarding it:

- products are produced on special machines that cut the bar layer by layer, due to the large amount of chips that are formed during operation, the cost of the material is high;

- the thickness of the lamellas, and this is what the finished elements are called, can be from 1 to 10 mm;

- products of this type are of especially high quality, therefore they are very often used in the production of musical instruments, they can also be used in the interior and in the manufacture of furniture, such surfaces practically do not require additional processing.

It is important to choose the option that is best suited in a given situation, and if the manufacturer has recommendations for use or special instructions for carrying out work, then all requirements should be followed in order to get a guaranteed high result.

One simple rule should be remembered: the thicker the veneer, the more reliable it is, so you should not save and purchase the thinnest options.Veneer is one of the materials, the popularity of which never decreases, moreover, with the rise in wood prices, the demand for this option will be even greater.

What raw materials are used for production?

Taking into account the need and wishes for the characteristics of the material and for the final product, veneer is made from various types of wood:

- Oak. These can be trees growing in European, American territories or in wetlands. Oak is a strong and durable tree. It will harmoniously fit into the interior, well suited for facing parquet, doors, furniture finishing. The color can be from white to brown.

- Nut. There are American, European, and Californian. Mostly the color of the material is brown.

- Maple. Used folded, curly, European. The wood is almost white. There are shades of brown.

- Cherry. Used European and American. The color of the product is red-brown. They are used in the assembly of elite furniture models.

- Wenge. It is an African wood, popular and widely used in decorative flooring. The color of the material is closer to dark brown.

In the manufacture of such a coating, pine, larch, linden and birch are used.

These types of wood are valued, used in the manufacture of furniture, and finishing works.