Advantages, disadvantages

Benefits:

- Corner connections are good at masking.

- Cover minor surface irregularities.

- Lifetime.

- Installation does not require knowledge, it is enough to cut the corners correctly.

- Large palette.

- Compared to aluminum, plastic is cheaper.

Disadvantages:

- Due to the fragility of PVC, it is likely that the elements will be accidentally damaged during trimming. Sometimes the scrap has to be thrown away.

- In the event of a fire, harmful substances are released. The decoration of the evacuation sites is not recommended by the fire services.

Views

The decorative corner is divided into types, depending on the material:

- Metal. Purpose - to strengthen the corner structure. Can be found on plasterboard structures.

Metal

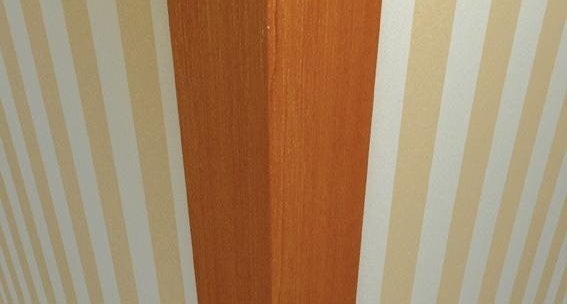

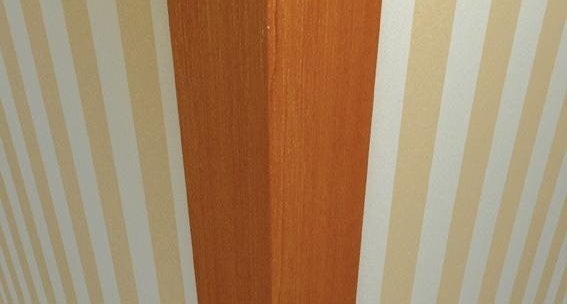

- Wood. It is often used on installed wooden windows to create a unified look. A selection of a wooden element under the pasted wallpaper is possible.

Wood

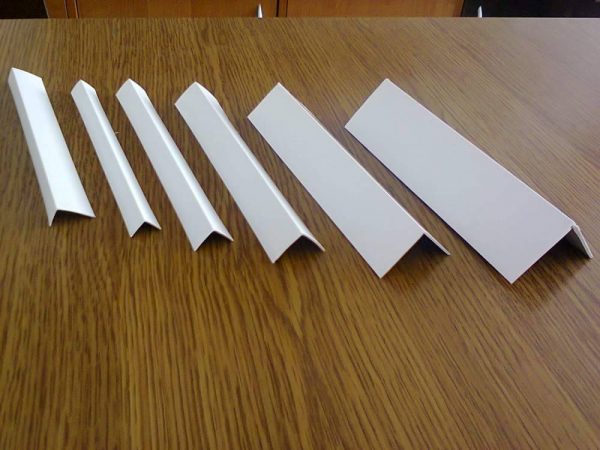

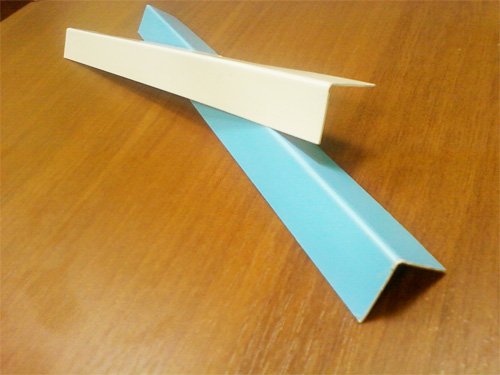

- Plastic. The most common type. Advantage - you can choose the color of the fittings in accordance with the interior. The laminated surface imitates other materials.

Plastic

How to choose a decorative corner for slopes

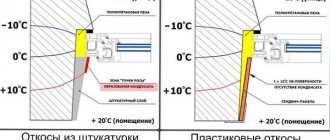

Neatly executed finishing of window and door slopes, outlined by straight lines of the opening, will decorate any room, regardless of the design style. However, for this, it is necessary to correctly select the decorative corners necessary for framing the sheathing of the inner surfaces of the window openings. As such, any corner profile is suitable: plastic, aluminum or brass (with the exception of the perforated version). The most accessible, due to their low cost, are polymer corners, however, special beauty cannot be achieved with their help.

