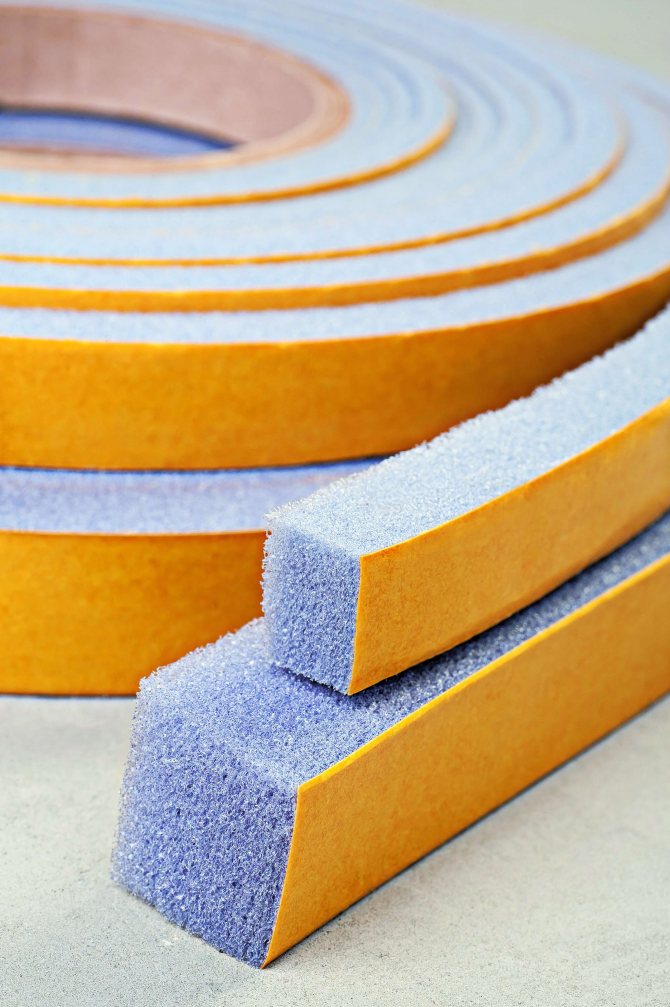

Butyl tape is a modern sealing material that is widely used in private and commercial construction. It is presented in different standard sizes, it can have a layer of aluminum foil, foil-clad polyethylene foam and even acoustic felt. But one thing remains unchanged: the presence of an adhesive butyl rubber surface, easy to use and environmentally friendly.

Liplent Sd - one of the varieties of butyl tape - designed for sealing the external joints of windows and doors

Diffusion tape vapor-permeable NL (for low tide) butyl

Diffusion vapor-permeable moisture-proof tape (based on non-woven material) NL butyl

DESCRIPTION of a moisture-proof vapor-permeable tape (for ebb) butyl NL:

Waterproof vapor-permeable (diffusion) tape subservient NL Profband made of synthetic non-woven material of the membrane type is intended for waterproofing the lower assembly seam from external moisture of a translucent structure (under the tide), as well as any other construction seams and joints. The tape has two adhesive strips on one side (or on different sides only on request). One strip is intended for fastening the tape to a translucent structure, the other is for attaching the tape to a wall or slope. A wide range of standard sizes of tapes allows you to choose a material for protecting seams of almost any size. The use of Profband waterproofing tapes provides reliable protection of the polyurethane foam from moisture penetration outside the room and promotes its removal from the foam to the outside, provides ventilation of the joint. The adhesive layers by the strength of the adhesive bond are much higher than those required by GOST 30971-2002.

APPLICATION:

Waterproof vapor-permeable tape subservient NL Profband is ready-to-use and does not require special tools for its installation. The surfaces of joints and seams must be free of dirt. It is necessary to glue the tape tightly along its entire length. Any gap or leak is a channel for rainwater to enter. At the corners, the tape must be bent in such a way that the folded parts form sides to protect the lower corners of the window opening. It is necessary to overlap the tape.

Size selection:

To ensure reliable protection of the seam or joint, the tape must be glued to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: add 40 mm to the width of the mounting gap (rounded up). If necessary, it is possible to use a wider tape.

Material properties:

• Resistance to vapor permeation: 0.053 (m2 * h * Pa) / mg • Adhesive bond strength: not less than 0.3 (3.0) MPa (kgf / cm2) • Water resistance: not less than 600 Pa • Operating temperature: from -36 to +70 C °

It is possible to manufacture according to non-standard and individual sizes.

