Do-it-yourself installation of flashing

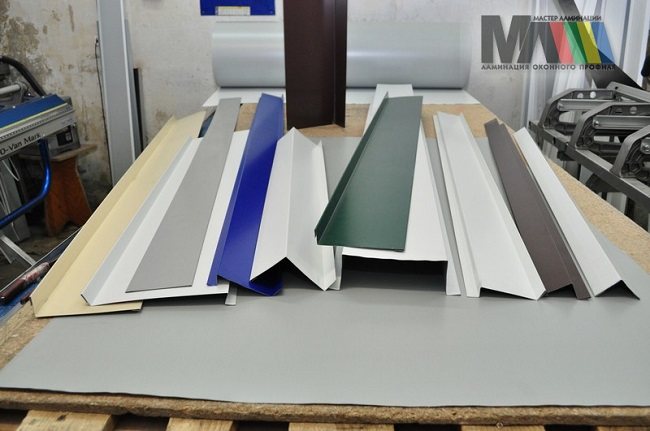

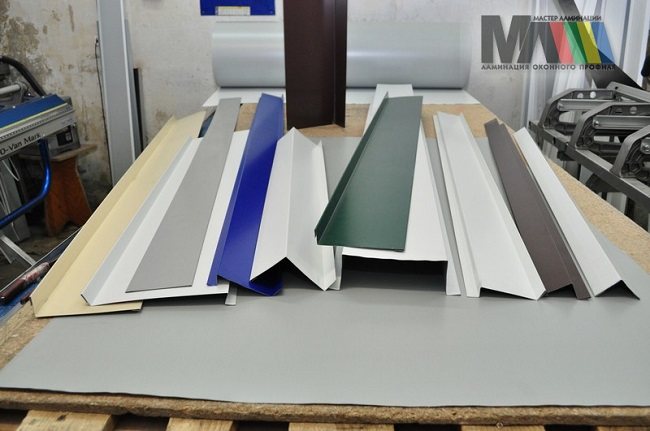

Plastic soft

Setting the soft look is possible with different initial data. They can be installed on wood, aluminum and plastic structures.

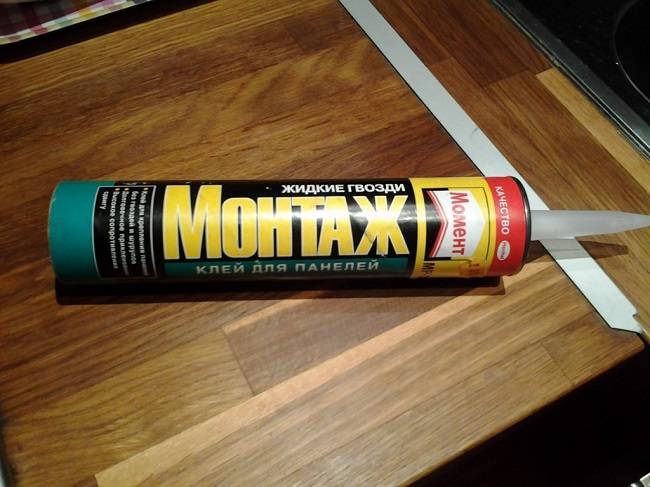

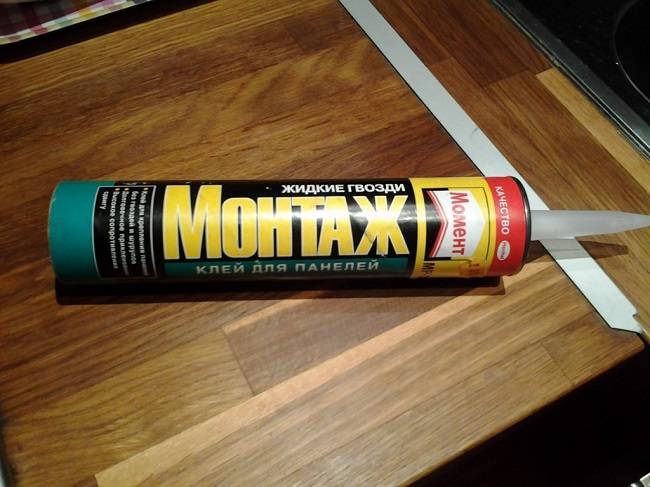

Initially, familiarize yourself with the features of the product - whether or not there is a sticky base. There is no reason - it is necessary to use liquid nails, or a sticky base (liquid nails are preferable). To start fastening, you need to measure the required length and cut off the correct gap.

