The heating equipment segment is currently in a transitional period. This is due to the emergence of new concepts and technologies for the development of units, as well as the introduction of electronic control systems. Boiler devices have always been considered the basis of this group of equipment. With the help of such installations, it is possible to provide heat and a small private house, and public buildings, and industrial premises. The buyer is offered a fairly wide range of options to choose from, including the Ferroli gas boiler in different designs. The Italian company has been known in Europe for more than 50 years, and for the last 20 years, Russians have also been getting acquainted with its proposals. The manufacturer strives not only to maintain the most successful technological achievements introduced during its activity, but also to actively improve the products with modern developments.

Features and benefits of Ferroli boilers

Of course, this is far from the only manufacturer using new technologies. Therefore, in a competitive environment, engineers strive to offer effective solutions in a variety of ways. First of all, the Ferroli gas wall-mounted boiler provides the required level of performance, consuming a minimum amount of fuel. Together with automated control and the ability to control temperature conditions, this allows the owner to optimize heating costs. By the way, about automation: the manufacturer also provides for the possibility of self-diagnosis of boilers, which is very important for users without technical training.

It is for Russian clients that it is valuable that the company adapts the models to harsh operating conditions. Poor water quality and voltage drops sometimes become the main problem of heating equipment. In turn, the Ferroli gas boiler is completely ready for use in such conditions: according to the manufacturer, the service life of the equipment is more than 40 years.