Compliance with these recommendations will allow the most correct installation of the PSUL tape and will help protect the assembly seam from harmful environmental influences. The pre-compressed sealing tape is packaged in boxes and requires delivery to the installation site while maintaining the integrity of the packaging. If the integrity of the packaging is violated, the manufacturing company is not responsible for the further use of the product. Storage and transportation of PSUL tapes should be carried out in accordance with the recommendations indicated on the package.PSUL tape should be stored and transported at temperatures from +5 to +30 C, in a dry place protected from direct sunlight. For the correct selection of the dimensions of the PSUL tape, it is necessary to remember that the tape performs its functions only in a compressed state. That is, for a gap of 5 mm, it is necessary to use PSUL tape, which has a maximum expansion of 20 mm, for a gap of 6-10 mm, it is necessary to use a PSUL tape, which has a maximum expansion of 30 mm, and so on. When choosing a tape, you need to consult with our specialist who will select the desired product for you. The use of tapes with the expansion of a deliberately smaller gap size will lead to the failure of this tape to fulfill its functions, as well as to the rapid destruction of the assembly seam. If the thickness of the PSUL tape is incorrectly selected, the manufacturer is not responsible for the use of the manufactured products. The pre-compressed sealing strip is used according to GOST 30971-2002 to provide vapor permeability assembly seam. PSUL tape is used at temperatures from +5 to +40 C. Application of PSUL tape at low temperatures will lead to an increase in the release time of the tape. To avoid an increase in the release time, the tape must be kept at room temperature for 24 hours. During installation, to speed up the release time, it is necessary to process the tape with a hot air gun. Otherwise, the release time will increase many times. The PSUL tape is attached to a pre-treated, free from dirt and dust, degreased surface of a window or door block (or any other mounted material). It is advisable to treat the surface on which the PSUL tape is attached using BR-1 or BR-2 solvent. When installing the tape, it is necessary to ensure a snug fit to the surface using a short-term (within 3-5 seconds) pressure.

Structure

The basis of the material is a butyl rubber polymer composition, which remains plastic and adhesive in the range from −40 to +100 ° С. It can cover the tape from one or both sides, and is protected from above with release paper. Due to the properties of butyl rubber, such tapes have high performance characteristics.

Butyl rubber is a synthetic rubber based on isobutylene. The substance is distinguished by high heat, cold, light and ozone resistance. Butyl rubber is approximately 20 times less air permeable than natural rubber. Resistant to moisture and aggressive media - solvents, alkalis, acids, alcohols, vegetable and animal fats.

Waterproofing vapor-permeable tape Robiband NL

This material is an integral part of the Robiband system used to organize a ventilated assembly seam. The Robiband system fully complies with modern technical standards.

The Robitex company in the line of ROBIBAND PREMIUM products uses the latest butyl rubber adhesive layer (BKKS), which provides ultra-high adhesive and cohesive qualities and adhesion to surfaces. The new BKKS has shown excellent durability results in tests. Conditional service life is more than 20 years.

How is PSUL produced?

The production technology is KNOW-HOW of each company producing PSUL, both abroad and in Russia. The technology of our company has absorbed all the best that Western manufacturers have and at the same time was supplemented with unique solutions, which gave us the opportunity, the only one in Russia, to receive a certificate for 20 years of guaranteed product operation.

The basis for PSUL is foamed elastic polyurethane (hereinafter PPU) with specified characteristics, which, upon entering the factory, undergoes strict incoming control.Further, to give it the required characteristics, polyurethane foam is impregnated with special compounds that give the finished product UV resistance, water resistance and other equally important properties. For many manufacturers, this is the most important stage of production, which is carefully guarded from outsiders. Impregnating compounds are the result of long research and development that does not occur overnight. Each modification of the impregnation must be tested not only within the laboratory of the enterprise, but also under the operating conditions of the product, taking into account the possible shelf life and operation, which is confirmed by tests for the durability of the product in Certified Laboratories. The impregnated workpieces are dried in special drying chambers with variable parameters of the effect of temperature and pressure. At this point, all components of the impregnation must go through the stage of a given polymerization, the excess moisture must be completely removed. Having passed the drying stage, the finished semi-finished products enter the "ripening" zone, where they are under special conditions until further processing - compression, application of an adhesive layer and rolling into rolls. The finished rolls go to the cutting section, where they turn into a finished product. Modern equipment allows us to produce PSUL of any standard size.

Product brief description

Waterproofing vapor-permeable tape made of synthetic non-woven material of the membrane type. The tape is intended for waterproofing the assembly seam of a translucent structure under the ebb, as well as any other construction seams and joints. The tape has two adhesive strips on one (optional) or two sides. One strip is intended for fastening the tape to the translucent structure, the other - for attaching the tape to the wall slope. A wide range of standard sizes of tapes allows you to choose a material for protecting seams of almost any size. The tape is supplied in rollers. The use of Robiband waterproofing tapes provides reliable protection of the polyurethane foam from moisture from the street side and provides moisture removal from the foam to the outside.

