Heating is the most important engineering section, without which comfortable living in a cottage is impossible. Heating a private house must be done correctly, and this is a great art. It is necessary to have knowledge of many subtleties and nuances in order not to make mistakes. Such knowledge can only be provided by a complex of theory and practical experience.

If you have questions about the organization of the correct heating of a private house and you need an engineer's consultation, then call or write to us. Specialists will be happy to answer questions and clarify the nuances that interest you.

Heating system selection

Choosing a heating system for a cottage is not an easy task. There are many pros and cons to be foreseen. In this case, it is necessary to consider and analyze the following parameters:

- Fuel availability

- Reliability - the technologies used must be time-tested

- The cost of both the heating system itself and its operation and maintenance

- The prevalence of technologies on which the heating of the house is built, and the availability of specialists for regular maintenance

- Maintainability

- Appearance and compatibility with design

- Individual wishes and their feasibility without sacrificing the overall quality of the heating system

Further, we tried to reveal the main nuances, the knowledge of which will help you make an informed choice. If you have any questions, you can always contact us for advice.

Installation of Flexalen pipes for the heating system

The laying of the heating system within a single apartment is always carried out taking into account the currently existing rules relating to the construction of ground and underground pipelines. In any situation, the installation of heating systems is considered a rather complex procedure that requires skill and certain knowledge.

The efficiency of the system will depend on the reliability of the installation in the future. But the track, the length of which is less than 300 meters, can be laid without all kinds of connections. Also, other additional elements are not used here. But rather high indicators of flexibility make it possible to lay pipes in a route of all kinds of shapes. Installation of pipes directly into the ditch is also allowed.

Thus, to order laying services heat and to purchase the pipes themselves, it is enough to dial one single number - 8(495) 211-17-01... Efficiency and excellent quality are guaranteed.

- Flexalen 600 pipeline and its use for the heating system

The Flexalen 600 pipeline is a two-pipe construction (it can also be used as a one-pipe system), which is effectively suitable for ... - Features of the selection and laying of heating mains for an autonomous heating system

The basis of any heating system is energy efficiency - it must not only generate a sufficient amount of thermal energy, but ... - Pipelines and heating mains

Technical characteristics of standard modifications of Flexalen. Areas of use. Mount method. Priorities and solution to the problem: where can you buy fl ... - Purpose and advantages of Flexalen pipes

The world of technology is thriving thanks to competition that prompts manufacturers to create ever more sophisticated and ready-to-use materials ... - Water supply pipe quick installation

Pipes for quick installation today can be purchased in excellent quality and at an affordable cost. It is enough to make one single call. ... - Advantages of Flexalen heating mains and their differences from conventional pipes

Modern Flexalen pipes have recently become the main choice when laying heating mains. This is due to the fact that these products have ... - Replacing water pipes

Country houses are not only luxury and comfort, but full responsibility for its maintenance. Many homeowners try to have everything of their own: private water ... - Pipes for water supply installation in soil

An indispensable attribute of any private housing is a pipeline that provides efficient water supply, so it should be treated with all of ... - When is it profitable to do the installation of a heating main

Are you wondering when it is profitable to make a heating installation? We will answer: "Always". Our company offers inexpensive sale of flöhalen pipes in Moscow and their ... - Sale of flexalen pipes for Russia

Due to the peculiarities of the climate and the length of the territories, high-quality installation of heat for transport is of great importance for our country ...

Types of heating in a private house

All heating systems can be classified according to the following parameters:

By type of fuel

Depending on the fuel consumed, heating systems installed in private country houses can be of the following types:

- Gas (main or liquefied gas)

- Electrical

- Solid fuel (firewood, sawdust, pellets, coal, etc.)

- Liquid fuel (diesel fuel, waste oil, etc.)

- Geothermal - systems based on renewable (alternative) energy sources

They all have their own advantages and disadvantages. Natural gas is the optimal fuel for Moscow and the Moscow Region. If a country house has the ability to connect to a gas main, then you can choose this option without hesitation.

By type of coolant

Based on the type used in the heating circuit of the coolant, the heating of the house can be of the following classes:

- Water

- Air

- Steam

- Combined - combining several types of coolant

In Moscow and the Moscow Region, the most common type of heating is the use of water heating systems. We will dwell on them in more detail.

Do-it-yourself polypropylene heating in a private house

For a private house, the most optimal choice would be a two-pipe system scheme. From the point of view of aesthetics, it is better to make a closed version of the arrangement of the system, but it is technically difficult to hide the pipes in the wall.

The development of a heating scheme from polypropylene pipes also includes a heat source for a private house. The boiler can be solid fuel, gas or electric. It is the electric ones that are considered the safest - if you plan to construct a heating circuit from polypropylene pipes with your own hands, it is better to choose this option. A solid fuel boiler is difficult to maintain, and connecting heating pipes to it requires special skills - for this it is better to invite professionals. And connecting to a gas boiler makes sense if gas is supplied to the house.

It matters which circulation method is chosen for the home heating system. There is a pumping and gravity circulation system. In the first case, the supply and circulation of water in the system will occur due to the operation of the pump. If gravitational (natural) circulation is used, it is imperative to install an air vent and an expansion tank, which serves to protect against pressure surges. If the heating scheme involves an upper wiring, these elements of the system are installed in the attic of the house.

Important! As for the operation of the heating system, it is important to have the correct arrangement of the booster manifold (branch pipe) - the vertical section of the pipe connected to the heating boiler. Which polypropylene pipe should be chosen for the booster heating manifold will determine the diameter of the rest of the structure: with a main pipe of 32 mm, the diameter of the nozzle will be at least 40 mm

The gravitational (natural) heating system made of durable polypropylene is very simple and quite durable, its device does not require additional costs for pumping equipment. But the gravitational system also has some drawbacks, including a limited range (less than 30 m) and a long time to be put into operation.

For a large house, you need to install a forced circulation system, but it will need more consumables

The gravity system can be chosen for a small private house, provided that the expansion tank is located in a relatively warm room (to prevent water from freezing in it).

The heating system radiator is connected to polypropylene pipes in the following ways:

The diagonal scheme involves connecting the supply pipe to the upper pipe, connecting the outlet pipe to the lower radiator pipe. It is noteworthy that the heat loss with this method does not exceed 2%. The diagonal connection is used for extended circuits (10-12 radiators). With the lateral type of connection, both the supply and the outlet pipes are on the same side of the radiator: the inlet is at the top, and the outlet is at the bottom. This method is very effective and is often used in apartment buildings. The lower scheme ("Leningrad"), in which the radiator is connected according to the "bottom-bottom" principle, is not recommended for multi-storey buildings, but it is acceptable for autonomous ones. The bottom routing can be hidden in the floor if necessary.