- if there is a sticky base It is necessary to peel off, sticking in parallel to the base. Do not peel off the entire protective layer first!

- if there is no sticky base. We must arm ourselves with liquid nails. Apply nails along the length of the tape and let them dry.

Next, we attach the tape and press it carefully.

This precaution is necessary. Use of adhesive tape or glue means no dust

Wind and precipitation can contribute to its appearance. As for the temperature, there is a possibility of solidification of the product, leading to the impossibility of correct installation.

Plastic solid

Some models may have a sticky base. The difference is the need to completely remove the sticky layer before fastening. If there is no layer, liquid nails can serve as a practical fastener.

Metal The metal version is the most structurally reliable. Its attachment can take place in any weather. Fasteners are possible with self-tapping screws. In order to avoid the absence of damage to the aesthetic component, it is necessary to carry out the fastening procedure, using each edge of the new product - in other words, with an overlap.

Sealant is selected moisture-proof

When choosing, study the composition and precautions. The selection of sealant is matched with the climatic features of the region

Wooden: Fixing wooden models is the most difficult - it requires extra attention to the quality of the connection. In order for each part to flow smoothly into each other, preparation is necessary - filing and adjusting the edges. Fastening can be done with liquid nails and self-tapping screws. Self-tapping screws leave an imprint on the visual component, liquid nails are less strong. Both methods have disadvantages. The quality of liquid nails depends on the manufacturer.

Reasons for the appearance

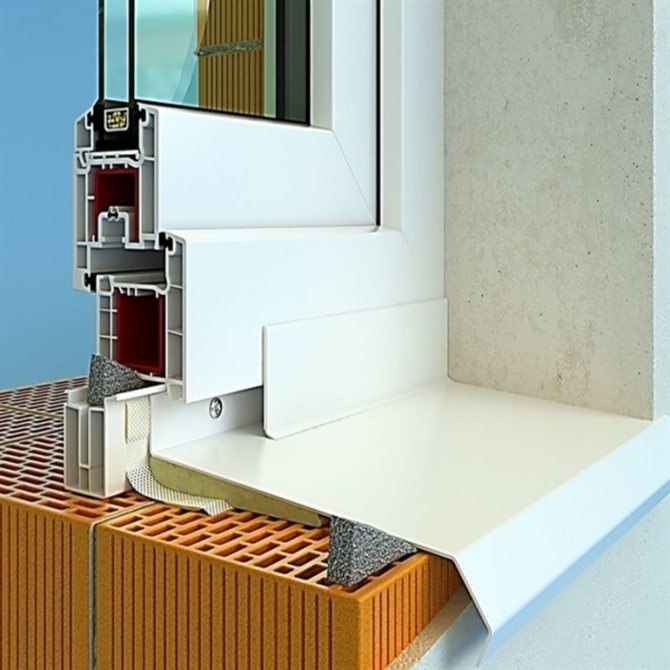

In order to understand the true reason why cover strips have become an integral part of fixing, it is important to know the installation process of the frame itself. The frame is attached first - it is the support

The action takes place within the selected wall leading to the street. The system implies certain dimensions, which are determined by measuring before the start of its manufacture.

To understand the required dimensions, you need to measure the opening and establish the possibility of crevices. From the point of view of installation, they will be necessary so that the installation proceeds without unnecessary tweaks in the direction of the angles of the support. The presence of additional space minimizes the possibility of damage to the structure during installation.

When the structure is fixed, there is a need for additional fixation and elimination of sources that contribute to a decrease in the properties of thermal insulation. For the next stage, polyurethane foam is used. It is applied around the perimeter, thereby assisting in filling unused voids. Thus, polyurethane foam:

- eliminates the formed cracks;

- strengthens the structure;

- does not affect the design features of the installation, which makes it an auxiliary element that has no analogues in the modern construction market.

The resulting fastening caused by the use of polyurethane foam is, from an aesthetic point of view, not the most successful compositional elements. Of course, excess foam can be easily cleaned up, but the installation requires additional materials to help create completeness.