Material characteristics

| Indicator name | unit of measurement | Requirement GOST 30971-2002 | According to the test report |

| Resistance to vapor permeation | (m2 * h * Pa) / mg | no more than 0.25 | 0,053 |

| Adhesive bond strength | MPa (kgf / cm2) | not less than 0.3 MPa (3.0 kgf / cm2) | not less than 0.3 (3.0) |

| Water resistance | Pa | not less than 600 | impenetrable |

| Operating temperature | C ° | from -36 to +70 | corresponds to |

| Durability | conv. years | not less than 20 | corresponds to |

Choice of size Robiband NL

To ensure reliable protection of the seam or joint, the tape must be adhered to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: 45 mm must be added to the width of the mounting gap (rounded up). If necessary, it is possible to use a wider tape.

Basic dimensions

| Width of belts, mm | Length, m |

| 80 | 12,5 |

| 100 | 12,5 |

| 120 | 12,5 |

| 150 | 12,5 |

It is possible to manufacture other standard sizes on request

Application of Robiband NL tapes

The Robiband NL tape is directly ready for use and does not require special tools during its installation. The surfaces of joints and seams must be free of dirt. Absorbent and fragile surfaces require priming. It is necessary to glue the tape tightly along its entire length. Any gap or lack of density is a channel for rainwater to enter the foam. At the corners, the tape must be folded so that the folded parts form sides to prevent leaks in the lower corners of the window opening. It is necessary to overlap the tape. It is recommended to glue the assembly seam "on wet foam". This is necessary so that the polyurethane foam, when expanding, sticks the tape to itself and tightens it a little.The installation of the tape should be carried out using the "from the frame" technology, having previously glued it to the SPK box. Only the complex application of the Robiband system provides the necessary reliability and durability of the assembly seam. The use of each material separately or their incomplete combination only partially improves the characteristics of the seam and does not provide comprehensive protection against a wide range of negative effects on the seam during its entire service life.

Installation of PVC structures and PSUL tape for windows

There is nothing difficult in installing windows equipped with PSUL. Moreover, the installation of the structure is carried out in several stages, which we will announce in order to simplify your choice and installation.

First of all, you need to carefully stick the tape on the front of the window frame so that everything is smooth. At the time of foaming the seam, the tape should be open, expanded. This will prevent foam from getting under and behind it, which is unacceptable.

It is impossible to keep the tape simply glued to the frame for a long time, as it may lose its properties.

Next, you need to install the structure in the opening. It is worth making sure that the tape matches the size and degree of expansion correctly, since it is thin or, on the contrary, thick, loses half of its qualities if used improperly.

It will also not hurt to install a special vapor-permeable waterproofing tape under the ebb, which is also important. Thus, you will avoid the impact of rainwater on this place, flowing down the window sill and glass surfaces. It is better to use ordinary specialized liquid sealants, which will not worry about the consequences.

External diffusion tape Bauset MR 1,5x70mm (25m)

Attention! The actual color and texture of the products may differ slightly from their images shown on the website of the online store.

Bauset MR vapor-permeable (diffusion) tape based on a synthetic non-woven membrane-type material protects the assembly seam from the outside from moisture and provides ventilation of the assembly seam to the outside.

For easy and secure fixation, two butyl adhesive strips are applied to the tape. It is recommended to install it under the external ebb, as well as around the entire perimeter of the window in cases where the installation of PSUL is impossible. In the latter case, the tape must be closed with a strip.

- Made from durable polyester fabric

- When used correctly, a guarantee of tightness of at least 20 years

- Ease of installation

| Material | diffusion tape (membrane type) made of durable polyester fabric with two butyl rubber mounting strips applied to one side |

| Working temperature | from -10 ° C to + 45 ° C (at temperatures from -10 ° C to -20 ° C, you must first keep the tape at room temperature for 24 hours) |

| Heat resistance | from - 60 ° C to + 140 ° C |

| Water absorption | not more than 0.3% |

| Resistance to vapor permeation | no more than 0.25 (m2 * h * Pa) / mg |

| Adhesion strength | not less than 0.1 MPa |

- Surface preparation. The surfaces to be treated must be clean, dry and free from grease. It is recommended to pre-treat porous surfaces with a primer (adhesive mastic).

- Cut the tape into pieces equal to the width and length of the window plus 10 cm (to form corner joints).

