Today we will talk with you about induction heating. Many are trying to present induction boilers as something innovative, which supposedly will save our money and ensure the existence of our heating system. And what is it really?

In fact, induction boilers are very expensive, large-sized, inconvenient to use and not endowed with a sufficient number of properties and qualities that are necessary for the normal operation of a modern electric heating boiler.

Those people who invent these boilers and try to sell them to you do not tell the consumer anything about these aspects of their products, but expose only positive qualities to the light. Here we will display all the pros and cons of induction heating at home.

What do induction heating manufacturers say?

Most often, manufacturers of induction heating boilers are compared with traditional ones, and traditional ones are 99% of all electric boilers on the market.

The boilers are always compared according to the following scheme: the imaginary flaws of the heating boilers and the positive qualities of the induction heating of the house are highlighted.

For example, such indicators:

- There are a lot of heating elements;

- That one or even several heating elements can allegedly fail;

- It is said that the boiler may lose its working capacity;

- They pay special attention to scale, which can appear as a deposit right on the very surface of the heating elements;

- The complexity and bulkiness of the design is due to a sufficiently large number of electrical contacts;

- The creators of induction boilers claim that their boilers last longer due to the fact that they can soften the water;

- Absolutely unfounded and unfounded assertion that periodic replacement of gaskets, heating elements and risers is required.

Induction heating: reviews. Induction heating at home

Modern development

As it turned out, induction technology began to be applied in 1900. At the same time, induction heaters and ovens appeared. Induction heating boilers appeared only in 2000. Boilers are not a new discovery, these technologies were simply not used by anyone in this direction, this can be said with a statement.

Bargain

There is a manufacturer's statement that induction boilers are able to save up to 30% of electricity compared to heating elements and electrode boilers. Why choose induction heating? Reviews of narrowly focused specialists confirm this fact.

Firstly, the efficiency of boilers is over 90%, this is achieved due to instant heating of the coolant,

Secondly, if you buy an ordinary electric boiler and use not very good water as a heat carrier, then no one will give you a guarantee on them. VIK boilers can use any coolant while maintaining the warranty.

Thirdly, boilers are equipped with a temperature sensor, so they do not work constantly, but only for heating. Due to this, induction heating is beneficial. Feedback from real users confirms these numbers in practice.

Long service life

Boiler manufacturers claim that they can be operated for a long time without maintenance, up to 25 years. And that, unlike other types (electrode or heating elements), the efficiency is much higher. Let's take a look at this statement.

Firstly, the design of the boilers is not demountable, since there are no quickly wearing parts in it. Therefore, no maintenance is required.

Secondly, the coil is made of insulated copper or aluminum wire, and its damage is excluded.

Thirdly, the pipe on which the wire is wound (induction coil) has a special layer to avoid metal corrosion, as it interacts with the coolant.

Fourthly, the security system will protect against power surges and possible overheating or coolant leaks. Therefore, many users are inclined towards induction heating. Reviews of people who are already using these units have only positive characteristics.

The above arguments prove the reliability of induction heating, in contrast to the use of heating elements or electrodes. Since they require constant replacement of heating elements, you will incur the ongoing costs of calling technicians.

Saving operating parameters

Aggregates based on electrodes and heating elements very quickly cease to meet their technical parameters, this is due to the formation of scale. Scale will quickly destroy the heating element and your heating system can "stand up" at the most inopportune moment.

The formation of scale can only be avoided in one way: the water in the system must be either distilled or soft (purified). This is achieved through a dual circuit and heat exchanger system, resulting in an overall increase in cost.

Induction units completely exclude the formation of scale, since the principle of magnetic induction implies heating the pipe (coil), which has a slight vibration, so scale cannot be fixed on the walls.

Noiseless

Long-term operation has shown in practice that induction electric boilers are practically silent. Noise can only be generated by pump motors or other electrical devices. So, the users' statement can be considered correct.

Safe

Induction heating systems have their own safety group, which protects the unit from power surges, ducts, overheating. Can you say that the device is safe? No doubt worth it. The vortex induction boiler has a non-separable design, since it does not require maintenance, so it is practically impossible to get any damage.

Criticism of the wrong heating boilers

It is indicated that there are no heating elements in a high-quality induction heating boiler. Of course, this is not the case, because without a heating element we would have nothing to heat the water with, that is, it is always there in any boiler!