Smooth aluminum profiles with a glossy or matt surface look more aesthetically pleasing, but not suitable for every interior. In particular, they do not go well with all classical styles (baroque, rococo, empire), as well as with country-style design. Corners made of aluminum will fit better into a room where minimalism, modernism, hi-tech or, in extreme cases, a gothic interior reign. Techno aficionados will also find a special charm in the finishing of window and door openings with aluminum.

And without any doubt, an expensive brass decorative corner for slopes will fit into any situation. In an alloy of copper with zinc, lead, nickel, aluminum and other additives, on which the type of profile coating depends, may also be present. It can be blackening, silvering, gilding or patina. Almost any corner option from the listed ones will be appropriate in a classic or modern interior style for decorating window and doorways. Patination, that is, artificial aging of the profile surface, looks especially beautiful. Uncoated brass corners are available in a natural pure yellow or grayish tint.

Where is used

Plastic corners are used when performing various jobs. Performs a decorative, practical function.

- Execution in color tones - decoration of windows, doors.

- With plasterboard structures, it is more logical to use metal elements. Constructions require mandatory treatment with plaster mixtures. Metal fittings will additionally strengthen the structure.

- Wooden and plastic elements are attached to the walls covered with wallpaper.

- Corner joints are internal, external.

Classification

There are many PVC fittings on the building materials market.

- The most common ones are with sides equal in width 2x2, 5x5cm.

- Material with asymmetrical sides, is often used to refine arched openings. The common size is 10x20mm.

- T, F-shaped. They are used to mask the joining elements of the slopes of the opening and the wall.

- Snap-on elements. Installation is more convenient, several times faster.

Dimensions (edit)

They differ in length (2m 60cm - 3m), width (1cm - 10cm).

Dimensions (edit)

Application:

- When installing an arched opening, strips with asymmetrical sides (5x17, 10x20, 15x25 mm) will help.

- If you need to join two surfaces, mask the seam, a T-shaped element (12x10, 18x10, 20x10 and 22x10mm) will do.

- To strengthen the slope, you will need wide products (20x20, 50x50mm).

- For a window opening - slats 10x10, 15x15mm.

Features of the

Due to the qualities, the material has become popular and is in great demand:

- Used as a concealer. After finishing the slope, it forms a right angle.

- With proper use, it will last a long time. The operational period is tens of years.

- Anyone can handle the installation of an element, even without experience.

- High moisture resistance.

- Does not rot and mold. Installation in rooms with high humidity is possible.

- Helps create even corners on plastered surfaces.

- Metal fittings strengthen the structure.

- Products made of wood, plastic, metal, do not harm health, do not emit aggressive substances into the atmosphere.

- Due to the small mass, the construction of window, doorways will not be loaded.

- Resistance to mechanical damage. When exposed to sharp objects, minor scratches remain, which can be removed by sanding the surface.

- Not prone to collapse, change color from exposure to direct sunlight.

The material has a share of rigidity, but it can break from significant mechanical stress. It is not recommended to install plastic corners from the street side, as fragility increases.

Do not place objects made of plastic near flammable materials, heating equipment. When burning, plastic releases toxic substances.

What is a plastic corner for slopes

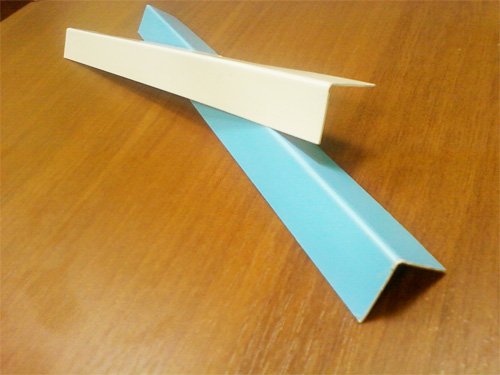

The inner surfaces of window openings today are very often finished with plastic, since this is the most affordable and cheapest material, even in comparison with drywall. However, the ends of plastic strips with partitions look unpresentable, and in order to decorate the finish, experts use plastic corners for window slopes. In fact, these are profiles that are included in the set of cladding panels and have an L and F-shape in cross-section. They are made by hot bending a rigid sheet of polyvinyl chloride.