There is another reason that exposes the foam seam to concealment - polyurethane foam, under the influence of certain conditions, can structurally change, thereby damaging the installation properties.

Factors due to which polyurethane foam is influenced include:

- excessive exposure to sunlight;

- mechanical damage, in the form of wind and precipitation;

- sudden changes in temperature.

There are two reasons why polyurethane foam should be hidden:

Since each window has a specific design, the need was created for the creation of an element that could not violate the appearance (and, preferably, improve it), as well as be of some benefit. An element that embodies all of the above properties is the cover strip.

Output

Cover strips for plastic windows are not such an expensive pleasure, if we take the cost of the most budgetary options at 30-100 rubles per square meter. At the same time, they are an excellent protection of window joints from moisture and ultraviolet radiation, while at the same time giving them aesthetics. You just need to choose the right part and install it in accordance with all technical requirements.

Installation of plastic window systems includes not only the direct installation of the frame, double-glazed windows. This process necessarily requires the design of the space adjacent to the window. Cover strips are used as one of the decorative elements. Despite the fact that their installation is not a prerequisite for the installation of metal-plastic structures, it is these components that give the window a complete and aesthetically pleasing appearance. You can easily attach these elements on your own; this does not require special skills or special construction tools.

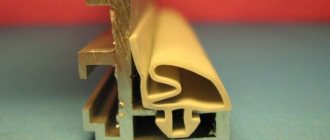

Cover strips with self-adhesive tape

Adhesive strips are available exclusively in PVC. This is due to the fact that the corresponding material is the lightest and it is well fixed even with adhesive tape, which is made from foamed tape. For protection, the adhesive tape is covered with a special film. It can be easily removed during installation. After that, it remains only to firmly press the bar to the required surface. The product fits snugly and lasts a long time on a plastic base, but if you adhere to certain conditions.

The most important requirement for an installation is temperature. If the ambient temperature has dropped below the + 5 ° C mark, then it is better to postpone this process, since the foam tape in such cases loses its quality

That is, it will be possible to glue the bar, but it will not last long. There is a possibility that it will disappear after a few days. Thus, you will not only add yourself extra work and lose money. For example, if you bought flexible PVC strip strips, you will not be able to reattach them. You will need to buy new material.

In the event that postponing the installation for some reason does not work, then you can resort to a radical method. Take a hair dryer and heat the surface thoroughly. Only then proceed with the installation. It is also additionally recommended to coat the joints and corners with liquid nails, which also have a good fixing property.You can also use self-tapping screws, but in this case, it is better to immediately buy flashing strips without glue.

The only advantage of self-adhesive strips is their low weight and quick installation. Otherwise, they are simply impractical, since they cannot be reused. Various small particles adhere to the foam tape and the surface loses its adhesive qualities. At the same time, the adhesive tape can be removed, and then a clean strip can be installed on liquid nails or self-tapping screws.

Fastening pretend strips

When a plastic window is placed, a gap is formed around the perimeter of the profile at the point where it joins the wall. The opening is closed with polyurethane foam - a material unstable to weather manifestations, which should be carefully closed. A good layer of plaster or sealant of a vapor-permeable type with further surface painting solves the problem. But the most technologically justified and reliable method, as practice shows, is the installation of special pretend strips.

It is possible to qualitatively install the cover strip without the help of professionals, if you follow the following recommendations:

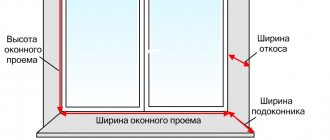

- inspect the window, slopes, measure the length of the openings and their width to determine the required footage to close all the seams;

- purchase material with the necessary quality and dimensional characteristics, make patterns of a suitable size;

- gradually opening the protective layer, press down the strip along the length with ironing movements;

- when installing the strip without a sticky base, apply the adhesive mixture with a brush and immediately press the strip to the surface.

Related article: Do-it-yourself repair of plastic windows of the swing mechanism

Proper installation requires compliance with certain conditions. All actions must be performed at a temperature of at least -15. The surface for finishing is pre-protected and degreased.

It is not recommended to install the strip outside the window profile by yourself. The safest and best solution would be to consult a specialist, especially when finishing should be done on the windows of the upper floors. The masters of the OKNA ROSTA company will carry out the installation of the strips quickly, efficiently, accurately and will provide a guarantee for their work.

