Polyfoam is an inexpensive material and is easy to work with. No special skills are required for work, it is easy to cut and quickly glued to the roof and walls. Its slabs are very durable and will not break during installation. Polyfoam is available with a density of 15, 25, 35. The thickness of the insulation offered for sale is from 20 to 100 mm. Polyfoam 100 mm with a density of 25 is the most commonly used in construction and is considered the most versatile. To improve the thermal insulation of your home while saving money, use 100mm 25mm Universal Foam.

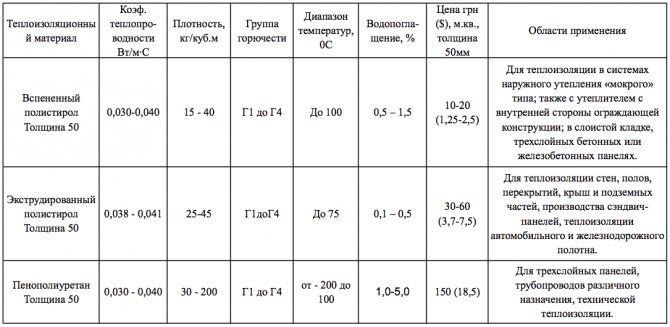

What it is?

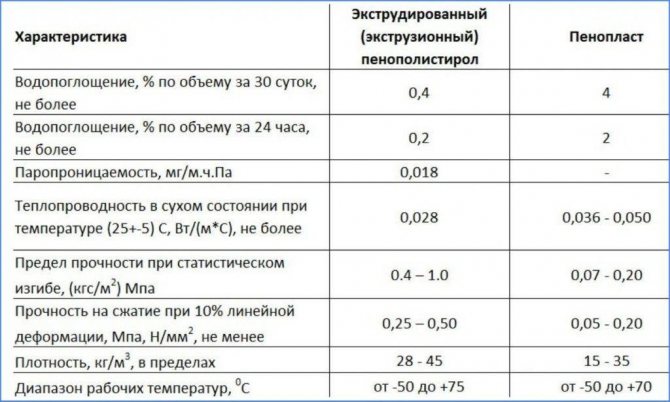

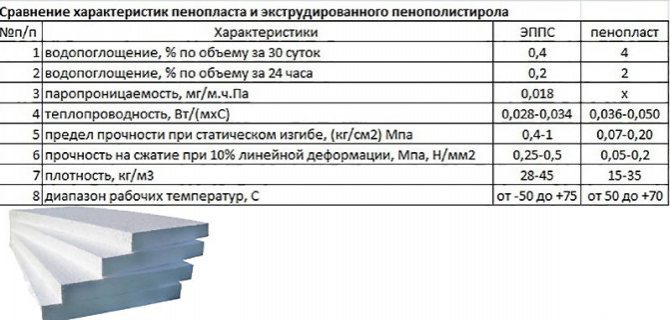

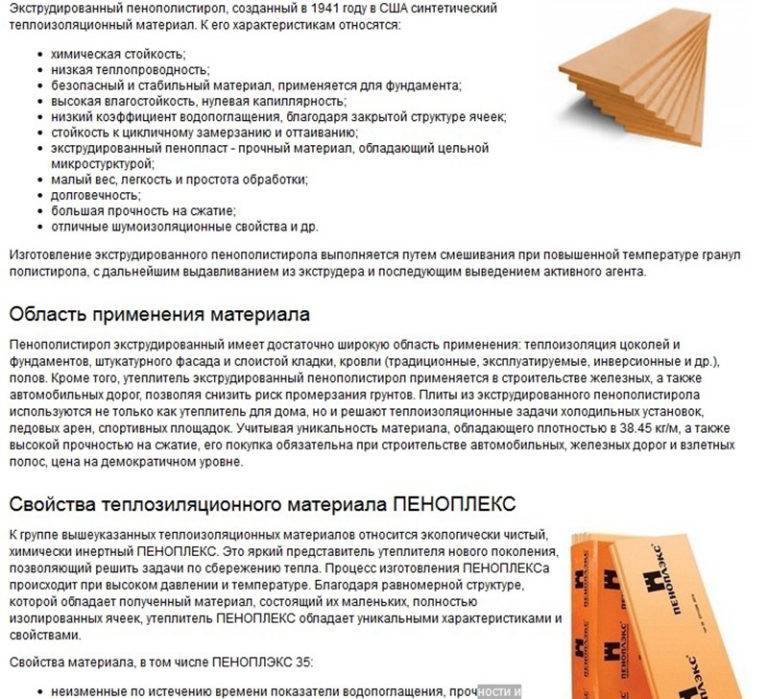

Today, the assortment of various finishing materials is so great that one can simply get confused in its richness. So, one of the most popular coatings with many positive qualities is extruded polystyrene.

This product is a special synthetic material that was first seen in the United States in 1941. Currently, polystyrene is used for a variety of purposes. It is to this raw material that they turn to when insulating structures such as foundations and roofs. In addition, extruded polystyrene makes good contact with facade plaster.

Which sheets are better to buy

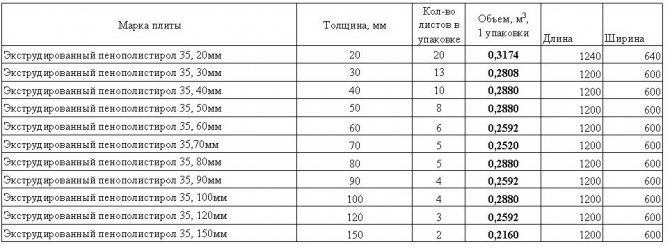

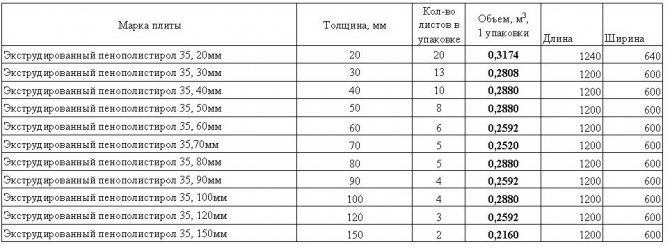

Styrofoam sheets vary in size and density based on where they will be used. Usually they are slabs with a width of 1 and 1.2 meters and a length of 1-4 meters.

Those who have chosen polystyrene as a heater should know that the price of all thermal insulation works depends on the price per sheet. In general, it is worth noting that the thicker and denser the foam sheet, the higher the price per sheet.

When buying, it is important to choose the right supplier. Polyfoam 100 mm has already a rather high price, so it is worth carefully examining the samples. Many companies offer additional benefits and discounts to their customers.

This type of insulation is easy to buy and install. It is a well-proven material in construction. Having protected the house with its help, there is no doubt that the heat will not leave it even in the most severe frosts.

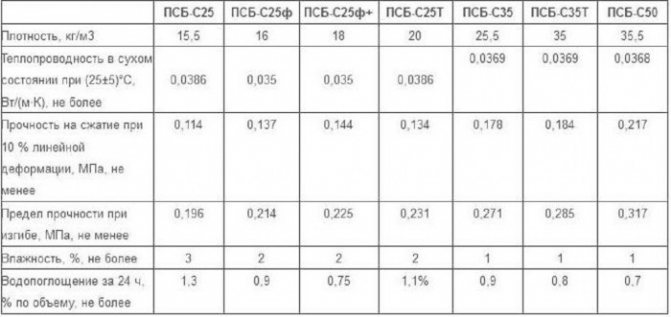

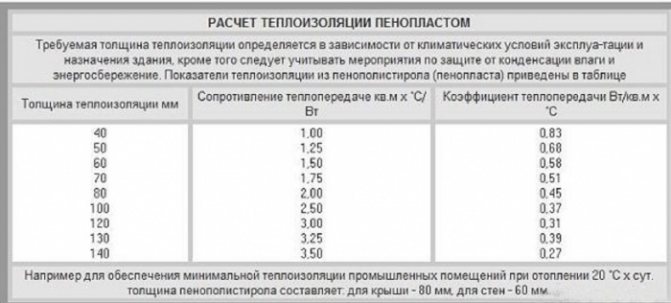

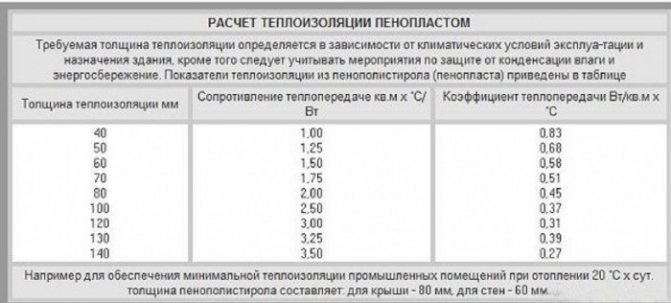

What affects the thickness of the heat insulator

When carrying out the calculation, several parameters should be taken into account:

Thermal insulation thickness calculation table.

Operational density. The insulator should be chosen in such a way that the density and thermal conductivity are optimal for walls made of a particular material. Structural load. All heaters have different weights, and the higher the density, the higher the weight. Almost any insulation is suitable for a stone or brick house, its weight will not be critical for the structure. For wooden and frame houses, this indicator is much more important, since with a large thickness, the load on the structure will be significant. Dew point

When calculating the insulator, attention should be paid to the fact that too thick or thin material will lead to the formation of a dew point inside the wall or insulation. Condensation will accumulate in this place, the material will quickly become unusable, and mold will begin to form on the walls of the house.

There is one more parameter that must not be forgotten. It concerns the material for the manufacture of the wall itself, the use of interior and exterior decoration. For example, in the presence of plaster, the thickness may be taken less than its calculated value, since the plaster layer itself is an excellent thermal insulation agent.