- Glue the duplicated tape with an adhesive strip to the window frame around the perimeter, after removing the anti-adhesive protective paper tape.

- Place the window in the opening level and secure.

- Apply polyurethane foam to the seam.

- After 15-20 minutes, close the assembly seam with foam with a duplicated tape, gluing it to the slope opening of the window using a butyl glue strip, after removing the anti-adhesive paper.

In its original packaging in a dry place, avoiding direct sunlight, the tape can be stored for 12 months at temperatures from 0 ° C to + 20 ° C.

Average product rating

0 based on 0 reviews

0% of buyers recommend this product.

Delivery by transport TBM-Market

Delivery is carried out FREE OF CHARGE in Moscow and the Moscow region for orders over 3000 rubles. Delivery period: Monday to Saturday 09:00 to 16:00.

Tverskaya, Vladimirskaya, Ryazanskaya, Tula, Kaluga, Smolensk, Bryansk regions and the city of Oryol - free delivery to the address is made when ordering from 15,000 rubles.

Important! Orders for next day delivery are processed until 13:30. Orders placed after 13:30 are delivered every other day.

For delivery terms to districts of the Moscow region, check with the managers of the online store.

Attention! Delivery of goods is carried out to the customer's entrance. The unloading of goods from the machine is carried out by the buyer. If it is impossible to deliver the order to the entrance, delivery will be performed to the nearest possible place of unloading. Delivery to closed areas with paid entry is carried out only after the customer pays for the pass. Otherwise, delivery will be made to the nearest possible location. The forwarder makes a test call by phone 30-60 minutes before going to the buyer. If it is impossible to reach the buyer, the delivery will be canceled.

The goods are shipped only to the Client indicated in the invoice, or by a notarized power of attorney.

Attention! Only paid orders are delivered on Saturdays!

| FREE SHIPPING |

Delivery of orders is carried out from Monday to Saturday from 09:00 to 16:00.

Attention! Only paid orders are delivered on Saturdays!

- Delivery cost within the Moscow Ring Road and within the city of Mytischi 500 rubles

- Delivery cost from the Moscow orbital to the 1st concrete ring with an order amount of up to 3000 - 990 rubles

- The cost of delivery from the 1st concrete ring to the borders of the Moscow region with an order amount of up to 3000 - 2000 rubles

- Orders for next day delivery are processed until 13:30. Orders placed after 13:30 are delivered every other day

- Tver, Vladimir, Ryazan, Tula, Kaluga, Smolensk, Bryansk regions and the city of Oryol - with an order amount of up to 15,000 rubles. delivery cost will be 450 rubles.

Delivery by transport company

Delivery is possible to any city of the Russian Federation where there is a terminal of the transport company. Part of the product (slopes, window sills, profile and some others) requires additional packaging. You can familiarize yourself with the tariffs for packaging, cargo insurance and delivery to your city on the website of the selected transport company.

The order is delivered to the transport company free of charge.

Check with the online store managers for details.

| PAID DELIVERY BY COURIER SERVICE |

Mastics and sealants from

About us

Welcome dear consumers of sealing materials!

The production plant has been successfully operating in the market of building and automotive materials since 2001. and currently our company produces and offers for delivery a wide range of butyl tapes, bitumen mastics and materials for waterproofing, as well as road joint tape.

Main types of products and fields of application:

- Butyl rubber assembly tapes (vapor barrier tape, duplicated tape, diffusion tape, vapor permeable tape, window tape). They are used for the installation of windows in accordance with GOST 30971-2012.

- Butyl rubber sealing tape for construction. They are used for the installation of sandwich panels, joints for sandwich panels, and as a roofing tape for waterproofing roofs.

- Butyl rubber mastic Plastilent-M. It is used as a mastic for waterproofing interpanel seams (inter-seam sealing mastic). Complete analogue of Technonikol-45 and Hermabutil mastics.

- Bituminous waterproofing mastics (Bitumen-rubber mastic, bituminous primer). Waterproofing of foundations, roofs, various junctions is used.

- Road connecting tape (tape for asphalt, tape for asphalt concrete).They are used for waterproofing joints between asphalt layers.

- Automotive materials. AUTO-7 mastic (51-G-7 sealant), AUTO-6 mastic (51-G-6 sealant), anti-noise bitumen mastic MPB-97, mastics for welding. They are used at various automobile plants, including AVTOVAZ, UAZ, OAG Izhevsk, Rostselmash, MAZ, BELAZ and others.

