Do-it-yourself external cladding of the balcony. Balcony cladding from the outside is one of the most important stages in the whole complex of works on the arrangement, due to which it will have an attractive and finished look.

To create an aesthetically pleasing and harmonious appearance is not the main goal when decorating a balcony.

Thanks to this operation, you can additionally insulate your balcony, as well as protect it from external influences, including temperature extremes, exposure to rain, ultraviolet radiation, snow, wind and others.

What is the external finishing of the balcony for?

Exterior decoration provides insulation, sealing of the room, protects against temperature extremes, leakage of the ceiling and walls

Exterior decoration of the balcony is performed not only for the aesthetic appearance of the building. It provides insulation, sealing of the room, protects against temperature extremes, leakage of the ceiling and walls.

The equipped stove is reliably protected from atmospheric influences, therefore, its service life lasts for tens of years.

If the balcony is being taken out, external finishing work is necessary for the complete completion of the repair work.

Before performing work on the external cladding of the balcony, we repair the walls and the base of the balcony. We treat all irregularities, cracks and chips with cement mortar, sealant, blow out with polyurethane foam. Simultaneously with finishing works, we carry out sealing and insulation. For outdoor installation of thermal insulation, mineral wool and expanded polystyrene are used.

Finishing outside the balcony can be done by yourself, but safety measures must be observed

The outer cladding of the balcony refers to the performance of work at height. There are many firms offering such services. The cost of these works is quite high due to their complexity and the need to equip additional lifting devices.

With experience in construction work, you can finish your balcony from the outside yourself. In this case, it is necessary to observe safety precautions and use safety belts. To complete this procedure, you will need an assistant who will insure, hold the ladder and provide tools.

Exterior finishing, in addition to plastic finishing, can also be performed using siding and profiled sheet. It includes the installation of handrails, balcony frame, roof and canopy.

Before starting work at a height, it is necessary to secure the construction site using a signal tape or rope with red rags tied to it. This is done so that the people passing below are warned about the work and bypass the fenced place by the side.

Helpful hints

If you are one of those who are used to doing everything in the house on their own, then, before sheathing the balcony with siding, you need to find out some of the features of this process. So that the material does not deform after mounting, it is necessary to take the plates outside before starting work. This will allow them to take their size, directly in the environment where it will be installed.

Your balcony is located on the third floor and higher, then it is still better to entrust this difficult task to professionals. If you want to take a chance, then be sure to stock up on a climbing belt and other fasteners.It is also necessary to remember about the safety of passers-by, so put the fence flags under the balcony in advance. This will ensure that no material or tools will harm you.

Prepare the plates of the required height in advance and at the same time try to make measurements very accurately. For those who are engaged in such a business for the first time, it is better to start sheathing the balcony from the sides. This way you can practice mounting low plates. And the main thing is that there is no need to tighten the panels at the moment of fixing the plank, otherwise it will be deformed. If your balcony lends itself to the influences of strong wind, then the platinum should be fastened in increments of no more than 5 cm - this will make the structure more reliable.

Fig. 14. When working at heights, insurance is required.

Preparatory work

Prepare a complete set of tools

Before starting finishing work on the balcony, we calculate the materials and prepare the necessary set of tools:

- building level, tape measure, stapler, hammer;

- jigsaw, grinder, drill, hammer drill, screwdriver;

- hacksaw for wood and metal.

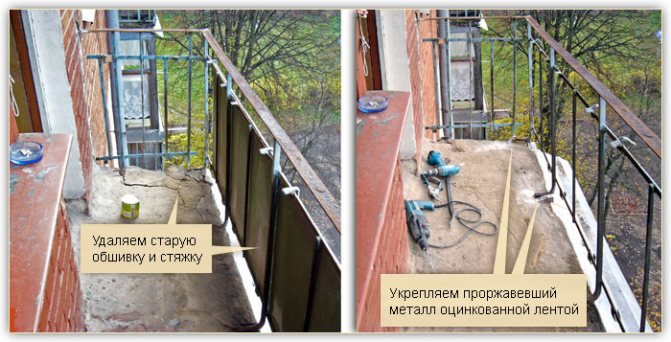

The second stage is to prepare the surface:

Remove the old covering from the balcony slab

We remove the old covering from the balcony slab, inspect it for cracks and peeling concrete. We carry out repair work: we concretize all cracks and joints, primer and coat with sealant.- If necessary, we replace the metal railings with new products. If we leave the old partition, then you should first clean it from rust and treat it with an anti-corrosion protective compound.