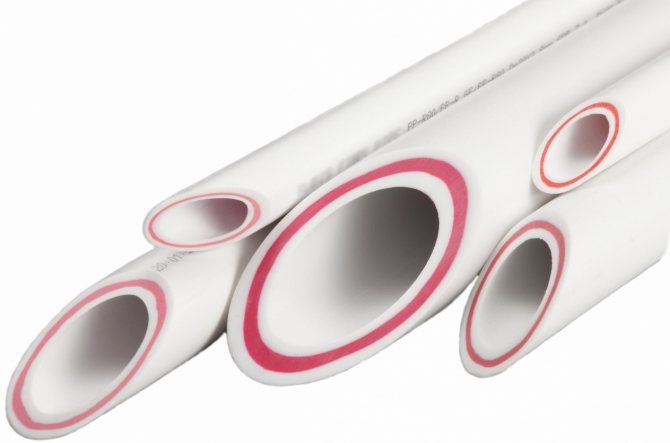

Based on the information provided, the answer to the question "Is it possible to use polypropylene pipes for the installation of a heating system" will be quite unambiguous. PPR products are not only a budget, but also a completely reliable option. In the rating of polypropylene pipes for modern heating systems, reinforced products occupy a special place, and just such structures will be the best choice.

Calculation of the home heating system

In order to be exactly sure that the heating system of your cottage will function correctly, it is necessary to carry out the design. But if the cottage is small, then the design can be omitted. In this case, it is necessary to carry out an engineering calculation of heat losses.

The essence of the calculation is reduced to determining the required thermal power. It characterizes the amount of heat that must be transferred to each heated room in the cottage. The required heat output corresponds to the heat loss. Heat loss - the amount of heat that leaves a country house through its enclosing structures (thermal circuit).

Calculation of heat losses is carried out for each individual room and cottage as a whole. On its basis, a heating boiler is selected, and radiators or other heating devices are selected.

There is a simplified technique that allows you to calculate the approximate thermal power required for each room in a country house. To do this, the area of the room is multiplied by 100-130 W (depending on how many external walls there are). However, this method gives approximate results that do not take into account a number of factors.

There are special formulas for precise calculation. First, the thermal resistance R is determined (in m2 * C / W). It is equal to the ratio of the thickness of the protective structures (in meters) to their thermal conductivity. This is a tabular value.

| Material | Thickness | R |

| Brick | 0.8 m | 0,6 |

| 0.7 m | 0,5 | |

| 0.6 m | 0,4 | |

| 0.3 m | 0,2 | |

| Log | 0.3 m | 0,6 |

| 0.2 m | 0,5 | |

| Beams | 0.2 m | 0,8 |

| 0.1 m | 0,4 | |

| Insulated frame | 0.2 m | 0,7 |

| Foam concrete | 0.3 m | 0,7 |

| 0.2 m | 0,5 | |

| Plaster | 0,03 | 0,04 |

| Ceiling or attic floor | 1,4 | |

| Wooden floor | 1,9 | |

| Wooden double door | 0,2 | |

After that, the formula is applied to calculate the amount of heat loss (in watts) that occur through the heat circuit:

Q = S * (Tvn-Tnar) / R

S - area of the heated room,

Tvn - required room temperature,

Tнр is the minimum outdoor temperature during the coldest period of the year.

Heat energy is also consumed through ventilation (both natural and forced). Its amount is calculated using the following formula:

Q = c * m * (Tvn-Tnar)

m is the mass of air in rooms (the product of the total volume of rooms and the density of air, c is its heat capacity, which is 0.28 W / kg * C).

To calculate the required total heat output, it is necessary to add the amount of heat loss through the walls, floor, roof and through the ventilation. The resulting amount is multiplied by a factor of 1.3.

In addition to the thermal calculation, a hydraulic calculation can also be performed. It serves as the basis for the selection of pipe diameters and parameters of pumping groups. This calculation is part of the heating project.

Varieties of flexible chimneys

The flexible corrugated chimney is divided into two types depending on the material from which it is made: aluminum or steel.

Chimney made of aluminum corrugation

Previously, for chimneys, pipes made of aluminum multilayer corrugation with a diameter of 10 to 15 centimeters, made of laminated foil, were used everywhere. It is a durable and inexpensive material.

But for fireplaces and boilers operating on solid fuel, such a pipe is not suitable, since it does not withstand high temperatures. Moreover, at present even gas workers do not recommend using it for the corresponding boilers and columns. The reason lies in the fact that when heated, the walls are deformed and there is a danger of fire.

It is interesting! In some regions, the use of aluminum corrugations is prohibited by law. This decision was made due to the fact that often burned out sleeves occurred, and, as a result, gas poisoning of people who were in the room.

Stainless steel chimney

The construction of chimneys made of stainless steel is the same as for aluminum pipes. However, the technical characteristics of stainless steel are significantly different. Chimneys made of stainless steel are capable of operating in systems operating on liquid and solid fuels, at temperatures reaching 900 degrees, and effectively cope with the removal of combustion products.

We recommend that you familiarize yourself with: Features of the production and use of ceramic sewer pipes

Flexible chimneys made of steel are used for different types of columns, boilers, boilers and fireplaces due to their excellent tightness and heat resistance.

But high security goes hand in hand with a high price. It is approximately three times higher than the cost of aluminum chimneys. When choosing a steel corrugation for arranging a chimney, you need to choose only certified products. Service life is also important. For example, Lex Flex corrugations last at least 40 years.

Note! If funds permit, it is preferable to use a steel corrugated chimney, as it has improved characteristics compared to an aluminum chimney.

Heating medium circulation

Depending on the method of moving the coolant through the pipes, the heating of the house can be designed in two ways:

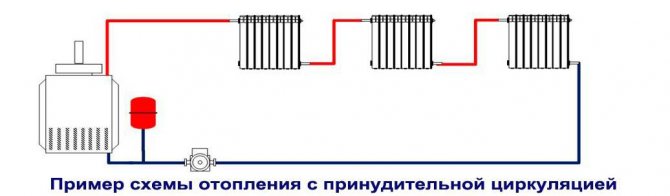

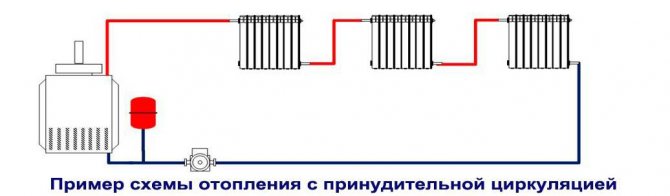

Option with forced circulation of the coolant

For a heating circuit of a private house with forced circulation, a circulation pump must be installed in the heating system. It provides the movement of the heated liquid through the pipes to the radiators. In this case, no slope of the lines is required. When radiators are installed in the system, it is necessary to install Mayevsky taps on them to displace air locks. The cooled heat carrier is fed back to the boiler room through the return loop.