The profile shelves have different sizes, the angle between them, as a rule, is 90 degrees. As for the dimensions, with a length of 2 meters, the width of the shelves is 10 × 10, 15 × 15, 20 × 20, 25 × 25, 30 × 30, as well as 35 × 35 and 40 × 40 millimeters. Less common corners with asymmetrical shelves, such as 25 × 10. It is not out of place to recall the profile for finishing arched openings. It is a flexible corner with a single standard for the width of the shelves, converging at an angle of 90 degrees, the length of which can be 2.5-3 meters.

The L-shaped profile is usually used to complete the surface cladding with plastic strips, installed on the inner corner with a butt joint. The F-shaped corner is mounted on the ends of the PVC panels, masking their uneven cuts with clearly distinguishable stiffeners, for this very purpose the profile has an additional jumper

... Often, the plastic slope corner has a shallow flow groove along the fold line, due to which the angle between the shelves can be changed without the risk of kinking.

Adhesive selection

Before installation, you must select the glue. Polyurethane will do.

A common tip is to stick the plastic corner onto the silicone sealant. Over time, the sealant turns yellow, becomes covered with a dark coating, requires replacement of the adhesive.

The composition "liquid nails" has proven itself quite well. Versatile, suitable for various surfaces. Crazy glue is often used. The composition adheres very well.

The choice of an adhesive base depends on the parameters of the surfaces to be glued.

Installation of plastic corners on slopes

In the case of a standard installation, the glue mass is applied to the inner surface of the product. An exception is latched elements. Installation is simple, the disadvantage is that dismantling is impossible.

Installation of corners is carried out after completion of finishing work.

Preparatory activities

Preparatory work:

- In the case of installing the hardware on an untreated surface, carry out a preliminary check for protrusions, potholes, protruding nails. For maximum adhesion, a flat surface must be achieved.

- When working with some surfaces, before installation, it is necessary to degrease, wipe the corner from dirt.

- Measure the window opening. When measuring, take into account small gaps so that gaps do not form when cutting the connection. The recommended overlap length is 1 - 5 mm.

- When cutting off parts, you do not need to cut corners right away, it is better to do it in place.

Docking options:

- By overlapping each other. The resulting drop is sealed with a sealant to match the color of the material.

- Undercutting the corner joint. Looks prettier, requires skill.

The plastic is cut with a clerical knife. A blunt instrument may damage the product.

Installation

After careful preparation of surfaces and materials, you can proceed to installation work.

- Installation can be started from either side.

- We take the corner, turning it over to the wrong side, apply glue. The method of applying the glue (dotted, dotted, solid line) is not important. If you need to save glue mixture, spot application will help.

It is necessary to apply glue closer to the corner part, for a stronger fixation of the element.

- The workpiece is placed on the surface and pressed. Any excess adhesive protruding must be removed immediately. Different cleaning agents are used depending on the adhesive composition. The most common, suitable for almost all mixtures, is white spirit.

- Additional fixation with masking tape is required. The measure is temporary, after the glue has hardened, it must be removed.

Sticking scotch tape

- Installation is in progress along the perimeter of the opening.

- After a day, the masking tape is removed.

Installation of plastic corners is simple, but skill is required when trimming. The main thing is the manifestation of accuracy, adherence to accuracy in calculations, pruning.

Where are aluminum slope corners used?