- We decide what material we will use for decoration.

Surface preparation for finishing

The preparation for the external cladding of the balcony begins with dismantling the old trim and cleaning the base plate. If wooden railings have been installed, they must be removed. The metal parts of the balcony or loggia are cleaned of rust and primed with a special anti-corrosion compound to protect against corrosion and decay. If there are gaps in the joints of the metal parts, then they are welded and cleaned. All exfoliated and fragile areas are removed from the concrete base, cracks and irregularities are repaired with the help of repair compounds.

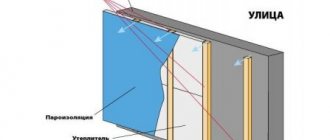

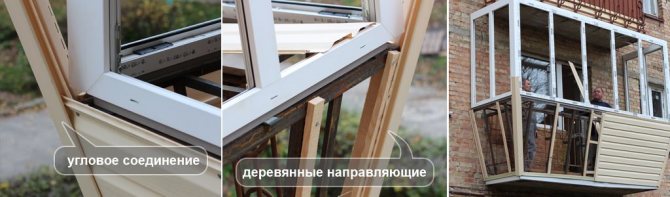

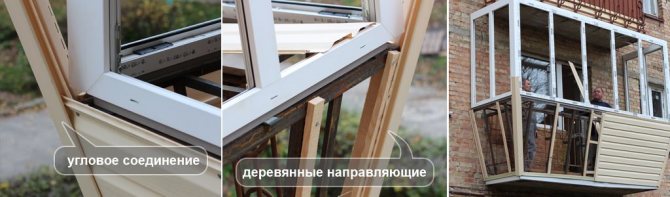

The last stage of the preparatory work is the installation of the lathing on which the selected finishing material will be attached. The frame is made of steel profiles or wooden bars. If it is supposed to clad the balcony with aluminum or vinyl siding, then the racks of the lathing are fixed perpendicular to the arrangement of the panels. The wooden crate must be treated with an antiseptic primer, and the metal profile is primed and painted with protective paint. For better thermal insulation, the finished frame is filled with mineral wool slabs.

Materials for outdoor decoration

Siding is great for finishing a balcony

When choosing a material for finishing a balcony, it must be borne in mind that the material will be affected by temperature extremes, strong winds, ultraviolet light and sudden temperature changes.

Exterior finishing is usually performed in front of or simultaneously with glazing.

Suitable for outdoor decoration:

- plastic lining made of polyvinyl chloride;

- aluminum or vinyl siding;

- profiled flooring.

Materials for outside balcony cladding

There is a wide range of finishing materials that can be used to sheathe a balcony outside. They have their own characteristics, positive and negative qualities.

Sheathing with corrugated board

Decking is presented in the form of corrugated galvanized steel sheets.

Decking can differ in structure, color, size and appearance. The positive qualities of building materials include:

- ease;

- good physical and technical parameters, including resistance to corrosion, fire resistance and tightness;

- durability;

- interesting design and color palette;

- ease of installation, wall decoration.

Balcony cladding with corrugated board

When working with corrugated board, it is forbidden to use a grinder with an abrasive wheel. This can lead to loss of quality of the material or its complete destruction.

Using siding

Siding can be metal and vinyl. Let's consider in detail the properties of both materials.

Advantages of vinyl siding:

- resistance to corrosion and deformation during operation;

- preservation of an attractive appearance for many years;

- ease of care;

- it is an environmentally friendly option;

- fire resistance;