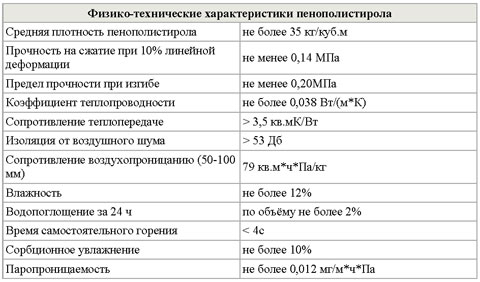

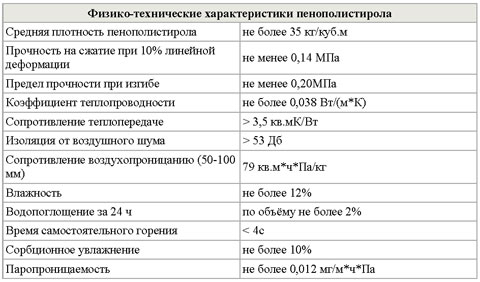

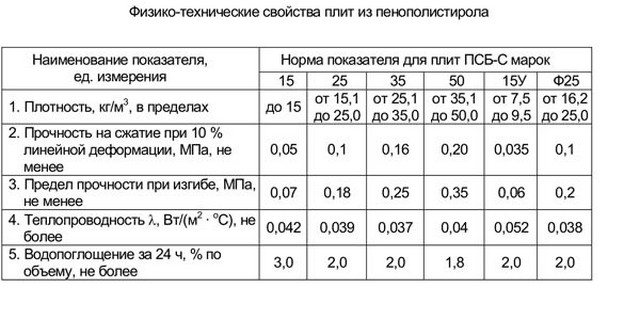

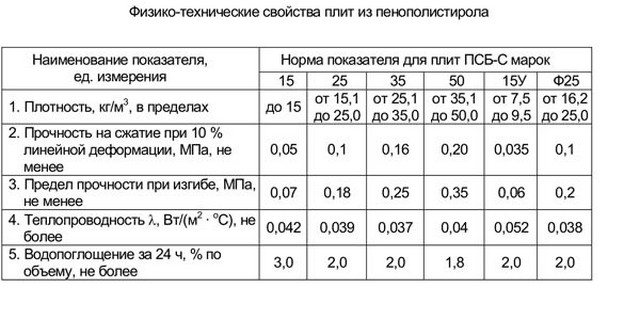

Physical properties of foam

The main characteristics of porous polystyrene include:

- strength - polystyrene does not differ in outstanding strength characteristics and is capable of crumbling and breaking even with weak mechanical stress. It can be easily damaged by sharp objects or simply by hitting the surface. To reduce the likelihood of destruction, the foam is covered with layers of a harder material that evenly distributes external loads;

- flexibility - polystyrene foam is weakly susceptible to bending effects and can break under them at any time. For the same reason, foam plates are installed only permanently, avoiding any torsional loads;

- thermal conductivity - the presence of gases (natural heat insulators) in hollow capsules provides the material with a low heat transfer coefficient. This is also facilitated by the absence of convection inside the pores due to their small diameter. It will take a long time to completely warm up a piece of foam to a predetermined temperature;

- tendency to shrink - free-lying expanded polystyrene slabs give in to slight shrinkage caused by gravity. The amount of shrinkage is 1.5-3 mm within six months. At the end of this period, the natural compaction of the material stops;

- thermal expansion - as the temperature rises, the linear dimensions of the slab increase (the process is reversible). The numerical indicators of expansion correspond to approximately 1 mm per 1 m of the foam plate when the temperature changes by 15-20 ° C;

- vapor absorption - polystyrene is less resistant to diffusional penetration of moisture than to the effects of liquid water, therefore, in especially humid rooms, its surface is additionally covered with a layer of metal foil. In its absence, part of the water vapor can penetrate through the layer of material and condense when the temperature drops, which negatively affects the entire thermal insulation system.

How much Penoplex will replace a brick wall

How much does Penoplex replace bricks? The latter is not the name of the building material. This is what one of the most popular brands of polymer insulation boards sounds like. This refers to extruded polystyrene foam, one of the best insulation materials available at the moment. It is worth figuring out in what respect it can be compared to a brick.

Clarification of terms

First of all, you need to understand to what extent expanded polystyrene can replace brickwork. These are completely different building materials.

Considering that both materials take part in the construction of the outer walls of buildings, only one comparison is relevant between them - in terms of thermal conductivity. It is this characteristic that is meant when posing the question, but it needs to be correctly reformulated: what thickness of Penoplex and brick will create the same thermal resistance. For the rest of the characteristics, the comparison is not in favor of the polymer.

Thermal conductivity indicators

The ability to resist the passage of a flow of thermal energy is characterized by the coefficient of thermal conductivity λ, expressed in units of W / m2 ° C. As a rule, sellers of various insulation materials provide the value of this coefficient for products in a dry state. At the same time, regulatory documents prescribe to calculate according to real performance indicators, the values of which are not so impressive.

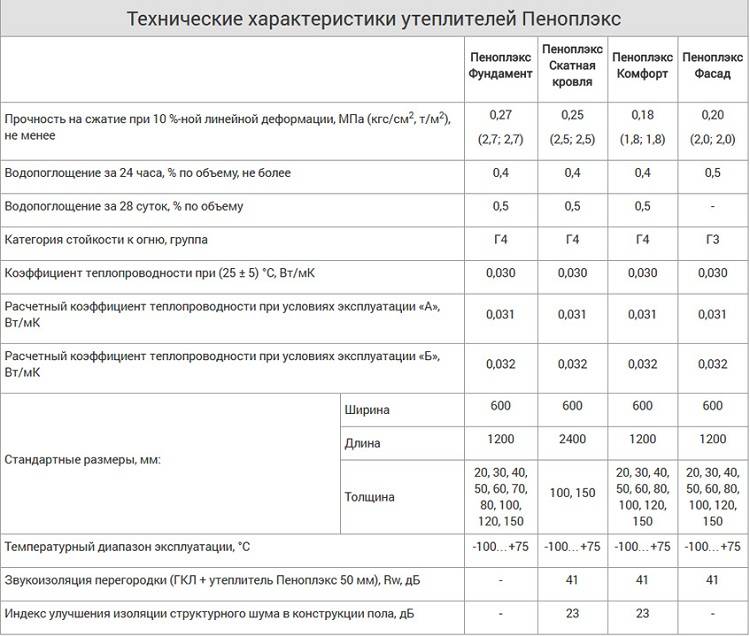

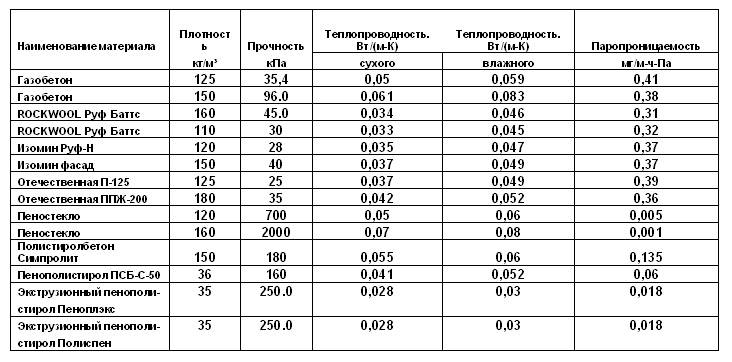

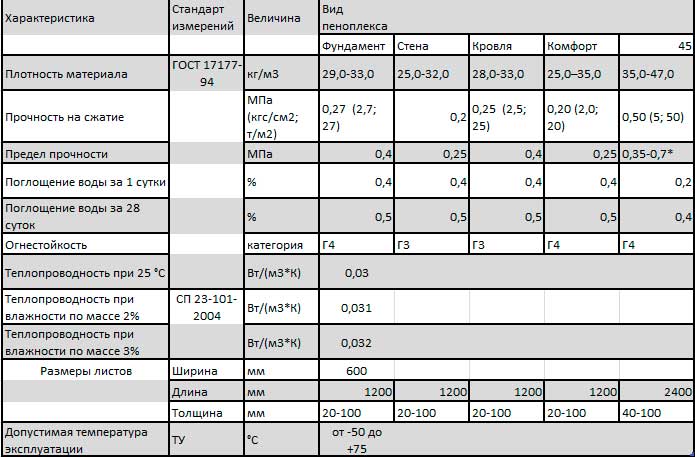

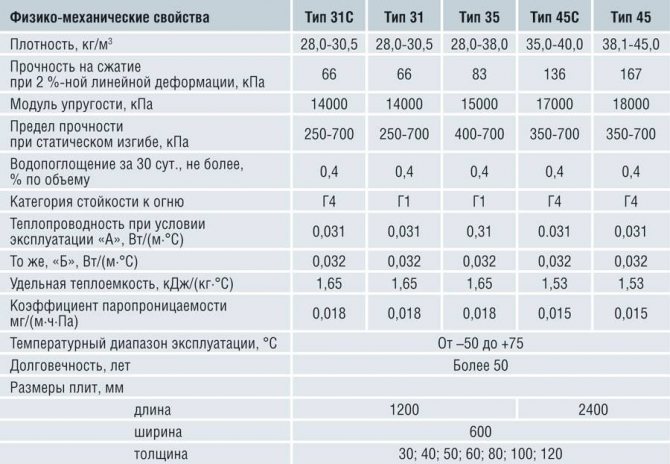

The materials in question are available in several varieties. Bricks are made from different materials and using different technologies. Grades of extruded polystyrene foam differ in density, which affects its thermal conductivity. The operational thermal indicators for products of different types look like this:

The list contains values for finished brickwork, erected on a cement-sand mortar. On other types of solutions, the indicators will differ slightly.The characteristics of extruded polystyrene foam of various densities are strikingly different in the smaller direction:

- Penoplex with a density of 30 kg / m 3, λ = 0.037 W / m 2 ° C,

- the same, with a density of 50 kg / m 3, λ = 0.038 W / m 2 ° C.

It is noticeable how much the thermal conductivity of polymer insulation is less than that of a brick wall. But these numbers are abstract and therefore hardly understandable for an ordinary person. To understand the situation, it is necessary to bring all indicators to one concept - thickness. To do this, it is necessary to determine one more characteristic - the resistance to heat transfer R, expressed in units of m 2 ° C / W.

