What happens in winter when applying polyurethane foam

Due to the reduced amount of moisture in the air in winter, the polymerization and curing period of the polyurethane foam increases several times. All this time, the applied foamy mass is very vulnerable: due to wind, rain, mechanical influences, irreversible processes occur in it that violate the structure. The foam becomes brittle, cracks and crumbles.

As part of winter polyurethane foam there are special additives that increase the rate of its polymerization and help maintain the correct consistency in frost and low humidity. Such a building material differs from the usual ratio of chemical components and is intended for use in the cold season at temperatures down to -10 ° C.

In winter, only special polyurethane foam can be used.

Manufacturers

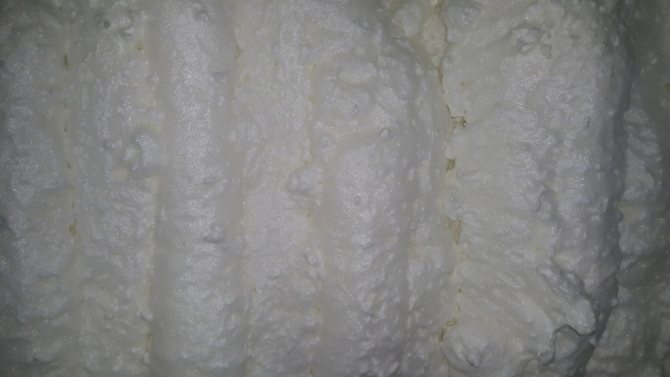

Frost-resistant assembly sealants are produced by various manufacturers of building materials, among which there are foreign and domestic brands. Quality winter foam has good primary expansion, uniform porosity, and dense structure.

The following compositions have proven themselves well:

1.Famous brand Soudal, which is one of the largest manufacturers of aerosol winter foams. Advantages - homogeneous consistency, good thermal insulation properties. Sealants have a long service life.

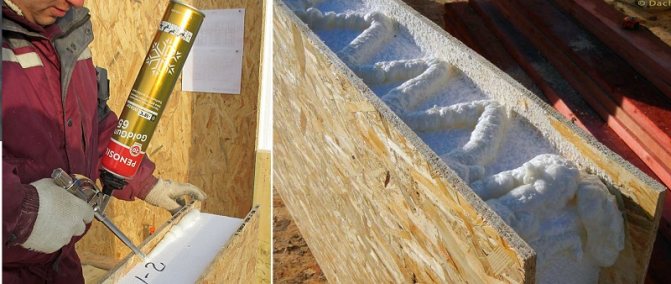

2. The Penosil brand has gained wide popularity among consumers. Winter formulations of this brand have insignificant secondary expansion, high coefficient of mass recovery from the tube, economical consumption.

3. Tytan Professional winter foams are designed for use at temperatures down to -20 degrees. The environmentally friendly formulations of the manufacturer have a dense fine structure; after solidification, shrinkage does not occur.

Winter foams Ultima, Axton, Macroflex received good customer reviews. Before purchasing, you must carefully read the operating conditions and application of sealants. In the modern construction market, frost-resistant foams are offered in a wide range, so there are no problems with the choice.

Winter polyurethane foam (2 videos)

Types and application of winter mounting foam (18 photos)

The fundamental difference between summer and winter polyurethane foam

- Summer - designed for application at temperatures from +5 to +35 ° C. After complete hardening, it can withstand a completely different temperature range - from -50 to +90 ° C. The limitation is relevant only when working with the material.

- Winter - applied at temperatures from -10 (-18) ° С to +35 ° С without compromising performance.

There is also an all-season variety that quickly polymerizes at temperatures down to -10 ° C. It can be used both in summer and winter. However, not all manufacturers offer such universal sealing materials. In addition, at lower thermometer readings, the risk of mass cracking increases.

What happens if you use standard polyurethane foam in winter

Do not be surprised that the technical indicators of standard foam, declared by the manufacturer in the instructions, are very different from the real ones. At temperatures below +5 ° C, the mass will harden much longer than it should, which will negatively affect the performance:

- the composition will not reach the desired consistency;

- the strength of the seam will suffer;

- the foamy mass will begin to crumble already when it solidifies.