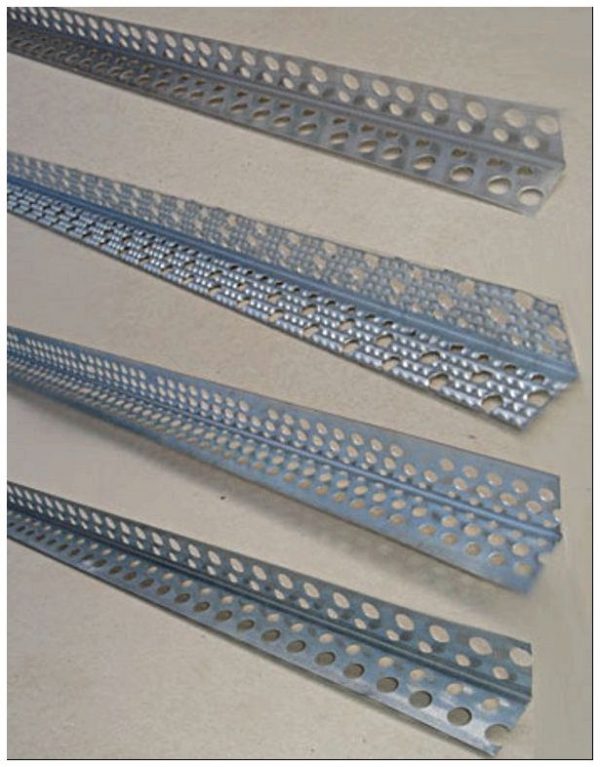

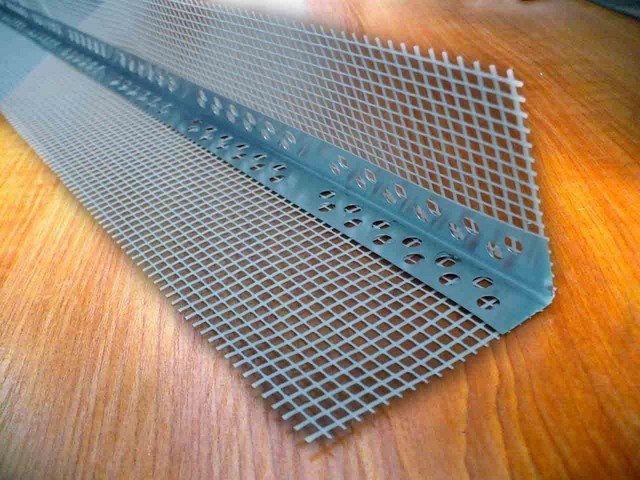

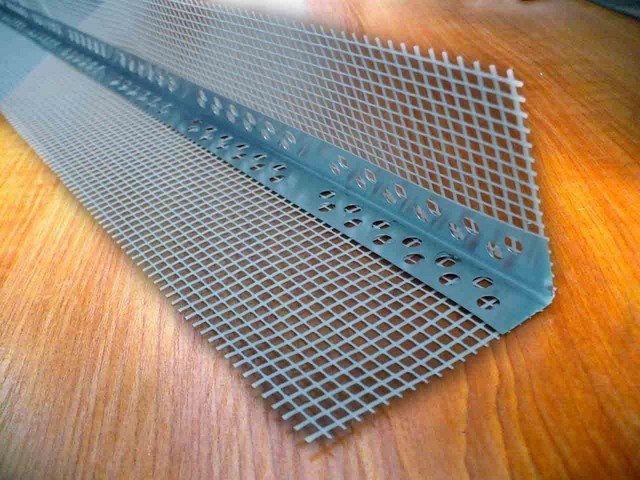

Very often, overlays of increased rigidity are required at the inner and outer corners. For this purpose, aluminum profiles are used, which are a narrow long corner, within 2.5-3 meters, with a shelf width of 2.5 centimeters. There are two types of this profile: decorative and perforated, the first has a smooth surface of the shelves, the second - perforation along the entire length. Holes with a diameter of 2.5 millimeters are drilled, as a rule, in a checkerboard pattern, they are necessary to firmly fix the corner in a layer of putty or plaster when forming the corners of the walls.

Aluminum corners are used as an overlay on furniture, for leveling the edges of tiled masonry, and, of course, for finishing the slopes of windows and doors. Such a decorative profile can be used for various needs; lightweight structures are assembled from it, in particular for false ceilings.Especially convenient is an aluminum corner with a reinforcing fiberglass mesh fixed on one of the shelves, which can significantly strengthen the layer of glue or plaster. However, only perforated corner elements are supplied with such an addition, while decorative ones are simply set on glue or silicone.

Aluminum profiles have straight or rounded corners, and are also supplied with paint, powder polymer or anodic oxide coatings for increased wear resistance.