Rainwater falling on a painted or varnished window sill causes wood to rot. The decay process quickly spreads to other parts of the window block. Concrete windowsills can crack when exposed to moisture and frost. If the wooden sill is cracked or chipped, it can be easily repaired. Remove paint with solvent, remove wood chips and wood chips with a spatula and wire brush. Clean the gutter under the windowsill with an old screwdriver. Fill cracks and gouges with wood filler and let dry. Then clean and paint the windowsill.

Rotting is already a serious problem. If the entire window sill has rotted, then perhaps the damage has spread to the entire window block, and it will have to be replaced. If a small area is damaged, it can be cut out and replaced with a fresh timber section. Hardwoods resist rotting better, but softwoods can also be used as replacements if they match the material of the window sill. If only the front part of the window sill has rotted, then the replacement section is marked and cut out so that it is wider in the back than in the front. The replacement section is then securely fitted to the healthy part of the sill.

Surface potholes and small areas of damage on concrete sills can be cleaned out with a wag and chisel, and then carefully repaired with mortar. A window sill with large damage, such as deep cracks, will require more renovation. To do this, you will have to remove the destroyed places, make the formwork in the shape of the window sill, press it tightly against the wall and the window sill and fill it with new concrete mortar.

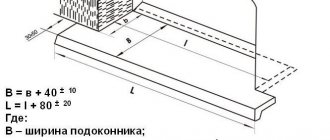

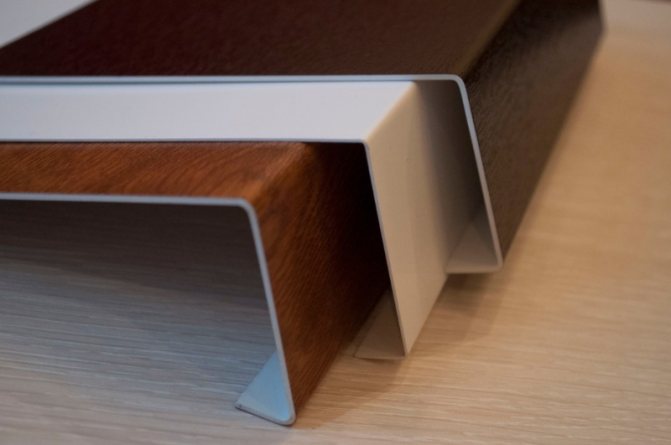

A protruding wooden window sill. The wooden section that hangs over the wall is attached to the sill of the window frame with a tenon connection. A U-shaped gutter groove, hollowed out at the bottom edge of the window sill, prevents rainwater from accumulating at the rear of the window sill and penetrating the wall. Instead of the prefabricated sill shown here, the overhanging sill can be part of a single window frame structure.

Concrete window sill. The lower transverse beam of the window frame of the swing casement window is located on a concrete sill that hangs over the wall. The surface of the concrete sill is sloped to allow rainwater to drain off. A stainless steel strip, which is embedded in the concrete and is located in a special groove between the concrete and wooden structures of the window, prevents water from entering the room.

Reasons and methods of window sill restoration

Window sill restoration is needed in case of mechanical damage, interior changes

Plastic is an economical and practical material. Elements made of PVC are easy to clean and easy to assemble. However, under the influence of high temperatures, they swell, and upon mechanical shock they burst.

Window sill restoration is also carried out in the following cases:

- The appearance on the surface of holes, chips, scratches as a result of mechanical stress and careless handling.

- The presence of traces from hot objects and flower pots - yellowing, deep grooves.

- Chipped surfaces and outer corners.

- Deformation of the coating or subsidence in the central part of the element.

- Burnout due to sun exposure.

- Chemical damage from improperly selected detergents.

If surface defects do not require replacement of the product, use restoration products. It is rational to install a new window sill when it burst.

Window sill restoration methods

The means and method of restoration depends on the nature of the damage

It is necessary to repair the structural element of the window depending on the level of damage. To restore the integrity of the coating, special products have been developed. Small scratches are eliminated by puttying, multiple chips are eliminated by surface lamination.

Methods for the restoration of a plastic window sill:

- Chemical cleaners remove minor blemishes, flower pot marks and heat. Use wax or solvent based products to restore the surface.

