What tasks do slopes perform?

Slope - the inner or outer part of the window opening. Performs decorative, masking and protective functions. It is an element of window insulation and waterproofing.

Different types of wood are used to install the slopes. The most commonly used are conifers. Wooden slopes are used in country houses and cottages. They are quite massive and heavy, so they will only fit in a private house. Slopes close micro-slots and joints, performing the function of insulation. The main tasks of wooden slopes include:

- protect from freezing;

- perform the function of thermal insulation, reduce the degree of heat transfer;

- prevent the appearance of condensation on the windows;

- protect against drafts and cold air penetration through gaps;

- protect the polyurethane foam from external influences and destruction;

- maintain a comfortable indoor climate;

- prevent the development of fungus;

- perform the function of decorative design of the window opening.

By means of wooden slopes, you can solve several problems at the same time:

- additionally insulate the window opening;

- provide waterproofing;

- decorate.

The slopes smoothly turn into the window sill. These structural elements are interconnected. They perform the task of a protective cage. Prevents cold air or rain from entering the room.

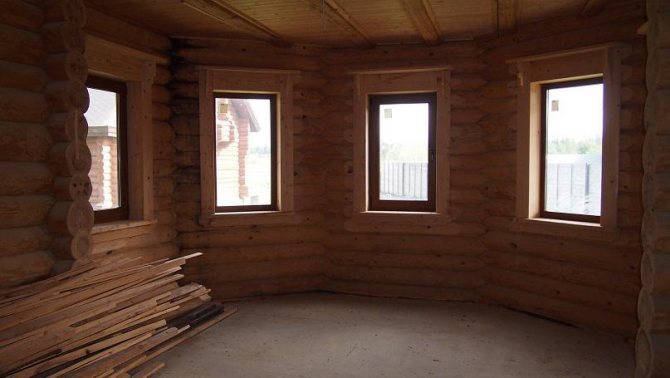

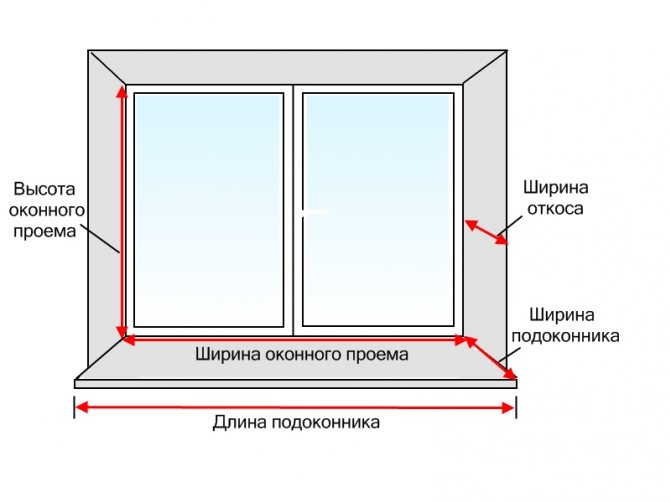

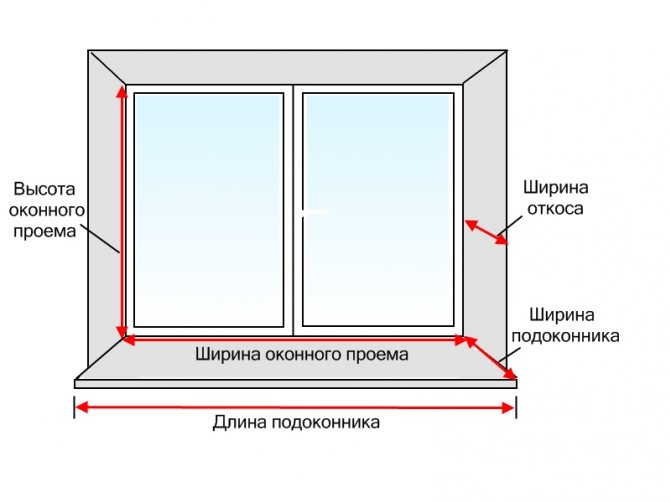

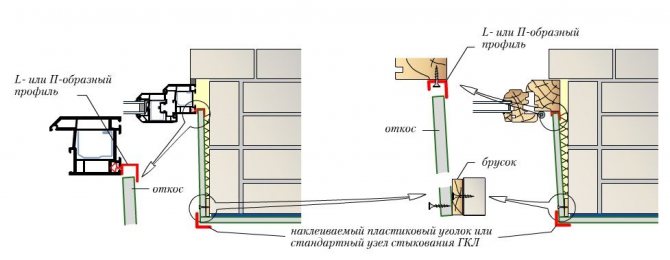

Fig. 2. The place of the slopes in the window opening

Required tools and materials

Installation of wooden slopes is possible with your own hands. In principle, you can use the same materials and tools that are left over from the installation of a wooden window. You can also buy everything you need at any hardware store. Everything should be prepared in advance. In the course of work you will need:

- plywood or sandwich panels;

- planing machine;

- manual jigsaw;

- corners;

- polyurethane foam or mineral wool;

- level;

- sandpaper;

- a circular saw;

- drill;

- primer;

- screwdriver;

- self-tapping screws;

- thickness gauge;

- silicone sealant.

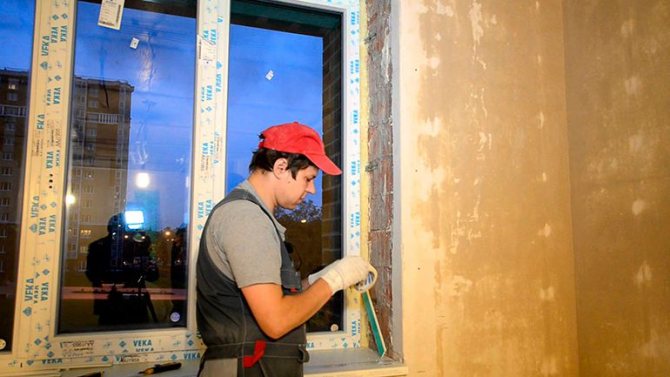

Installation of wooden slopes is carried out at the finishing stage. First, it is necessary to prime and putty the inner part of the window opening in order to fix the panels on it. For finishing work you will need:

- putty knife,

- putty,

- falcon,

- metallic profile,

- trowel, etc.

Also, you will need material for finishing and staining wood. Varnish is often used to preserve the appearance of the wood. Tools and materials depend on the installation method and the technology used.

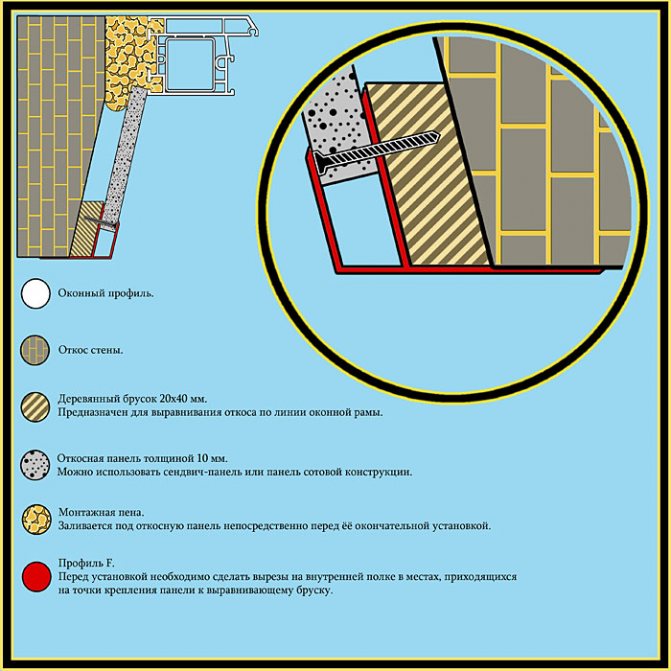

Fig. 3. Materials and tools for mounting slopes

What kind of wood to choose for the slopes on the windows?

For the installation of wooden slopes, the same material is used as for the window frame. That is, if the entire window structure is made of oak, then oak should also be used for the slopes. This is necessary in order for the color and shade of the opening to match everywhere. For slopes, hard tree species are usually used, more often conifers. They have increased strength. They are distinguished by resistance to external influences. They have a long service life.

A good solution for slopes is to use:

- pine trees,

- larch,

- oak,

- lindens, etc.

If the frame and slopes are made of oak, then the same wood should be used for the window sill. In fact, you can make slopes from any type of wood. But then you will have to treat it well with a protective varnish to protect it from the sun and rain.

You can use natural wood to decorate the slopes or sandwich panels. FSF is often used - plywood with increased moisture-resistant properties. The top layer is covered with natural wood veneer. The surface is treated with varnish to emphasize the type and pattern of the wood. Sandwich panels are used:

- one-sided - from 1200 rubles;

- bilateral - from 1450 p.