Settings for gas boilers Ferroli

___________________________________________________________________________________________

- Domiproject, Domitech, Pegasus models

- Ferroli boiler errors

Tell me how the pressure in the system is measured with a gas wall-mounted boiler Ferroli Domina N, and also, more importantly, is its transmission via the OT interface implemented in it? This is why I need it. I have installed the OpenTherm interface. It is set to a pressure of 1.4 bar. When I add water or I have a pressure drop in the system, the pressure gauge is working correctly. As I understand it, this may be due to rather warm weather and a rare start of the unit? But yesterday, in general, the system stopped by mistake, as the pressure became lower than the set one. OT support is not implemented on Domina H models of the first years of release. It all depends on what the fee is. 39848640 - DBM33 control board for model F (without OpenTherm). 39848641 - DBM33 control board for model C / F N (with OpenTherm). Your boiler has a simple on / off control relay. And it reacts only to changes in the set pressure. Namely, at a pressure of 0.8 bar, a closure occurs. And from Open Therm it cannot receive anything physically, since it is not a hall sensor. I want to install a boiler in a private house, and the planned installation site is a basement. Initially, I chose the gas model with a closed chamber and coaxial chimney. But the store told me that in my case, its installation is impossible, since the top of the chimney pipe must be raised above the ground by at least 2 meters. In my case, this is technically impossible to implement.To resolve this situation in the store, I was asked to pay attention to the Ferroli Fortuna F24 Pro, arguing that its design will allow them to mount systems without violating the installation rules. I would like to understand why he is so good? This model has no special design differences. This is the most common unit, which has two heat exchangers and a closed combustion chamber. Working power 24 kW. There is a table that shows all the recommended indents from the place of emission of combustion products into the atmosphere through the outer wall of a gasified room without a vertical channel from gas-using heating equipment with a sealed combustion chamber and a device for forced removal of combustion products. Absolutely any hinged gas boiler can be equipped with a separate smoke exhaust system. It's just that on the model recommended to you, the necessary connections are already included in the kit. The Ferroli Diva F24 boiler is in operation. A two-pipe system 32 with a lower supply 25 was installed. House area 52 sq. M. The unit system is filled with water. The pressure in the cold system is 1, and when everything heats up to 70 C, then 5. All equipment is no more than a month old. The rooms have a thermostat. At first everything worked fine, but recently the following problem appeared. When heating from 54 to 70, an extraneous sound appeared, somewhat reminiscent of the sound of a boiling kettle. Moreover, it is present only when the burner is operating at medium modulation. If you reduce the power of the flame, then there is silence. I tried to bleed the air, reduced the power of the entire heating system - it did not help. The water entering the unit is very hard (determined by the inner walls of an ordinary kettle - they are all covered with scale). The filter that protects against dirt is installed only on the return pipe, but it is clean, I have already examined it. The installation and installation of the boiler was done by a specialist, but he did not adjust the pressure on the burner. Is the heating radiator clogged in such a short time? The first thing you should do is adjust the gas valve. If you are convinced that everything is in order there, and the problem persists, then do the following: Focusing on the display, reduce the power in test mode to 70 degrees; then (if the sound persists) you can temporarily remove the diaphragm (43 mm in diameter) from the chimney. If all these manipulations do not help, then you will have to change the heat exchanger. We want to buy a Ferroli gas boiler for installation, but we cannot choose between two models: Domina N and Fortuna F. How do they differ from each other? Fortuna models are wall-mounted boilers with an open combustion chamber. They also come with a set of pipes for a separating smoke exhaust system. It should also be noted that they have a reduced noise level. There is a boiler for a private house Diva F16 with a ROMEO control panel connected to it. The temperature is set to 23C on the remote control, and, in principle, the unit keeps it. But I don't like his work itself. When the temperature in the system is 23.1C, for some reason the burner turns on and it heats up to the set 65 degrees. Extra clockings are clearly present. Observations have shown that heating takes a very short time (2-0-30 seconds), and it works for itself through the bypass pipe (water does not enter the system). But if in the rooms the temperature drops to 22.8C, then heating and work goes as expected. Why is this happening? We recommend that you check the operation of the system without a remote control. If the problem persists, then you have comfort mode turned on. Disable it. I would like to know what quality the Ferroli Fortuna F24 pro gas boiler has. We heard that they may have noise and rattling during operation. Is it so? And if so, is it possible to reduce it by installing the chimney according to a separate scheme. Or is it worth paying attention to some other model? And another question: do you need a voltage stabilizer? If necessary, tell me its power. We would recommend you to buy a Ferroli Diva F 13-16-20-24 kW (you can choose any power, as it is adjusted on the spot).And at the expense of the stabilizer - look at the voltage of the incoming network. If there are jumps, then it is better to install. We also recommend paying attention to the Arena model. It differs from Diva only in control (no display and control of rotary encoders). Repair and maintenance of the Ferroli Domina N wall-mounted boiler was required due to the fact that it does not see the opening of the contacts on the thermostat. Reboot doesn't help. It works as it did by maintaining the temperature that was manually set. When connecting, I had to install a jumper, since it did not want to start due to attempts to track the readings of the temperature sensor. Now there is a need to restore this function. What should I do? Remove the cover and note the terminal box to the right of the board. Find there two white wires attached to the board. There, from below, they must be connected by wiring - this is the very jumper. A thermostat can be installed instead. If you have two terminal blocks available, then one of them is for the outside temperature. Look for the one where there is extra wiring. I decided to do maintenance of the heating boiler Ferroli Diva C 32. Reason: two gaskets of four of them leaked in the secondary heat exchanger. After inspection, I was left puzzled by the technical solution: why only 2 bolts were installed on all four gaskets. I tried to tighten them, but it didn't change anything. And at the beginning of the cycle, when heating is in progress, the unit emits an incomprehensible loud noise. This problem occurs on other models as well. The reason is an unidentified mixer. The analysis of water went through a ball