Summer polyurethane foam crumbles and cracks under the influence of low temperatures

Storage rules

The shelf life of winter foam in sealed original packaging is 12 months on average. An open bottle must be used up to the end. Store the sealant upright to prevent components from clogging the valve. Use winter foam only at the temperature indicated by the manufacturer on the packaging, otherwise the sealant will lose its quality.

Important: You cannot store winter foam at negative temperatures - its technical characteristics are lost.

Advantages of winter polyurethane foams

Winter polyurethane foam is used to seal windows and doors, gaps in walls and partitions made of concrete, brick, wood, metal and gypsum plasterboards.

- It hardens and maintains operational properties at temperatures down to −10 ° С (polyurethane foam REALIST 70 - up to −18 ° С) and low ambient humidity.

- Excellent adhesion to smooth surfaces, painted walls, glass or PVC.

- Suitable for sealing even wide and deep gaps and joints.

- Has high sound and heat insulation characteristics.

- It is used if necessary all year round, including in summer.

Winter polyurethane foam cannot be applied to oily surfaces, polyethylene, polypropylene, silicone, Teflon - it will not provide strong adhesion. Substrate of a suitable composition must be free of ice.

Scope of application

The scope of use of polyurethane foams is very wide, it covers different areas of industry, the compositions are used for domestic needs. Winter sealant has good adhesion, firmly adheres to various materials and can withstand low temperatures without losing its properties.

Where is frost-resistant cold-resistant polyurethane foam used for exterior and interior work:

- Installation of boxes of entrance structures.

- Installation of plastic and wooden windows.

- Foaming the gaps of interior doors.

- Sealing facades and interpanel seams.

- Insulation of pipe joints, plumbing.

- Installation of heating equipment, fireplaces.

- Fixation of materials for facade insulation.

- Insulation of communications and cable channels.

- Foaming deformed surfaces.

Winter foams work effectively as a sealing or fixing agent. The compositions quickly fill voids, holes, cavities and technological gaps. With their help, you can eliminate defects in concrete walls, cement screeds.

Note: Foam can be used as a heater for the construction of plasterboard partitions, insulating materials can be glued on it to fix wall panels and sheet insulation.

A few tips for using winter polyurethane foams

- It is not worth using a cold and frozen cylinder: this increases consumption and reduces the quality of the seam. It is advisable to bring the temperature of the cylinder to room temperature, for example, keep it at + 15 ° C for at least a day.

- Short-term freezing of a cylinder, for example during transportation in the trunk of a car, does not lead to serious changes in the properties of the foamy mass, in contrast to prolonged freezing.

- Shake the can for 15-30 seconds before use to thoroughly mix the components and increase the foam yield.

- Apply foam to a third of the gap volume - on a surface free of dust, debris and ice, slightly moistened with water from a spray bottle.

- If necessary, make several layers, but wait until the previous one is completely polymerized (the fragility period for winter polyurethane foam is from 3–6 to 5–9 hours).

- After applying the foam in winter, the joint does not need to be sprayed, as it is done in summer, in order to improve adhesion.

- The seam must be protected from precipitation and ultraviolet radiation, which can destroy its structure and increase porosity. Such protection can be achieved, for example, with a heat shield.

- You can cut off winter polyurethane foam no earlier than a day after application: it must completely harden and dry.

When applying, the can with winter polyurethane foam is held upside down

A little about the expense

The manufacturer indicates the average foam consumption for the cylinder. For example, for REALIST-65 this is a maximum of 65 liters - depending on environmental conditions. The lower the temperature and humidity, the smaller the volume of the foam. Therefore, at lower temperatures, the consumption increases and the work costs more.

But there is also a positive side. If the volume of the foam decreases, the density increases, the consistency becomes more uniform and durable - the sealing material acquires improved performance. Therefore, do not rush to postpone the sealing of joints and cracks until spring. An assembly seam made of correctly selected foam will last more than one year, reduce heating costs and will delight you with an aesthetic appearance!