The advantages of the option with forced movement of the coolant are:

- High speed of movement of the coolant. As a result, the liquid in the return loop practically does not cool down. This allows you to optimize the use of fuel or electricity (depending on the type of boiler)

- The ability to adjust the temperature regime of each of the heating devices

- Minimization of the internal cross-section of pipes without reducing the resistance of the medium in the lines

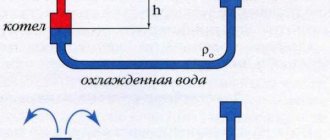

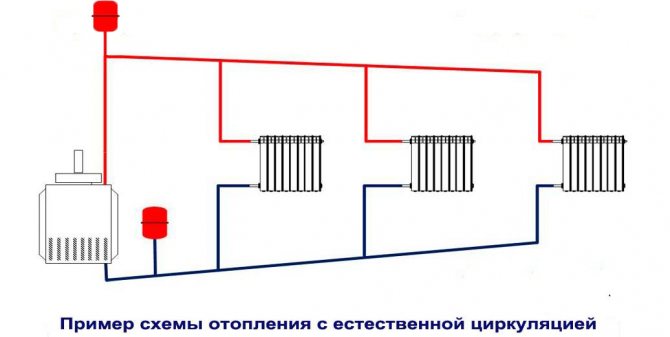

Version with natural circulation of the heating medium

Other used names for this system, built on the basis of this option, are gravitational, convective. Heating a private house with natural circulation of the coolant - an economical option

The principle of operation is as follows. When heated, the density of the water decreases. Therefore, the hot water in the supply circuit is forced upward by the heavier chilled water in the return circuit.

To prevent water hammer due to an increase in volume (and, as a result, the pressure of the coolant in the system), an expansion tank is installed in the upper part of the system. As a result, more heated layers enter the radiators, and the cooled coolant enters the boiler along the return circuit.

In addition to the convection principle, the gravitational principle also works in this heating scheme for a private cottage. For this, a slight slope is made in the incoming circuit from the riser to the heating devices, enhancing the movement of the coolant by gravity. Accordingly, the return circuit provides for a slope towards the boiler.

This method has few advantages:

- Low price

- No circulation pump needed, which needs power supply. This allows a heating system independent of electricity (provided that a suitable boiler is used)

The main disadvantages of such a heating system are that the circuit with natural circulation of the coolant has a low level of comfort and reliability.

Features of installing corrugated steel pipes for heating

The process of installing a corrugated stainless steel pipe for heating has some nuances. First, do not abuse the ability of the product to bend: multiple bending in the same place will sooner or later lead to cracks and leaks. The flexibility of the material has a certain norm, so, having given the desired shape to the pipe once, it is not worth changing its configuration.

Installation of a stainless steel corrugated pipe for heating resembles the method of connecting pipeline elements using compression fittings. The difference is that there is no union in the corrugated fittings. Crimping occurs due to the internal gasket of the fitting. Before operating the system, it is necessary to supply water as part of a test to determine if there is a leak at the joints.

The stainless steel corrugated pipe is a progressive solution for arranging a home heating system. Provided that the installation work is carried out correctly and the quality of the component materials and the pipe itself, the corrugated metal will be strong and wear-resistant.

Methods for laying heating pipelines

In the heating system of a cottage, pipes can be laid in two ways:

Open way of laying

In this case, they are laid along the walls, parallel to the skirting boards. Throughout their entire length, they are in sight.

The advantages of this method:

- Access to pipes without dismantling structures

- Low heat loss

- Simple heating installation

Main disadvantages:

- The pipeline often spoils the appearance of the premises, does not fit into the design

- In order to avoid sagging and deformation, not all types of pipes can be used.

Hidden way of laying

The pipe is walled up in the wall, in the floor, or decorated with external material.

The main advantages of hidden pipelines:

- The ability to hide the highways so that they do not spoil the interior

- The ability to use pipes made of modern materials

Among the disadvantages are:

- Access to pipes is difficult if necessary for their possible repair, replacement of individual sections, elimination of emergency situations

- Due to the high heat losses of the line, it is necessary to insulate

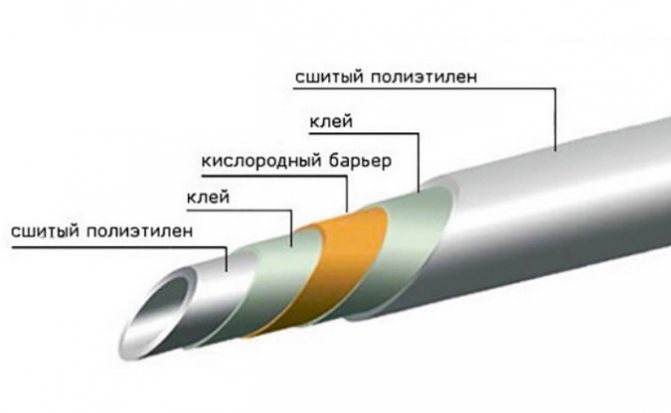

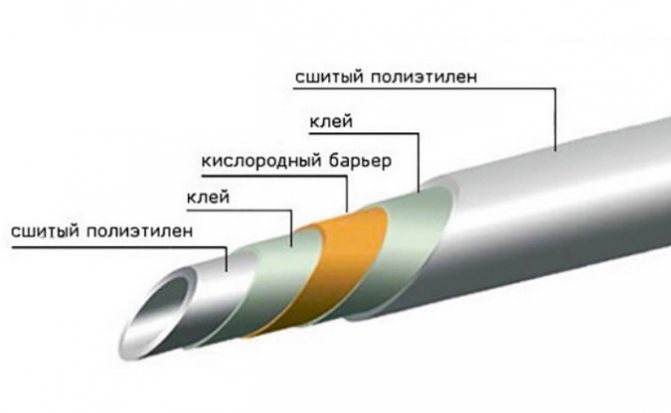

When routing in a covert manner, only reliable and proven pipes should be used. The best option is cross-linked polyethylene pipes.

Filling the coolant with this method must be performed only after a hydraulic test of the heating system.

Advantages of polyethylene pipes for heating

Cross-linked polyethylene pipes have a large number of advantages, thanks to which they stand out from the general group of pipes used for the installation of heating systems. Of the most significant advantages, the following can be distinguished:

- High temperature resistance and excellent strength characteristics... Unlike polypropylene and conventional polyethylene pipes for heating, the new material will not change its shape when exposed to high temperatures.

- Resistance to the formation of foci of corrosion... Compared to copper products, XLPE pipes do not corrode. Moreover, this process does not occur either within the structure of the material or on the surface.

- No build-up inside the pipes... The inner walls of PEX pipes are not covered with layers after transporting any aggressive medium. This makes them different from most steel pipes, which after a certain period of time become less productive due to a decrease in flow velocity.

- Restoration of the previous form... Many pipes lose their shape as a result of certain mechanical influences. However, XLPE pipes can expand or contract to certain parameters when exposed to low temperature or mechanical stress.

- Low weight... The light weight of the material makes it more convenient to transport XLPE pipes and facilitates the installation process.

- Easy installation and great possibilities... PEX pipes can be laid in any pattern, including kinking or a large number of bends. Connecting with fittings simplifies the installation process, as it eliminates the need for welding equipment, soldering and gluing.

- Environmental Safety... Cross-linked polyethylene belongs to the group of environmentally friendly materials, therefore, PEX pipes can be used to transport clean drinking water.

However, such pipes cannot be called completely flawless due to the presence of some shortcomings.

Basic rules for the installation of heating pipelines

It must be remembered that the routing of pipelines is carried out after all the heating devices are installed in the selected places. The optimal assembly sequence is as follows:

Marking the passage of heating pipes

It is better to do this in advance, before installation. In the process of marking, as a rule, installation difficulties are revealed, which are caused by the architectural and construction features of the cottage. Knowing them, you can prepare in advance for their solution or change the paths of the routes.