valve, and the pressure in the system was 4 atm. If the tap was cut off abruptly, then a water hammer occurred. In your case, installing mixers will help to limit the flow rate. With the help of specialists, I made the connection and installation of the Ferroli Domina N. gas boiler. It has been in operation for two winters and it has been working for me. For all the time of work, not a single mistake. But now there is a need to increase the heated area by 50%. As I understand it, all similar devices are structurally the same. Can I readjust my 16 kW unit to 24? Yes, you can do it. In your case, you just need to reset the heating power with parameter P06 in the control menu. Setting is possible in the TEST mode. I installed a Ferroli Diva F24 boiler (power 24 kW). This power is enough for me in abundance. I wanted to buy a less powerful system (16 kW), but when buying, the seller discouraged and recommended taking with a margin, so that it would be enough for DHW heating. Already sorting out at home, I realized that all parameters are subject to adjustment. The first thing I did was set the minimum and maximum pressure values. Then, using the program, I set the maximum power limit. I set it to 12 kW. But the hot water supply still continues to consume 24 kW of power. All models of this type have a special service menu. Working in it, you need to find the parameters P06 and P12. Parameter P06 is responsible for the maximum power consumption by heating, and P12 regulates the water supply. All parameters are set and displayed as a percentage. If you have not changed anything, then according to the factory settings, it is set to 100%. These parameters are controlled independently of each other. That is, if you reduce the value of DHW, then the power supplied to heating will remain unchanged and vice versa. It is important to return all boiler settings to the factory settings before manipulating these parameters. Only in this case will we be able to understand exactly what value we are setting. For example, the standard power of the unit is 32 kW, and it reaches its maximum value when the system pressure is 12 mbar. After that, the problem is solved simply by 32 - 100%, therefore, for example, 80% is 25.6 kW. I am having problems dispensing hot water. In this mode, the Ferroli DivaTech gas boiler is fired up only the second time. After the first ignition, the flame must go out.I studied the instructions for use, namely the section on cleaning the electrode, but did not find instructions on how to carry out this event. I decided that cleaning with a piece of alcoholized cotton wool would be the right decision. It did help in part, but not completely. Than in service centers this electrode is cleaned. And yet, earlier, when I watched the ignition process, I noticed that the spark always strikes from one point and in the same place. And today the first few sparks flew out as standard, and the next ones were from the sides of the electrode. Is this the correct way to work? When I turn on the hot water supply, there are no problems with ignition, but a slight pop is heard. When I started a stopped and cold (it stood for about 10 hours) unit at -25C, it started up smoothly and without any extraneous sounds. I immediately got involved in the work. Before that, I cleaned the electrode like this, there were problems with starting every second time, and after that not more often than once a day. The pop is heard due to the very weak electric arc. You just need to clean the electrode one more time. Also remember that the gap needs to be set on a well-heated electrode. If this condition is violated, damage is possible. In the presence of a gsm-module with a thermostat and a sensor that measures the temperature in the room. It has the function of controlling parameters via SMS, by closing and opening the contact. Can it work with the Diva f13 gas boiler (if I'm not mistaken, then the connection is made through the terminals for the remote control). What kind of remote control can be connected to it (is ROMEO suitable for wired)? Is the burner flame regulated by the installed room thermostat, if so, how? Yes, in your case, you can use both a wired and a wireless remote control. However, modulating the burner flame is only possible with the installation of the ROMEO wireless remote control. See Open Therm. However, if the DBM32 board is installed on the Diva model, then work is possible only with wired consoles. On modern versions, the DBM32A board is already installed, which allows you to choose the type of ROMEO connection. Also note that if an OSCAR thermostat is installed, then the OpenTherm protocol cannot be enabled. I am choosing a gas boiler for a private house and I tend to think that the Diva F24 will suit me. I do not need a unit of such power, but as I figured it out, it can be adjusted according to needs by setting the maximum gas supply. That is, having bought it for 24 kW, I can use it as 16. Moreover, they are at the same price. I would like to understand what then the differences between the Divatop and the simple Diva in terms of quality and service life. Connectivity options for additional equipment are not important to me. The main difference is the lack of individual firmware. We recommend taking any device of the Diva series (power from 11 to 24 kW). But be sure, when installing and connecting the boiler, set it so that it works for heating as 13 kW (optimal for your area), and for DHW as 24 kW. It is required to repair the Ferroli Divatech gas boiler. Problem: ignition is delayed. Is there any way to fix this? You have two bullet solutions to the problem. Pressure setting. Cleaning the electrode itself. You may need to do both. Also check the "electrode-board" circuit, you can still clean the heat exchanger itself. The chimney would also not hurt to check, since in the warm season, the draft always deteriorates. The Ferroli Diva F24 gas boiler broke down. For repair, specialists from the service center were called. After examining them, the conclusion was that the board was faulty and replacement was required. Bought a new DBM32 board. While reading the instructions, everything was simple and clear. I did everything as it was written there, however, when I tried to start the unit, error 04 appeared, indicating an incorrectly configured board. When trying to start, the noise of the fan turned on is heard, but ignition does not occur. Errors F 05 also appear (problems with the air relay). When setting up, I set the following parameters: b01 - 0, b02 - 2, b03 - 0, p16 - 0.After the third start-up attempt, a new error A015 appeared, and the boiler was blocked. I could not find what this error means. Can you tell me where I got it wrong? You have set the correct settings, which means that your problem is not at all with the board. Consider error F05, it denotes a problem in the dum removal system. We must look at the pipes themselves. A malfunction of the manostat is also possible. You can also check the presence and need of a diaphragm. The initial incorrect installation of the chimney is possible, and the tightness in it is broken. It is also possible that there is condensation in the monostat tube, or poor connection. There may be a problem with the fan due to its breakdown or too low voltage in the network. If you have an old model manostat, then the problem is probably in it, they often fail. By the way, errors F04 and F05 on the same unit cannot appear at the same time.