Our advantages

Delivery all over Russia

Competitive prices, wide assortment, prompt delivery to any region of Russia, delivery to a transport company - free

High adhesion of butyl

Butyl adhesion to various surfaces (concrete, brick, melall, etc.) differs for the better

Modifying components

The presence in the composition of several modifying components that have a positive effect on the preservation of the properties of the sealant over time

Application of mastics and sealants

Tapes for installation of windows and sandwich panels

Mastics for interpanel seams

Roof waterproofing

Full butyl tapes

Description

When installing a window in accordance with GOST at, you will definitely need window sealing tapes (tape sealant) to protect the assembly seam. They provide reliable protection of the polyurethane foam from atmospheric influences and maintain high performance of the assembly seam for a long time.

A tape sealant is a synthetic material (non-woven fabric, foil or film) and an adhesive layer (butyl rubber and / or acrylic) applied to it.

Tape sealants vary in application:

- • for the outer layer of the assembly seam;

- • for the inner layer of the assembly seam.

For the outer layer is used vapor-permeable (diffusion) waterproofing tape. Provides UV protection and waterproofing to the outside of the joint and releases moisture from the joint to the outside.

For the inner layer is used vapor barrier (full-butyl duplicated or economical foil) tape. Provides protection of the seam from moisture penetration from inside the room.

Steam waterproofing tapes (PGL).

Vapor barrier tape made of aluminum foil reinforced with high-strength synthetic thread. The tape is intended for internal vapor barrier of assembly joints, followed by plastering of slopes. The tape has two adhesive strips on one (optional) or two sides. One strip is intended for fastening the tape to the translucent structure, the other - for attaching the tape to the wall slope. On the side of the strip intended for attachment to the translucent structure, the tape is backed up with non-woven material to create adhesion of the tape to the plaster mortar. A wide range of standard sizes of tapes allows you to choose a material for protecting seams of almost any size. The tape is supplied in rollers. The use of vapor barrier tapes provides reliable protection of the mounting foam from moisture from the room side and prevents moisture from escaping from the seam on the surface of the inner slopes.

| To ensure reliable protection of the seam or joint, the tape must be adhered to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: 45 mm must be added to the width of the mounting gap (rounded up). If necessary, it is possible to use a wider tape. |

Vapor permeable tapes (PPL).

Waterproofing vapor-permeable tape made of synthetic non-woven material of the membrane type. The tape is intended for waterproofing the assembly seam of a translucent structure under the ebb, as well as any other construction seams and joints. The tape has two adhesive strips on one (optional) or two sides. One strip is intended for fastening the tape to the translucent structure, the other - for attaching the tape to the wall slope. A wide range of standard sizes of tapes allows you to choose a material for protecting seams of almost any size. The tape is supplied in rollers.The use of waterproofing tapes provides reliable protection of the construction foam from moisture from the street side and ensures moisture removal from the foam to the outside.

| To ensure reliable protection of the seam or joint, the tape must be adhered to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: 45 mm must be added to the width of the mounting gap (rounded up). If necessary, it is possible to use a wider tape. |

PSUL – pre-compressed sealing self-expanding self-adhesive tape ... The material is a self-adhesive elastic polyurethane foam tape impregnated with a special compound. The belt is delivered in a compressed state, rolled into rollers. A wide range of standard sizes of tape sealant allows you to choose a material for protecting joints of almost any size. There are two types of PSUL tape: gray and black. The tapes differ slightly in characteristics and type of impregnation. The gray tape has a higher performance than the black one. Placed in a joint or seam, the tape expands on its own, completely filling all irregularities and gaps, providing reliable protection of the seam from all adverse climatic influences.

Application PSUL :

- • protection of the assembly seam from moisture, air and UV rays;

- • removal of water vapor from the assembly seam;

- • sealing of external construction joints;

- • additional sound and heat insulation of window and door openings.

The main quality characteristics of tapes PSUL are:

- • density (from 30 to 150 kg / m³);

- • resistance to vapor permeation (no more than 0.25 m² hPa / mg);

- • resistance to UV rays;

- • limit of water resistance (not less than 300 Pa);

- • adhesion (not less than 0.03MPa);

- • durability (at least 20 years).

All characteristics must meet the requirements of GOST.

When choosing a tape, you must adhere to the following rule:

The maximum degree of protection is provided by the tape, the size of which in the sealed seam does not exceed 20% of the height of its full expansion. When expanded by 80%, dust and soundproofing will be ensured. Any expansion of the tape will protect the foam from UV rays. A WARNING: The use of PSUL tapes with a deliberately smaller size than necessary in a particular case can lead to undesirable consequences, such as the occurrence of leaks, blowing out of the PSUL by a strong (hurricane) wind, as well as squeezing out the PSUL by foam. High-quality sealing and protection of the seam is ensured only by correctly sized tapes.