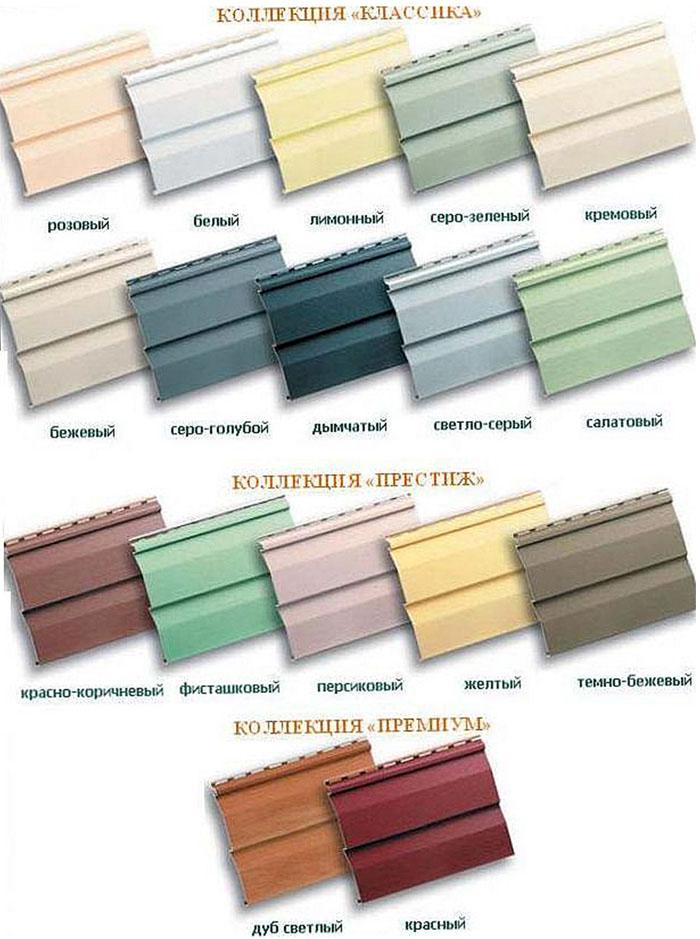

- a wide range of colors.

The disadvantages of siding include the complexity of working with it. This will require certain skills to sheathe the siding.

The pros of using metal siding are as follows:

- low cost;

- ergonomics;

- interesting design;

- resistance to adverse weather conditions, the appearance of fungus and mold.

Aluminum Panels

The aluminum panel consists of two aluminum sheets with a special filling between them.

The pluses include:

- strength;

- rigidity;

- shock resistance;

- aesthetics of appearance;

- elasticity;

- resistance to corrosion;

- durability.

The main disadvantage of aluminum panels is their high price.

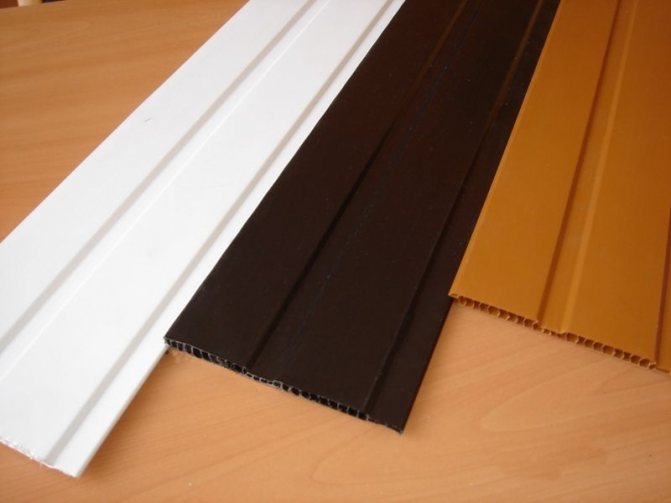

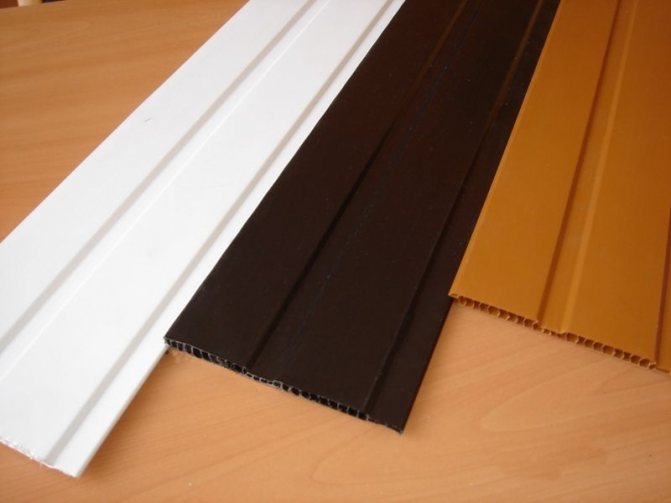

Plastic lining

The use of plastic in the plating process has several advantages:

- low cost;

- attractive appearance;

- ease of use;

- short terms of installation;

- the possibility of interior decoration.

Plastic lining

Plastic lining is an inexpensive and popular material for outdoor decoration of the balcony

An inexpensive option is to cover the balcony from the outside with plastic panels, which are installed on a crate made of a metal profile or wooden beam.