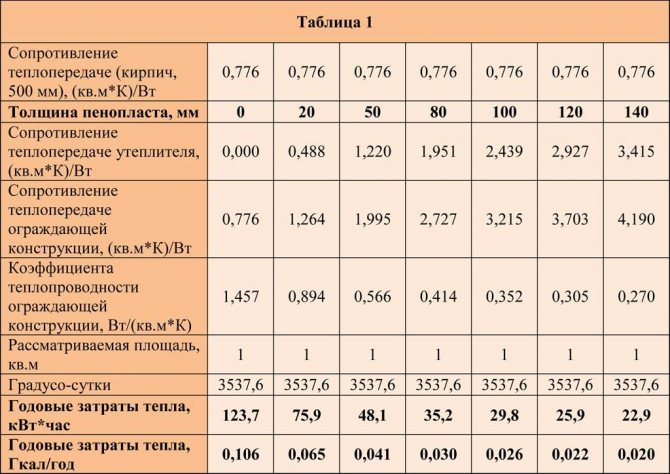

Thickness calculation

The heat transfer resistance R is tied to the thickness of the building structure, and its minimum value established by regulatory documents varies depending on the climatic conditions in the region. For example, in the southern regions of the Russian Federation, the walls of residential buildings must have a heat transfer resistance of at least 2.1 m2 ° C / W. It is proposed to take this value as a basis and calculate how many bricks and Penoplex will be needed to comply with it. The minimum indicator is calculated using the formula:

- δ is the value of the thickness of the wall structure, m,

- λ - thermal conductivity of the material from which the wall is built, W / m 2 ° C.

- R - resistance to heat transfer, in the example it is equal to 2.1 m 2 ° C / W.

If we take the thermal conductivity coefficient of ordinary brickwork λ = 0.7 W / m 2 ° C, then in the southern regions of the Russian Federation, the thickness of the walls made of a ceramic product should be: δ = 2.1x0.7 = 1.47 m.

The same wall, but made of Penoplex with a density of 30 kg / m 3, will have a thickness: δ = 2.1x0.037 = 0.077 m, or 77 mm.

The difference between the materials is 1.47 / 0.077 = 19. This is how many times the brickwork must be thicker than the expanded polystyrene layer in order to achieve the same rate of thermal insulation of the building. The complete picture showing a comparison of different types of brick walls and polymer insulation is shown in the table:

Benefits for insulating balconies and loggias

Considering the above, polystyrene, the properties of which make it possible to operate this material in different weather conditions, is well suited for the production of work on the insulation of various premises, including balconies and loggias of urban-type apartments.

For external and internal insulation of walls, floors and ceilings in these rooms, PSB-S 25 expanded polystyrene sheets with dimensions of 1000x1000 and 1000x500 mm are most often used. It is convenient to work with them due to the minimum number of joints during installation.

Benefits of Styrofoam:

The use of expanded polystyrene on the balcony

Low cost.

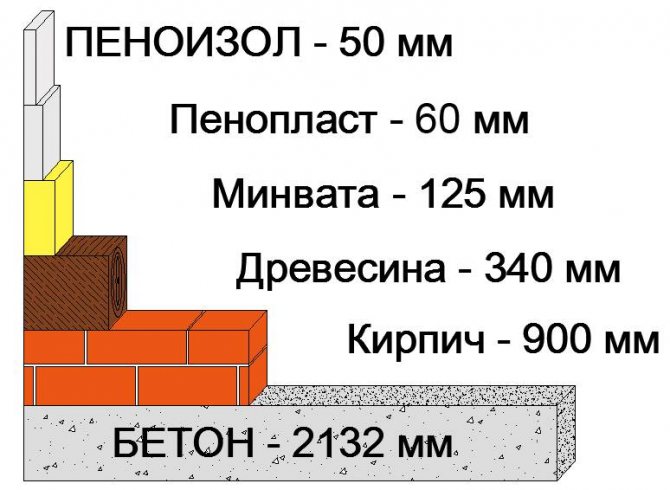

The use of this material allows you to reduce the cost of improving a balcony or loggia, without losing the quality of the thermal insulation performed. High thermal insulation characteristics. In terms of its thermal conductivity, a foam sheet with a thickness of 80 mm corresponds to 100 mm of mineral wool, 274 mm of wood, 760 mm of brickwork and 1720 mm of concrete. Thus, with its minimum weight, it provides a sufficient level of thermal insulation for the balcony, without creating additional stress on the load-bearing parts of the structure.

Polyfoam is easy to carry, cut and install, so it is well suited for insulating various surfaces of balconies and loggias, including their outer part. Polyfoam has excellent antistatic characteristics and does not absorb moisture, which compares favorably with another popular insulation - mineral wool. It is also an environmentally friendly and non-toxic material.

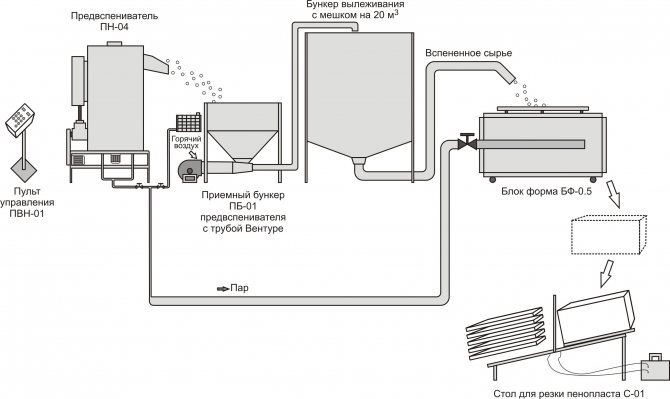

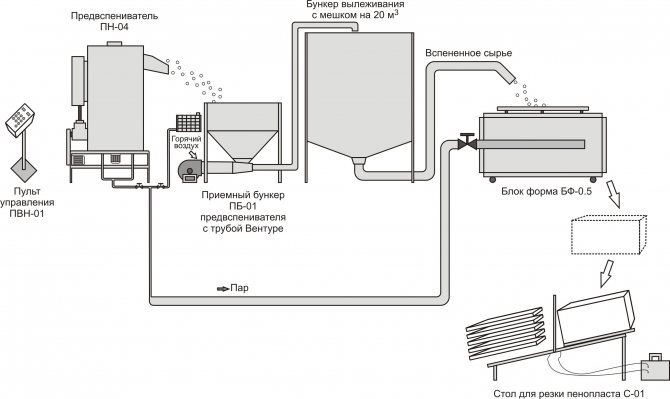

And below is a short video showing the process of foam production.

- Date: 12-03-2015Comments: Rating: 42

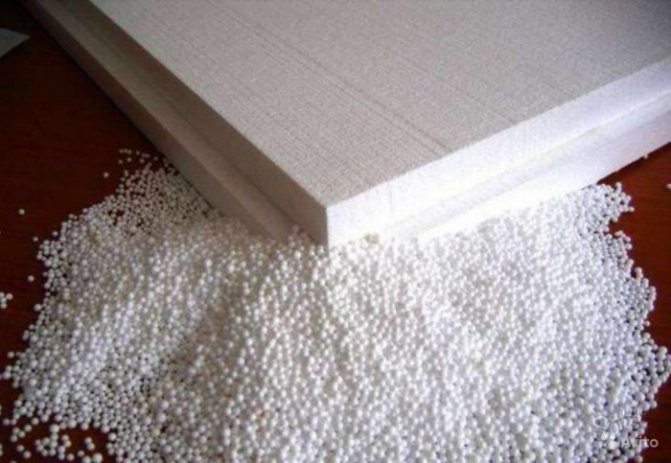

Expanded polystyrene has another more common and well-known name to many - polystyrene foam. Its appearance has also been known for a long time.It is a lightweight material that floats on water because it has air chambers inside its white balls.

It is they who give the material its unique properties. It has flaws. It is fragile and flammable.

Expanded polystyrene is a gas-filled material that is made from polystyrene and is used as a heater.

The manufacturer produces it in sheets of various lengths, widths and thicknesses. The last parameter is the main one in the choice of this material.

The thickness of the product can be from 20 to 100 mm. This material is very popular with builders. It is used to increase thermal insulation during brickwork with solid bricks.

Pieces of polystyrene are placed under plywood, which is used to finish the floor under parquet or laminate. They can insulate the walls from the outside while decorating the walls with plasterboard. Most often it is used from the outside.

Styrofoam sheets are available in standard and custom sizes.

The scheme of production of expanded polystyrene.

The length and width of a standard sheet are 1000, 2000 mm.

The manufacturer can cut products in other non-standard sizes. You can often find sheets of 1200x600, which meet the needs of the buyer and are in good demand. It can be a sheet with dimensions of 500x500, 1000x1000, 1000x500 mm.

On order, you can get a batch of expanded polystyrene with sides of 900x500 or 1200x600 and other sizes that do not contradict the standards. GOST allows you to cut products 10 mm less if its length is more than 2000, and its width is 1000 mm. In thickness for slabs up to 50 mm, a difference of ± 2 mm is allowed, and over 50 a difference of ± 3 is allowed.

If the length is not suitable for the buyer, then the companies selling such products offer individual cutting. Length and width are only relevant for the transportation of building materials from the manufacturer to the customer. The main role is given to the thickness of the material.

The conventional designation of plates according to GOST consists of letters and numbers, which includes:

Technical characteristics of various brands of expanded polystyrene.

- Type of plate. Brand. Dimensions of the sheet. Designation of the standard.

If the sheet has such characteristics as a plate made of expanded polystyrene with the addition of a 15 grade fire retardant, 1200 mm long, 600 mm wide and 40 mm thick, then the record will look like this: PSB-S-15-1200x600x40 GOST 15588-86.

If the foamed polystyrene plate does not contain a fire retardant and belongs to grade 15, and its dimensions are the same, then the record will change and will look like this: PSB-15-1200x600x40 GOST 15588-86.

Using the technical requirements of the State Standard, for the manufacture of foam boards, expandable polystyrene containing a blowing agent: isopentane or pentane is used. The residual styrene monomer is added to the total mass.