- Putty mixtures are intended for sealing small chips and cracks. The product is sold in the form of a powder, complete with a spatula. To prepare the mixture, use the instructions. Dilute the composition not with water, but with a deep penetration primer. It is not difficult to putty the window sill - after applying the mixture, the surface acquires the properties of PVC.

- Liquid plastic is a material for filling dents. The tool is used for advanced cases, including deformation of the product. Apply the composition according to the instructions to renew and obtain a smooth surface.

- Laminated film is a budget solution, for the implementation of which it is better to remove the window sill. It is recommended to work with two people, as this facilitates dismantling and allows you to evenly stick the film.

- PVC linings are suitable for do-it-yourself window sill repair, if the product is not more than 6 cm in thickness. The elements are made of polyvinyl chloride resistant to moisture and UV radiation. Use this restoration option to update your interior.

Use polyurethane foam to remove the gap between the wall and the window sill. Treat the damaged area. After the product has set, remove the excess with a construction knife. Apply white acrylic sealant on top of the foam.

If a laminated film is used for the restoration, first remove the block, and put it back after work. This will ensure that the surface is evenly coated and will not bend in the future.

Replacing a damaged section in a wooden window sill

- Window sill markup. Scrape off excess paint from the window sill, then use a screwdriver or other sharp tool to check the condition of the window sill and the size of the damaged area. Parts of the windowsill that are soft or spongy to the touch should be removed. At a distance of about 50 mm from the border of the damaged area, draw lines at an angle of 45 degrees towards the edge. Behind the damaged area, draw a pencil line connecting the two corner lines parallel to the edge of the sill.

- Selection of the decayed zone. On the protruding part of the window sill, you can remove the rotten area using a hacksaw. In the part of the window sill that lies on the wall, the sampling along the lines is done neatly with a chisel and a mallet. Take care not to blunt the chisel against the stone wall.

- How to cut an insert. Measure the height, width and length of the sill to be replaced and add 2mm to each measurement as a finishing tolerance. Using a tape measure and a thickness gauge, transfer the dimensions to a bar that is slightly thicker than the remote part of the window sill. Saw the workpiece along the marked lines, trim it to the desired thickness so that it tightly fills the selected part of the window sill.

- Gutter gouging. Draw two parallel lines on the bottom of the piece of wood so that they line up with the gutter on the remaining part of the window sill. Clamp the workpiece in a vise or clamp. Using a chisel and hammer (you can use a fluted chisel instead of a chisel), select the groove between the marked lines to the depth of the existing gutter.

- Securing the insert. Drill the fixing holes along the edge of the prepared section - approximately two holes for every 300 mm of the sill length - and countersink the holes. Lubricate the insert on the sides and back with waterproof glue and push it in place, using a little mallet to help it. Remove excess adhesive if necessary. Screw the insert to the window sill with copper chrome screws # 10. The screws must go into the window sill at least 25 mm deep. Fill countersink holes and any cracks in the windowsill with putty. Use a regular plane to trim the inserted section flush with the window sill. Then prime and paint the entire window sill.

Preparation for restoration

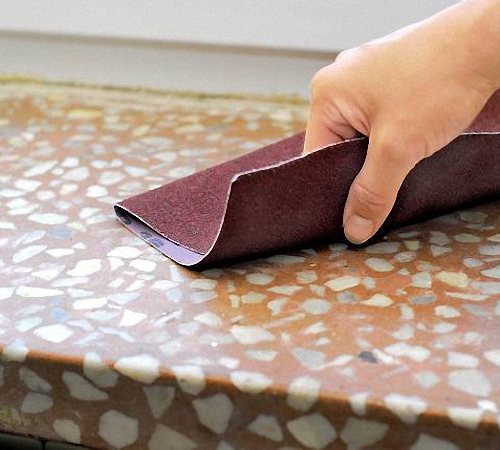

Small scratches are rubbed with sandpaper

Before restoring the window sill, clean the surface from dust and degrease. Prepare materials that will be needed in the course of the work. It is recommended to select a product that will harmoniously look with the design of the room. For example, overlays allow you to restore the surface and refresh the interior of the room.

For shallow scratches, such as those from an animal's claws, rub with white sandpaper. Apply PPC polish and rub into the surface with a soft cloth.

