11.01.2020Repair0

Renovation is not just wallpapering or painting the floor, it is also renovation work that uses polyurethane foam. But how to save it, if not the entire can is used - the question is mandatory at the stage of rough work.

- 1 Polyurethane foam and its preservation

- 2 Are we storing it right or wrong?

What is polyurethane foam?

Maxi (Profflex) all-weather (pack 750 ml - 218 rubles). Photo: Profflex

One-component polyurethane foam is an aerosolized polyurethane sealant. The base of the foam is a prepolymer (prepolymer) synthesized from polyol and isocyanate. As a result of the polymerization reaction, partly taking place inside the cylinder, and mainly in air, after being released outside, these substances form polyurethane. Coming out of the balloon, the prepolymer sharply increases in volume (20–40 times) and turns into foam. Expanding, it penetrates into hard-to-reach cavities, fills the voids. Then the cellular mass gradually polymerizes (hardens), absorbing moisture from the air or from a previously moistened surface. After a day, it becomes a chemically stable substance - polyurethane. It is non-toxic, does not deteriorate for a long time, and is resistant to moisture. This rather rigid, finely porous material consists of closed cells and serves as a good insulator.

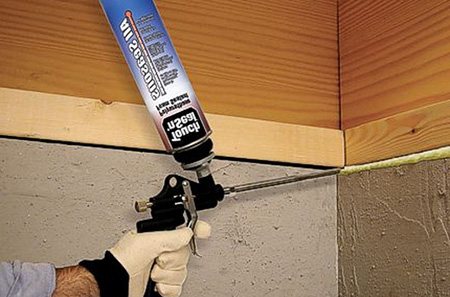

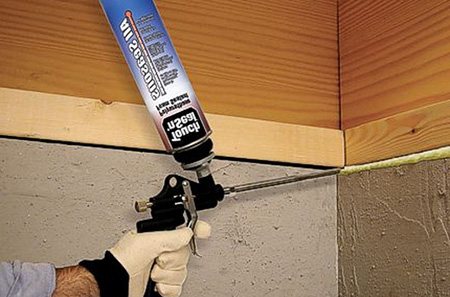

Installing the cylinder on the gun

To learn how to properly use a foam gun, you need to go to practical work, starting with charging it:

- The top of the container is closed with a protective cap, which must be removed before installation. The pistol is positioned with the handle down and the cylinder is screwed to the adapter in a vertical position. During the connection, hold the pistol firmly by the handle with one hand, and with the other hand twist the cylinder onto the adapter with rotational movements.

- After connecting, the contents of the container must be shaken well. This process brings the polyurethane foam substance to a homogeneous composition. The container installed on the pistol is held firmly by hand and shaken sharply from top to bottom about twenty times. When shaking, the handle should only be at the top.

- After shaking, the device is moved with the container up, and with the handle down. This is his working position. Turn the adjusting screw a quarter of a turn and try to pull the trigger. After filling the entire barrel with foam, the tool is ready for use.

During operation, it may be necessary to adjust the flow of the mixture. This can be done by turning the same adjusting bolt.

Working position of the pistol - balloon up

How does household foam differ from professional foam?

Tytan Professional STD (Selena) summer (pack 750 ml - 315 rubles). Photo: Selena

The household foam cylinder is equipped with a special applicator tube. Thanks to this device, no additional tools are required to exit the viscous mixture. Household foams are generally disposable products. The mass yield is difficult to dose, and it itself is distinguished by its high density and low polymerization rate. Professional foams are designed for repeated use and better sealing. In them, the supply and metering of the foam stream occurs with a plunger pistol. It is screwed onto a special ring on the cylinder. It is professional foam that should be preferred when installing doors and windows.

Replacement for a lost tube from a cylinder

It is impossible to work with foam without a tube-nozzle on the balloon. But it is often lost and, as a rule, I discover it at the most inopportune moment, when there is no opportunity to go to the store. When this happened for the first time, I was forced to go to a neighbor and ask him for a pipe from a spare set. The neighbor did not have one, but he suggested an excellent "substitute" option - a heat-shrinkable tube. It is enough to put it on the nozzle and warm it up so that it is well fixed.

And to make it convenient to press the button, you should use a regular washer, putting it on the tube and shifting it down.