In the overwhelming majority of installed electric boilers, the heating element does not fail almost the entire service life of the boiler.

If the heating element still fails, then we can easily change it, since it is under the flange or on the thread. If suddenly, for no reason at all, the unit breaks down during induction heating, then it is almost impossible to replace it.

Now about the scale... It exists in a kettle, but in home heating systems it does not exist, because there water does not boil at all, deposits are present always and everywhere, in any systems: on gas, diesel, wood-burning, electric, heating, electronic, induction boilers. It doesn't matter which boiler. Sediments will always be present as these are deposits that are always present in the water. This is not a disadvantage or an advantage, but a reality.

About electrical contacts. Manufacturers write that there are no electrical contacts in an induction heating boiler. But in fact, electrical contacts are always and everywhere. And if we talk about heating boilers, then electrical contacts, terminal blocks. absent there for many years. There are electrical contacts under the screw connections that do not require tightening, and there are spring clips that are not worth servicing either.

Regarding the service life of the heating element and the numbers arguing this period. It is not clear where these figures are taken from and how they are confirmed. In addition, here the authors confuse water supply and heating systems. The heating system does not have as many impurities as there are in the water supply system. Water softening in the carrier of the heating system is not required.

It should be noted that in an induction heating boiler, the replacement of units is practically not possible at all, because everything is in a sealed flask and it must be cut in order to pull something out of there.

We reveal the main myth of induction heating

Recently, they have already stopped saying that the efficiency at induction heating higher than the efficiency of a heating boiler 2-3 times. But the supporters of the induction boiler argue that the heating boiler quickly loses its properties and goes out of service, because scale builds up on it!

It is said that during the year the capacity of the heating boiler decreases by 15-20%. Is it really?

Yes, deposits are not really present, but the heating system and the water supply system should never be confused. For example, scale actually forms in the water supply system, just like it forms in the kettle that we see in the kitchen every morning. This never interferes with our work, we know, and there is no doubt that water boils in a kettle anyway.

On the contrary, in the heating system known to us, impurities rarely enter the water. The deposition layer is very thin and does not pose any significant obstacle to heat transfer.

If the energy has gone somewhere from the network, it does not completely disappear anywhere. It turns into absolute heat and the heat carrier is heated, which, in turn, heats up with exactly the same efficiency as it was heated before and how it will always be heated. If it were not so, the ten would have burst with surplus energy.

As soon as scale appears, heat exchange takes place at a higher temperature. There can be no talk of any decrease in efficiency, no matter what temperature is in the heating element.

The efficiency of induction boilers

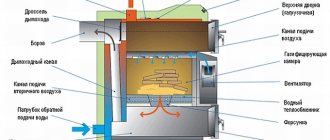

Simply put, it is a labyrinth of pipes, to which an inductor - a transformer “goes” in a special way. Due to the electromagnetic field, the inductor quickly and very effectively heats the core, which in turn heats the coolant. There is nothing to "burn out" in such a design. The core is made of ferromagnetic steel up to 10 mm thick, the service life of such a boiler can reach 30 years.

Scale. Now the market is actively promoting various systems of hydromagnetic protection of HMS water.

We will not dwell on them. Let's just say that induction heaters, structurally and fundamentally, incorporate the advantages of HMS, but they also have additional properties of water treatment. Micro-vibration with a frequency of 50 Hz inside the boiler also provides maximum protection against scale.

Let's count further and estimate the costs for at least 4 years ahead.

The first year of operation of the heating element boiler.

We bought and installed a heating element boiler - 24 kW, 30,000 rubles. The average monthly temperature in the coldest month outside is -20 ° C. The average monthly temperature for the heating season of 222 days or 7 months is -5.6 ° C. How much will you have to pay for electric heating?

The new heating element boiler in the first year of operation works quite efficiently. For heating 240 m2 of the area during the entire heating period, it will work on average in total continuously, 10 hours a day. Work cyclically, i.e. turned on, warmed up to the set temperature, turned off, etc.

We assume that 24 kW is multiplied by 10 hours a day, multiplied by 30 days, multiplied by the tariff of 2.70 rubles per kW. Total: 19,440 rubles per month. Or in general for the heating season 136,080 rubles.

Second year of operation.