Before repairing a window sill, prepare the tools:

- assembly glue, silicone;

- roulette;

- saw;

- solvent;

- sandpaper;

- construction hair dryer;

- brush.

Depending on the type of work, some materials may not be required.

To independently restore the sill of the old window and avoid damage to the frame, cover its surface with masking tape.

Window sill repair or complete replacement: what to choose

Of course, almost every one of us will say: why waste time. After all, you can take and replace the old copy with a new one and forget this question forever. Moreover, modern building technologies offer us various options for solving this issue, from plastic products to decorative granite window sills.

In reality, everything is so, but not always replacing the old window sill will be the right decision. Many simply do not pay attention to the positive aspects that a simple window sill repair gives you. Here are some of them that may prompt you to decide in favor of repairing, rather than overhauling, this part of the window block.

- Saving money is probably the most important point in any repair and construction issue. In fact, major cosmetic repairs will be much more profitable than installing a new element of the window block.

- No inconvenience from dismantling work - the planned replacement of the window sill will always be accompanied by the dismantling of the old one and, accordingly, the subsequent installation of the new one. In this case, you will not be able to avoid destruction and natural construction waste, which causes enormous inconvenience in a residential apartment or house.

- Possibilities of design solutions - if you started repairing a window block, then with the right creative approach, you can give your old window sill almost any look. Due to the huge selection of materials for decoration, the window block can be turned into a masterpiece according to your special project.

In any case, before starting such work, you must carefully weigh everything and make the only correct decision.

Lamination of a plastic window sill with decorative film

Lamination is the easiest way to restore a plastic window sill. For this, special decorative films are used. They are glued to the surface. It is necessary to carry out pasting in several stages:

- pre-putty the surface (cracks, chips, scratches);

- sand bumps and bumps;

- degrease the windowsill with soapy water;

- remove the edge of the protective layer and gently distribute the film over the surface.

It is imperative to level the surface with a rag. The resulting bubbles should be pierced with a needle. The corners need to be warmed up with a hairdryer. The size of the film should be 4 cm larger than the width of the window sill.

Fig. 3. Laminated window sill

Coloring or art painting

You can pick up paint with a brush and show your imagination. If it is not too developed, you can use stencils with the most uncomplicated images. With different combinations of colors and lines, you will make your windowsill unique and irresistible. Let it be an abstract theme with an undefined theme - it will still attract attention and look better than a solid color. Artistic painting has always looked beautiful and unusual, especially when it is found on elements of interior decor.

Distinctive features of plastic window sills

Reinforced-plastic windows have won prestige long ago. They are very popular with consumers due to the fact that they are characterized by high performance characteristics, are easy to install and have a long period of operation. After replacing the window, the installation of the slopes and the window sill is immediately carried out.

Due to the presence of stiffening ribs, the surface of the window sill is very durable

A metal-plastic window is a versatile product that can be matched with different options for a window sill, which is selected in accordance with the stylistic task. The most common option is plastic products. This design is best combined with the material of a modern window, creating a single composition with it.

The plastic window sill has distinctive advantages. The product is resistant to moisture, sunlight and temperature extremes, not prone to rot, mold or corrosion. At the same time, the surface does not deform, does not change its original shape and appearance. The material is completely safe for human health, is durable (due to the presence of stiffening ribs), reliability, resistance to chemical influences. It has high thermal insulation properties due to the presence of air chambers in the construction of the window sill.

The product is lightweight, which ensures easy installation of the PVC window sill, while it does not shrink during further operation. The surface does not need painting and other treatment options to prevent possible rotting or corrosion. It is easy to look after her. A plastic window sill is characterized by a low cost in comparison with other materials.

Despite the advantages, the plastic window sill has its drawbacks. With careless use, dents or holes may appear on the surface of the product, which is a consequence of the fragility of the product. If a glossy finish is present, scratches may form on it, which will cause an unsightly appearance.

