Why is it necessary to insulate slopes

Often, after replacing windows, they are limited only to decorative finishing of slopes, which is wrong and can lead to problems in the near future, because:

- Seams between the wall and the glass unit are filled with polyurethane foam. But this material does not have sufficient resistance to high humidity, ultraviolet radiation and low temperatures. Very quickly unprotected polyurethane foam will begin to deteriorate under the influence of weather conditions, which will lead to heat loss through the voids in the seams.

- Multiple cracks on untreated slope surfaces are a common cause heat leakage from the room.

- In the voids between the wall and decorative panels moisture can accumulate, which means that condensation is possible.

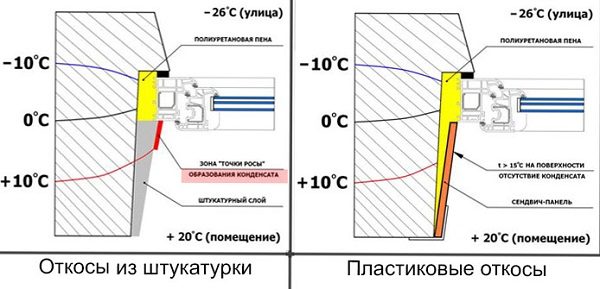

Plaster slopes get damp in winter

Plastering of slopes without additional insulation is a kind of "first aid". This finishing method will help you out for a while, if immediately after installing double-glazed windows you do not have the opportunity and time for high-quality work. But in the long run, this is not the best way out. Small cracks will form on such a surface, which will require constant minor adjustments. In addition, such slopes do not have good thermal insulation. You will soon have to return to the issue of serious insulation.

It is advisable to carry out the work immediately after the installation of windows in the warm season. In the cold season, this will be more problematic, since many adhesives and sealants can only be worked at a certain temperature.

Criteria for choosing a heater for windows

Insulation materials with good heat-reflecting properties are purchased for finishing the interior parts of window openings. The best options are sandwich panels, foamed polyethylene, mineral wool. The material for external insulation must have the following characteristics:

- resistance to atmospheric factors;

- good thermal insulation properties;

- vapor permeability.

These requirements are met by stone wool, expanded polystyrene.

Applicable materials

The range of materials used to insulate slopes on their own is quite diverse. Each of them has its own advantages and differs in the features of installation and operation:

- Mineral wool (not to be confused with glass wool - this material is highly undesirable to use for interior work). The main advantages are excellent heat and sound insulation properties. The disadvantage is high moisture absorption. If you notice that the windows "sweat", then it is better to refuse this type of insulation, as over time this can lead to the formation of mold and mildew.

The easiest way to insulate with mineral wool - Styrofoam. Inexpensive and easy-to-use material, which led to its popularity in various types of work.

- Penoplex. It has improved performance compared to foam, but it is also more expensive.

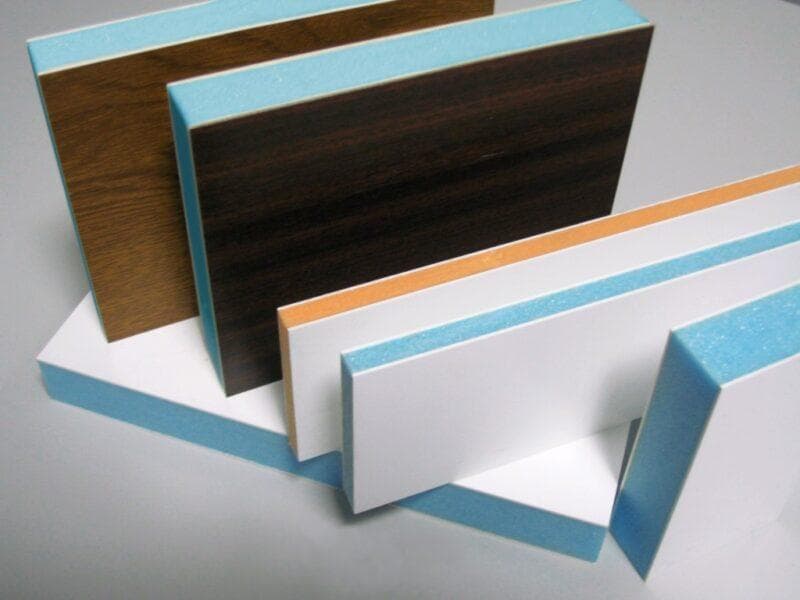

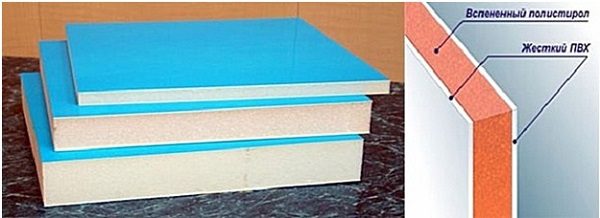

- Sandwich panels. The most modern and most convenient type of material. Already includes thermal insulation and protective layers. Harmoniously complements plastic windows, usually fits into any room design. Cons - the relative high cost.