For heating elements, the second heating season means a power loss of ≈ 15%. For a heating boiler, this means that it will work longer in order to reach the set room temperature and, accordingly, will consume more electricity. In other words, consume 24 kW from the network, and give 20.4 kW of heat to the system.

In this mode, the total continuous work will be on average 11.5 hours. We carry out the same calculations. Now we pay 22,356 rubles a month, and for the heating season we will pay 156,492 rubles.

The third year of operation.

The heating element "sags" by another 20%, turns on for 13.8 hours, burns 26,827 rubles a month. and 187,790 rubles. for the season. In other words, it consumes 24 kW from the network, and 16.3 kW gives off heat to the system.

Fourth year.

Another 20%, 16.5 hours daily, 32 076 rubles per month, 224 532 rubles per season.

In other words, it consumes 24 kW from the network, and 13 kW gives off heat to the system.

Disappointing results, for four years the cost of operating a heating element boiler can double.

Consider an induction heater.

The first year of operation.

For the same house, with the same area of 240 m2 and the same volume, 20 kV is enough. The power of a boiler operating on the principle of electromagnetic induction is 20 kW.

The conditions are the same, we believe. Multiply 20 kW by 10 hours a day, multiply by 30 days, multiply by the tariff of 2.7 rubles per kW. Total: 16,200 rubles per month. Or in general for the heating season 113,400 rubles.

The costs for the heating season will remain unchanged throughout the entire period of operation.

Due to the absence of scale, the efficiency does not drop, scale does not interfere with the boiler operation. He worked an average of 8 hours a day, and works throughout the entire period of service.

The figures are most clearly visible on the charts.

Every month of operation of the induction heater allows the owner to save a certain amount of money. And if during the first year the savings in relation to the heating element boiler are 3,240 rubles. per month, then for the 4th year of operation the owner will save more than 15 thousand rubles. monthly.

A vortex induction heater will save the owner a decent amount of more than 250 thousand rubles in 4 years. Unlike heating boilers, induction heaters do not require water treatment and seasonal maintenance.

It can be seen from the graphs that induction boilers are not in vain classified as energy-saving devices. The difference in price between an induction and an average-price heating element boiler pays off during the first heating season, and the colder it is outside, the faster it will pay off. And we compare this with the average price representative of the "family" of heating elements boilers. Really reliable German and Polish boilers are not inferior in price to induction boilers, although they have the same "family" disadvantages.

And so, starting from the first year of life, the induction boiler begins to actively "gain points" in relation to the heating element boiler - saving the owner's money.

Area, sq.m.

| 240 | |||||

| Ceiling height, m | 3 | ||||

| Heated volume, m3 | 720 | ||||

| Estimated power of the heating element boiler | 24 | ||||

| Design Power of Vortex Induction Heater | 20 | ||||

| Electricity price kW | 2,7 | ||||

| Exploitation | |||||

| 1 year | 2 year | 3 year | 4 year | ||

Vortex induction heater | |||||

| Boiler efficiency | % | 98,0 | 98,0 | 98,0 | 98,0 |

| Rated power | kw | 20,0 | 20,0 | 20,0 | 20,0 |

| Thermal power | kw | 20,0 | 20,0 | 20,0 | 20,0 |

| Average working hours per day | hour | 10,0 | 10,0 | 10,0 | 10,0 |

Heating element boiler | |||||

| Boiler efficiency | % | 98,0 | 83,3 | 66,6 | 53,3 |

| Rated power of heating element boiler | kw | 24,0 | 24,0 | 24,0 | 24,0 |

| Thermal power | kw | 24,0 | 20,4 | 16,3 | 13 |

| Average working hours per day | hour | 10,0 | 11,5 | 13,8 | 16,5 |

Monthly electricity bills for heating | |||||

| Induction boiler | rub. | 16 200 | 16 200 | 16 200 | 16 200 |

| Heating element boiler | rub. | 19 440 | 22 356 | 26 827 | 32 076 |

Seasonal electricity costs for heating | |||||

| Induction boiler | rub. | 113 400 | 113 400 | 113 400 | 113 400 |

| Heating element boiler | rub. | 136 080 | 156 492 | 187 790 | 224 532 |

Savings arising from the use of an induction boiler | |||||

| Per month | rub. | 3 240 | 6 156 | 10 627 | 15 876 |

| For 7 months | rub. | 22 680 | 43 092 | 74 390 | 111 132 |

In the future, the operation of the heating element may suddenly end, and it is possible that the heating element will continue to work, drawing out more and more money. A way out of the situation, only in replacing the heating element itself, and then everything is still the same scenario

At the same time, the vortex induction heater, throughout the entire service life, will perform the assigned tasks without losing its efficiency. If they bought it to heat 240 m2, then it will heat them. The heating element, on the other hand, due to design flaws, in 3-4 years can effectively heat only two-thirds of the room and you will have to think about replacing it.