The advantages of plastic panels:

- you can choose the desired color, the panels are available with a glossy, matte surface, patterned, monochromatic;

- easy and quick installation: the material is easily cut, processed, has a reliable tongue-and-groove connection;

- reasonable cost.

Disadvantages:

- plastic lining is fragile, strong wind can tear the panels out of the fasteners;

- weakness in front of ultraviolet light (over time, the surface begins to fade gradually).

In the course of finishing work, measures are taken to waterproof and warm the premises.

Installation of plastic lining

First of all, mount the lathing from a wooden bar or metal

The first step is to prepare the surface: we fill up all the cracks, we seal the joints. The plastic strips are easy to cut with a utility knife or hacksaw.

Stages:

- We install a crate made of a wooden bar or a metal profile.

- We fix with self-tapping screws (or on staples), strictly at the level of the guide starting strip.

- The first strip is inserted from below into the starting profile, then the remaining strips are fastened in turn into the thorn-groove connection;

- Install corner overlays to hide all the bumps.

The general appearance of the finish will depend on how correctly and evenly the first strip is attached.

How to choose siding to match the color of the roof

To select the color of siding for the roof of the house, it is better to use constructor programs, on which you will see the design of the facade live. As for the color palette from which it is worth considering the design option, I will offer several:

- Blue roof... A good choice of siding color would be light colors (warm or cool) or white. A good option would be if you use blue or white siding accessories for finishing corners, windows, doors and other parts of the house;

- Brown roof... For her, light green, cream, white, gray panel colors are suitable, and components are the best option for white or brown;

- Green roof... For a green facade, light green, white silt and light gray are suitable; Complementary elements will be better combined if they are in the same color as the roof or white;

- Cherry roof... The facade looks nice with many colors except turquoise, blue, brown, green. The accessories look great in white, brown and cherry colors.

The house will look more interesting when combining panels with basement siding under a stone, where they will be slightly darker than usual. The decoration can be carried out both by making inserts and by decorating part of the walls (bay window, balcony, terrace).

Profile decking

The profile decking is made of galvanized steel sheet by hot-dip galvanizing. A profiled sheet is a sheet of steel with a thickness of 0.7 mm to 1.5 mm, on which a profile is applied with a certain step and height. Waves and corrugations are stiffeners and come in various variations. The surface of the profile decking sheet is galvanized and polymer coated.

For the technology of external finishing of the balcony, see this video:

Benefits:

- durable, tough and light enough material;

- has a service life of 30-50 years;

- beautiful appearance, does not fade, does not need additional coloring;

- fairly inexpensive cost;

- simplicity and high speed of installation;

- environmentally friendly material: safe for humans, animals and the environment;

- has a wide range of colors: you can choose the color of the sheet for any interior.

Installation of profile decking

Follow the sequence of actions

When installing the profile decking, the sequence of actions is followed:

- A metal or wooden frame is attached to the outer perimeter of the balcony. Before starting installation work, all metal and wooden parts of the frame are treated with protective equipment.

- The profile deck is fixed with self-tapping screws with rubber pads. The installation starts from the corner, the sheets are overlapped by one wave.

- The corners are closed with end caps.

Wood and plastic panels

Exterior finish of the balcony with wood

Both the internal and external facade of the balcony can be finished with pvc panels and wood. Many people think that the removal of wooden material outside the interior is impractical, since it is prone to decay, but this is not the case. For protection, an antiseptic is used, which makes it possible to protect the lining and other types of natural cladding. Plastic panels will cost much cheaper than wood lining, but at the same time they perfectly imitate and even surpass in some way such a finishing option. So:

- Plastic is flexible - the idea of rounded or convex parapets becomes possible.

- No additional processing required.

- The loggia inside can be made out with the same material.

- The cost of finishing will be much cheaper.

Important! The innovative thermal panel makes it possible to move the living space outside of it, that is, to create a warm and comfortable atmosphere on the balcony, even on cold winter evenings.

A brick house does not have the ability to preserve a large percentage of heat, and therefore the outer side of an apartment building is additionally insulated at the expense of its residents. Remember that they independently trim the walls and lower balconies on the 1-3 floor, but if you live higher, then take care of equipment or attracting professionals to this process. The step-by-step process consists in preparing the base, constructing the frame and securing the finishing material with the front side.