The choice of the preferred material is based on climatic conditions, the general condition of the walls of the house, the material capabilities of the owner, the level of qualifications of workers.

If the width of the gap to be bridged is more than 4 cm, use sheet materials (Styrofoam or Penoplex). To seal a gap of a few millimeters, mineral wool and a decorative panel are enough.

Select the required thickness of insulation.

Varieties of designs

Slopes are made of plasterboard, plastic, plaster.

Each option has its positive and negative sides.

Plasterboard slopes

For finishing window openings, moisture-resistant sheets are used. The structure assembled from them has the following advantages:

- reasonable price;

- long service life;

- small amount of waste;

- installation without the use of complex equipment;

- compatibility with wood or plastic windows;

- quick installation without the use of putty or plaster;

- good noise insulation properties;

- mold and mildew resistance.

Decorating slopes with plasterboard is one of the most budgetary and easy-to-use methods.

The main disadvantages are:

- low strength;

- the impossibility of partial replacement of the damaged area;

- sensitivity to sunlight;

- reduction of the window opening.

Using plaster

Plastering openings has the following advantages:

- the ability to perform work in rooms with any temperature and humidity;

- low cost;

- resistance to negative factors;

- lack of joints and gaps;

- ease of restoration of damaged areas, the ability to stain in any color.

The negative sides of the method are:

- the complexity of the job;

- the appearance of a large amount of dirt and dust;

- low thermal insulation properties;

- peeling of plaster from the frame.

Plastic

Installation of PVC panels is the most common way of finishing window openings. Their advantages are:

- low price;

- smoothness, flatness of surfaces;

- tight fit to the frame;

- simplicity of thermal insulation of the structure;

- quick installation;

- moisture resistance.

Plastic structures are unstable to mechanical stress and cannot be partially repaired.

Complementary elements turn yellow over time, which is why they have to be replaced.

Preparatory work

Regardless of which method of insulation and the type of material is chosen, first of all, it is necessary to conduct a visual inspection of the window structure and carefully check the condition of the assembly joints. If the glass unit was installed a long time ago, and the assembly seam was not protected, then most likely the foam has already begun to collapse and crumble. You can identify problem areas with a lighter. Run it along the entire perimeter of the window. Where the flame is deflected and leakage occurs. It is necessary to clean and re-foam such areas. After hardening, cut off excess polyurethane foam.

How is it determined from where it blows?

Even if there is only one defect, the window will blow. You can determine the place where this comes from in one of three ways:

- By running your hand around the perimeter of the window block;

- Lighter. Just as with the hand, the light will change in the place of the draft;

- Putting a plain sheet of paper in an open window and close the sash. If, when pulling on the tip of the sheet, it easily stretches out, then this will indicate a poor pressing of the seal.

Insulation of slopes inside with foam or foam

Sheets of polystyrene or polystyrene foam are the most common types of materials for insulating slopes. Work with their use is carried out after the installation of a double-glazed window in the following sequence:

- Slopes and areas between the frame and the wall, filled with polyurethane foam, must be plastered with cement mortar.

- After drying, treat the surface with an antibacterial compound.

- Cut the insulation to the required size. It is better to cut off a larger piece - the excess can be easily trimmed after installation.

- Sand the surface with sandpaper. Grease with special foam glue. If you are using Styrofoam, do not apply a lot of adhesive. This type of insulation expands when heated - in hot summer months, an abundant layer of glue can crack, and the coating will lose its thermal insulation properties. Apply the prepared insulation to the slope, partially overlapping the window frame.

- After the insulation is glued, we fix it with plastic umbrellas.

- The next step is mesh reinforcement.

- Then, we put the perforated corner on the putty, set it right on the level.

- Apply a decorative coating to the front part of the insulation in accordance with the renovation concept. It can be drywall with subsequent painting, plastic panels, colored plaster.

Also to help - a small video tutorial:

Finishing options

After completing the installation of insulation, you should think about the aesthetic side. For facing the slopes, the following methods are used:

- Dyeing is the most common and easiest finishing method. There are several ways to decorate. The easiest way is to perform the procedure with a sponge soaked in paint. With its help, prints are left on the surface. When painting slopes, you can combine several tones. Drawing pictures using a stencil is considered an interesting way.

- Facing with cork slabs. The material provides additional thermal insulation. If desired, the panels are coated with a protective varnish.