Purpose of window strips

What is a window strip? These objects are necessary for the exterior decoration of the window system. When using them, you lose the need to spend on the purchase of putty, covering the joints with it.

A feigned strip (this is another name for the strip) greatly simplifies the procedure for finishing the space between the frame and the wall. This joint can be protected from damage caused by sunlight, wind and moisture. In addition, in this way it is easy to increase the thermal insulation performance, to give the window opening an attractive look.

Important! It is also allowed to use planks indoors, they differ in a variety of color materials, textures, materials, which allows you to accurately select these elements for the overall design style of the room. Experts advise not to neglect the installation of these structures, many years of experience constantly confirm the great importance of such elements

They are easy to install, both inside and outside the room, ennobling the appearance of the opening. Cover strips easily protect the room from the effects of ultraviolet radiation, atmospheric precipitation, wind, humidity and the fungus that develops due to it

Experts advise not to neglect the installation of these structures; many years of experience constantly confirm the great importance of such elements. They are easy to install, both inside and outside the room, ennobling the appearance of the opening.Cover strips easily protect the room from the effects of ultraviolet radiation, precipitation, wind, humidity and the fungus that develops because of it.

The false plank, not being an obligatory integral structure of the window block, nevertheless, gives the window or balcony a truly respectable look. The rail is indispensable for framing slots at the end, places where profile structural elements are connected.

The installation procedure for the rail does not cause any difficulties, it can be mounted in different ways:

- liquid nails;

- ordinary screws;

- self-tapping screws.

Advantages and disadvantages

In the modern world, the use of cover strips is no less important than the installation of slopes and window sills. The main advantage is the versatility of the products, because they can be used both indoors and outdoors. These properties make it possible to give the building an aesthetic exterior and interior. In addition, false planks have a number of other advantages:

- protect from the wind;

- have a long operational period;

- are easy to install and dismantle;

- have decorative properties;

- hide irregularities at the junction of surfaces;

- resistant to ultraviolet rays, temperature fluctuations and precipitation;

- there is a wide range of slats in color, size and shape;

- trims are affordable.

Such products have practically no drawbacks; with proper installation, they can serve for many years. User reviews indicate that flexible plastic slats are inconvenient to fasten, because they roll up into a roll. This problem can be solved by using two people during the installation process. In addition, plastic strips are allowed to be installed only at positive temperatures. Self-adhesive strips are a disposable option, they cannot be reused, however, there are no such problems with metal or wood structures.

How to choose the right window strip

Window strips, provided that they are selected correctly, will ideally frame the window space, keep the seams protected, and increase the level of thermal insulation.

When choosing slats, metal or PVC for windows, you should take into account the preferred installation method, as well as the shade that the window frame has

Important! Before purchasing the material, you should carry out the necessary calculations and measurements, clarify exactly how many components will be needed to frame it

Important! Before purchasing the material, you should carry out the necessary calculations and measurements, clarify exactly how many components will be needed to frame it. Experts recommend purchasing planks at specialized points of sale, only certified products will be presented there.

Having bought such a material, you do not have to worry that it will not last long or will have poor properties. In addition, cheap material will be difficult to attach neatly

Experts recommend purchasing planks at specialized points of sale, where only certified products will be presented. Having bought such a material, you do not have to worry about the fact that it will not last long or will have poor properties. In addition, cheap material will be difficult to attach neatly.

Therefore, before buying, it is worth examining the offers and choosing a certified product.

When choosing strips, it should be borne in mind that wooden or metal strips are not suitable for double-glazed windows framed by a plastic frame. In addition, PVC strips do not look very advantageous on wooden windows.

Cover strips for plastic windows: a highlight to the design, frugality to heat

The final chord of the installation of a plastic window is such a decorated object as a strip, presented in the professional construction market in various types and forms of execution.It is not difficult to install a modern strip for plastic windows on your own, or, as it is also called, a pretend strip: it is enough to enlist useful advice from specialists when buying a piece of decor that is relevant to you. It is worth considering when this choice is: the type of the strip, the manufacturer and the installation features.

Positive qualities of plastic platbands

- Availability and low cost. Polymer materials used to make plastic casing are much cheaper than metal or wood. Modern processing technologies significantly reduce the cost of the process. For example, the final cost of products made by extrusion will be noticeably less than that of milled wood decor.