Aluminum siding

Polymer-coated aluminum siding is ideal for outdoor balconies.It is attached to the crate, made perpendicular to the location of the panels. Additionally, insulation is carried out.

Benefits:

- the polymer coating does not fade, has a service life of up to 40-50 years, is not afraid of temperature changes, is frost-resistant;

- does not burn and does not support combustion;

- is an unfavorable environment for the development of microorganisms and fungi;

- not subject to destruction when exposed to moisture and water.

Preparing the necessary tools

To cover the balcony with siding panels, it is necessary to prepare all the tools in advance:

- level;

- pliers;

- screwdriver;

- drill with magnetic attachments;

- wire staples;

- fasteners and anchor bolts;

- wooden blocks for the formation of the frame;

- inner and outer corners;

- fishing line 10 m;

- metal brush;

- starting and sill strips.

In addition to all this, it is necessary to prepare a hacksaw for metal and an assembly knife, depending on the type of finishing material.

Vinyl siding

Most often, vinyl siding is used for finishing balconies.

Vinyl balcony cladding is suitable for outdoor use.

Benefits:

- does not absorb dust, dirt;

- resistant to weathering, temperature extremes, ultraviolet light;

- made from environmentally friendly ingredients;

- does not support combustion.

Siding of balconies is performed most often, it has an optimal ratio in terms of price-quality criterion.

Choosing the color of the siding for the facade

Vinyl siding is mainly available in pastel colors and shades. However, there are manufacturers whose lines contain rich and vibrant siding colors that allow you to create original facades by combining bright and pastel shades.

In order to choose the right material for finishing the facade of the building, you need to know what types of this material the market offers. There are several types of siding panels, which differ not only in the material of manufacture, but also in the form of manufacture.

Installation of vinyl and aluminum siding

Exterior decoration of the balcony with siding is quite simple, if you have the skill to perform such work, you can do the installation yourself. When calculating the required material, do not forget to purchase a starting guide, a window sill strip (installed under the balcony window and ensures the tightness of the connections), external corner fittings and end caps.

Watch this video and you can start installing siding on the balcony:

Installation steps:

- We mount the battens made of wooden beams or metal profiles.

- The first panel is attached with self-tapping screws to the crate and is located at the bottom of the structure. Self-tapping screws are screwed in the middle of the perforated holes.

- We attach the following panels to the connection of the starting strip, starting from the bottom edge. At the joints, we leave a gap for expansion and contraction of the profile by 0.5 mm.

The lathing should be mounted perpendicular to the position of the siding panels. The siding is attached from the bottom up. We set the guide starting strip strictly according to the level.

Features of the cladding from the street

Having decided on what material will be used to decorate the balcony outside, it is necessary to prepare all the necessary tools. So, getting to work can not do without:

- level;

- pliers;

- knife;

- hammer;

- drills with special attachments.

During installation, a rope is often used, with its help the material lays down more evenly.

Before proceeding with the main stage of work, the closed balcony needs strengthening. For this, a metal frame is used; it is often attached directly to concrete walls. Working with this type of cladding requires tremendous effort and skill in welding. After all, it is initially necessary to make a metal frame and only then attach the skin directly over it.When metal corrugated board is used, the planking of beams can be omitted, since the structure will be strengthened due to the material used.

Regardless of what type of balcony is sheathed, this work has a number of features. The experts have compiled detailed step-by-step instructions for this. So, the old cladding is removed from the railing, taking precautions. The slab under the feet is initially repaired, and only then pulled together. For this, a special bar is applied to its entire length. Most often it is made of wood and the structures are pulled together with tongue-and-groove piles. Meanwhile, wooden beams are stuffed onto the upper surface of the balcony, thereby creating a so-called frame.

Everything made of metal must be pre-painted.... Holes for self-tapping screws are made on the material that will be fastened, thereby creating additional convenience for installation. Using a drill, it is attached to the frame, joining them together so that there are no gaps or cracks.

After the fastening stage is over, the cladding begins. Then special fittings and fasteners are attached at the edges.

The loggia also needs cladding. It is somewhat more difficult to make it than for an ordinary long balcony. One of the features is the fact that you should not forget about the hinged protection. So, in order for the loggia to be closed, hinged canopies are often used (for more details, see the article “how to make a canopy on the balcony”). In order to install them, you can bring the strips up, and then sheathe everything with plastic, or, conversely, lay the slate overlap. What is important, in the case when metal profiled sheets are used for cladding, it is possible not to install a wooden frame. They do this when the metal structure is initially tightly made. Better from iron.