Styrofoam size table.

On the surface of the manufactured slabs ready for sale, there should be no bulges and depressions with a width of more than 3 mm and a height of more than 5 mm. Dullness of the ribs and corners can be observed, but not more than 10 mm from the apex of the right angle.

The sides of obtuse corners may have bevels of no more than 80 mm in length. All expanded polystyrene sheets have the correct geometric shape. Deviation from the plane of the face is allowed no more than 3 mm for every 500 mm of its length.

The difference in diagonals for slabs up to 1000 mm in length should not exceed 5 mm, from 1000 to 2000 mm - no more than 7 mm is allowed, from 2000 mm - no more than 13 mm.

When accepting a batch, the linear dimensions, the correctness of the geometric shape, and the appearance are always checked.

The consumer can be sure that all products in the purchased batch will have the same dimensions.

Back to the table of contents

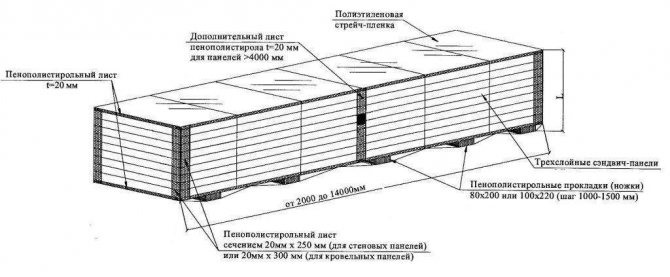

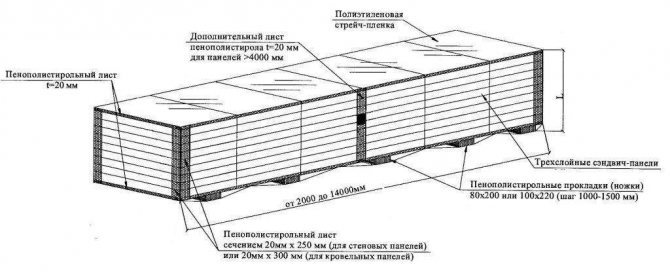

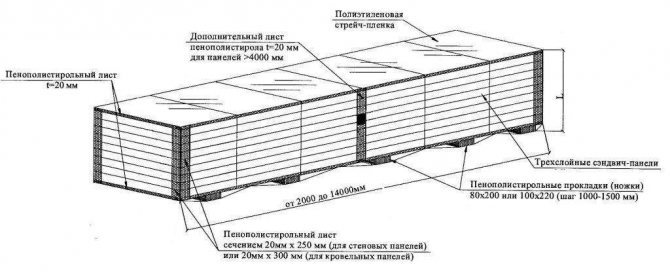

Styrofoam packing diagram.

The cut and ready-to-sell expanded polystyrene is packed by the manufacturer in transport bags and transported.GOST permits transportation unpacked if there is a guarantee that the sheets will not be damaged on the way.

When forming the package, the requirements of GOST 21929-76 must be observed. The height of the formed package should not be more than 0.9 m. With a slab thickness of 500 mm, the package is formed from two slabs.

On the side edge of the product or package, there must be a marking containing the stamp of the Quality Control Department of the enterprise that manufactured these products, the type and brand of the plate.

Marking must be made in accordance with GOST 14192-77 and contain the name of the enterprise or its trademark, the date of manufacture of the product, its name and batch number. Indicate the brand and type of plates, their number in the package.

There should be a designation of the standard on the basis of which these products were manufactured.

Back to the table of contents

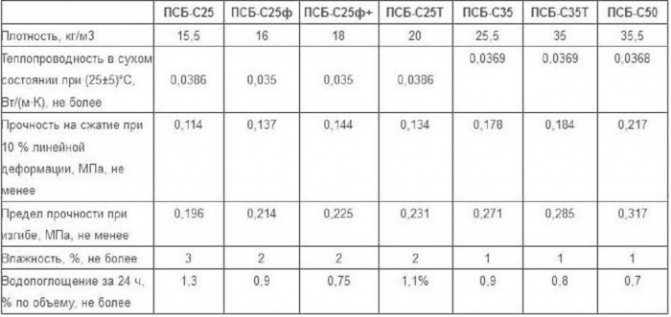

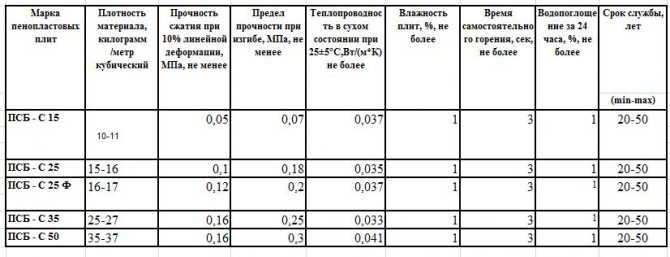

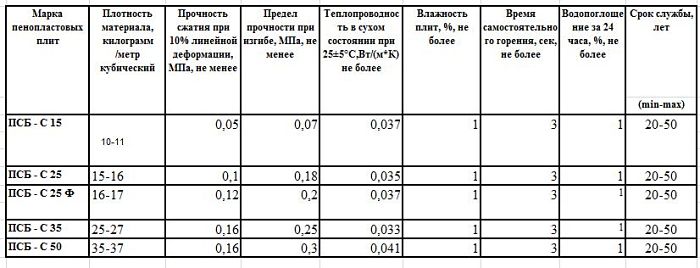

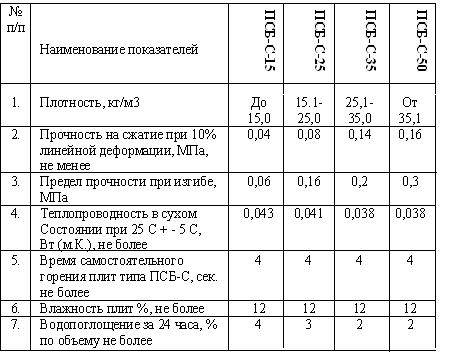

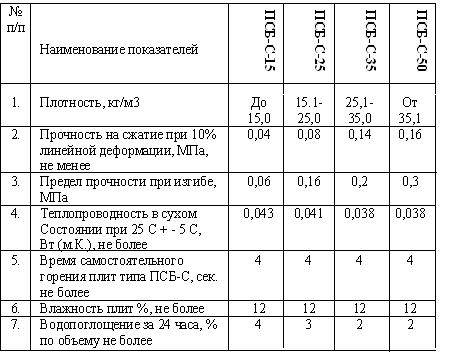

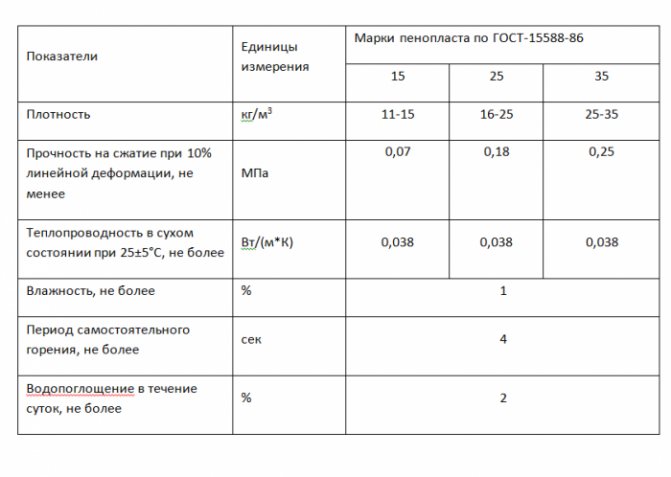

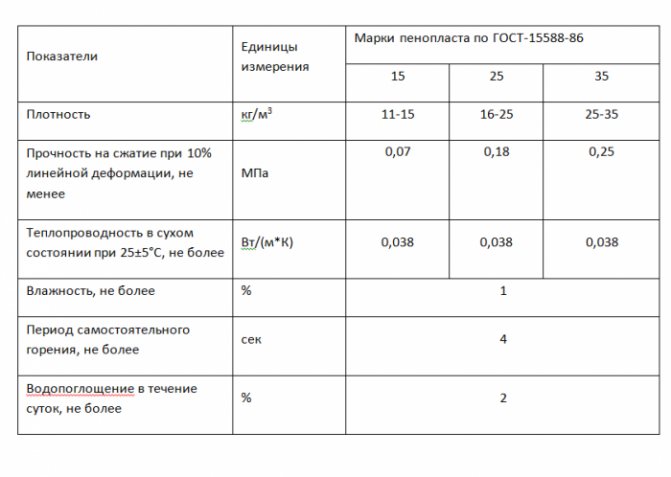

For insulation, several main brands of foam are used. Each brand is distinguished by its density, which is expressed in kg / m³. The higher the density of expanded polystyrene, the lower its thermal conductivity and higher strength.

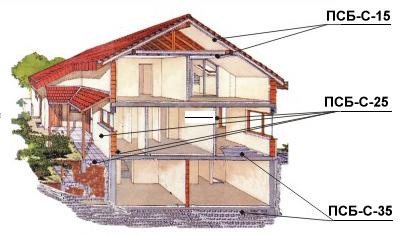

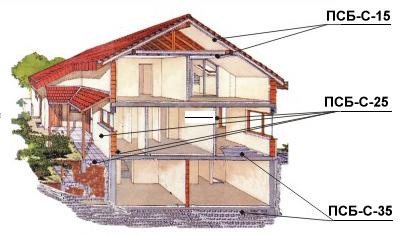

The most common brand of PSB-S foam sheet. The numbers in the markings indicate the density. So, PSB-S 15, standing at the very bottom of the density table, has only 15 kg / m³.

It is the lightest, it is used to insulate places of temporary residence of people: change houses, wagons, as well as containers for keeping heat. This brand is used for insulation in warm areas with mild winters. Walls are trimmed with it to reduce sound insulation of interior partitions.

The use of various brands of foam.