- Features of plastic. The strength characteristics of PVC or polyurethane (the most common materials for manufacturing) are with a margin sufficient for the loads to which the platbands are subjected. The service life, as a rule, is at least 50 years, while the functionality and appearance are almost completely preserved.

- Appearance. Plastic is made mainly of white or dark brown color, but there is a possibility of polymer pigmentation in other tones. It is possible to cover the profile with a textured film imitating valuable wood species, metal or stone. This allows you to make the framing of the block in harmony with any stylistic solutions of the interior or facade of the building.

- Easy to care for. PVC platbands are easy to clean, do not require periodic painting or any specific maintenance, such as wooden products.

- Resistant to weathering. The platband, made of polymer, is not subject to deformation when used in high humidity conditions or with regular temperature changes.

- Low weight. Even products made from a monolithic profile are lighter than wooden or metal counterparts. This facilitates installation and reduces the load on the supporting elements.

- Possibility of hidden laying of communications. Some platband modifications consist of a bottom profile and a front cover. The void between the two can be used to accommodate wiring.

There are no significant disadvantages. Basically, people refuse to use plastic because of a bias towards this material or its too low price, inappropriate to the status of the building.

Criterias of choice

For an ideal combination of a strip with a window, you should observe a number of points when choosing and buying. In this case, it is possible not only to provide an elegant appearance of the window group, but also to effectively protect the seams from the effects of ultraviolet radiation and dampness.

As practice shows, the most high-quality cover strips, like other additional components, are produced by well-known companies that manufacture profiles for plastic windows. These brands include:

It is recommended to purchase false strips in specialized stores that sell accessories for plastic windows. Or directly from the official representatives of the window profile manufacturers. The cost of the cover plates depends on the material of manufacture and the manufacturer. Flexible plastic self-adhesive elements will cost an average of 20-50 rubles per running meter. Rigid PVC strips will cost from 50 to 300 rubles per meter. The price for wood and metal, depending on the width, decorative finish and type of wood / type of metal, ranges from 100 to 1000 or more rubles per running meter.

Cladding materials

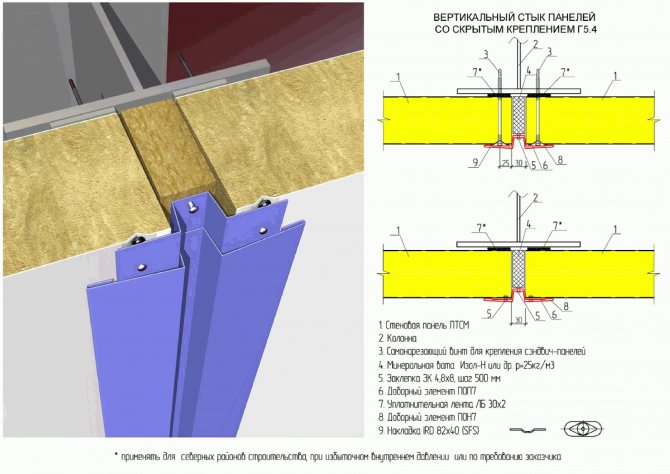

A sandwich panel is a three-layer facing material that consists of two rigid galvanized sheets filled with insulation.

The filler for a sandwich panel can be:

- mineral wool;

- polyurethane foam;

- Styrofoam;

- basalt insulation;

- expanded polystyrene.

Rigid parts are made of galvanized iron, aluminum. And covered with specialized paint. This provides protection and aesthetics to the panels.

Installation of flashing strips on a sandwich panel occurs immediately after installation. For the installation of any sandwich panels, you need:

- self-tapping screws of the required length (it will depend on the type of panels);

- polyurethane foam;

- sealant;

- cover plates.

Installation of such panels is not difficult, even for a non-professional builder. The installation procedure is as follows:

- Walls are being prepared (if necessary).

- The panels are being installed (from the corner).

- The panels are fixed with self-tapping screws.

- The joints between the panels are filled with foam.

- Cover strips are installed.

- All joints are sealed.

Installing flats is a very important part of the job. With proper installation, the panels will last a long time. First, let's find out what a sandwich panel strip is.

Advantages of metal strips

Metal strips, which are the best option for installation in brick or panel houses, are very popular due to their durability and reliability, as well as simplicity and ease of installation. There are several design features of the strips:

- Elements can be made from various types of metal, but the most commonly used are aluminum and galvanized steel.