IN Group of companies "PARTNER-SERVICE" you can wholesale ROBIBAND steam waterproofing tapes. You can get acquainted with the assortment on our website in the section "CATALOG". Check the price and terms of purchase with the sales managers by phone (8202) 26-74-90, 63-79-99 and in the sales office: Cherepovets, st. Borshodskaya, 46, office 201.

Sizes of PSUL tape for windows

PSUL, or pre-compressed sealing tape, is made of expanded polyurethane and is used for mounting window and door blocks. Its width reaches 10 (mm) - 15 (mm) in width.

The compressed width ranges from 2 (mm) to 8 (mm). The roll contains from 4300 (mm) to 12500 (mm) tape.

Typical dimensions of PSUL tape:

- Belt width: 10 (mm), 15 (mm), 20 (mm).

- Compressed width: 2 (mm), 3 (mm), 4 (mm), 6 (mm), 8 (mm).

- Tapes per roll: 4300 (mm), 5600 (mm), 8000 (mm), 10000 (mm), 12500 (mm).

Important: the main standard sizes of the PSUL tape: 10x10, 10x15, 15x15, 15x20, 15x30, 15x40, 20x40. When installing windows, the recommended minimum size of PSUL in width should not exceed 20 (mm).

Important: in order to avoid bending of the tape for horizontal and vertical openings, an allowance of 10 (mm) in height and 15 (mm) in width should be left.

Among the spectrum of advantages of PSUL tape, one can single out: water repellency, thermal insulation, sound insulation, resistance to natural factors (UV, mold, fungus), chemical neutrality, non-susceptibility to deformation.

Description of the tape

Self-expanding tape is a black or gray rectangular strip made from an elastic, porous material similar to foam rubber - a porous polyurethane elastomer.It is impregnated with an acrylic-based compound that provides resistance to adverse external influences. An adhesive layer is applied to one side, protected by a foil.

After opening the roller, unwinding the tape and placing it in the seam, the thickness increases to the parameters indicated in the marking, while the width of the product remains unchanged.

What is PSUL?

PSUL is a self-expanding type tape, consisting of an elastic polyurethane film, which is pre-impregnated with an acrylic modified solution. The acrylic component significantly improves the working properties of polyurethane seals, in particular, wear resistance and durability. PSUL goes on sale in rollers. Since the sealant is available in various sizes, it can be easily matched to any joint. An adhesive layer is applied to the surface of PSUL used for window openings, which simplifies its operation and also prevents displacement. The compressed film expands significantly as a result of unpacking, and the magnification can be up to five times. PSUL window tape has such advantages as elasticity, the ability to take various shapes, resistance to ultraviolet and moisture, as well as the ability to drain condensed water from the product into the environment. The plasticity of the tape makes it possible to use the material to fill any gaps. It can also be used with concrete, wood, plastic, brick, steel and other building materials.

Purpose, scope

According to GOST 30971-2012, the PSUL sealing tape is used to create ventilated assembly joints when installing window blocks. Such a product solves a whole range of tasks:

- protects polyurethane foam from moisture and sunlight;

- serves as an obstacle to the development of fungus and mold;

- due to vapor permeability, it removes moisture formed in the pores of the foam due to condensate falling out during temperature changes;

- increases the service life and reliability of the seam;

- prevents freezing and water seepage, air penetration from the street and dust into the building.

In addition to insulation and protection of seams during the installation of plastic windows in accordance with GOST, PSUL tape is used for the following purposes:

- sealing the seams of concrete parts, window sills, gaps between the wall and window and door frames;

- sealing of dormer windows, openings, roof structures;

- isolation from noise and vibration during the installation of air conditioners, fans;

- sealing the joints of parts of prefabricated structures, roof elements, free-flow pipelines (sewerage, storm drains);

- external insulation of wall panel joints;

- sealing the joints of wall beams made of wood and other building elements;

- filling gaps and gaps in the areas where the chimney adjoins the roof, ventilation duct joints.

Due to the specific properties of the material, joints with uneven surfaces can be sealed with self-expanding tapes.

Application of PSUL in the construction of wooden houses

For the first time, foreign companies began to use PSUL in the construction of wooden houses as a mezhventsovy sealant, whose work consisted in the construction of houses from glued profiled timber.

But over time, this technique has passed to us, having won trust with its simplicity and reliability.

Moreover, the fashion for the construction of wooden houses continues, which means that specialists are in search of the most optimal options for work, but the PSUL tape remained in high esteem, because no material could replace it.

Psul tape for the installation of windows and the construction of wooden houses When a wall kit is installed, made of profiled timber, the tape is usually laid in two rows, and is located in the extreme grooves of the upper part of the timber.