___________________________________________________________________________________________

___________________________________________________________________________________________

Repair of gas boilers AOGV Borino, ZhMZ, Siberia, Alpha Calor, Thermotechnik. Adjustment of gas automatics Eurosit 630. Replacement of the thermocouple and maintenance of the ignition burner.

Malfunctions and repairs of Baxi boilers Models Luna, Luna 3 Comfort, Luna Duo Tec (F / Fi). Double-circuit, turbocharged. Recommendations for eliminating errors and malfunctions. Settings and adjustment of operating modes.

Gas heating boilers Bosch Models ZWC, ZSA, ZSC, ZWR, Gaz 5000, Gaz 3000 W ZW, WBN 6000. Wall-mounted, double-circuit. Repairs, adjustments and malfunctions. Options for setting functions and modes.

Repair recommendation Navien Models Deluxe Coaxial, Deluxe Plus, GA. Errors and malfunctions. Work with remote control Ksital. System control. Setting work on temperature and pressure.

Floor standing boilers Buderus Repair of Logano G124, G125, G215, G234, G334 models. Breakdowns and malfunctions. Operation with Logomatic control system and indirect heating boiler. Modes and functions.

Operation of Vilant boilers Turbotec Atmotec pro / plus VU / VUW INT models. Components and work functions. Adjustment programs. Gas system. Installation and assembly. Maintenance and prevention.

Floor standing boilers Protherm Repair of the Bear models KLOM, KLZ, TLO, PLO with a capacity of 20 to 50 kW. Breakdowns and malfunctions. Operation, maintenance. Recommendations for setting operating parameters.

Lemax - repair and settings Models of gas floor boilers Premium, Leader, Patriot. Performance characteristics. Prime, Wise models. Adjustment of automatic equipment Eurosit, Minisit, Sit Nova. Solid fuel boilers Forward.

Wall-mounted coppers of Protherm Repair of the Panther, Cheetah, Jaguar, Lynx, Leopard models. Breakdowns and malfunctions. Operation and service. Recommendations for adjusting operating modes.

Beretta - repair and adjustment Repair and operation of boilers Ciao, City, Novella, Exclusive. Wall and floor models. Malfunctions and error codes. Working functions and setting of service modes. Maintenance.

Boilers Teplodar Kupper PRO Operation and adjustment of solid fuel boilers with a capacity of 22, 28, 36 kW. Installation of an automatic pellet burner APG-25, 36, 42. Settings of operating modes.

Repair of gas boilers Oasis Models of wall-mounted boilers ZRT, ZRN, BM. Malfunctions and error codes. Troubleshooting tips. Operating modes and setting of service parameters. Maintenance.

Heating boilers Alfatherm Description of Beta floor-standing boilers and Sigma wall-hung gas boilers. Malfunctions and error codes. Repair and troubleshooting questions. Basic maintenance work.

Wolf - malfunctions and repairs The Wolf boiler is installed. I noticed that over time, the pressure in it gradually decreases (by about 1 in 2 days). I checked all the pipes for leaks but found nothing. What else to check?

Gas boilers Junkers After 7 years of operation, the gas boiler Junkers ZW-23-KE has the following problems. When DHW starts working, it either turns off or stops working ...

Repair of boilers Neva Lux Neva Lux 8224 (Baltgaz), discovered the following problem: the post-circulation pump does not turn off, no matter what the temperature is. To make sure that this is so, he raised the temperature in ...

Wall models

This is one of the most common types of boiler equipment, which in the line of the Italian brand is represented by the Diva, Divatop Domina, etc.Due to its affordable price and uncomplicated design, the Arena model is in the greatest demand. This is a gas double-circuit wall-mounted boiler Ferroli, which has two heat exchangers. The combustion chamber of such models can be open or closed, depending on the modification. The design itself allows for high heat transfer, but there are other advantages of boilers of this type precisely in the idea of Italian designers.

In particular, the developers use a primary heat exchanger made of copper, and its secondary counterpart is made of stainless steel. Branded parts are also used as accessories. For example, the valve is from Siemens, and the three-speed circulation pump is from WILO. To ensure stable operation, the Ferroli double-circuit gas boiler is equipped with a control board that is resistant to changes in the network. Together, the listed components ensure high reliability of equipment and safety during operation.