At what temperature can the foam be used?

Soft foam cleaners: PU Foam Cleaner Click (Soudal) (pack of 500 ml - 257 rubles). Photo: Soudal

Depending on the range of operating temperatures, polyurethane foams are divided into summer, winter, all-season. For the first, the range of permissible temperatures is in the zone of positive values: from 5 to 30 ˚C. Winter and all-season foams are used in a wider range: from –10 ° С (some from –25 ° С) to 30 ° С. In this case, it is worth considering the manufacturer's advice on the temperature of the cylinder. In the cold season, with low air humidity, the course of chemical reactions slows down, the viscosity of the mixture increases, and the pressure in the cells of the foamy mass decreases. For normal operation of winter foam, many manufacturers advise to warm up the cylinder to room temperature (23 ° C), keeping it in a living room for about a day or immersing it in warm water (about 30 ° C). However, there are products for which the use of a cold bottle is acceptable.

Winter foams contain components that help to better absorb moisture from the environment and maintain the desired consistency at low temperatures. Winter foams can be used in cold and warm seasons without any deterioration in performance. Photo: ShutterStock / Fotodom.ru

The advantages of MP include:

- High coefficient of expansion of the material, allowing you to perform a large amount of work with a single foam canister.

- Sealing the seam with foam at the same time increases its sound and heat insulation characteristics.

- MP does not conduct electric current and is not afraid of moisture.

- There are several types of foam on sale, which can be divided according to the degree of fire resistance (B3 - combustible material, B2 - self-extinguishing, B1 - fireproof). Therefore, it is possible to choose the material depending on the operating mode of the sealed structures.

Why do you need to shake a can of polyurethane foam before work?

ECO Tytan Professional (Selena) (pack of 500 ml - 235 rubles). Photo: Selena

A container with polyurethane foam contains several components of different densities. When stored for a long time, they can be distributed in layers. Therefore, before starting the process, the cylinder should be shaken vigorously for half a minute to mix the components. Also, shake it periodically during use and especially after smoke breaks. Insufficient shaking can result in a coarse foam structure and reduced foam volume. During operation, the cylinder is held upside down. In this position, the propellant gas sinks below the polymer mass and maximizes the use of the contents.

The surfaces on which the polyurethane foam is applied must be thoroughly dust-free, free from dirt, oils, grease and ice. Photo: ShutterStock / Fotodom.ru

Reusing the balloon

If you need to reuse the cylinder without a gun, for example, within a month, then you need to bend the tube, fixing the fold with tape. Then push the valve down to keep the pressure in the tube... So a cylinder with polyurethane foam can be used for 2 months without any problems.

If the balloon is needed again only after 5–6 months, there is another way of storage. Acetone can be used. The tube is carefully removed from the cylinder and rinsed with acetone. They are also dripped into the valve opening.Repeat the manipulation two or better three times. So the balloon will stand up to six months.

To work with a professional-type cylinder without a pistol, you will first need to select a suitable plastic tube and figure out how to press the valve.

For this purpose, a hand-made tube of 3 parts is suitable:

- the first is flexible;

- the second is solid;

- the third is flexible.

The first part presses the valve, the second helps prevent splashing, and the third directs the foam stream to the desired location.

Prices for polyurethane foam with a straw

How much foam is needed to fill the cavities?

Cleaner for solid foam: Tytan Professional (Selena) (pack of 100 ml - 379 rubles). Photo: Selena

In order to prevent the deformation of insufficiently strong walls during the expansion of the foamy mass, it is recommended to fill the voids and cracks with foam by no more than a third. When installing interior doors, it is advisable to use several spacers to fix the box. Then the expanding foam will not be able to deform it. However, with the correct professional dosage of foam, this is not necessary.

The volume of the finished foam depends on the capacity of the cylinder and its filling, the temperature of the air and the cylinder, the humidity of the air, the quality of the gun and the qualifications of the master. High-performance foams yield 65 liters or more, and regular foams - 25–45 liters.

Do the surfaces wet before applying the foam?