Wooden slopes from manufacturers are practical designs. They are grooved for easy installation. Convenient connection of the slope elements allows you to install the structure yourself without unnecessary problems.

Benefits of using wood for a window sill

After special processing, wood reliably resists weather adversity, humidity and temperature extremes, provided it is solid, withstands significant weight loads, is a natural material that is safe for health and gives special warmth to the interior.

Window sills made of valuable species of wood such as oak, beech, mahogany, among other advantages, are more durable and ranked among the elite types of materials that can decorate even the most expensive and sophisticated homes.

Our experts will help you make the best decision and place an order for the installation of wooden windows and sills. We employ only experienced craftsmen who, in the shortest possible time, will make measurements, manufacture and install wooden window structures according to your sketches or according to their own project, taking into account all the nuances.

Durability of wooden window sills

Some types of wood are remarkable for their strength and durability. For example, oak or larch only gets stronger over time, and the service life of window sills made of these types of wood can reach 100 years.

A wide range of colors allows you to make wooden window sills a decoration of any interior.

Natural wood has a pleasant natural color and characteristic grain pattern, unique for each species. Window sills can be tinted with special varnishes or opened with persistent modern paints to achieve the desired shade of the wood surface.

Convenience and cosiness

With proper care, wooden window sills will perform their functions for a long time and reliably. Varnishes and paints that are used to treat wooden window sills are resistant to moisture, abrasion and scratches, and are able to preserve the beauty of the tree for many years.

Prestige

Natural wood trim has always been considered an element of luxury and aristocracy. The stronger and more beautiful the structure of wood, the more elite material it is considered to be. With the participation of competent designers and experienced carpenters, an ordinary window sill turns into a real interior decoration.

Quality

The wood we use for the production of window sills is of high quality, undergoes careful processing and lengthy preparation before getting into your home. And an experienced team of installers will make a high-quality installation with strict adherence to building requirements and standards.

Professional approach

Our employees are well-trained craftsmen who are well versed in the specifics of working with natural wood. We provide monolithic products with high quality processing and a choice of a wide range of wood species and shades of the final product.

Benefits of wooden window slopes

Wood is a practical, attractive and sustainable material. It is often used for decorative purposes. Wooden slopes are hygienic, safe, reliable and practical structures. They are able to make the window opening much more attractive. They do not require special care. Wooden slopes have a long service life. The advantages of wooden slopes are as follows:

- wood is an environmentally friendly material;

- natural wood is not susceptible to the development of fungus;

- the material has an aesthetically pleasing appearance and is able to advantageously complement any design;

- wood "breathes", promoting air circulation in the room;

- the tree does not accumulate moisture;

- wooden slopes prevent condensation from forming.

The advantages of wooden slopes make them practical. The tree is not exposed to temperatures. Has increased hardness. Can be coated with a protective varnish to prolong the life.

Fig. 4. Slopes with your own hands

Sustainability of wooden slopes

Undoubtedly, wood is an environmentally friendly material. Wooden slopes are made from natural wood. No formaldehyde used. The material does not have a negative effect on the indoor microclimate. The window is the only source of air. The use of environmentally friendly materials is a must.

The environmental friendliness of wooden slopes allows you to install them in any room, even a nursery. Wooden construction is much safer than plastic construction. Wood paints dry quickly. There is odorless varnish, for example:

- Tikkurila - from 680 rubles;

- Kompozit - from 470 rubles;

- Alpina - from 530 p.

Hygiene of wooden slopes

Wooden slopes are hygienic. The material is not susceptible to the development of fungus or decay. To achieve the hygiene of wood slopes, antiseptics are used. They prevent the growth of bacteria, mold and mildew. The tree does not require much maintenance. It is enough to regularly wipe the slopes from dust. The coating of wooden slopes makes them resistant to moisture, ultraviolet radiation and dirt. To maintain hygiene, the tree should be covered with an antiseptic "Senezh", "NPO NORT", "Olvia".

Practicality of wooden slopes

Wooden slopes are able to withstand almost any impact. They resist sun, rain, snow, frost, stress, etc. This material can last up to 25 years. The tree possesses:

- high heat and noise insulation,

- maintains a comfortable indoor climate,

- provides an optimal level of humidity,

- prevents the formation of condensation;

- prevents the appearance of drafts.

The practicality of wooden slopes makes them the best solution for installation in residential buildings.