Wall mounted gas boilers Ferroli

Wall heater of the Italian firm Ferroli.

Wall-mounted boilers Ferroli are available in different configurations and capacities, so you can choose a unit according to your requirements and budget. The first characteristic is the number of contours. So, heaters can work not only to heat water in the heating system, but also supply the house with hot water at the same time. Accordingly, single-circuit and double-circuit boilers are distinguished.

The second aspect is the type of combustion chamber and its configuration. The combustion chamber can be open or sealed. Open combustion chambers, like a conventional hob burner, burns air out of the room (there is no fire without oxygen). Sealed chambers draw air from the street through a special chimney called.

A heat exchanger (one or two) is installed in the combustion chamber. One heat exchanger (bithermal) is a pipe in a pipe, into which nozzles for separate smoke extraction are cut. The heat exchanger is made of copper. If there are two heat exchangers, then they are separated from each other. The primary is made of copper, and the secondary is made of stainless steel.

The richer the equipment, the more expensive it is to repair Ferroli gas boilers.

Complete set of Ferroli gas boilers according to the instructions:

- heat exchanger (one or two);

- gas valve - Siemens or HoneyWell;

- three-speed Wilo;

- smoke exhaust pipes - separate smoke exhaust system;

- Control block.

There are models with and without an LCD display. The display shows information about the parameters of the heater and errors that occur during operation. The display lights up in blue. The DivaTop 60 is available with a 6 liter built-in boiler.

The efficiency of a wall-mounted heating boiler Ferroli of any model is approximately 93%. The minimum power is 7.2 kW, the maximum is 40 kW. The unit heats the coolant for high-temperature heating systems up to 85 degrees, and the water for hot water supply - up to 55 degrees. The boilers run on natural and liquefied gas. The nominal energy consumption is indicated in the passport for each model. The gas inlet pressure must be at least 20 mbar for natural gas and 37 mbar for liquefied gas.

Units for floor installation

This variety is represented by the Pegasus and Atlas series in various modifications. As a rule, these are cast iron units supplied with atmospheric or hinged burners. The advantages of such models are well illustrated by the Ferroli floor-standing gas boiler in the initial version - Pegasus. The model is equipped with a cast iron heat exchanger, a Honeywell valve, a single-stage burner, a signal contact, as well as connectors for a circulation pump and a room thermostat. To facilitate operation, the developers have provided electric ignition and the ability to connect a boiler.

Security is also worth noting.The boiler has a smoke exhaust control, an ionization sensor for the flame, and also offers the ability to monitor overheating using a Ferroli bimetallic indicator. Gas heating boilers of this category also have an additional option. Suffice it to note the cascade control unit, means for connecting an external thermostat and a turbo nozzle.

Condensing models

Ferroli condensing equipment is available in the Econcept, Energy and Bluehelix series. These are already single-circuit units, among which there are options for increased power. For example, the Econcept model is capable of delivering power up to 300 kW. The features of condensing devices include the presence of weather-dependent automation and a large liquid crystal display. In addition, the Ferroli gas wall-mounted boiler in the Econcept series has an aluminum heat exchanger and a ceramic burner. The use of these materials is due to lower safety requirements. Actually, the purchase of a condensing unit is beneficial from the point of view of wide functionality and increased ergonomics. The user will be able to view all the main operating parameters, use the boiler modes depending on the season, and control the connected boiler using a remote control.

Components

For each category of boilers, the manufacturer also provides additional accessories. In particular, wall-mounted models of the double-circuit type can be supplemented with a kit for smoke exhaust systems and devices that allow the equipment to operate on liquefied gas. In turn, the Ferroli floor-standing gas boiler can be equipped with boilers, DHW priority systems, turbo nozzles and cascade control devices. Condensing units have the largest range of additional options. They can be provided with outdoor temperature sensors, control boards for multi-circuit systems, hydraulic switches, a mounting manifold frame, as well as special sets of fittings for connecting boilers.

User's manual

Most Ferroli models are fitted as standard or optionally with automated controls for ease of use. The user sets the modes and makes settings through a special panel. To start the equipment, it is necessary to open the burner and carry out the ignition. But before that, you should turn on the unit to the network, and then press the special start button, which is equipped with the Ferroli gas boiler. The instruction also provides for a situation in which starting the equipment will not work. If the boiler does not start up within 15 seconds, the system should be restarted. The boiler should be turned off not only by closing the valve and turning off the button. It is recommended to disconnect the unit from the mains, but it is important to take into account that in this state the boiler will not be protected from freezing. To avoid this, you should either drain the water or add antifreeze to it.