Let's summarize.

- It is possible and necessary to save on electric heating.

- The new generation of heating systems operating on induction technologies rightfully belongs to energy-saving equipment.

- Vortex induction heaters actually reduce the operating cost of electricity from 30% to 50%.

The cost and maintenance of induction heating boilers

Induction heating boilers are 2 times more expensive than heating boilers. Despite the fact that they are qualitatively lower, as we saw from a critical analysis of their so-called "advantages".

They also weigh 2 times more than heating boilers, have large bulky dimensions, and all the electronic filling is outside. While in heating boilers, it is hidden in the boiler itself. And here there is an additional box, which sometimes there is nowhere to place, especially when it comes to a very small room for a boiler room.

In induction boilers there is no automatic power selection, that is, only a heating element boiler can choose itself at what power it needs to work at the moment.

With induction heating at home, there will be constant voltage surges and overloads, and in heating boilers, the relay works very quietly. And you can only notice it as quiet clicks, being next to a working boiler.

Even in induction boilers, thermal protection for overheating and freezing is completely absent, which is available in heating boilers.

There are no low water pressure sensors in induction heating boilers. There is no error indication that allows you to accurately establish the malfunction due to which it got up (the corresponding indicator will blink on the display of the heating boiler).

But the most important thing that induction boilers do not have is the ability to connect a boiler!

Advantages and disadvantages

Induction heating boilers are currently one of the most popular methods for heating residential premises.

This is achieved due to the following advantages:

- High efficiency and, as a result, low energy consumption.

- If desired, the boiler can operate at low pressure and from a different type of current: direct, alternating.

- Scale resistance. This is due to the structure of the boiler.

- Cost savings, since such a unit works faster on average by 25%.

- There are no detachable connections in the design, so you can forget about the leak.

- There are no items to wear out. Long term: about 30 years.

- This boiler can function in conjunction with other systems: wood, gas, etc.

- Water may not be the only type of heat carrier. Antifreeze or oil can be used.

- No separate ventilated room required. Plus, you can install it yourself.

You can read about antifreeze for the heating system in this article.

In addition, the induction boiler also has enough disadvantages:

- First is the cost. For example, SAV 5 kW with a cost of about 40 thousand rubles, and Protherm Skat 6 kW about 23 thousand rubles. Quality always means a good price.

- Secondly, these are the dimensions of the unit and its weight. The smallest boiler weighs at least 20 kg, so it is most often installed on the floor.

- Thirdly, if you install the unit in a house with 2-3 floors, you will need a circulation pump of good power.

To buy or not to buy an induction heating boiler?

Of course, you yourself must make a decision for yourself which boiler you should buy: a high-quality heating element or still a more bulky, less efficient and expensive induction boiler.

But you must consider the following: an induction boiler is not a unit for heating systems, especially if they are individual and do not require large capacities. Of course, it is impossible to do without induction heating in some industrial areas of technical production, but this applies to production tasks.

Still, there is nothing to drag a complex, heavy and expensive unit into your house. You can get by with a more elegant solution - a heating boiler.

Manufacturers of induction heating boilers deliberately give incomplete information about their products, which misleads those who make a choice in the direction of one or another boiler. It is important here to tell the truth and show your product from all angles so that people know what they are buying.

Expert review of an induction heating boiler

One of the leading Russian experts in the field of boiler installation and maintenance in Russia Vladimir Sukhorukov in one of his YouTube programs "Induction boiler - a big misunderstanding", released on December 12, 2020, he proved in detail and in detail that induction heating boilers are inferior to traditional heating boilers.

Vladimir Sukhorukov did not find any reason for using an induction boiler in a boiler room. Moreover, he strongly advises not to buy induction boilers under any circumstances when there are high-quality heating boilers that work stably and smoothly.

Perhaps you need to heed the advice of an expert.