- Assembly of plasterboard construction. Sheets are installed on a frame made of guides and hangers. After assembly, the structure is painted.

- Plastering with wallpapering. This method is undesirable to use in rooms with high humidity.

- Installation of plastic panels.

The best solution for facing slopes is painting.

Combined insulation inside

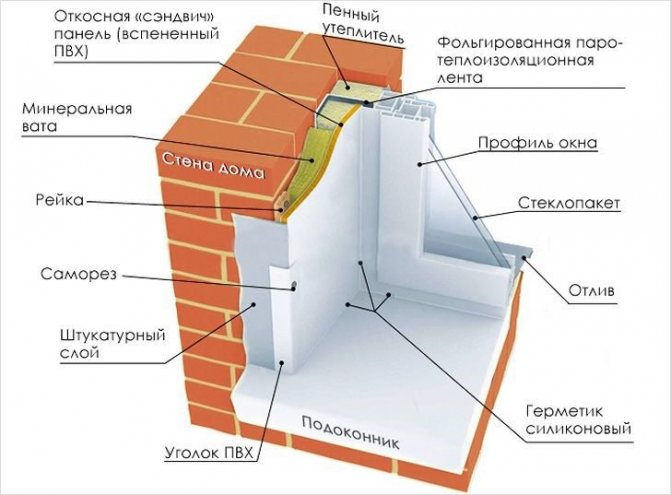

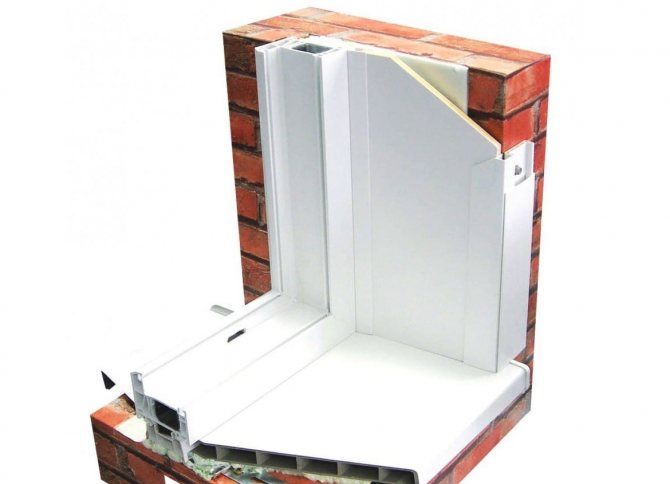

The use of two or more different types of insulation gives the best results. For example, you can use mineral wool in combination with sandwich panels. Additionally, foil-clad insulation can be used. The technical process looks like this:

- As usual, carry out all the necessary preparatory work: clean the surfaces, level out potholes and cracks with a sealant.

- Cover the assembly seams with foil insulation, the material should go over the adjacent walls.

- Fasten the U-shaped profile for the subsequent installation of the slopes.

- Cut pieces of the required size from the sheets of sandwich panels and fix them in the profile.

- The voids between the panels and the wall are filled with mineral wool.

- Mount the finishing profile.

Instead of expensive sandwich panels, the foam sheets already described above can be successfully used. But it will require a finishing decorative finish.

conclusions

The presence of warm slopes for plastic windows is a must. And already, which option to choose the insulation of the slopes of the windows from the outside or from the inside depends on:

- Households - private or multi-apartment;

- The experience of the owner himself;

- Financial opportunities.

In this article, the theoretical aspects of window insulation were highlighted. Also, practical points were noticed: for example, do you remember how to properly seal the joint between the profile and the wall and why exactly? This has been described above.

Be sure to leave any remaining questions in the comments.

Outdoor work

For more reliable protection of the premises from heat loss, it is necessary to insulate the window slopes from the outside. The best material for these purposes is penoplex. You will also need a special outdoor sealant.In a private house, work can be done by hand, and in a multi-storey house it is better to use the services of professionals.

The technological sequence of operations is as follows:

- Clean the surfaces of external slopes from dust, dirt, paint residues, finishing and building materials.

- Smooth out with cement mortar, let the layer dry.

- Cut the insulation into pieces of the required size.

- Coat the sheets with glue and install on the slopes. Additionally secure in several places with dowels.

- Mount the corners. This step should not be neglected. As a result, you will get not only warmed, but also smooth slopes.

- Treat the front surface of the foam with special glue and fix the reinforcing mesh.

- Level with putty.

- After drying, apply water based paint or other finishing materials.

Do not ignore the issue of slope insulation. The microclimate in the house and the size of electricity bills depend on how well and in a timely manner this will be done. Moreover, the whole process can be done independently.