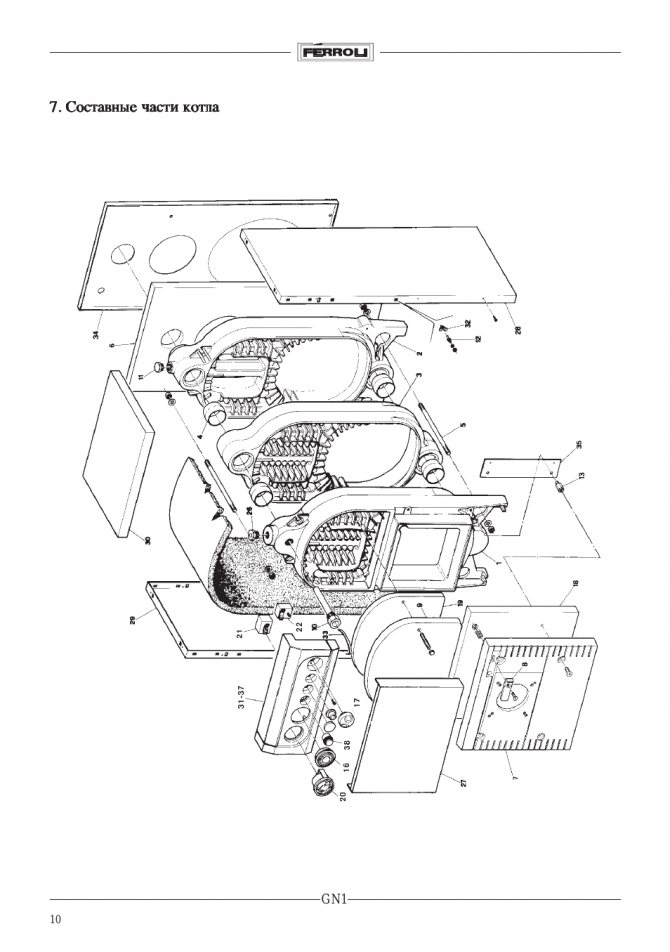

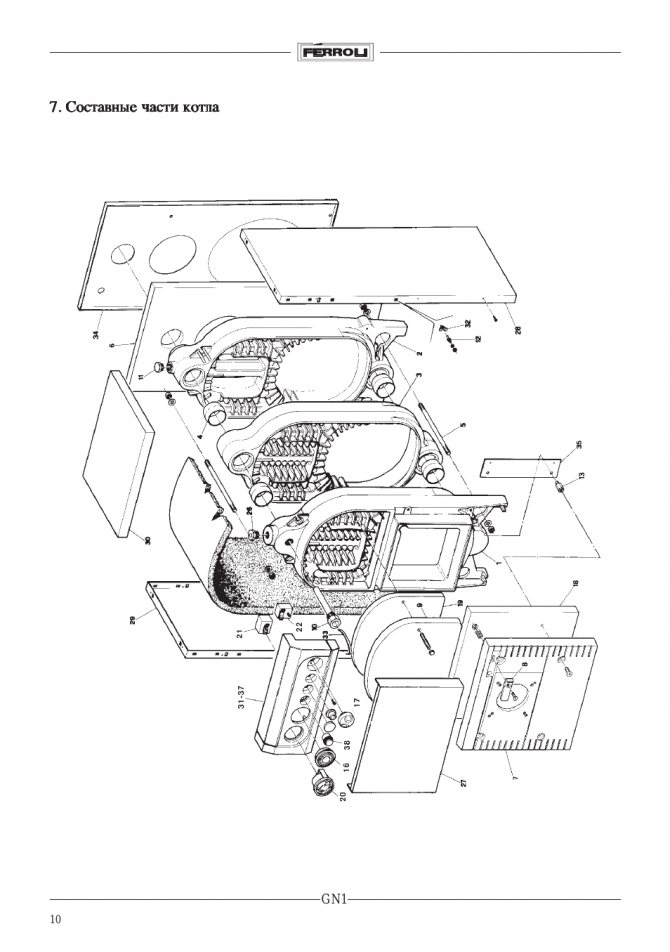

... Boiler components ...