Most often, the marks of the passage of highways are applied to the walls. In some cases, they can be performed on the floor, but in this case they can be overwritten by people passing through the premises.

Making the necessary technological holes and strobes

It is also better to complete this stage in advance on the entire front of the work. The locations of the necessary holes and the passage of the strobes are determined during the marking.

The grooves can be cut with a chasing cutter. If this tool is not there, then they are first marked with a grinder, and then hollowed out with a perforator.

Thermal insulation of pipes

This must be done if you are routing hidden. The main purpose of insulation is to prevent heat loss and increase the efficiency of the system as a whole.

Insulation is carried out with a special heat insulator, which is made for the diameter of the pipes. It is put on the pipes by hand, at the installation site.The most effective and durable is a rubber-based heat insulator. But its price is also higher in comparison with analogues.

Laying and fixing pipes on building structures

Pipes must be secured not only with open, but also with hidden wiring of the heating system of a private cottage.

With open wiring, the pipes are attached to the walls with special clips. Self-tapping screws or nails are used as fasteners (depending on the material of the walls).

If hidden wiring is performed, then the pipes are fixed to the wall in grooves or to the floor with special clamps or punched tape. If the line consists of several pipes, for example, coming from the collector, then they must be fastened into loops. The fasteners that are used in this case are the same.

Connection to heating devices

Depending on the design of the radiator, pipes can be connected to it either directly or by means of a multiflex. In any case, for connection, the connecting fittings are used, which are supplied in the kit.

With collector wiring in the heating system of a private house, the connection is made not only to heating devices, but also to floor collectors. As in the previous case, the connection is carried out with complete connecting fittings.

Hydraulic and pneumatic tests

This is a necessary part of the installation work. During their implementation, the system is filled with water or air. Then, with the help of a special pump or compressor, an excess pressure is created in it (~ 1.5 workers when tested with water). An hour later, the results are taken - there should be no pressure drop.

If during the test there is a drop in pressure in the system, then leaks are identified. Then work is done to eliminate the causes of the leak. After that, the hydraulic tests of the system are carried out again.

Sealing holes

Pouring the floor screed and sealing the grooves with hidden pipe laying should be performed only after successful hydraulic tests. These are general construction works. The sealing of the chase is usually done by hand, most often with plaster.

"Classic" metal-plastic pipes for a private house.

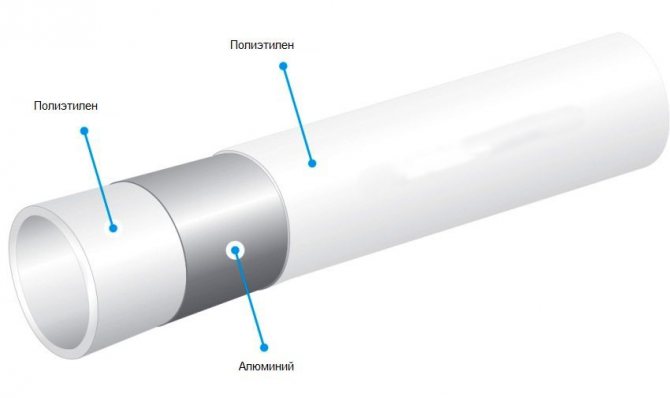

Metal-plastic has replaced the "good old" pipes made of black steel as a result of attempts to simplify installation, abandoning welding, which requires certain qualifications from the installer, and the desire to use lightweight, sufficiently strong and well-formed aluminum as a pipe material, while a chemically more active metal it was necessary to isolate from the liquid flowing through the pipe with a layer of plastic. The main one is an aluminum pipe that retains its shape and withstands the required pressure and temperature, the inner insulating layer is made of high temperature resistant polyethylene (PERT) or cross-linked polyethylene (PEX). Outside, the aluminum tube is covered with a decorative layer of the same white plastic.

By the method of connections, this type of pipelines can be divided into 2 types - using collet threaded connections and a system with pressfitting.

Collet connections.

These fittings consist of an inner part that is inserted into the pipe and equipped with rubber seals, a collet (for example, a split ring) located on the outer wall of the pipe around the inner part, and an outer nut with an inner cone that compresses the collet around the pipe, squeezing the pipe on the inner parts of the fitting. Temperature differences (hot pipes during the heating season, cold in summer) and micro-vibrations can loosen the nut tightening, therefore it is recommended to periodically check and tighten such connections. Over time, the nut may be pulled to the end of the thread and it will no longer be possible to tighten the leaking fitting.

Advantages:

- easy to assemble;

- pipes without connections can be walled up in a screed or walls of a country house;

- installation does not require a special expensive tool, the nut is tightened with an ordinary wrench.

Disadvantages:

- connections require periodic inspection and tightening, a complete replacement of connections may be required;

- rubber seals lose their elasticity over time and can cause the joint to leak;

- due to the possible appearance of leaks in the joints, it is not recommended to brick the fittings into the screed and walls;

- when using ethylene glycol-containing (non-freezing) liquids in the heating system, the service life of rubber seals is sharply reduced;

- connections are critical to the quality of installation - the possibility in the process of damaging or moving the rubber sealing rings, overtightening or not tightening the compression nut.

Press fittings.

As with push-in couplings, press fittings for multilayer pipes are fitted with rubber O-rings on the inside. The outer part of the joint is a deformable thin-walled steel skirt, which, when installed with a special tool, is crushed with specially shaped jaws towards the center of the pipe (radial pressing), thus squeezing the pipe around the rubber seals.

Advantages:

- easy enough to mount;

- you can do hidden wiring of pipelines in a private house (it is advisable to make connections outside);

- correctly assembled connections are more reliable and durable than collet;

- suitable for replacing collet fittings.

Disadvantages:

- rubber seals in the heating system lose elasticity over time and can cause a leak in the connection;

- it is not recommended to brick fittings into a screed or walls of a country house;

- when using ethylene glycol-containing (non-freezing) liquids in the heating system, the service life of rubber seals is sharply reduced;

- installation requires a special expensive crimping tool;

- the system is critical to the quality of installation - the possibility of damaging the rubber sealing rings, the need to control the evenness of the pipe cut and pushing the pipe onto the fitting;

- high cost in comparison with collet connections.

Collector (beam, fan) heating circuit

With manifold wiring, each heater is connected to the manifold with two lines - supply and return.

The main advantage of collector heating is that the circuit allows you to regulate the temperature of the coolant on each specific heating device or in each of the circuits in the water underfloor heating system.

When using heating pipelines made of modern materials (for example, cross-linked polyethylene or metal-plastic), there are no pipe joints between the collectors and the heating devices. This increases the reliability of the system. In this case, do not worry about the formation of leaks in the cavities. The collector circuit for heating a private house is carried out only in a hidden way. In cottages, this type of wiring is in demand more than others.