A relative humidity of more than 50% is sufficient for the normal foam polymerization process. In such conditions, it is not necessary to moisten the surfaces. However, at low humidity (less than 50%), which is typical for the cold season and hot summer days, moistening the joints and cavities will increase adhesion and improve foam hardening. This should be done without fanaticism, so that there are no drops on the surface and no water accumulates, otherwise its excess will prevent the foam from connecting to the surface.

The construction gun must be cleaned of foam immediately after removing the empty cylinder, avoiding hardening of the mass inside the gun. Photo: ShutterStock / Fotodom.ru

The procedure for changing a used cylinder

During the execution of large volumes of work, of course, it will be necessary to replace the spent empty cylinder with a new container. This action has its own order:

- Even if the mixture no longer flows from the nozzle, the container may contain some residual pressure. Before replacing the cylinder, it must be vented by directing the barrel into the debris and pulling the trigger. After the complete cessation of the hissing sound, the instrument is placed with the handle up, and the empty container is unscrewed.

- The junction, that is, the adapter, will be covered with excess foam. They must be washed off immediately with flushing solution and quickly screwed on a new bottle. Delay in these actions will lead to solidification of the remaining mixture in the barrel. Then, for further work, you will have to completely clean the entire tool.

Having made a quick change of capacity according to all the rules, you can proceed to further work with the tool.

When replacing the cylinder, it is necessary to quickly wash off the remaining foam from the adapter, do not allow them to solidify.

When can excess foam be cut?

The polymerization time of the polyurethane foam is influenced by the temperature of the environment, the cylinder itself and the size of the cavity. On average, professional foam in a cavity 30 mm wide hardens in 20–30 minutes, and household foam is somewhat slower - in 40–60 minutes. The expansion process ends in a day, and then you can begin to remove the solid mass.

The vertical gaps are filled with polyurethane foam, moving from bottom to top. Photo: ShutterStock / Fotodom.ru

The hardened foam is carefully cut with a sharp knife. Photo: ShutterStock / Fotodom.ru

Polyurethane foam cleaners

Winter professional polyurethane foams: Makroflex Premium Mega 70 (Henkel) (pack of 870 ml - 390 rubles). Photo: Henkel

The foam remaining after mechanical cleaning of the gun, cylinder (valve and the cylinder itself outside), clothing and other surfaces can be easily removed using a special aerosol cleaner. There are two types of cleaners:

- for soft foam;

- for hardened foam.

They all contain strong solvents. Therefore, before use, it is advisable to check the effect of the aerosol on a hidden area of the surface to be cleaned.

Release form

All types of polyurethane insulation differ according to several criteria.

Depending on the method of application and the form of release, they can be of two types.

- Professional foam is produced in special cylinders that are inserted into a plastic gun with metal clips. Such a gun allows you to use polyurethane economically and in equal portions. The main thing is to thoroughly rinse the device after use so that the residues of the substance do not freeze in it.

- Instead of a gun, household foam packs are equipped with a small tube that is put on a lever. It is not suitable for large repairs, but it will perfectly cope with minor flaws.

Depending on what time of the year and at what temperature the polyurethane will expand and solidify, the following types of polyurethane foam are distinguished:

- summer - used at temperatures from +5 to +35 degrees;

- winter - used at temperatures from -18 to +35 degrees;

- universal - it is much more expensive, but it can be used all year round.

It is worth noting that the temperature ranges are indicated not for air, but for the surface on which the composition will be applied. The lower its temperature, the less the expansion of the finished layer will be.

In addition, foam can differ in types depending on the flammability class:

- B3 is a combustible substance;

- B2 - self-extinguishing substance;

- B1 - refractory compositions.

Finally, polyurethane foams differ in composition. They can be one- or two-component. However, the latter type of foam is so difficult to handle that it is practically not used for private construction and when repairing a room with your own hands. Two-component foam hardens in a quarter of an hour and there is practically no time left to eliminate defects, therefore only experienced professional builders use it.

How to store and reuse a foam canister?

Soudafoam Maxi 70 (Soudal) (pack of 870 ml - 336 rubles). Photo: Soudal

You can interrupt work with household polyurethane foam, the cylinder of which is equipped with an applicator tube, only for a short time, no more than half an hour. The mixture dries quickly in air and is able to block the release of the remaining foam. When using professional foam, manufacturers recommend not removing the gun from the cylinder until it runs out of contents. During storage, the pistol trigger is locked with a metering screw.

