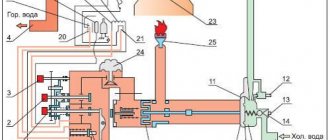

The reason that the gas water heater pops strongly when the water is turned on is that too much gas accumulates before ignition.

Ideally, the gas should mix with air in a certain proportion and then ignite. If more fuel has entered, or combustion products are mixed into it, then the flame breaks out with a loud unpleasant pop. To fix the breakdown, it is important to understand why this happens. All operations to repair the water heater must be carried out with the gas valve turned off.

Reason 1 - Poor cravings

The combustion products must be discharged through the chimney. When they are hot and there are no obstructions, it happens quickly. If carbon dioxide and steam have time to cool down, they can sink back into the column and contaminate the gas-air mixture.

Traction check

To check the intensity of the draft, you need to bring a burning match or lighter to the chimney hole (there are also special control holes for this in some models). The flame should actively deflect towards the water heater. If it stays in place, it indicates poor traction.

The main reason for poor draft is chimney clogging. Over time, soot accumulates in the chimney, which narrows the diameter of the pipes. Debris can also get into the chimney from above. If the blockage is small, you can remove it manually. If the chimney is clogged much higher up the riser, you need to call the utilities for cleaning.

Also, if an active hood with a fan is installed in the kitchen, then the exhaust gas can be drawn into it, in the place in order to go up. It is necessary to turn off the propeller when the water heater is running.

If metal-plastic windows are installed in the room and they are closed, then the lack of incoming air can interfere with the draft. For safety reasons, you should use a gas water heater only with an open window (or with a plastic window open for ventilation).

Why is cotton most common?

When turned on, cotton most often occurs in old-design columns, where there is a constantly burning wick. In the columns of the new generation, where the gas is automatically ignited, a malfunction occurs, but not so often.

So, a clap is heard due to the late ignition of gas in the burner, which has time to accumulate in large quantities. Therefore, when the gas finally ignites from the flame of the wick or from the spark of the ignition device, a loud bang is heard by the user. But such a situation is extremely dangerous if left unattended - over time, the gas-air mixture, before it ignites, will begin to fill part of the chimney, which is fraught with a serious explosion.

A serviceable column of any configuration should turn on without flames and pops, softly and quickly.

There are common causes of power-on pop that you can diagnose yourself and quickly fix.

Let's consider the most common reasons for such a nuisance in columns of all types:

- malfunction of the ignition retarder;

- insufficient supply of fresh air to the room;

- insufficient or no draft (in the chimney).

For columns with a wick, the most common breakdown is when the flame is in the wrong position in the ignition wick element.

For models with automatic ignition, the reason may be:

- incorrect position of the candle;

- malfunction of the microswitch;

- discharged power supply in the control unit.

Let's consider in more detail the main causes of cotton and the specifics of determining the source of the problem.

Reason # 1 - poor cravings

Combustion products are discharged through the chimney. This happens quickly, but if steam or carbon dioxide does not have time to cool down, they can fall back into the column and provoke contamination of the air and gas mixture. We also recommend that you familiarize yourself with the causes and ways of eliminating the back draft in the chimney.

In the presence of weak traction, the column often ignites with certain pops. Once you identify the cause of poor traction and eliminate it, excess noise will cease to bother

To check the draft, there is a special hole in the upper part of certain columns and boilers - a control hole. It is located on the casing. The check can be done simply: bring your hand to this hole, you should feel the pull. You can also use a match. Adequate thrust is determined by the deflection of the flame tongue from the vertical.

A similar operation can be performed using the hatch, which is equipped with the chimneys of gas boilers. If necessary, through the same hatch, you can clean and remove debris.

You can check the channel for the presence of debris using an ordinary mirror. It is stirred through the hatch inside the channel. If a gap is visible, then the channel is clear. And if there is no draft, then in this case the help of specialists will be required to remove the accumulated soot, which has become the reason for the narrowing of the pipe diameter.

Also, the reason for insufficient or lack of draft can be poor ventilation when there is no air flow into the room. Safety measures indicate that it is possible to use a gas water heater if the room is ventilated (open window, window on ventilation). Also, in such a situation, the installation of a supply valve in the wall or installation of the valve on plastic windows will help.

Reason # 2 - batteries are dead

If the batteries in a column with an automatic ignition system are dead, then a pop will appear when the water is turned on. The lack of electricity for the instantaneous generation of a spark provokes a crackling sound that is continuous. At this moment, the fuel accumulates in the working area, and when a spark occurs, there is a loud pop.

Dead batteries provoke a problem with the emergence of serious popping and popping when turning on the column. Therefore, the batteries must be replaced in a timely manner.

One of the main factors in determining this problem can be considered the presence of a characteristic crackling, which indicates that the ignition was not carried out. You can fix the problem by simply replacing the batteries.