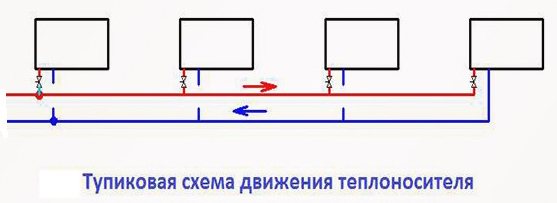

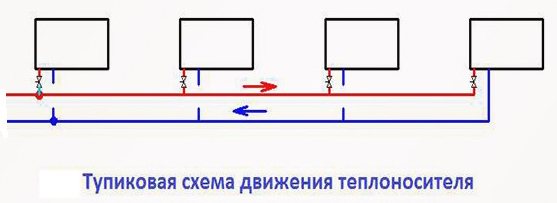

Two-pipe scheme

Heating a house with a two-pipe scheme involves connecting radiators in series. At the same time, the lines are common for all heating devices.

There are two options for implementing a two-pipe system:

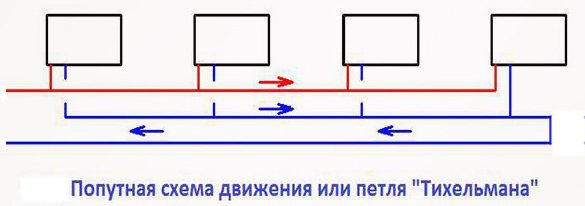

Twin-pipe passing (Tichelman loop)

The movement of the coolant in the forward and reverse circuits occurs in the same direction. The return loop starts with the first radiator and the feed ends with the last one. The correct movement of the coolant is organized by selecting the diameter of the pipelines. Using the Tichelman loop, you can achieve uniform heating of the premises.

Double-pipe dead-end

It differs from the previous type in the multidirectional movement of the coolant in the forward and reverse circuits and consists of several branches (arms). The last heatsink in each branch is a dead end. The return circuit begins from this radiator.

A two-pipe dead-end heating system is more difficult to implement than a passing one. Careful calculation of the hydraulic component of the system is necessary. In addition, it is necessary to observe the equality of the load on each shoulder. It is recommended to equip each arm with no more than five heating devices.

The advantages of two-pipe systems are low selling price and reliability of operation (in comparison with one-pipe systems).

Among the shortcomings, one can single out - the need for a large number of heating pipe connections. This significantly reduces the reliability of the system, and is especially critical with hidden laying.

In addition, there is no possibility of individual adjustment of each heater separately, which often does not allow setting the required temperature in a particular room.

With two-pipe wiring, the lines can be laid, both open and hidden. In the first case, copper or polypropylene pipes are usually used, in the second - from cross-linked polyethylene. Cross-linked polyethylene is used due to the increased reliability of the pipe-to-fitting connection.

Copper piping for a private house.

Copper is a long-lived metal both in the entire history of mankind and in the history of the existence of pipelines. For a very long time, copper has been used in plumbing systems, but in the modern world, copper pipes can be found in a variety of systems and devices.

For heating and water supply systems, annealed and unannealed copper pipes are used. Omitting other technical details, these two types of copper pipes differ in their rigidity - unannealed rigid pipes are supplied with straight rods, usually 5 m long, annealed pipes are plastic and are supplied twisted into coils.

The most commonly used connections in copper piping are capillary brazing fittings or crimp press fittings.

Soldered connections.

The connections are assembled with a gas burner and suitable solder. The pre-processed end of the pipe is inserted into the socket of the fitting, after which the place of the future connection is heated by a burner, solder is supplied to the heated surface, due to the capillary effect flowing into the space between the outer wall of the pipe and the inner wall of the fitting. Since the connection point is heated by the open flame of the burner, immediately after installation, the connections look very unaesthetic.

Advantages:

- a reliable sealed connection will last for many years;

- the use of non-freezing liquids does not affect the service life of the connections;

- pipes and connections are not sensitive to high temperature conditions (for example, steam heating) and possible overheating in heating systems.

Disadvantages:

- the connections are critical to the quality of the installation and must be carried out by a qualified, experienced installer;

- with open wiring, the unprotected surface of the pipes can oxidize over time and lose its presentable appearance;

- local pipeline repair can be difficult due to the need to use an open flame;

- when using aluminum radiators in a heating system with copper pipelines, electrochemical corrosion may occur (copper and aluminum form a galvanic pair);

- the cost of pipes, fittings and installation work is one of the highest.

Copper press fittings.

By analogy with press fittings for multilayer pipes, radial pressing is used in the installation of copper press fittings. The fitting contains rubber-like polymer O-rings in special grooves.The jaws of the crimping tool evenly puncture the material of the fitting and the pipe, forming a strong mechanical connection.

Advantages:

- the use of non-freezing liquids does not affect the service life of the connections;

- pipes and connections are not sensitive to high temperature modes (for example, steam heating) and possible overheating in heating systems;

- high installation speed compared to soldering joints.

Disadvantages:

- with open wiring, the unprotected surface of the pipes can oxidize over time and lose its presentable appearance;

- installation requires a special expensive crimping tool;

- when using aluminum radiators in a heating system with copper pipelines, electrochemical corrosion may occur (copper and aluminum form a galvanic pair);

- the highest cost of pipes and fittings.

One-pipe scheme ("Leningrad")

One-pipe heating distribution is an outdated scheme, but sometimes it is still used. It uses one pipe, forming an annular contour. Radiators are connected in series to this pipe. Through this pipe, the coolant is supplied to the radiators and through it it goes back to the boiler.

The only plus of "Leningrad" is its low price. A significant drawback is the different temperature of the coolant in the radiators. The radiators farthest from the boiler do not heat up sufficiently. For heating in private houses in today's realities, the Leningrad scheme is practically not used precisely because of this.

Heating pipe materials

When developing a system, depending on the method of laying pipes, their material is selected. This is due to its thermal expansion and flexibility.

For example, steel pipes can be installed both inside and outside. It is recommended to lay cross-linked polyethylene and metal-plastic in a hidden way. An open way of laying them is undesirable, since the aesthetics of the interior is disturbed due to significant sagging. It is advisable to lay polypropylene lines openly. Otherwise, possible leaks at the joints may not be detected in time.

Next, we will take a closer look at the main types of heating pipelines and list their main advantages and disadvantages.

Crosslinked polyethylene

Modern technologies for the manufacture of pipes from this material make it possible to achieve high consumer properties. The pipes produced by cross-linking methods are marked with PEX.

Leading manufacturers of XLPE pipes produce press fittings for them. They are crimped using a special tool. The resulting compounds are highly durable.

Benefits:

- Flexibility, tensile strength, the ability to return to its original state even with severe deformation

- Ability to withstand high pressure - up to 10-12 atmospheres

- Simple installation of heating, when using these pipes

- Resistant to high temperatures and aggressive environments

Disadvantages:

- UV Vulnerability

- The softness of the coating (this can lead to the fact that the walls of the pipes will be eaten by mice and rats). This is also why such pipes are used mainly in internal communications. It is recommended to lay them in the ground in metal shells.