- Metal strips can have flexible edges or a special polymer coating.

Installation of metal strips is straightforward. They are fixed to the surface using self-tapping screws with press washers, which provide a more reliable fixation of the structure.

If the strip is equipped with a flexible edge, it provides an additional advantage during installation, making it easy to hide any irregularities and imperfections that may be present on the slopes. A strip with flexible edges can be positioned in such a way as to maximally protect the window structure from the penetration of drafts and cold air from the outside.

Window strips made of galvanized steel are usually installed in hangars, garages and other non-residential, warehouse or industrial premises. To give a more attractive design to the products, they can be coated with a layer of polyester. The thickness of the steel strip is in the range of 0.5-1.3 mm.

The thickness of the aluminum strips is about 1-2 mm. A distinctive advantage of aluminum products is the ability to paint them in any color using special powder paints.Such a strip will retain an attractive appearance for a long time, without being exposed to corrosion and not deforming under the influence of changes in high or low temperatures.

How to clean the window from traces of fastening strips after dismantling them

If it is necessary to remove the glued parts for repair or replacement, it may be difficult to clean the slopes and frame from traces of adhesive. There are several proven ways to do this.

You can use a regular school eraser, but this is a rather long and laborious process. In addition, this option is suitable for removing traces of glue from a smooth surface of a small area.

Vegetable oil is the most readily available remedy for removing strip marks.

They can clean large areas. Vegetable oils react with adhesives containing acrylic. Such substances are most often used in the manufacture of self-adhesive strips for parts. After processing with vegetable oil, after a few hours, the glue loses its properties and is easily erased with a damp cloth.

Important:

The option with oil is not recommended for use when it is necessary to install planks on treated surfaces. You will have to either thoroughly wash off the residual oils, or fix the strips in other ways, for example, by means of self-tapping screws.

If the windows are made of high quality PVC, you can use white spirit or another available solvent,

having previously tried to apply it in some inconspicuous place, check its effect on plastic. As long as the frame material is not damaged, traces of adhesive can be effectively removed with this solvent.

Features and distinctive advantages of PVC strip strips

One of the main criteria, on the basis of which the masters select the strips, is the material for making the products. The most popular material for the production of flat strips is considered by many to be PVC profile, which is characterized by a large list of operational advantages:

- Long service life without loss of performance and attractive appearance;

- Resistance to high humidity and low temperatures, as well as mechanical damage;

- Retention of shape and color under the influence of direct sunlight and high temperatures.

PVC strip strips are produced in the form of convenient rolls, which greatly facilitates the process of material transportation. Thanks to well-thought-out packaging, when installing the strips, a minimum amount of waste is left, constituting no more than 1% of the material from each roll.

Some PVC strips are offered by the manufacturer with a self-adhesive layer, the presence of which greatly facilitates and speeds up the installation process. But there is also a small drawback - it is possible to install self-adhesive strips only in warm weather. If the air temperature is less than five degrees, the material will have to be preheated to securely fix the strip on the window.

What to look for when choosing

It is important to choose the right cover strips to preserve the ideal appearance of the window, protect the window seams and ensure maximum thermal insulation. First of all, it is necessary to take into account the features of the installed windows. The color of the part must match the window frame.

Before buying planks, you need to calculate the required footage so as not to purchase too much. To do this, measure the window block around the perimeter and make a small margin. The width is determined based on the dimensions of the gap between the window and the wall.

Advice:

Purchase parts from reputable manufacturers. Qualified consultants will tell you in detail about the most suitable options and help you choose the best one.

You shouldn't skimp on buying parts.Often, their cost is directly proportional to the quality, and therefore the length of the period of use. If required, the gaps can be made to order according to the individual wishes of the customer.

Various coverage

The order of prices for coverings, depending on the coverage you choose. Comparative calculation for a 100 x 100 element with a length of 2000 mm.