The PSUL is also laid on the so-called cups - the places where the bars are connected to each other.Thus, the tape seals the joints, making them airtight, protecting them from moisture. As for the principle of use, it is the same as when installing a window, so there is no point in describing it again.

It is worth noting that PSUL can be different, so among the huge number of proposals you can find tape with different thicknesses, lengths or even the degree of expansion. Of course, the thicker the tape, the more reliable the seal will be, so 40 mm is considered to be the best option.

As for the degree of expansion, it is better to consult with specialists here, because this is purely individual, and depends on the opening or the distance between the parts. The length must also be chosen depending on the situation, because the tape should be enough for all the work.

The quality of the tape itself directly depends on the impregnation, which was mentioned earlier. But this characteristic can also be controlled, because the quality also depends on the strength of the pressure for which the tape is designed. The pressure is usually expressed in Pascals, so the higher the value, the better. It is believed that 600 Pa is a good level, which corresponds to GOST.

The tapes differ in the degree of vapor permeability, but these differences are not so big, therefore, when choosing a tape, they practically do not pay attention to this indicator.

Technical characteristics and properties of PSUL

The PSUL sealing tape has the following properties:

- resistance to the effects of various natural factors - precipitation, ultraviolet radiation, etc.;

- non-susceptibility to deformation;

- compatibility with any materials;

- preservation of elasticity throughout the service life;

- chemical neutrality;

- water-repellent properties;

- mold and mildew resistance;

- the ability to withstand pressure up to 600 kPa for several hours;

- high heat and sound insulation characteristics.

Specifications of self-expanding acrylic-impregnated polyurethane foam tape:

- operating temperature - from -50 ° С to + 90 ° С (varies depending on the brand within 5 ° С);

- resistance to deformation - from 14%;

- dimensions in thickness in a compressed form - from 2 mm, in an expanded state - up to 8 cm;

- thermal resistance - up to + 1000 ° С;

- fire resistance class according to GOST 30402-96 - B1 (hardly flammable building materials).

Advantages and disadvantages of the material

Self-adhesive waterproofing tape has excellent physical and chemical properties, giving it a number of advantages:

- durability;

- moisture resistance;

- wear resistance;

- wide operating temperature range;

- ease of installation;

- good adhesion properties;

- high elasticity;

- vapor permeability;

- affordable cost.

In addition, the variety of adhesive sealing tapes allows you to select the material not only in terms of technical characteristics, but also in appearance, which will be in harmony with the design of the house.

Among the visible shortcomings of the material, one should highlight its limited fire resistance. One of the common reasons why butyl rubber tape breaks is high operating temperatures.

Indicators of water resistance and frost resistance according to GOST

State standard GOST R 53338-2009, which contains a description of the material and gives its classification, subdivides self-expanding tapes into 3 classes in terms of the limit of water tightness in a state of working compression:

- Class A - over 600 Pa.

- Class B - not less than 400-600 Pa.

- Class B - not less than 200-399 Pa.

Also, the specified GOST provides for the division of products into types of performance:

- I - optimal for regions with an average monthly air temperature in the coldest season up to -10 ° С. The minimum operating temperature is -25 ° C.

- II - for regions with an average January temperature up to -20 ° С. Minimum working temperature - -45 ° С

- M (frost-resistant option) - for regions with an average monthly temperature in January below -20 ° C. Minimum operating temperature - -55 ° С

Ribbon tips

When working with PSUL tape, do not forget that air temperature affects its expansion.

In the cold season, you should use a building hairdryer, this will speed up the expansion process.

Do not use tape that is smaller than necessary.

There may be the following negative points:

- Leaks occur.

- A strong wind will blow out the tape.

- The foam will squeeze it out.

- Destruction of the assembly seam.

The correct choice of product will ensure high-quality sealing and the seam will be protected.

The use of an already expanded strip during installation complicates the technology and leads to poor-quality work.

To protect the tape, you can use a plastic self-adhesive strip, it will perfectly cover the installation seam from the outside from ultraviolet rays and extend the service life.

Ribbon marking

The labeling of the tape should include:

- Brand name.

- The class of the seal in terms of the limit of water resistance.

- Fractional numbers, where the numerator is the width of the product and the denominator is the range of the optimum width of the gap to be sealed.

- GOST number.

Liplent PSUL A 20 / 8–20 GOST R 53338-2009

Tape of the Liplent PSUL trademark, class "A" according to the water tightness limit, 20 mm wide, suitable for sealing joints with a thickness of 8–20 mm.

The type of product for frost resistance is indicated additionally.