Plastic window sills are resistant to moisture, temperature extremes, sunlight

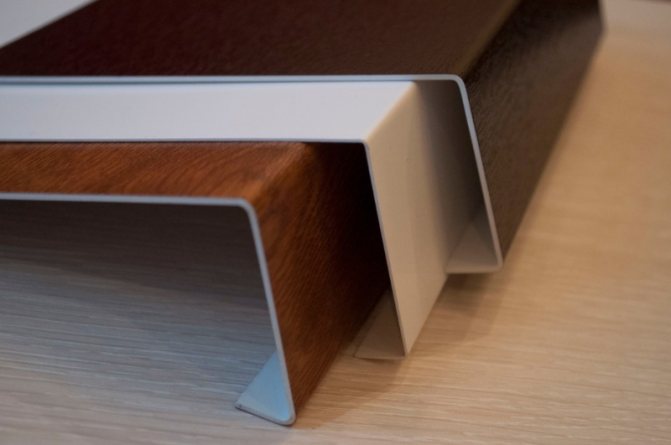

PVC lining

Installing the cover does not require any additional preparation of the window sill, but quickly and easily solves all the problems of stains, chips and scratches. You can order it according to the size of the window sill, and it is installed on glue. The biggest challenge you will face is deciding on the color of the material.

Pros:

- easy installation;

- no preliminary surface preparation is required;

- long service life;

- low cost.

There were no downsides to this method.

How to repair a windowsill?

Restoration of a concrete window sill - a set of works to eliminate damage and restore the integrity of the object.When renovating windows, few people now resort to restoring wooden frames. They simply dismantle them and install plastic double-glazed windows, but you can still fight for the windowsills and not dismantle them, but restore them. A solid advantage of concrete products is that they are much stronger than common plastic structures. In addition, by avoiding dismantling the window sill, you can save money. The only condition is that the window sill must be intact (not cracked).

A few words about the repair of a concrete window sill

Today, in residential and public buildings, you can find such a product as a concrete window sill. Of course, initially, such products were installed on a window block based on its durability. But concrete also tends to collapse, and if this happens, it can be corrected by carrying out a simple complex of repair work.

As a rule, the main defects are delamination and chips, this is considered a common occurrence in concrete. To make the repair of a concrete window sill as high-quality as possible, we recommend using fine crushed stone and cement. In this case, it is not necessary to add sand, since it imparts looseness to the composition and may subsequently be subject to destruction. Well, we are getting down to work.

- We prepare the surface, remove all layers and clean the chips to a solid concrete base.

- Be sure to prime the work surface, removing all dust from it.

- We prepare a mixture at the rate of one part of fine gravel and one part of cement, gradually adding water to the dry mixture. The consistency of the finished mixture should resemble sour cream.

- We apply the ready-made solution to the damaged areas and level it, if you are dealing with chips at the edges, it is recommended to install the rail as a formwork and then apply the solution.

- Let the solution settle and gain strength, preferably at least two days.

- After the concrete has gained strength, we grind the surface with a grinder using coarse emery cloth.

Do not forget that the surface to be treated is periodically watered with water during grinding. It is also recommended to use a moisture-resistant emery cloth for grinding, any other will wear out quickly and will not give the desired effect.

- Author: Mikhail Malofeev

Rate the article:

- 5

- 4

- 3

- 2

- 1

(4 votes, average: 4.8 out of 5)

Share with your friends!

Window sill cover color

Manufacturers offer cover plates in different colors, but they try not to deviate from the popular color style of windows. Therefore, the portfolio of offers of window companies is dominated by wood colors (oak, beech, apple), brown, white, as well as imitating stone colors, for example, marble.

Sill covers are usually sold complete with side trims, available in the same color, so that, thanks to a good combination, the structure looks like a whole.

Choice of paint

Before starting the restoration, it is important to consider different paint options and understand how to paint a plastic window sill and a surface made of natural materials.

For natural materials, it is better to use the following types of paints:

- Alkyd enamel. It is characterized by durability, elasticity, waterproofness, dries quickly, does not lose its color, does not turn yellow.

- Acrylic. The paint is odorless, easy to apply, dries quickly, is "breathable" (that is, it allows air to pass through), strong, durable.

For a PVC window sill, it is better to choose the following paint:

- Aerosol for car plastic. Evenly applied, can be used in several layers. It is characterized by durability, strength, has a rich color range, so you can easily choose the right option.

- Polyurethane or alkyd-urethane.Resistant to damage (do not wear out or scratch), tolerate temperature changes well, can withstand heavy loads, have a variety of colors.