- XLPE pipes and fittings are relatively expensive

- The high cost of a tool for joining a pipe to a fitting

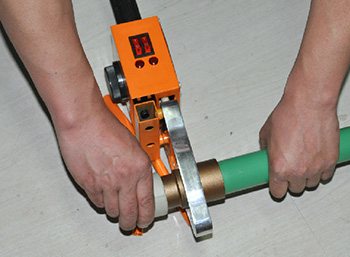

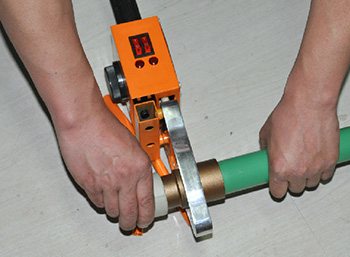

Polypropylene

It is a lightweight material derived from petroleum products. Both the pipes themselves and the fittings are made from it. Pipes are connected to each other by soldering fittings.

Benefits:

- Low price

- Resistant to aggressive chemicals

- Ease of assembly

- Low price of tool for soldering connections

Disadvantages:

- Deterioration of properties due to exposure to sunlight

- Flammability

- Criticality to high (above 70 degrees C) coolant temperature

- Low durability

Installation of heating in a private house, using polypropylene pipes, is used for open laying of an internal heating system.

Modern polypropylene pipes are reinforced in order to improve their consumer qualities and reliability. Reinforcement materials - fiberglass or aluminum. The best option for heating is fiberglass-reinforced polypropylene.

Metalloplast

The name of the material reflects its structure. It consists of layers of polyethylene, aluminum and an adhesive layer. Pipes made from this material are used with brass fittings.

Benefits:

- High strength

- Durability

- Resistant to high temperatures, sunlight and aggressive environments

- Flexibility

- Ease of mounting metal-plastic pipes

Disadvantages:

- Poor resistance to system pressure

- Relatively high cost

- Thermal deformation tendency

- Delamination when exceeding the maximum allowable pressure

- High cost and non-versatility of the tool for working with material

Heating in a private house with metal-plastic pipes is used mainly for internal laying.

Steel

This material is traditionally used for the manufacture of heating pipes. Until recently, almost all pipes for space heating were made only from this material. The mains are connected by a welded method or by means of threaded fittings.

Benefits:

- High strength, resistance to mechanical stress

- Ability to withstand any temperature and pressure of the coolant

- Low price

- Low coefficient of thermal expansion

Disadvantages:

- Time-consuming and complex installation of heating in a private house on these pipes

- Lack of flexibility

- Corrosion susceptibility

- Internal "overgrowth"

- The service life (in comparison with modern materials) is relatively low - up to 15-20 years, depending on the operating conditions.

Copper

Heating systems built on copper pipes are rare. The reason is the high price of such pipelines.

Benefits:

- High strength, resistance to mechanical stress, high temperature and pressure

- Long service life

- No corrosion

- Aesthetics (with open padding)

Disadvantages:

- High material price

- Criticality to the presence of impurities in the coolant and to its composition

- Time-consuming heating installation in the house

- Negative galvanic processes when docking with some materials

It should be remembered that it is not permissible to install copper pipes in front of steel pipes and radiators. This leads to negative galvanic processes. To avoid this, it is necessary to lay copper pipes after the steel sections along the flow of the coolant or to make a galvanic gasket from a neutral material (for example, bronze, brass).

Stainless steel

Heating a house from stainless steel pipes is significantly more expensive, but they are devoid of one of the main drawbacks - susceptibility to corrosion. As a result, stainless steel pipes last much longer and can be used in almost any heating system. But their cost is very high and they are used in very rare cases.

Bellows pipes

They are corrugated stainless steel flexible hoses. They are not often used in heating systems. Sometimes they act as inlets to radiators or convectors, if the use of ordinary pipes for this purpose is difficult for some reason.

Production of corrugated stainless steel pipes for heating

The production of corrugated metal pipes is a responsible process, therefore each stage is fully automated. The stainless steel sheet takes a cylindrical shape when passing through the forming conveyor, after which a seam is welded to the workpiece.

The ribbed structure of the pipe is ensured by rolling with special rollers

The ribbed texture is imparted during the rolling procedure by rollers of various sizes. The elasticity of the corrugation is given by processing at high temperatures. The bulk of the corrugation is produced in South Korea. Most often, products from the following brands are on sale:

- Lavita. Lavita is a manufacturer of corrugated stainless steel pipes for heating, which sells its products at fairly reasonable prices. There are complaints about the strength of the pipe walls: when tightening the O-ring of the fitting, sometimes the stainless steel cuts through, which causes leaks. True, this shortcoming can be attributed to the consequences of illiterate editing.

- Kofulso. A stainless steel corrugated pipe for heating manufactured by Cofulso is considered to be the standard among other analogues. True, its cost will be several times higher than the prices for pipes of the previous brand. Fittings for connecting these pipe models have special thickened O-rings, which contributes to the best quality of installation.

- Hydrosta. The pricing policy of the Hydrosta company is close to the cost of products from Lavit, that is, it belongs to the budget segment. But there is evidence that these pipes often have a factory defect. Leakage of fittings occurs on average in 7 cases out of 100, and regardless of the degree of professionalism of the installation.

- Meibes. The quality of products from Meibas is at a good level. But the cost of their corrugation is considered unreasonably high.

High temperature and pressure in the heating system require the use of high-quality pipes, so you need to choose products from well-known companies

Heating devices

Various types of heating devices can be used for water heating in a house - radiators, convectors, registers, underfloor heating. We will tell you more about each of these devices below.

Radiators

The most common heating devices are radiators. They may differ in the number of sections (in addition, there are non-sectional radiators) and material. The larger the frontal surface area, the more heat the device generates.

Radiators are divided into the following types:

- Steel

- Panel

- Tubular

- Bimetallic sectional

- Aluminum sectional

- Cast iron

They can have the following connection type:

- Lower

- Lateral

- Diagonal

Convectors

In addition to radiators, home heating can be done with water convectors. Their principle of operation is based on the fact that heated air rises upward, displacing cold air. This phenomenon is called convection, hence the name of this device. As a rule, convectors are installed under windows. The warm air coming up from them creates a "curtain" that blocks the flow of cold air from outside.

By their location, convectors can be:

- Wall mounted

- Floor standing

- Embedded

Wall-mounted appliances are attached to the wall using special brackets. They have a small mass, therefore, unlike radiators, they can be installed even on plasterboard partitions.

Floor convectors are mounted on the floor using the legs supplied. They are small in size, but have high heat dissipation.

Built-in convectors are installed in a niche under the floor. The grill at the top of the appliance is flush with the floor. In some cases, this lattice is decorated to match the style of the interior.

By the type of convection, convectors can be divided into devices:

- Natural convection

- Forced convection

In the first case, streams of warm air flow upward, cold air flows downward due to the difference in density, where, in turn, they are heated by the converter. Further, this process occurs cyclically, in a natural way.

In models with forced convection, electric fans are built into the devices.Due to the operation of the fans, the convection process is accelerated, the heat transfer is increased.

Convectors, as a rule, look more aesthetically pleasing than radiators, and built-in ones are not visible at all (except for the grille). Therefore, they are often installed when design is of great importance. They are also used where traditional radiators cannot be used, for example:

- In front of the glass doors of the balconies

- With "low windows"

Convectors are often used not only for heating living quarters, but also in swimming pools and winter gardens.

Polypropylene pipelines for a private house.