The most popular brand of polystyrene is PSB-S 25 with a density of 25 kg / m³. Sheets of expanded polystyrene of this brand, having various sizes, are used for insulating buildings, structures, structures. Foam is laid to improve the quality of thermal insulation and sound insulation of walls, roofs, floors, facade insulation.

Expanded polystyrene is used for the manufacture of panels, reinforced concrete structures, which are used in frame houses.

Sandwich panels and reinforced concrete structures, which are created by the method of permanent formwork, contain PSB-S 35 expanded polystyrene with a density of 35 kg / m³ in their structure. Such products, in addition to their main functions, perfectly provide wall waterproofing.

PSB-S 50 with a density of 50 kg / m³ is used for arranging the floor of refrigerated warehouses, heated soils, in road construction.

Back to the table of contents

This durable moisture-resistant insulation is used when performing outdoor work. To insulate the wall with foam, you first need to determine what density, size, type of polystyrene foam will be required for work. The choice depends on the expected loads that this material will bear during the period of operation.

When insulating a vertical wall, the loads will be minimal; a sheet of any brand will do. Even PSB-S 15 will give the same result as PSB-S 25 when it comes to wall insulation in areas with mild winters. This is due to the fact that the principle of operation of the foam is based on gluing polystyrene balls, between which and inside there are multiple air chambers.

It is known that the less mass and more air, the better the effect of thermal insulation is. It is inconvenient to work with sheets of low density, which are more fragile and break. PSB-S 25 has a high density, it is easier to finish with it.

Properties of expanded polystyrene.

Expanded polystyrene 25 is often used for external insulation of walls of non-residential premises.

They are used to decorate balconies, loggias, garages, shopping centers, and various institutions. For northern regions with cold winters, it is believed that a leaf thickness of 5 cm is enough to keep warm indoors on the coldest nights. Polyfoam grade 100 is used for thermal insulation of industrial freezers, as well as for warming houses in the harsh climate of the Far North.

A sheet size of 10 cm will maximize the thermal protection index.When choosing a brand of expanded polystyrene, you can choose a sheet that has various parameters. A non-standard sheet 500x500 is sometimes much more convenient to work with than a standard long sheet with dimensions of 2000x1000 mm.

For insulation of the walls of the house, sheets of 1000x1000 and 1000x500 mm in size are suitable. It is convenient to work with them, there are fewer joints that will have to be hermetically sealed. To fill smaller areas, the existing sheets are cut into suitable pieces.

For all non-standard situations in finishing, it is better to use a large sheet to make it easier to cut configurations. In the process of laying, such sheets are adjusted to the desired parameters, cutting the expanded polystyrene into pieces. This material is easily cut.

Expanded polystyrene with dimensions of 2000x1000 mm is more difficult to install. Working alone, it is easier to stack two sheets of 1000x1000 than one sheet measuring 2000x1000 mm.

Expanded polystyrene is a popular material in the construction market, because its thermal insulation capacity is much better than that of other building materials. It ensures long life for buildings in all climatic conditions.

Comparing it with other materials in terms of thermal conductivity, we get the following results: foam plastic with a thickness of 80 mm is equivalent to 100 mm of mineral wool, 274 mm of wood, 760 mm of brickwork and 1720 mm of concrete. This characteristic and low cost make this material especially popular in construction.

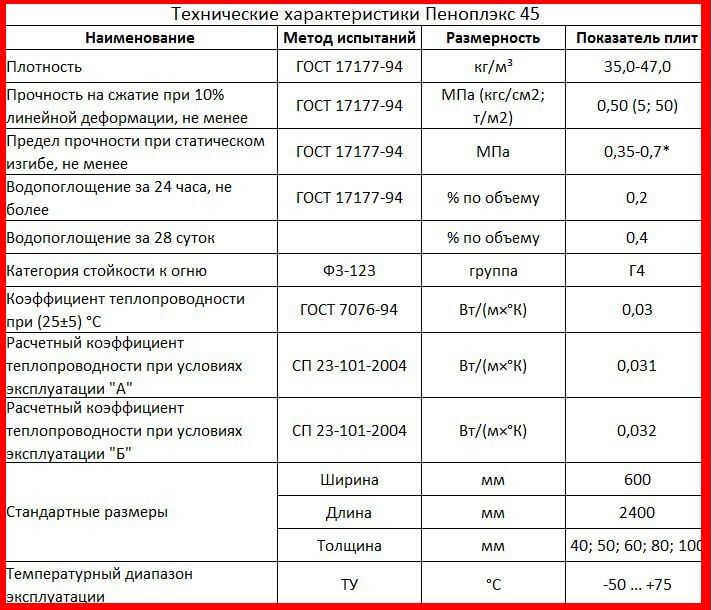

Low thermal conductivity, minimal water absorption, frost resistance and rotting resistance are only a small part of the advantages of extruded polystyrene foam. Thanks to all these qualities, the material stands out favorably among other options for thermal insulation and is widely used in construction.

Reference: structurally, EP is a flexible sheet made of closed cellular polystyrene. They are obtained by extrusion (forcing) polystyrene foam through special holes under the influence of high pressure and temperature. This provides increased strength and thermal insulation properties.

Thermal conductivity.

The thermal conductivity is 0.03 watts per meter per Kelvin. Low thermal conductivity allows the material to be used in housing construction and even when laying wells or insulating roofs of private houses. The smallest closed cells in the structure of the material minimize water absorption of the material.

Even if the slab is completely immersed in water, the liquid will only get into the side honeycombs, which are in an open state. Extruded polystyrene foam is excellent for Russian conditions due to its high frost resistance. The working temperature range is -50 - 750C.

EP does not lose its performance properties even after repeated freeze-freeze cycles. Durability and reliability. The service life of the material varies within 50 years or more, depending on the specifics of the application. At the same time, EP is not subject to decay and does not support biological activity, minimizing the risk of mold and mildew development.

For comparison: a slab with a thickness of 20 mm is similar in terms of vapor permeability to a layer of roofing material. High density, which is 15-200 kg / m3. Efficiency. The low cost of the material allows you to insulate the building for little money and create a comfortable microclimate in the premises. Despite the chemical basis, the composition does not contain components harmful to health, making the material suitable for insulating residential buildings and medical institutions.

At the same time, when burning, it does not emit harmful vapors, which makes it fireproof. For photo-ecological compatibility of extruded polystyrene foam. High strength. Compression capacity within 18,000 kg / m2.The specific indicator depends on the density and thickness of the material. Resistance to external influences.

The material is resistant to water, salt solutions, acids, alkalis, alcohol and other chemicals. Expanded polystyrene is easy to install, does not crumble and does not emit dust. And the low weight of the sheets does not require special equipment for unloading and installation.

At the same time, the material can be mounted both at the construction stage of the object and during the decoration of premises. The material is suitable for waterproofing basements, foundations, thermal insulation of buildings, construction of enclosing structures. It is actively used for thermal insulation of refrigeration and freezing systems, isothermal vans and ice arenas.

On video extruded polystyrene foam:

Among the shortcomings of the material, there is a weak resistance to acetone with turpentine, some brands of varnishes and drying oils, as well as ultraviolet light. However, this is solved by using special protection for the material.

Another disadvantage of expanded polystyrene obtained by extrusion is low sound insulation. The proper value for this parameter can be obtained only when using thick sheets, therefore, other materials will need to be used to protect against noise.

You may also be interested in learning about how to glue polystyrene foam to concrete, but what are the properties of polystyrene foam and polystyrene foam and where it can be used. This article will help you understand. What is and where is the foam polystyrene substrate under the laminate is used? This article will help you understand: https://resforbuild.ru/paneli/utepliteli/vidy-podlozhek-pod-laminat.html

What are the best polystyrene ceiling slabs and where can they be used. This article will help you understand.

Selection Tips

When choosing a heater, it is necessary to pay attention to the thermal conductivity index. Not only the amount of material required for insulation depends on this, but also the degree of moisture resistance

The higher the coefficient, the worse the protective properties, the more insulation you need.

The surface structure of polystyrene boards must be firm and even. Otherwise, there is a danger of moisture accumulation, which in the future can lead to the appearance of dangerous microorganisms that not only destroy the material itself, but also harm health. The material can be tested by immersing it in water for several weeks.

A high-quality composition is characterized by the absence of crumbs or the ability to change shape during insulation work.

When choosing a heater, you should check the evenness of the edges. A surface can be tested by clicking on its base. In case of a slip, it is better to refuse such a heater.

You can learn how to insulate walls with Penoplex with your own hands by watching the video below.