Most affordable for functionality

This flashing

Has its main function:

- Protection against external influences

- Simple yet functional element

- Sufficient anti-corrosion properties

Polyester

Most popular for decor

This flashing

Decor and protection of your building:

- In color according to the RAL catalog

- Galvanized with multiple layers of primer

- Service life from 10 years

- Easy care

- Fitting to the exterior of the building

This flashing

Protection, decor and durability:

- Premium material

- Scratch resistant

- Service life from 15 years

- Unusual texture

- Choice of colors according to RAL and RR

- Multilayer protective coating

What are window strips

On the construction market, you can find cover strips of various materials of manufacture. The most "popular" are metal, wood and plastic products. Each type of plank is divided into subspecies and for the choice you need to know the features of each of them.

Metal strips

This type of false strips is mainly made of galvanized steel, as well as aluminum. Products can be with a flexible edge and coated with polymer paint. Metal strips have an attractive appearance, they are durable and strong.

Galvanized steel slats are used in the construction of garages, hangars and other structures. For a more attractive appearance, the surface of the strip can be coated with a polyester layer of the desired color. The thickness of the galvanized metal strips ranges from 0.5 mm to 1.3 mm.

Metal strip for plastic windows

Aluminum strips, in contrast to galvanized ones, have a number of advantages. The planks are resistant to corrosion and weather factors, do not deform as a result of temperature jumps, their surface can be coated with powder paints. Cover strips are made of aluminum sheets with a thickness of 1-2 mm.

Installation is carried out using a self-tapping screw with a special press washer. Products with a flexible edge can close any irregularities and protect the window from drafts. It is recommended to use metal strips on panel or brick houses.

Cover strips for windows made of wood

Wooden planks are divided into flat, semicircular, curly, corner or book-shaped. Also available in varnished, painted and laminated. Most often, conifers, such as pine, are used in the manufacture of planks. Wood trims are in demand when installing similar windows in country houses from a bar and for interior decoration "under a tree". The advantages of natural slats are their environmental friendliness, strength and attractiveness. The only drawback is the considerable cost compared to metal or PVC products. Wooden planks with a thickness of 1.5-3 mm are produced, attached to self-tapping screws or liquid nails.

PVC plastic strip for windows

Plastic strips are the most popular. Available in flexible and rigid, laminated or white. Flexible strip for plastic windows is produced in rolls of 30-50 m, has a minimum waste level and is easy to use. Most often, manufacturers apply self-adhesive tape to the inside of the product, so even a non-professional can install such a strip. If there is none, then the rail is attached to liquid nails or self-tapping screws. Flexible strips are 20-70 mm wide. Install such strips both inside and outside, the only caveat is that self-adhesive products must be mounted at a temperature of at least 5 degrees.

Rigid PVC strips are produced in separate strips 3-6 m long and 20-100 mm wide. Products can be flexible or solid edge, laminated or white. Like flexible slats, rigid ones are mounted using liquid nails, self-tapping screws, or attached to an adhesive base.

Plastic strips for plastic windows

Cover strips for plastic windows attract with their accessibility, convenient transportation, resistance to temperature changes and natural factors, as well as a smooth and even surface. The disadvantages of such products are that installation is possible only in the warm season. If something went wrong, then you cannot reuse the bar, because the adhesive layer is broken.

Types and material of manufacture

However, it is possible to mount the strips not only on the external joints, but also on the internal ones. For these purposes, various decorative options for these additional elements are made, which allows them to organically fit them into the interior of the room.

Ceiling strips can be made from various materials:

- Wood.

- Plastic.

- Metal.

For the production of metal strips, most often aluminum alloys, galvanized sheet steel, sheet metal with an outer polymer coating are used. Their thickness varies from 0.5 to 2 mm. Such modifications are durable in operation, they are not afraid of external aggressive influences - dampness, temperature extremes, solar ultraviolet radiation. They are produced in various colors, which allows them to be successfully combined with the colors of the walls and window frames.

Wooden strips are made in the form of flat strips, corner or triangular in cross-section. Thickness - up to 3 mm. Outside, they can be painted in various colors, varnished, or laminated with polymer compounds. Wooden false strips are used both outside the window and inside. Most often, pine wood is used for their manufacture, as a more accessible and inexpensive material.

However, on sale you can also find more exotic options intended more often for interior decoration - from wenge, mahogany, or from the more familiar to us beech, birch, oak. They fit well into the wood-like interior decoration. At the same time, along with high aesthetic properties and environmental friendliness, they have a number of significant disadvantages:

- They are afraid of dampness.

- Under the influence of temperature changes, they can crack.