Accessibility of wooden slopes

The availability of wooden slopes should be understood as the ability to buy ready-made structures everywhere. You can make your own wooden slopes yourself. Wood is an affordable material and at a price. Unlike plastic or drywall, you can use wood, MDF, sandwich panels for slopes.

Any installation technology will do. You can use available tools and materials. Wooden slopes are cheap. They look attractive and comfortable.

Slope types

Slopes are installed outside or in an internal opening. Depending on the material of manufacture, this element of the window structure is divided into the following types:

- plastering,

- plasterboard slopes for windows,

- slopes from plastic panels,

- durable wooden slopes, usually installed on the same "breathing" windows made of oak, pine or larch.

Thus, the advantages of wooden slopes are obvious.

- Excellent insulation of the room from external sounds, cold, dampness.

- Aesthetic indicators - high-quality wood, varnished, decorates the interior, creates an atmosphere of comfort and security.

- Environmental friendliness of wood fibers.

This property is especially true for dwellings in which children live.

- Strong fixation to the window structure.

- The variability of the shapes and parameters of the slopes, which is important when you make wooden slopes on the windows with your own hands.

- Wear resistance, durability.

A properly processed tree does not "sweat", mold and fungus do not start on it (pine, larch have their own bactericidal properties).

Wooden slopes are practical and allow you to hide minor flaws and errors in the self-installation of window products (chips, irregularities).

Manufacturing of wooden slopes

Wooden slopes for windows can be purchased ready-made. It's cheaper to make them yourself. To do this, you need to prepare wooden boards and process the material. To make wooden slopes, you need to perform a phased processing of the material:

- it is necessary to level the surface of the board. To do this, it is better to use a planer, which allows you to get rid of the surface of irregularities and roughness and turn it into an ideal base for wooden slopes;

- then you should remove the excess part of the board and make it the desired thickness. For this purpose, it is better to use a machine that will align symmetrically to the plane and make all the boards of the same thickness;

- you need to wane one edge. To do this, cut a 90 пил angle with a circular saw. To do this, press one edge to the guide and make an edge on the jointing wall;

- now you need to cut the board to the required width of the slope;

- then it is necessary to make cross sections so that the slope turns out to be inclined.

One face should be rounded. You should get a smooth slope angle. After that, you can proceed to the installation. Wooden slopes can be installed, both from the inner and outer sides of the window opening.

Fig. 5. Parameters for measuring the size of slopes

Installation of wooden slopes on wooden windows

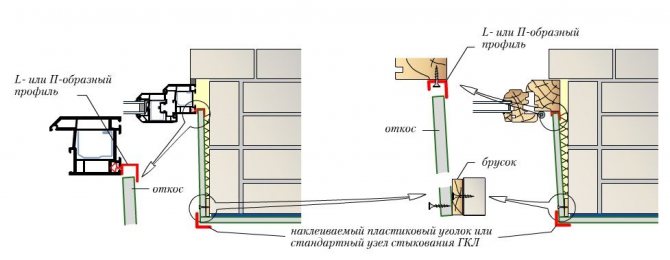

Wooden windows look harmoniously with slopes made of the same material, therefore wooden slopes are often used to frame wooden windows. This design looks solid. Installation of wooden slopes on wooden windows is carried out in several stages:

- finished panels must be sanded and smooth ends. To do this, use a square;

- then you should make holes in the slope. To do this, use a drill and a wood drill, then insert screws into these holes;

- then you need to place the slope to its location. If there is a distance between the slope and the box, then you need to block the ledge with wooden blocks. Then you need to insert self-tapping screws and fasten the panels;

- self-tapping screws need to be screwed in with a screwdriver so that they enter the tree a little. The places of the caps of the self-tapping screws must be treated with putty;

- vertical slopes are made in the same way as horizontal ones. After installing wooden slopes around the perimeter of the window, it is necessary to attach the platbands.

Wooden slopes should have the width of the window opening, not protrude or sink into it, therefore, before installation, it is imperative to make all the necessary measurements.

What is the purpose of finishing window slopes outside?

Many believe that after the installation of plastic windows, the repair is completed. But almost always builders do not consider it necessary to finish the outer part of the window opening, considering that this is a waste of time and money.

You need to know that finishing plastic windows from the outside helps to prevent the appearance of severe problems.

If you leave everything in an unfinished state, the window will look very ugly. Untreated slopes over time are able to make the gaps leaky. The polyurethane foam will evenly begin to collapse under the influence of wind and sunlight and crumble, at times falling out of the opening.