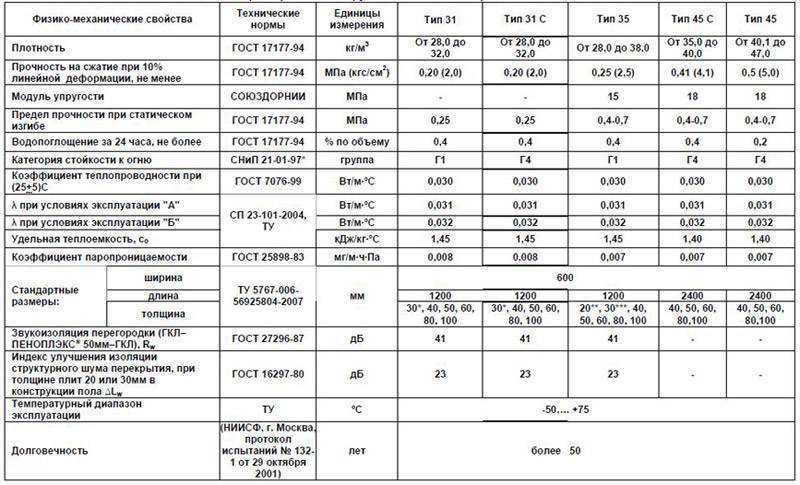

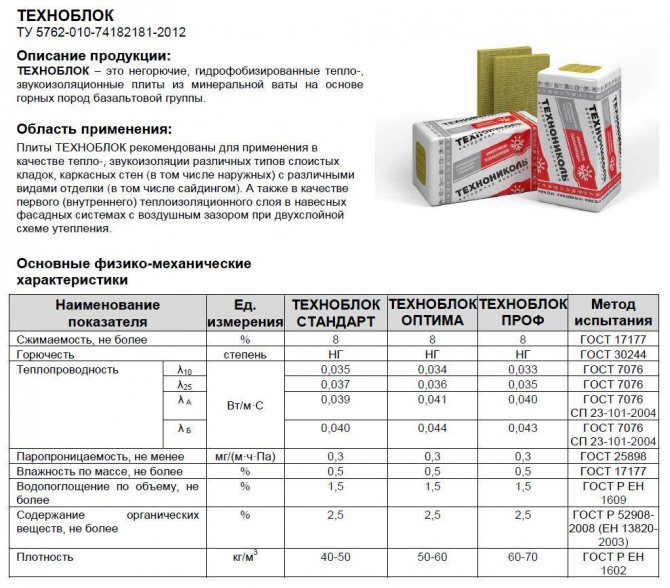

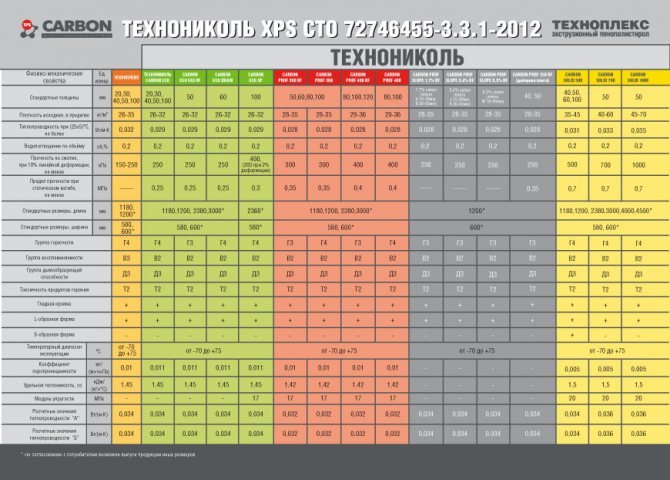

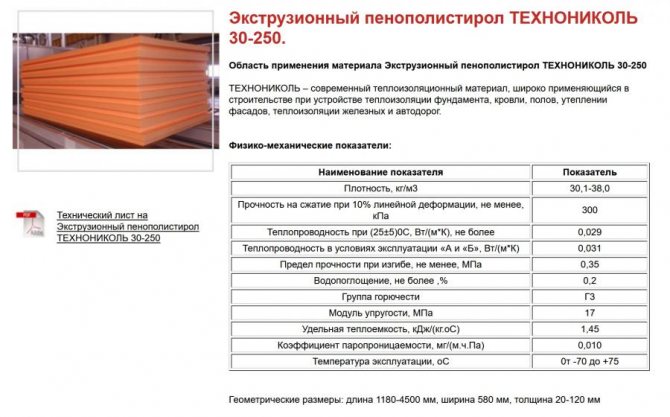

Comparison of different types: URSA XPS, TechnoNIKOL

BrandDescription "Technonikol" and "Technoplex" Durable and reliable insulation, suitable for industrial and civil construction. It is used for insulation of walls, roofs, foundations, as well as for the creation of sandwich panels. The thickness in the model line varies between 20-120 mm. Model classification: for floors, walls and balconies in apartments - XPS "Technoplex", for road construction - Carbon Solid, for industrial and civil construction - Carbon Prof and Prof Slope, for cottages and private houses - ECO, Carbon ECO SP, Carbon FAS, Carbon DrainURSA XPS Differs in the lowest thermal conductivity and increased environmental friendliness among analogues.

It can be used for both heat and steam, hydro and sound insulation. The service life is 50 years or more when used in external thermal insulation Penoplex is distinguished by a variety of edges - from straight to thorn-groove, which makes it easier to fit and install the plates. Temperature range is -50 - 800C

But how to use TechnoNIKOL foam glue for expanded polystyrene and where exactly it can be used is described in great detail in this article.

It will also be interesting to know which glue for expanded polystyrene for outdoor use is best used

How to properly use extruded polystyrene foam or foam and where you can use it, this information will help you understand.

But what can be used to paint a foam plastic ceiling tile and how it can be done correctly is described in great detail in this article.

It will also be interesting to know how to use penoplex plaster.

What properties of Penoplex determine the high level of consumer demand?

When choosing a material, its uniquely low thermal conductivity, low weight, easy installation and long service life are taken into account.

- Extruded polystyrene foam insulation of a new generation differs from foam plastic in its perfect homogeneous structure, resistance to compression loads and other adverse external influences.

- For all its advantages, mineral wool has strict weight restrictions. Therefore, to insulate devices that do not have a sufficient margin of safety, lightweight materials based on polystyrene foam are used.

Disadvantages of Penoplex Facade, which you can buy in our company at any time of the year - zero vapor permeability and rather low temperature resistance, are partially or completely compensated for by using in facade systems with slot ventilation and arranging heat-resistant protective and decorative coatings.

As for the insulation of underground, including foundation structures, in this version, moisture and frost-resistant polystyrene foam has no worthy alternative.

The strength of the foundation lining is sufficient to protect the waterproofing from damage by seasonal movements of heaving soils. The range of expanded polystyrene insulation includes panels of different standard sizes: from 30 to 100 mm thick. In most central regions, panels with a thickness of 50-60 mm are in high demand. You can buy Penoplex 50 mm in Moscow with substantial discounts at promotional and seasonal sales of building materials.

Expanded polystyrene insulation in country and cottage-type houses

Many developers use the material for external insulation of facades and ceiling structures of country houses, which are converted for year-round living. The main range of application of polystyrene foam insulation is finishing of foundations, blind area, insulation of cement screeds under floor tiles.

Unlike mineral wool, expanded polystyrene does not need film or mastic waterproofing, therefore it can be mounted directly on a flat ground surface.

Video: Styrofoam: myths and reality

https://youtube.com/watch?v=Ea94bC7aIp0

Frequently asked Questions

- What is better for a screed expanded clay or expanded polystyrene?

The coefficient of thermal conductivity of expanded clay is on average 0.12, and that of penoplex is 0.03 W / m * C. Those. almost an order of magnitude. Thus, to provide the required thermal insulation of the floors, the kermazite backfill will be much thicker than the foam sheets and the like. As a result, the entire structure of floors with expanded clay will be much thicker than the structure of floors with foam.

- Polyurethane foam or expanded polystyrene which is better?

Having made a comparative analysis of both heaters, we can say the following: polyurethane foam has higher characteristics in noise insulation, moisture resistance, heat resistance. Has a higher fire safety class. However, its thermal conductivity is an order of magnitude lower.

Considering that we are talking about the choice of material for insulation, polystyrene foam will be the best. Although, given the user experience, there is no need to use a material with such high performance as polystyrene.Therefore, preference when buying should be given to polyurethane foam.

- Is expanded polystyrene harmful to human health?

No, the material is completely safe to use. The only thing is that corrosive smoke is emitted during combustion.

- What surfaces cannot be insulated with expanded polystyrene?

It is impossible to insulate surfaces, the temperature of which exceeds the specified limits: -50 ... +75 ° С. Another limitation: in wooden houses where good vapor barrier is required, it is undesirable to use the material. The formation of mold, mildew between the wall and the insulation is possible. Humid air will not come out of the house. The room will have constant high humidity.

What is Extruded Polystyrene Foam? Universal insulation. It is considered one of the modern samples of materials of this class. When using it, it is worth observing the established temperature standards and other important requirements. If EPS insulation is done correctly, manufacturers give a guarantee for a polystyrene service life of at least 50 years.

How not to be mistaken with the choice of sizes?

Professional builders use special computer programs. It is necessary to enter information about the room: ceiling height, wall width, doorways, window sizes. The marking will be made automatically and the optimal length and width of the foam will be selected.

If there is no such software, you can make an estimate yourself, armed with a tape measure, a pencil and a piece of paper. Having built a drawing on paper, you can make a sketch of the cutting and determine the number of sheets, taking into account their area.

Thermal conductivity coefficient of foam plates

House insulation can be carried out in various ways, for example, with the help of polystyrene, which is characterized by high performance characteristics. These include: practicality, environmental friendliness, light weight, ease of installation, immunity to temperature extremes, as well as an affordable price. But the main advantage is the low thermal conductivity of the foam, which makes it possible to achieve excellent energy savings.

What determines the characteristics of the material?

The ability to conduct heat is influenced by many factors, in particular:

- Layer thickness. Sometimes, to achieve high-quality energy savings, you have to apply a lot of insulation. For example, the thermal conductivity of 5 cm foam plates will be lower than 1 cm with the same density values.

- Structure. The porous structure enhances the insulating properties, because the cells contain air, which perfectly retains heat.

- Humidity. During storage, the boards must be protected from moisture. This is due to the fact that the liquid does not have a very favorable effect on the characteristics of heat-insulating foams: the more it accumulates, the worse.

- Average layer temperature. Its increase leads to a deterioration in the efficiency of using the insulator.

Types of foam and their indicators

A huge number of insulation boards are presented on the construction market. In general, polystyrene foam has a low thermal conductivity, but it varies depending on its type. Examples: sheets marked PSB-S 15 have a density of up to 15 kg / m3 and a thickness of 2 cm, while the described indicator is up to 0.037 W / (m * K) at an ambient temperature of 20-30 ° C. Its value for sheets 2-50 cm marked with PSB-S 35, with a density of not more than 35 kg / m3 and 16-25 kg / m3 marked with PSB-S 25 of the same size - 0.033 W / (m * K) and 0.035 W / (m * K) respectively.

Best of all, the dependence of the thermal conductivity of foam insulation on its thickness can be traced when it is compared with various materials. So, a sheet of 50-60 mm replaces twice the volume of mineral wool, and 100 mm is equivalent to 123 mm of expanded polystyrene foam, which has approximately similar characteristics. Basalt wool also loses a lot.But the thermal conductivity of Penoplex is slightly lower than that of polystyrene: in order to obtain normal temperature conditions in the room, it will take 20 and 25 mm, respectively.