If a closed balcony is sheathed, which has glazing, then in the event of an airtight space, it can be used as another room, which adds an advantage to this type of finish. But you need to decide on the interior design.

Features of finishing a closed balcony

In a closed balcony, before starting finishing work, we strengthen the floors, make a frame from metal corners, attach it to the walls and balcony base, and at the same time install a fence. The metal frame removes some of the load from the slab and transfers it to the walls.

If there is a living room on the balcony, but it is necessary to carefully insulate it

If the finishing is done with siding, a crate is stuffed onto a metal frame. It is permissible to mount profile sheets without lathing.

After finishing and insulating the parapet, we install the balcony frame.

If a living room will be equipped on the balcony, external finishing is necessary to increase the thermal insulation of the room.

Common mistakes

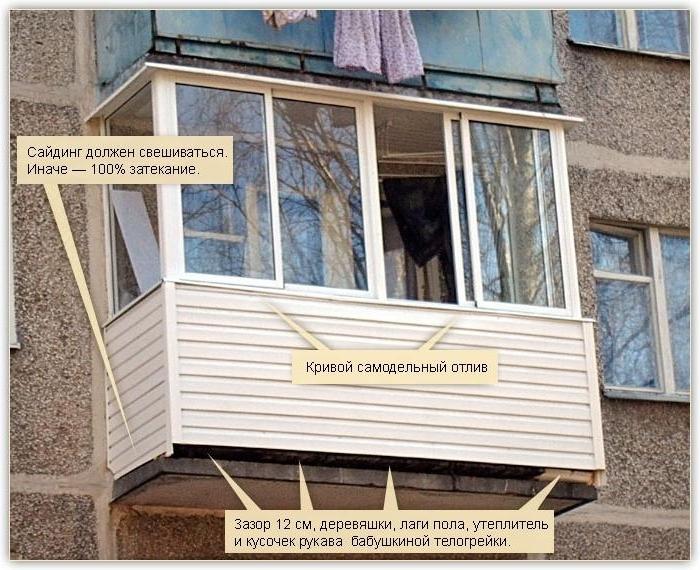

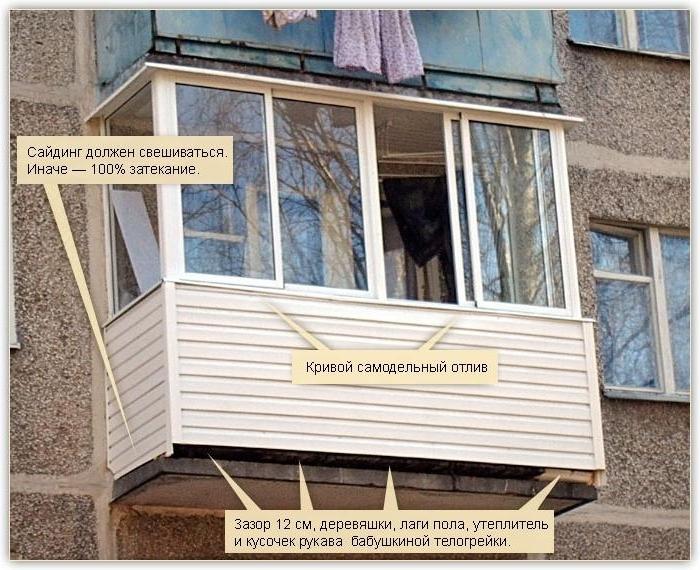

If the hand of a master takes over, then the result will be perfect. But beginners often make common mistakes, which leads to disastrous results. To prevent this from happening to you, we propose to consider the most common mistakes. Most often, amateurs install fasteners directly into the panel. This cannot be done as they must be centered on the holes. They are deliberately made oblong to allow the panels to move freely. Remember, if you do not do this, at high temperatures they will heat up and, due to the inability to walk, it may fall off the mount.

Another common mistake is screwing the panel tightly. Remember to leave a gap of at least 1 mm between the cap and the surface of the panel so that they can expand. Newbies are not used to leaving a gap between the fastening element and the end of the panel, or making it very small. Do not forget - in this case, the size of the gap should be 7-10 mm.As you can see, all these mistakes will ultimately lead to a change in the shape of the panels, which will make the appearance of your balcony not the best.

Fig. 15. Errors in siding.