If we recall a little the school course in organic chemistry, it becomes clear that the material of these pipelines is based on a slightly more complex hydrocarbon, and accordingly the internal structure of this polymer is different. Due to this, polypropylene pipes, unlike polyethylene pipes, are quite rigid and fragile to break (they cannot be bent in the same way as ordinary metal-plastic), as a result of which any turns and pipe bends are realized using a wide range of fittings (angles, tees, contours).

Polypropylene pipes are produced with different wall thicknesses, designed for operation in heating systems with different working pressures:

- thin-walled - designed for pressures up to 10 atm. and are intended mainly for use in cold water supply systems;

- thick-walled - maximum working pressure is 16 atm. or 20 atm., different manufacturers indicate this or that pressure for almost identical pipes; are used mainly in hot water supply systems, sometimes in heating systems, which, in principle, is not entirely correct;

- thick-walled reinforced - the wall thickness of such pipes is approximately the same as that of ordinary thick-walled ones, but in addition they are reinforced with a layer of aluminum foil, most often perforated, and are designed for pressures up to 25 atm.; just these pipes are intended for use in heating systems.

The installation of the connections is carried out by strong heating with a special tool (in common parlance "a soldering iron", the process itself is accordingly called soldering) of the end of the pipe and the inner surface of the fitting, after which the pipe is inserted into the fitting, the preheated plastic cools and polymerizes, forming a strong connection. A properly assembled fitting forms a single polymer monolith with the pipe. However, the seeming simplicity of installation should not be misleading - an inexperienced installer can overheat the parts on the "soldering iron", underheat them, overexpose them in the air, "aiming" when connecting, and involuntarily cool unnecessarily, skew the parts relative to each other when connecting. Each of these possible oversights most often leads to problems: when overheated, the pipe wall inserted into the fitting can bend inward or become "chamomile" (this problem especially concerns thin-walled pipes) and significantly narrow the inner bore diameter, thereby significantly impeding the flow of liquid; underheating or skewing during the installation process can lead to the fact that the material of the pipe and fitting fusion unevenly, perhaps not over the entire contact surface, as a result, the connection can leak or even fall apart.

To complete the description, we note that on the modern market there are polypropylene pipes and fittings of different colors - white, gray shade lighter and darker, green, blue, and among some installers there are beliefs that pipelines of a certain color (moreover, of a color, and not of a specific brand) better or worse than analogs of other colors. In fact, the quality from manufacturer to manufacturer may vary slightly, and more depends on the quality of the source material, and what color the granules purchased by the plant - if it is plastic of proper quality, the color will not affect it in any way.The assortment of fittings produced by different factories may vary, but since the outer diameters of the pipes are standard, it is possible to use fittings from another manufacturer, as long as the color matches, if you are worried about the external aesthetics.

Advantages:

- monolithic connections without rubber seals;

- non-freezing liquids do not affect the service life of pipelines and connections;

- fairly simple installation using an inexpensive tool;

- low total cost, widespread distribution of pipes and fittings in retail trade.

Disadvantages:

- it is not recommended to brick the joints in a screed; it is desirable to have access to the joints;

- complicated installation of heating systems (for reinforced pipes, preliminary cleaning with an additional tool is required);

- connections are critical to the quality of the installation.

Registers

Another type of heating devices are registers. They are welded or assembled structures made of metal (usually steel) pipes. The pipes are connected to each other by jumpers through which the coolant circulates. Cottages are rarely heated by registers due to their unattractive appearance. Registers are used most often at industrial facilities.

Heating the house with underfloor heating

In recent years, water-heated floors have been gaining popularity. If the room is large, radiators do not always effectively heat the entire space, especially in the center of the room. In this case, in addition to radiators, it is advisable to install underfloor heating. The heated air rising from them fills the entire space evenly.

Materials (edit)

What pipes to use for heating? Let's take a look at the most popular materials in terms of suitability for the intended operating mode.

Steel

Steel pipes for heating began to be used from the very beginning of the use of pressure heating systems. Their undoubted advantages are the highest mechanical strength and heat resistance. The theoretically possible maximum - 25 atmospheres at 140C - is far from the limit of the capabilities of steel.

The traditional solution remains the most reliable today.

Clarification: in addition to the pipes, the possibilities of the circuit are determined by the heating devices and fittings used. As you might guess, the strength of the system as a whole is equal to the strength of its weakest link.

However, the classic solution has several disadvantages:

- Steel is subject to corrosion. Steel pipes for heating are designed for 15-25 years of operation, depending on the wall thickness.

- Over time, the inner surface becomes overgrown with limescale deposits, rust and clogged with sand (primarily in central heating systems).

- During installation, rigid pipes need to be precisely dimensioned. Each branch pipe must be manufactured with a tolerance of no more than 1-2 millimeters. The installation itself using threaded connections is quite laborious.

The first two disadvantages are completely devoid of galvanized steel pipes. The author had a chance to open galvanized heating pipes in stalinka after half a century of operation. The condition of the pipes was no different from the new ones.

Stainless steel

Stainless steel pipes for heating systems differ not only in the content of chromium in the melt. This is a fundamentally different material: stainless corrugated pipes with a wall thickness of 0.5 millimeters are bent at an arbitrary angle with a radius equal to their own diameter, and are connected with quick-release fittings with silicone high-temperature seals.

The maximum working pressure is 15 atmospheres, but the burst pressure exceeds 50. The permissible temperature is up to 150 C.

The only drawback of the material is the high price. A Korean stainless steel pipe for heating Kofulso costs about 200 rubles per running meter; German Rehau will cost 2-2.5 times more.

Corrugated stainless steel in the heating system.

Metal-plastic

Metal-polymer pipes for the heating system were actively used in our country in the 90s; now the enthusiasm has subsided. Three-layer XLPE and aluminum pipes are strong enough, but connections using compression fittings have a limited number of heating and cooling cycles. After two to three seasons, the connections begin to flow.

However: connections using press fittings are devoid of the described problem, but for assembly they require a special tool.

As a rule, the working pressure is limited to 12-15 atmospheres, the working temperature is 95 degrees. It is possible to use metal-polymer pipes without restrictions in autonomous systems, but for centralized heating, in the author's humble opinion, it is still better to prefer galvanized or stainless steel.

Polypropylene

For polypropylene pipes, most manufacturers declare an operating temperature of 90 - 95 C. Pressure - 20-25 atmospheres at 20 degrees; however, when heated to 90, it decreases to 6-7.

And these pipes for heating can be unambiguously recommended only for autonomous systems. They obviously will not survive a water hammer or long-term heating up to 140 C; the consequences of the complete destruction of the riser or eyeliner in the apartment, to put it mildly, are unpleasant.

Polypropylene is afraid of overheating.

There are two nuances associated with polypropylene that are useful for a potential buyer to know.

- For heating and hot water supply systems, pipes reinforced with aluminum or fiber are used. They are somewhat stronger and, more importantly, have a much lower coefficient of thermal expansion. Elongation of long straight sections of the circuit during heating can be a serious problem.

- Contrary to popular belief, ecoplast is not a material. Czech polypropylene pipes are produced under the Ecoplastic brand; products of quite decent quality, but the chemical composition is no different from competing solutions.