Reason # 3 - nozzle contamination

Semi-automatic models equipped with a piezo ignition have a flame formation system from a wick.

If the jet gets clogged or starts to work incorrectly, the intensity of combustion of the wick becomes minimal - insufficient for timely ignition. To fix this problem, the jet just needs to be cleaned.

Cleaning the jet is done carefully, since damage to this element will require its replacement, and this is a rather time-consuming procedure

Cleaning the jet is a simple process. After removing the cover, the holes are simply cleaned with a thin and soft wire. You also need to check the position of this element. If necessary, move it a little closer to the burner.

Reason # 4 - clogged burner holes

If the holes of the main burner are clogged, besides the fact that there will be a pop when turned on, significant noises will be heard during operation. In order to fix this problem, you need to disassemble part of the column. The burner is cleaned with a soft brush (debris will be visible). It is not necessary to unscrew the jets from the frame, but it is also recommended to clean their holes.

You can clean the gas column burner immediately after removing the casing, using a thin and flexible copper or aluminum wire. But cleaning must be done with extreme caution.

Reason # 5 - poor gas quality

Often, the cause of cotton is gas, which in its composition contains a significant amount of additional impurities. Due to the presence of such impurities, it flashes loudly - this noise is similar to cotton.

To make sure that the reason really lies in the quality of the gas, you just need to ask your neighbors about the existence of the same problem. With poor fuel quality, a similar situation will be present for all residents of the house.

Reason # 6 - casing deformation

Heat influences (heating and cooling) can deform the casing. This problem occurs frequently. In the event that deformation occurs inward, then the spark plug can pierce the body.

If deformation is detected, the concave part will need to be bent slightly.

The cause of a pop when turned on may be a deformation of the casing or poor gas quality. In the first case, the situation can be corrected on your own, and in the second, you can contact the gas service

Reason 2 - Batteries are empty

If you have an automatic dispenser that lights up when the water is turned on (for example, Vector JSD 20-W), then the reason that the water heater bangs when the water is turned on may be discharged batteries.

If the batteries are low, there is not enough electricity to quickly create a spark to ignite. In this case, the crackling sound is longer. During the time until the flame is ignited, too much fuel has time to accumulate in the working area.

Replace the batteries with new ones. You should purchase expensive alkaloid models from popular manufacturers.

If the equipment is still noisy?

If, after the manipulations done, the geyser is still lit with cotton when the water is turned on, then it is better to stop further independent research. In such situations, you will have to seek help from qualified specialists.

They will make competent diagnostics of the equipment, will be able to clearly establish what is the cause of the cotton and, based on the data obtained, will be able to provide you with options for solving the problem.

In certain cases, self-repair is impossible, then cooperation with qualified specialists will be a rational solution.

Reason 3 - Clogged nozzle

In semi-automatic models with piezo ignition, the main flame is ignited from the wick (the reasons why the wick of the Demrad gas column does not ignite are described here). If it is clogged or located incorrectly, then the intensity of its combustion may not be enough for timely ignition.

It should be cleaned. For this, the casing is removed and the orifice of the jet is cleaned with a thin wire. You should also check that it is correctly positioned and, if necessary, move it closer to the burner. When the wick is on, its flame should go over the edge of the burner.

Troubleshooting tips

Why doesn't the gas water heater light up? Proper operation of gas equipment begins with a competent choice of systems, since each manufacturer of gas water heaters has its own "pain points":

- for example, Bosch's thermocouple and igniter are initially weak. Why does the wick in the Bosch gas water heater go out? After 3-4 years of operation, the thermocouple needs a global cleaning;

- the Russian water heater Ladogaz VPG 10 is sensitive to water pressure;

- the popular "state employee" OASIS quickly starts to junk with poor water quality. All these points and the upcoming operating conditions must be taken into account when purchasing equipment.

If troubles have begun, you need to act as follows:

- stop using the column;

- read the instructions to understand the possible causes;

- call a gas service specialist.

Gas equipment maintenance standards require hardware fault testing, and a technician must be authorized to service networks.

Therefore, in case of any problems with speakers and boilers, the services of home craftsmen are not the best way out. Entrust repair work only to employees of professional certified organizations for the maintenance of gas networks and equipment.

Here you can watch a video on how to repair a gas column igniter yourself:

See also Phones for consultation 29 Nov 2020 kasjanenko 392

Share the entry

Discussion: 2 comments

- 5master5 says:

02.12.2018 at 16:59Extensive and detailed instructions on the cause of problems with the gas water heater. But, there is only one answer - turn off the gas and immediately call the gas service. Another tip is to conclude a contract for the maintenance of gas equipment.

Reply

- Serge says:

02/29/2020 at 18:50

Pi @ op

Reply