How do you determine which sheets to buy?

To most effectively apply one or another method of insulation, it is necessary to select the correct material dimensions.

Expanded polystyrene 100 mm: decoration of the building and its reliable thermal protection

Expanded polystyrene is created from polystyrene granules. They are filled with pentane and heated with steam. After that, the granules increase in volume by 20-50 times. They are very elastic and are 98% water. Next, hot steam is applied to the granules, as a result of which the balls adhere and a soft, durable material is obtained, which is used as insulation.

Expanded polystyrene is a durable material that provides a high degree of insulation. It is suitable for any application.

In 1952, BASF developed foam. Since then, it has conquered the construction market and its popularity is constantly growing. Expanded polystyrene is easy to transport, it is lightweight.

Expanded polystyrene is used for insulation:

- Foundation;

- Floors;

- Sten;

- Roofs.

The price of this material for 1 cubic meter is the lowest in comparison with other heaters. This type of insulation material will keep your walls and floors dry and keep your room warm all year round.

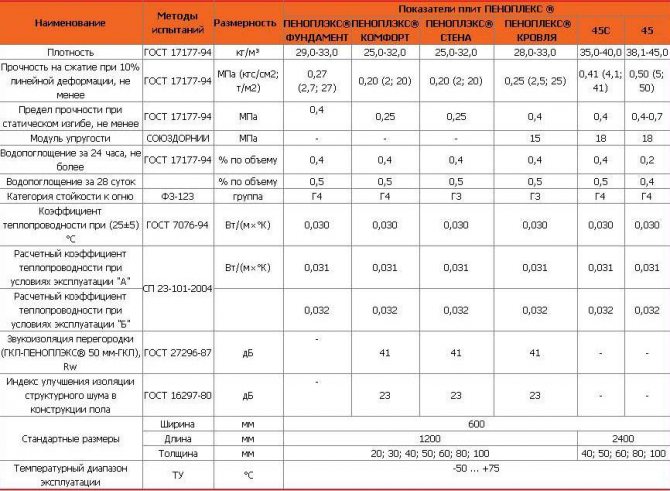

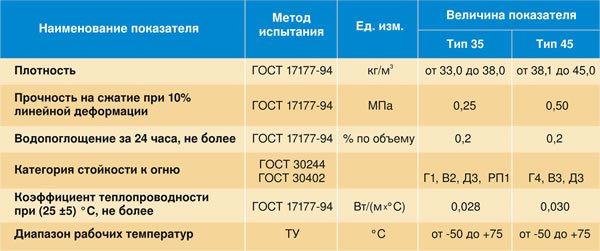

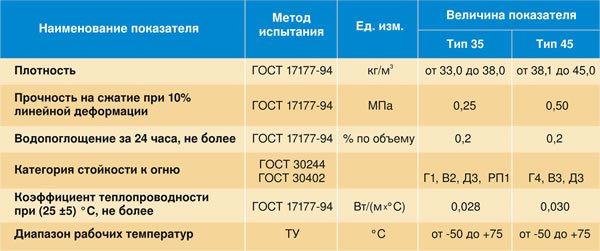

Specifications: table

| Indicator | EPS, Extruded polystyrene foam | Polyfoam PSB-S-15t - PSB-S-50 | ||

| Type 30 | Type 35 | Type 45 | ||

| Water vapor permeability mg / (m * h * Pa) | 0,008 | 0,007 | 0,007 | 0,05 |

| Density kg / m³ | 25 – 30 | 28 – 38 | 38 – 45 | 8 – 35 |

| Water absorption per day, not more than% by volume | 0,4 | 0,4 | 0,2 | 1,8 – 4 |

| Compressive strength (10% linear deformation) not less than MPa (kgf / cm²; t / m²) | 0,20 | 0,25 | 0,50 | 0,4 – 0,20 |

| Thermal conductivity at 25 ± 5 ° C W / (m * K) | 0,027 | 0,028 | 0,030 | Dry 0.038 - 0.043 |

| Fire resistance, category | G1 * | G1 * | G4 * | G3 * |

| Specific heat kJ / (kg * ° K) | 1,45 | 1,45 | 1,40 | 1,26 |

| Static bending strength, mPa | 0,25 | 0,4 | 0,4-0,7 | 0,6 – 0,35 |

| Sound insulation improvement index, dB | 23 | 23 | 23 | |

| Self-burning time, sec. | 1 | 1 | 1 | 4 |

- * G1 - Weak flammability;

- * G3 - Normal flammability;

- * G4 - Strong flammability.

Scope of extruded polystyrene foam

This material is widely used for thermal insulation of foundations, basements of buildings and floors of the first floor. It can be used in plaster facades and layered masonry.

In addition to the construction of buildings, extruded polystyrene foam, the technical characteristics of which will be discussed below, is used in the construction of various types of roads, since it prevents the soil from freezing and, consequently, the destruction from the phenomena of frost heaving. Agricultural specialists include the material in the construction of greenhouses, greenhouses and vegetable stores.

The material is also used for thermal insulation of ice arenas, sports grounds and refrigeration units. The special characteristics of extruded polystyrene foam, such as density and compressive strength, allow it to be incorporated into the construction of railways and runways. The materials used in these areas are subject to increased demands on service life and reliability.

The structure and main parameters of the foam

The composition of the cellular structure of the foam is extremely simple - the material of the usual white color contains 2% of polystyrene, the remaining 98% is occupied by air. Manufacturing technology is based on foaming polystyrene granules with subsequent processing of microscopic elements with a gas generator. Multiple repetition of the procedure provides the building material with a significant reduction in weight and density.

The foamed mass in the next stage is subjected to a drying procedure, as a result of which the residual moisture evaporates. The process takes place in drying tanks in the open air, after which the foam acquires the structure familiar to the consumer. The sizes of granules vary in the range of 0.5-1.5 mm, the wall thickness does not exceed 0.001 mm.

The finished granules are compressed to shape into slabs.To obtain the required parameters, the blocks are treated with steam and cut with a special tool. Depending on the order, the dimensions of the foam can be of standard or non-standard shape. Usually, the technical characteristics of the material indicate a thickness from 20 to 1000 mm, while the plates can have the following dimensions:

- 500x500 mm;

- 500x1000 mm;

- 600x1200 mm;

- 1000x1000 mm;

- 1000x2000 mm.

The variety of forms of production of expanded polystyrene plates and its technical characteristics, among which thermal insulation properties are especially appreciated, make it a popular building material for insulating premises with various functional loads.

Application area

Thermal insulation boards "Penoplex" 30 mm are used for thermal insulation of walls, roofs, foundations, plinths and floors in private estates. And also the extrusion product has found wide application in the insulation of balconies, loggias in urban high-rise buildings.

Penoplexom 30 mm insulates enclosing structures, garages and other types of outbuildings.

When the slabs are laid between the working surface of the insulating material and the facing surface, "cold bridges" are not formed, which creates an optimal microclimate inside the living space. The ambient temperature is always pleasant to find a person in any weather conditions.

Due to its high strength, "Penoplex" 30 mm withstands high loads both in horizontal and vertical positions.

In any condition, it does not deform during the facing work. Plates of extruded material do not absorb moisture, so the products are successfully used for cladding baths and saunas, wine cellars, swimming pools and other rooms where the humidity level is constantly high. If you need to insulate an apartment, make repairs in a country house or waterproof the foundation, you do not need to overpay by buying Penoplex of more expensive series.

For interior work, 30 mm Penoplex extrusion is sufficient. The cost of packaging for this product will be significantly lower compared to the same "Penoplex" 100 mm, in addition, the smaller thickness will not "eat up" the useful area of housing.

Insulation plate "Penoplex" with a thickness of 30 will be useful when arranging:

- underfloor heating systems;

- waterproofing the basement and foundation;

- any type of roof and ceiling;

- partitions or "well" masonry walls;

- garden paths.

Choosing the length and width of the sheet

The speed and ease of installation of expanded polystyrene depends on the area of the plate. Standard dimensions are multiples of 0.5 meters, therefore they often coincide with the parameters of the walls. The easiest way is to calculate the surface area that needs to be insulated. The sizes of sheets are selected taking into account the overall geometry in order to reduce the amount of scrap.

The conditions in which you have to work are important. It is more convenient to use large slabs on the outside of the house. This will take less time to install and require fewer fasteners.

The use of foam for interior work has its own nuances:

- limited area: interior partitions, interfloor ceilings, a certain distance between the rafters;

- it is difficult to lift large slabs to the floor along the cramped staircases of the entrance.

On the one hand, it is more economical to buy large sheets. A 1x1 m slab costs less than two 0.5x1 m. Fasteners are consumed less, and the installation time is reduced. However, this option also has a second side of the coin: a large sheet can break, it will take 2-3 people to lay it.

Description

Density

High-quality EPS has a homogeneous structure and closed pores of a much smaller size than that of conventional expanded polystyrene (no more than 0.2 mm). Due to its increased compressive density, EPS can be used where the foam is too soft. Extruded polystyrene foam can withstand a load of 35 tons per 1 m2!

Installation work

Another advantage that this material structure gives is the ability to handle it comfortably. Many people know how difficult it was to cut the foam. The balls crumbled, scattered, and became magnetised to hands, instruments, and surfaces. And even with careful handling, the stove could crack and break in the wrong place.

House insulation with Penoplex

Extruded polystyrene foam is devoid of all these disadvantages. It is easy to cut it with a regular hacksaw. The cut is precise and even. And the slabs are laid directly on the base, - it does not require additional layers of steam - waterproofing. The joints are sealed with polyurethane foam. EPS does not emit toxic substances, unpleasant odors. Working with it does not require special equipment for installers.

Moisture absorption

The dense structure increased the moisture resistance of the material (against the background of vulnerable mineral wool, water absorption of 0.2 looks like an error). In the first 10 days, the side cells on the cut collect the minimum amount of moisture. Then water absorption stops, water does not pass inside.