Page 10

- Picture

- Text

RENNOi

7. Components of the boiler

-OK1-

10

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

Supplement to the instructions for the export version of the TT pistol: - Not intended for playing Russian roulette.

Manualza! Manualza.ru

Still not with us?

Maintenance instructions

To maintain the boiler in good condition, the user must regularly clean the equipment casing with rags and soapy water. A complete technical inspection must be carried out at least once a year. Combustion analysis is also recommended. It is important to monitor the operating parameters at which the Ferroli gas boiler operates. The instruction instructs the owners of the equipment to carefully monitor the indication of faults. Most of the cases of incorrect operation of equipment are associated either with voltage surges or with a lack of gas.It is recommended to contact the service center only after the elimination of such problems and the next check of the boiler.

Ferroli boilers reviews

There are practically no frankly negative reviews about Ferroli products. On the other hand, there is a high performance, well-thought-out design and low fuel consumption. Separately, the owners point to the low noise level of the equipment, which is very important when installing in residential buildings. And yet there are nuances of operation that should be remembered when buying Ferroli gas boilers. Reviews quite often note leaks in heat exchangers. This is a common problem, but it has nothing to do with the quality of the hardware. Similar phenomena occur due to improper operation when working with hard water is allowed. Therefore, you should initially focus on models that can work with both gas and water. For example, bimetallic heat exchangers are not suitable for such needs.

Known faults of Ferroli boilers

The list of typical faults is quite wide, most of them are inherent in budget wall-mounted models, but the rest cannot be called absolutely problem-free.

Most often, due to even small voltage drops, the control board (automation) fails, the boilers must be connected to the mains through a voltage stabilizer. A less painful, but also common problem is a breakdown of the make-up tap or its leakage (located under the boiler, the tap handle is painted black), in Ferroli models it is simply made of rather fragile plastic. Less often, the circulation pump, the thrust sensor fail, there are cases of a heat exchanger leaking after 3.4 or 6 years of operation.

In more detail, it is worth disassembling the most common operational problems, not necessarily related to breakdowns (click to expand):

+ Double-circuit boiler does not heat hot water

If you open the tap at the point of consumption, hot water does not flow after 10-15 seconds, most likely the problem is in the heat exchanger clogged with scale. This is especially true for models with a bithermal heat exchanger such as Domiproject, since they have a much smaller coil section and even a relatively small layer of scale can clog it. Most often, a full replacement is necessary, but sometimes the heat exchanger can still be flushed. Much less often, the problem may be a malfunction of the flow sensor (flow meter).

+ The boiler does not hold pressure

A drop in pressure clearly indicates a leak in the heating circuit: piping, safety valves, expansion tank, make-up valve, etc. Normal operating pressure in most Ferroli models should be 1.2 bar. If it falls below the critical value, the boiler generates error F37. Most often, the reason is a leakage of the make-up valve or expansion tank, in order to raise the pressure, you need to check and seal all the elements of the system. All causes of a drop in water pressure in household gas boilers

+ No ignition or weak spark

There are two main reasons: a banal clogging of the ignition electrode / its malfunction, or a partial failure of the automation (it is necessary to check the condition of the board).

+ The boiler does not turn on and does not start at all

The problem is almost guaranteed in a control board that has failed due to a voltage drop. Ferrols are extremely vulnerable to the domestic unstable power grid and require connection through a stabilizer, which is neglected by almost all buyers.

Also from the known, but rare problems, there are breakdowns associated with the turbine, when its fan makes noise or fishes, there are breakdowns associated with traction and temperature sensors.

Most common error codes

+ Error A01

Burner ignition failed... See the point about no ignition above. Most likely the reason is a clogged ignition electrode or a malfunction.You should also pay attention to its contacts, check the condition of the control board and wiring in the boiler.

+ Error F05

The air pressure switch does not work after 20 seconds. after turning on the turbine fan... A common reason is ice on the chimney headband in severe frosts, in order to correct the situation, it is enough to gently knock it down. If everything is in order with the exhaust of gases, the reason may be an incorrect diaphragm, poor contact of the air pressure switch (draft sensor) or its malfunction.

+ Error F37

Insufficient water pressure in the system... It occurs when the pressure in the system drops below the critical mark (0.7-1 bar). There can be two reasons: insufficient amount of coolant in the system or depressurization (leakage). All heating circuit modules must be checked for leaks, including inside the boiler.