Methods for mounting flashing strips

Many companies involved in the production and installation of plastic windows provide. It includes the whole range of related work, including the installation of slopes, window sills and cover strips. If you decide to save money, then you can easily make a cosmetic decoration of the windows yourself. Installing feigned planks is not difficult, so you can mount it yourself, without the involvement of specialists.

All cover strips are available in two versions of fasteners - with a self-adhesive compound already applied to them, or without it. In the first case, they are simply freed from the protective film applied to the glue base and glued to the window block. In the second case, either liquid nails or self-tapping screws are used for fasteners. In addition, the features of the installation process depend on the material of manufacture, design and other nuances.

Preparation for work

Before starting work, you should prepare the necessary tools:

- Roulette.

- Pencil or marker.

- Miter box for trimming joints.

- Tools for cutting. It is selected depending on the material for making the trims - jigsaw, grinder, metal saw, construction knife, etc.

- Fastening tools and consumables: a gun for applying liquid nails and mounting glue, or a screwdriver and self-tapping screws.

Next, we clean the frame from all types of dirt - we wash it off of dust and dirt, remove the remains of polyurethane foam.After that, you can start installing the pretend strips.

Installation of plastic cover strips

Recessed strips made of polymer materials are usually attached with glue. It can be a self-adhesive strip applied to the additional element at the factory, during its production. Before proceeding with gluing, the required length of the strip is measured. Its joints are sawn off with a miter box at an angle of 45o. Flat plastic strips can, in principle, be joined at right angles, but the version with a 45-degree joint looks more aesthetically pleasing.

Next, remove the protective film applied to the adhesive base from the inner surface of the strip.

If we are dealing with a flexible strip, then the protection must be removed gradually, immediately gluing the surface freed from it to the window block.

When gluing a rigid strip, the entire protective film is removed at once, after which the strip is installed on the frame.

When working with plastic strips, on which there is no self-adhesive layer, installation is carried out on liquid nails.

Using a pistol, the glue is applied in a thin strip to the inner surface of the strip along its entire length. After that, the plank is firmly pressed against the window, and the excess glue that has come out is immediately removed with a dry cloth. Due to the nature of the material, the installation of plastic strips is recommended only at positive temperatures, preferably above + 5 ° C.

Installation of metal strips

Metal strips are produced without a pre-applied adhesive base. Their installation is most often carried out using self-tapping screws. The step between them, for better fixing of the plank, should not be more than 30 cm.

Less commonly, metal strips are glued to the window frame with assembly glue. With glue, in order to avoid freezing, it is necessary to work only at positive ambient temperatures. The joints of the planks, for better sealing, are overlapped, and carefully sealed with a moisture-repellent sealant.

Installation of wooden planks

The installation of solid wood strips is the most time consuming due to the nature of the material. As in the case of metal additional elements, wood products can be fixed either on self-tapping screws or on mounting glue. The edges of the wooden strips are marked according to the miter box and cut at an angle of 45o. Otherwise, the joint of the planks, especially triangular in cross-section, will look ugly.

Before applying the glue, the inner surface of the plank and the window frame are cleaned of dust and dirt. When fastened with self-tapping screws, the thin wood plank may crack. To avoid this, it is recommended to drill small-diameter holes in the marked places, with an interval of 25-35 cm. And only after that the strip is attached to the window block using self-tapping screws.

Installation features

Recessed plastic strips can be installed on metal, wood and PVC windows. First you need to measure the length, and then use a miter box to cut the ends at an angle of 45 degrees. In the case of work with a flexible glue strip, the protective tape must be removed gradually, and the cover strip must be immediately pressed to the joint. If a rigid structure is being installed, all protective film is immediately removed. In the absence of an adhesive base, the product is fixed with liquid nails. The latter are applied to the bar using a special pistol.

Metal structures can be installed in any weather. The plank is fixed with self-tapping screws, for which holes are pre-drilled at a distance of 30 cm. To prevent the structure from delamination and loss of aesthetic characteristics, the metal rails are overlapped, and the butt joints are sealed with a waterproof sealant for protection.

The most responsible and time-consuming process is the installation of wooden structures. In order for the flashing to have a smooth transition, the edges should be well cut and adjusted. Fixation can be done with adhesive or self-tapping screws. It is important to understand that self-tapping screws violate the integrity of the structure and the smoothness of the surface, and liquid nails are less durable.