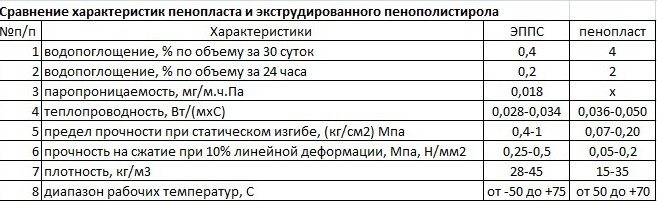

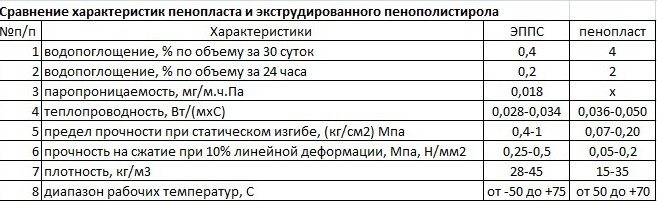

Thermal conductivity

In the battle to conserve heat, even the smallest difference in thermal conductivity matters. For different brands of expanded polystyrene, this indicator ranges from 0.037 to 0.052 W / (m * ° C). Extruded polystyrene foam has an indicator of 0.028 - 0.03 W / (m * ° C)!

Chemical resistance

EPPS has shown itself to be resistant to:

- various acids (organic and not);

- salt solutions;

- ammonia;

- cement and concrete;

- lime;

- alkalis;

- alcohol dyes, alcohol;

- carbon dioxide, oxygen, acetylene;

- freons (fluorinated hydrocarbons);

- paraffin;

- water and water-based paints;

- bacteria and fungi.

Other properties

The thickness of the slabs produced can be from 2 to 12 cm.

For ease of installation, three types of edges are available:

- Straight.

- With the selected quarter (Marked with the letter S).

- Thorn - groove (letter N on the marking).

The outer surface can be smooth or corrugated (indicated by the letter G on the marking).

The color range of extruded polystyrene foam is varied. Uniform standards do not yet exist, so each manufacturer molds boards of different sizes, thicknesses and different colors denotes EPS of different quality.

The properties of EPS do not change even after 1000 freeze-thaw cycles, after prolonged immersion in water. Extruded polystyrene foam remains unchanged, being in conditions of -60 +85 ° С!

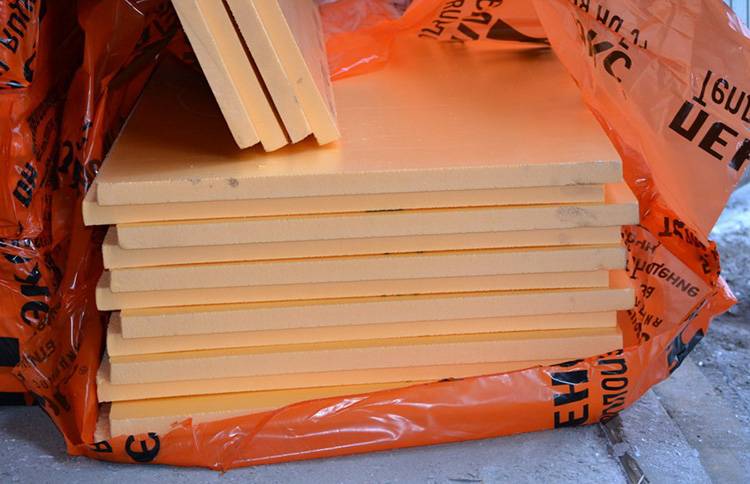

Orange colored slabs

Cons and Weaknesses:

- Penoplex is vulnerable to solvents, some gases (methane), petroleum jelly, tar, gasoline, oil and fuel oil.

- It is subject to destruction on contact with polyvinyl chloride (siding).

- Flammability. It corresponds to the level of flammability of wood, but all foams release toxic substances during reflow that suffocate a person faster than carbon monoxide.

- The material must be protected from direct exposure to ultraviolet radiation (not used open).

- There are temperature restrictions when insulating baths, saunas and stoker rooms. The surface should not be heated above +75 ° C.

- Just like styrofoam, extruded polystyrene foam can damage rodents. They do not eat it, but grind it and build nests in it.

There are no ideal materials, therefore, knowing about its shortcomings, you need to be able to adjust technologies for them. For example, in order to protect residents in the event of a fire, it is not advised to use EPS for internal insulation of ceilings, and plastering should be done on top of the insulation layer.

To protect the wall from rodents, Penoplex slabs can be covered with a fine mesh.

Material properties and characteristics

Polyfoam can withstand temperature fluctuations from -50 to + 75 ° C without changing technical characteristics. To get acquainted in detail with the technical characteristics of the foam, a detailed description of its properties will help:

- Thermal conductivity.A special production technology provides high heat-insulating properties to foam plates. The cells in the form of closed polyhedrons, the size of which does not exceed 0.5 mm, prevent the penetration of cold air and significantly reduce heat transfer. With increasing density of the material, this indicator changes.

- Soundproofing and windproof. The walls of the room, in the decoration of which foam plates are used, are reliably protected from the wind. Among the technical characteristics, a high degree of sound insulation deserves attention, which is also provided due to the cellular structure of the material. Comment! To reduce the level of noise penetration, it is enough to use foam plates with a thickness of 2-3 cm. The thicker the plate, the better sound insulation can be achieved.

- Moisture resistance. Expanded polystyrene is appreciated by builders for its low hygroscopicity relative to other materials. Water is not able to penetrate through the walls of the cells, but only seeps through the channels.

- Durability and strength. Polyfoam retains its original technical characteristics for a long time. Plates are able to withstand significant pressure without deformation and destruction. The use of polystyrene in the arrangement of runways can serve as a striking evidence. The thickness of the expanded polystyrene plate directly affects the degree of strength of the material, and the correct laying is also important.

The stability of the foam in front of an aggressive environment deserves careful study. The stability indicators of expanded polystyrene plates directly depend on the composition of the acting substance. Foam plates are resistant to solutions:

- cement;

- gypsum;

- bitumen;

- acids, alkalis and saline solutions;

- sea water;

- not susceptible to waterborne and acrylic paints.

Prolonged contact with substances that contain oils of vegetable and animal origin, diesel fuel and gasoline can negatively affect the technical characteristics of the foam.

When expanded polystyrene boards are used in the construction of objects, contact with compounds that aggressively affect the structure of the material should be avoided. Among them:

- turpentine;

- acetone;

- organic paint solvents;

- ethyl acetate ether;

- all kinds of saturated hydrocarbons and substances obtained by oil refining.

This includes fuel oil, diesel fuel, kerosene and gasoline. Contact with the above components leads to a violation of the structure and loss of the qualities specified in the technical specification, and can also provoke complete dissolution.

Attention! The artificial origin of the foam acts as an unfavorable environment for the appearance and development of microorganisms. But with significant contamination of the surface of expanded polystyrene plates, the reproduction of microorganisms becomes possible.

Among the positive qualities of foam plates, which are not reflected in the technical characteristics, ease of use and simple installation are noted. The light weight makes it easy to carry out work, the structure does not create difficulties when cutting and subsequent installation is necessary.

Expanded polystyrene is included in the category of environmentally friendly building materials; during operation, it does not emit toxic substances. When working with him, the use of personal protective equipment is not required. Numerous summary tables of technical characteristics do not reflect the numerous positive qualities of a building material. It does not form dust when cutting, is valued for its lack of odor, does not irritate mucous membranes and skin, and is not poisonous.

Fire safety is an important quality characteristic of foam. When choosing a building material, special attention is paid to this indicator. Quality products must be resistant to open fire. Expanded polystyrene plates belong to 3-4 class of flammability.This material does not support combustion. The temperature at which it is capable of flashing is 2 times higher than that of wood (+ 491 ° C compared to + 230 ° C).

If a fire retardant is present in the polystyrene foam, the flammability class of such a material is reduced to G2-G1. In the marking, this feature is expressed by the letter C. The ignition of the foam plate can occur as a result of prolonged contact with an open flame. Termination of exposure to fire leads to its attenuation on the surface of the expanded polystyrene board within 4 seconds.

Separate technical characteristics of foam plates are set out in the summary table:

What sizes will you need

You can answer this question in such a way that it all depends on which object you are purchasing this material for to insulate. To insulate a residential building, it will be enough standard sheets measuring a meter by a meter, as well as a meter by half a meter, while they should be forty or fifty mm thick. The most popular sheets are meter by meter, and they are great when you need to fill in the gaps.

But if you do not want to trim the foam, then you will need to buy a certain amount of foam plastic measuring a meter by half a meter, but in this case you will need to roughly calculate how much of it will be needed, establish the area of the walls where these foam sheets will be needed.

To avoid these problems, it will be necessary to level the walls or adjust the size of the foam. It is precisely these circumstances that are decisive when choosing a foam plastic measuring meter by meter. Styrofoam of these sizes fits quickly enough, and is also easily cut to the required sizes.

Also, an important role in choosing the size of the foam is the issue of savings. It is often cheaper to buy one sheet per meter than two sheets of half a meter per meter. Also, meter by meter is easier to mount than two meters by meter.

Also, when choosing the size of the foam, it is important to choose the correct thickness and density. This is a very important question, since it depends on how the foam will cope with the task of warming the room, as well as how long the room will be used.

Installation of foam sheets

The installation of this insulation depends on what size and quality the sheets are used, and where exactly the work is carried out.

- Sheet thickness 15 mm it has a low density, is very fragile, therefore it can often be found in internal partitions. Usually they are not attached in any way, but simply fit between the lags.

- Styrofoam 25 mm and 35 mm already suitable for facade work. Plates are fixed with glue to the surface, and then additionally screwed with dowels. It is better to install the sheets in a checkerboard pattern to avoid cold bridges. Outside, the wall is either covered with plaster or bricked. The sheets are suitable for floor insulation.

- Styrofoam 50 mm and 100 mm has the highest density and is suitable not only for construction work, but also for road work.