Cast iron

From it, the so-called economizers are made - ribbed cast iron products that provide a sufficiently large heat transfer with the highest mechanical strength.

The products are used, along with water, in steam heating systems and in chimney heat exchangers of enterprises. The method of connection with each other and with pipeline sections is flanges with paronite gaskets.

XLPE

With an operating pressure of 6-10 atmospheres and an operating temperature of up to 85-95 C, this material can definitely be recommended for autonomous heating systems. Typical applications are water underfloor heating or hidden radial distribution.

Flexible pipes of small diameter (like all plastics, polyethylene has a low coefficient of friction and does not overgrow with deposits) can be laid in a screed or masked with a false wall of drywall.

The warm floor is made with sewn polyethylene.

Other components of the heating system

Heating a house, in addition to pipelines and heating devices, may include the following elements.

Circulation pump

The circulation pump is used in schemes with forced movement of the coolant. A circulation pump is installed on the return pipe between the boiler and the nearest radiator located along this pipe.

Its principle of operation is as follows. The pump motor is driven by a rotating rotor. The pump begins to take the coolant from the circuit on one side, and on the other to push it through the pipes.

Expansion tank

It is a steel tank with two chambers inside. These chambers are separated by a membrane. One of them is intended for filling with water, the second is an air expansion joint.

Expansion tanks are installed in closed-type heating systems to compensate for possible water shocks.

Buffer capacity

Its purpose is a supply of heated coolant and ensuring the operation of the heating system for a certain time with the heat source turned off.

Heating in a house with solid fuel functions optimally when using this container. During the day, when a solid fuel boiler is operating, the coolant is heated in a buffer tank. And at night, the cottage can be heated from this container with an inoperative boiler, while the coolant has not cooled down.

Heat carrier

The main types of heat carriers in heating systems are water, various antifreezes and their mixtures in certain proportions.

Antifreeze is a liquid that is an aqueous solution of ethylene glycol, propylene glycol or potassium acetate with the addition of modifying additives. They lower its freezing point.

Heating a house using a coolant, to which special inhibitors are added, prevents oxidation, corrosion, and scale formation. Their content can be from fractions of a percent to 3-4% by weight.

Which coolant to choose is decided individually, depending on the situation. If the probability of failure of the boiler is small, there are no problems with fuel, it is better to use water. Many boiler manufacturers prohibit the use of antifreeze agents; there are frequent cases of refusal of guarantees on this basis.

Preparatory work

Before starting work on the installation of heating a private house, it is necessary to carry out preparatory work. Their goal is to reduce the possibility of downtime for the assembly team to a minimum during the production process. Preparatory work includes:

- Ensuring construction readiness - the heating circuit must be closed, the premises must be cleared of construction debris, there must be interfloor floors or logs

- Arrangement of niches for the installation of radiators and manifold cabinets - if necessary

- Preparation of the wall surface for the installation of radiators - preferably a fine finish

- Complete finishing of the boiler room

- Making all the necessary holes in the floors, making grooves and niches

Read other articles on this topic

| Private house heating project | How to heat your home without gas |

| The best heating for a private house | Water heating in a private house |

| Features of heating a country house with electricity | Autonomous heating of a private house |

| Heating a private house made of polypropylene with your own hands | Heating system installation: rules and description |

| Heating a house with liquefied gas | How to save on heating a country house |

| Collector heating system of a private house | Heating wiring for a two-story house |

| Heating a private house from metal-plastic pipes | Heating scheme for a two-story house |

| Installation of a heating system in a private house | Heating wiring diagrams from a boiler in a private house |

| Gas consumption for heating a private house - consumption calculation | Heating and water supply of a country house: a description of the installation technology |

| Heating system of a private house with natural circulation | Heating a private house with electricity |

| Heating options for a frame house | About heating schemes for a private house with a gas boiler |

Services on this subject

| Heating design | Turnkey solid fuel heating |

| Turnkey gas heating | Turnkey heating |

| Heating in a turnkey wooden house | Turnkey water heat-insulated floor |

| Installation of a water heated floor | Heating a two-story house |

| Heating installation in a cottage | Heating a country house: options and prices |

| Heating installation | Heating installation in a private house |

| Installation of engineering systems for water supply and heating | Diesel heating of a country house |

| Turnkey autonomous heating | Air heating of a country house |

| Prices for installation of heating in a private house | Design and installation of heating systems |

| Water heating in a private house | Electric heating of a country house: options and prices |

| Heating in a townhouse | Gas heating design |

| Heating design cost | Private house heating calculator |

| Installation of a water-heated floor in a private house | Price for installation of a water-heated floor |

| Installation of a water-heated floor on a wooden floor |

Varieties

To begin with, it must be said that there are many varieties of similar products, which have their own characteristics and properties. Along with this, they have their own areas of operation, for which they were created. But it is worth emphasizing that a typical installation instruction does not require the use of a certain type, but it is developed just for it.

Heating

- Much more often, iron products were used to install heating batteries, which do not have flexibility... But with the development of the latest technologies, flexible bronze pipes or metal-plastic products are used for these purposes. They allow you to create a montage in virtually arbitrary places and with different eyeliner.

- It should be emphasized that flexible pipes are not used in this area for water supply, because they cannot always withstand high temperatures in the system.... Based on this, for such cases, special materials created for heating are used.

- If all work on such an installation will be done by hand, then it is extremely important to pay attention to the connecting elements and the fact that bends are not allowed in this area... For approximately 20 centimeters, the assembly line should be straight before the joint is formed.

Advice! When choosing similar materials, you should pay attention to the products of popular manufacturers, which have already established themselves as important and high-quality pipe suppliers.

Insulated floors

There are flexible plumbing pipes designed for underfloor heating. They differ in the material of their manufacture and are made with the correct heat transfer in mind.

Such a heat-resistant flexible pipe is excellent at taking virtually any shape, in addition to forming a ring. These characteristics are deliberately created in order to reduce styling and uniform filling of the entire area of the room.

It is fundamentally important to mention that this type of material is used as a one-piece product. In most cases, the creation of connections is not allowed, because they will not act in places in the system, but because it is under a layer of concrete, then it is unacceptable to leave such areas.

Advice! Such products are sold in roll form, cutting off the piece required by the client. Based on this, experts recommend that you first make all the necessary calculations, and later buy goods with a small stock.

Plumbing and sewerage

In most cases, a flexible pipe for a water supply system has a multilayer structure and is much more often presented in the form of metal-plastic products. It should be emphasized that polyethylene systems do not belong to these types. They are not flexible enough to create even corners.

It is fundamentally important to emphasize that the price of such products is also possibly lower than that of simple plastic pipes. Along with this, the price of fittings and other elements for connecting pipes is much higher, because they have a complex structure and are composed of various parts.

There is also a flexible drainage pipe. It has a corrugated structure and is used to connect the main system to the points of consumption. These products are available in various shapes and diameters, depending on the application.

Advice! When creating sewer systems, they try not to use corrugated products. They are a source of waste collection and quite often it is they that congestion is formed. But there are such cases, at a time when you simply cannot do without them.