As a result, it will be very much through the window. In addition, polyurethane foam can be used by birds to create their own nests. So that all this does not work out, you need to know how and by what means they create the decoration of the windows from the outside.

Installation of wooden slopes on plastic windows

There are two ways to mount wooden slopes on plastic windows. Plastic double-glazed windows and wooden slopes look harmonious, so these materials are perfectly combined. To make the design look attractive and reliable, you can use two mounting technologies:

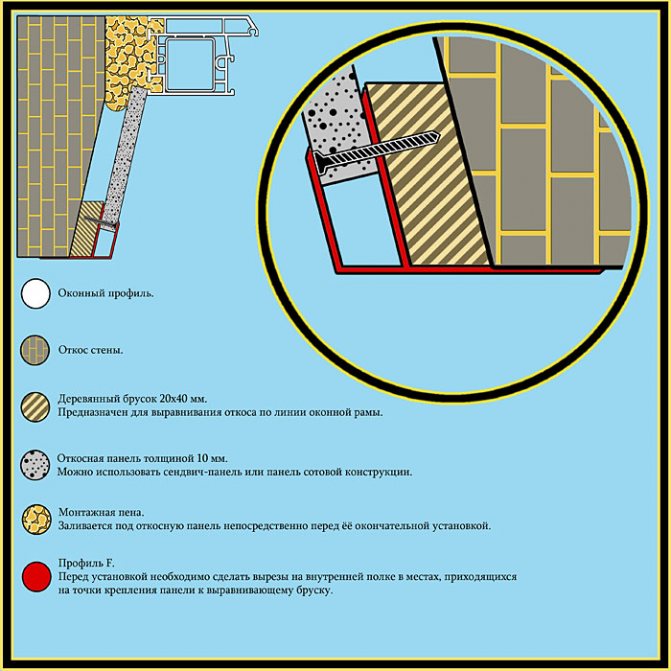

- on polyurethane foam. This method is quite simple and requires preliminary preparation of the slopes and the presence of polyurethane foam. Each panel is attached separately. Be sure to process the corners so that they match perfectly. Then it is necessary to apply polyurethane foam over the window wound. It will quickly grow in size, so you shouldn't overdo it. Then the slopes are collected and connected to the opening. The foam will provide insulation, and the slope will protect it from the external environment. You can additionally treat the joints with silicone sealant, which prevents moisture from entering the slopes.

- on the fasteners. This method is a little more complicated, as it requires the pre-installation of special fasteners that will hold the panels. After the slopes are leveled and have suitable parameters, mineral wool is inserted into the gap between the frame and the opening, which acts as a heater. The cotton wool is covered with a film, for which you can use masking tape. Then a frame of panels is attached, which is connected with self-tapping screws. They must be twisted very carefully so as not to damage the panel. Then the whole structure is attached to the frame and fixed on the fasteners.

If you are not sure that you can install wooden slopes yourself, then contact the professionals. This work has a lot of specific nuances. It depends on them how well the slopes will perform their functions.

Fig. 6. Wooden slopes with your own hands

DIY slopes

The easiest way is to buy ready-made wooden slopes for wooden or PVC windows in the same company where the latter were purchased. Their length can reach 3 m, width - 1 m. Thickness - 12 - 15 cm.

The selection of wood is important - not too dry or damp, not knotty, suitable for the frame.

To understand how to make slopes for wooden windows, please be patient and study all the nuances, as well as the price list for wooden window slopes. It may turn out that the budget does not allow making elite ones throughout the house, for example, oak slopes. In this case, you can save money on the inner slopes by finishing them with a joinery board - clapboard.

Regardless of whether you are going to make wooden slopes on the windows with your own hands or invite experienced carpenters, you need to mount them after a certain time interval after applying the polyurethane foam (at least 12 hours later for the sealant to dry). But it is also dangerous to delay the installation - no one canceled the atmospheric factors, and they quickly destroy the seal.

Features of wooden slopes

Wood slopes are made from well dried wood sandwich panels. If the wood is damp, it can dry out. It is better to install slopes the next day after installing the glass unit. At this point, the polyurethane foam should be completely dry.

After installing the slopes, the tree must be varnished. This will emphasize the naturalness of the material. You can also paint the slopes with paint. Better to use oil or acrylic.

The main features of wooden slopes are their practicality and aesthetics. They look very elegant and attractive. They have many protective properties that other materials do not have. Wooden slopes can completely change the look of the window. They do not require special care and additionally insulate the window opening. It is more practical and faster to mount them.