In this state, the cylinder with the pistol can be kept for 1-2 weeks. But its prolonged stay in warm and humid conditions significantly reduces the shelf life of the polyurethane foam. But a dry and cool room is ideal for storing a cylinder. Moreover, they install it vertically, with the valve up, since the horizontal position leads to valve malfunction.

Characteristics

The quality of the polyurethane foam is determined by several characteristics.

- Foam volume.

This indicator is influenced by temperature conditions and humidity of the environment. At lower temperatures, the volume of the sealant is less. For example, a bottle with a volume of 0.3 liters, when sprayed at +20 degrees, forms 30 liters of foam, at 0 temperature - about 25 liters, at negative temperatures - 15 liters. - Degree of adhesion

determines the strength of the connection between the surface and the material. There is no difference between winter and summer species. Many manufacturing plants are trying to produce compounds with good adhesion to wood, concrete and brick surfaces. However, when using foam on top of ice, polyethylene, teflon, oil bases and silicone, the adhesion will be much worse.

- Expanding ability

Is an increase in the volume of the sealant. The higher this ability, the better the sealant. The best option is 80%. - Shrinkage

Is the change in volume during operation. In the event that the shrinkage capacity is too high, the structures are deformed or the integrity of their seams is disturbed. - Excerpt

Is the duration of the complete polymerization of the material. With an increase in the temperature regime, the duration of exposure decreases. For example, winter polyurethane foam hardens up to 5 hours at temperatures from 0 to -5 ° C, up to -10 ° C - up to 7 hours, from -10 ° C - up to 10 hours. - Viscosity

Is the ability of the foam to stay on the substrate. Professional and semi-professional polyurethane foams are produced for widespread use. Semi-professional options are ready for use after installing the valve on a foam cylinder, professional ones - they are applied with a mounting gun equipped with a dispenser.

The advantages of the installation staff include the following:

- multifunctionality;

- heat and sound insulation properties;

- tightness;

- dielectric;

- resistance to temperature extremes;

- long service life;

- easy application.

The disadvantages of the sealant are represented by the following features:

- instability to ultraviolet radiation and high humidity;

- short shelf life;

- some species are capable of rapid ignition;

- difficult to remove from the skin.

Polyurethane foam is a versatile product that performs several functions.

- Tightness. It fills in gaps, insulates interiors, removes voids around doors, windows and other details.

- Gluing. It fixes the door blocks so that there is no need for screws and nails.

- Secures the base for insulation and insulation, for example, for cladding a building with polystyrene, the installation composition will be the best option.

- Soundproofing. The building material fights against increased noise during the operation of ventilation, heating systems. It is used to seal up the gaps between pipelines, the connection areas of air conditioners and exhaust structures.

Does the foam need to be protected from sunlight?

Tytan Professional ICE 65 (Selena) (pack of 870 ml - 340 rubles). Photo: Selena

Polyurethane foams are very sensitive to UV rays. The solidified mass darkens and crumbles under the influence of sunlight. The foam must be protected from light by plaster, panels, etc. In addition, the solidified mass does not tolerate temperatures above 110 ° C, the effect of alkalis, acids and compounds used to remove foam residues.

Foam Adhesives

GoldGun 65 (Penosil) (pack of 875 ml - 345 rubles). Photo: Penosil

The scope of application of polyurethane foam is expanding. Many manufacturers, including the TECHNONICOL corporation, Henkel, Selena, offer glue-foams for fixing foam insulation boards, extruded and extruded polystyrene foam, when installing external and internal thermal insulation systems on concrete, brick, plastered surfaces, etc. , foam glue is used in the construction of walls and partitions from aerated concrete, ceramic and other blocks. Unlike conventional foams, adhesive foams are characterized by higher adhesion and low expansion rates.

Professional polyurethane foams: all-season Construction 70 (Penosil), application temperature from –10 to 30˚С (pack of 870 ml - 336 rubles). Photo: Penosil

Summer Soudafoam Professional 60 (Soudal) (unit of 750 ml - 390 rubles). Photo: Soudal

Summer Tytan Professional Gun (Selena) (unit of 750 ml - 343 rubles). Photo: Selena