Ribbon selection

When choosing a self-expanding seal, it is necessary to focus on the following parameters:

- The width of the adhesive layer - the adhesion strength depends on it. When installing windows, you should choose a tape with a width of 2 cm or more.

- The degree of expansion of the product - determines the density of filling the gap. The optimal value is 20–30% of the initial compressed state, but not more than 60%.

When buying, do not forget to ask the seller for a certificate of conformity.

Correct application on PVC windows

Question: How to use vapor barrier tape for PVC window structures correctly, what should be the temperature? Answer: Installation of vapor barrier tapes on plastic window structures is carried out as usual in rooms with high humidity levels (swimming pool, sauna, kitchen).

The material protects the assembly seam from the penetration of steam and moisture emanating from the room, the tape thus prevents condensation from escaping onto the window slopes. The vapor barrier strip can have one or two adhesive surfaces. The tape with two adhesive surfaces is conveniently attached to slopes and windows. All vapor barrier tapes are divided into winter and summer, the choice depends on the season and weather conditions.

Summer belts are designed for operation at temperatures of 5-35 degrees, winter ones have proven themselves perfectly in conditions below zero. The width plays an important role in the choice of tape, it should be 45 mm larger than the width of the assembly seam. Compliance with this condition will help to achieve the required level of vapor barrier.

The technology of installing windows and gluing a vapor barrier tape consists of several stages.

It is necessary:

- clean the window opening from dust and dirt, install the frame without fixing it, mark the installation lines of the vapor barrier tape on the frame and the walls of the opening;

- pull the frame out of the opening, stick the tape on it, without removing the protective strip from the area intended for gluing on the wall.

Installation of a vapor barrier tape on a plastic window is carried out in one piece, breaks are unacceptable.

The next stage is the assembly of the window structure with sashes and the capital installation in the opening. At the final stage, the vapor barrier strip is glued to the window sill.

An example of installing PVC windows with vapor barrier films in the video:

Installation

PSUL is completely ready for use, its installation does not require the use of special tools and devices.The sealant is matched to the seam width.

The pre-compressed sealing strip is installed as follows:

- The PVC window and the window opening are prepared for installation. To do this, dirt and loose plaster are removed, the surface is cleaned of dust with a vacuum cleaner, wiped with a damp cloth.

It is recommended to treat the surface of joints and seams with a special dedusting compound.

- The surface of the quarter is covered with an acrylic outdoor primer.

- Marking is done, fasteners are installed.

- A few centimeters (3-5) from the beginning and end of the roller are cut off and not used. A piece of the sealant is cut off to the required length, the paper layer is removed.

- The tape is mounted on the outer side of the frame facing the street, so, with an indent from the outer edge of the quarter by 3-5 mm. The product is pressed against the surface.

The PSUL is glued end-to-end, there should be no overlap. Vertical seams are filled without tape breaks at cross joints. Do not bend the seal at the corners.

- After filling all the gaps between the window and the wall, you must wait until the tape expands to its free state.

The rate of increase in the thickness of the self-expanding material to the working state:

- at a temperature of 0 ° C, the tape expands to its optimal size in 48 hours;

- at an outside air temperature of + 18–20 ° С, the expansion process lasts 2–3 hours;

- at + 30 ° C, expansion occurs in 0.5 h.

Advice. You can speed up the process of expanding PSUL using a hair dryer.

The last steps after the tape has been taken to its final dimensions will be the sealing of the joint between the frame and the window opening and its closure with a strip and drainage.

Article rating:

Save yourself to:

Diffusion butyl tape technical characteristics Link to main publication

Similar publications

- Putty vetonit TT technical characteristics

Butyl and bitumen tapes: what's the difference?

Despite similar names, sealing materials have fundamental differences:

Resistant to high temperatures

: bitumen dries up and cracks, after one and a half to two years visible cracks appear in it, allowing moisture to pass through. At a temperature of +70 ° C, the material melts and flows. Butyl rubber is resistant to high temperatures and retains hydro, steam, and sound insulation properties in the range up to +100 ° С.

Ease of installation.

For the installation of bitumen sealant, special tools and skills are needed: the material is heated. It is much easier to stick butyl rubber tape: just remove the anti-adhesive layer and apply it to the base with the sticky side. Work can also be performed at subzero air temperatures - up to –15 ° С.

Health safety:

bitumen exudes the "aroma" of oil products, therefore it is undesirable to use it in residential construction. To seal the joints between windows, doors and walls, it makes sense to buy butyl tape - an environmentally friendly material that does not emit harmful odors.

Butyl tape adheres well to metal, concrete, wood, glass