Who releases

Produces boilers "Keber" Russian, part of the corporation "Tactical missile weapons". This company was registered in 2004. That is, it has been operating on the market for about 15 years. This company delivers exclusively heating equipment to specialized stores. The products from this manufacturer have earned very good reviews from consumers. Heating units from LLC "Trading House" Zvezda-Strela "are actually very popular among the population.

In addition to the boilers themselves, this manufacturer supplies the market with components for them. Finding spare parts for Keber equipment for owners of country houses, if necessary, will not be difficult.

Varieties of fireplaces with a water circuit

According to the material of manufacture, the furnaces are divided into:

- brick,

- metal,

- combined (outside the body is faced with brick, and the firebox is made of metal).

Long-burning fireplace stoves with a water circuit, faced with bricks, will perfectly complement the interior. It should be borne in mind that during the laying process, the heat exchanger is installed. Then the connection to the water circuit is carried out.

It may look like a metal fireplace stove with a water jacket

Metal samples are less attractive and very expensive if you order the device from reliable manufacturers. Devices made of steel or cast iron can heat the room due to their surface. But they are not installed in rooms. For this, separate rooms are used with subsequent connection to radiators.

Combined fireplace stoves consist of a metal insert. Outside, it is faced with bricks. It uses a fireproof glass fuel door. Such fireplace stoves with a water circuit are often used for summer cottages (We recommend that you study the material on an effective fireplace for a country house).

Combined fireplace stove with a metal insert. Facing the device from the outside with bricks

The fireplace combines the aesthetic properties of a conventional fireplace and an excellent heating device. It will significantly reduce heating costs and improve comfortable living in the house.

Owners of country houses, where there is no gas main, most often install a water heating boiler. Its main advantage is the use of inexpensive raw materials. To correctly install the system, you need to understand the principle of operation, design features, installation and operation. Even before purchasing, it is advisable to find out what advantages and disadvantages the unit has.

Range

The Zvezda-Strela Trading House Ltd. supplies to the market boilers intended for installation in premises of various purposes. In addition to household, this manufacturer is also engaged in the production of industrial models of similar equipment. If desired, today you can also purchase gas boilers "Keber", both single and double-circuit. The first type of equipment is intended exclusively for space heating. Double-circuit boilers are additionally used to heat water.

Main technical characteristics

The assembly of Keber boilers is quite reliable. They can serve for a long time. Among other things, the manufacturer gives a guarantee for their operation for as long as 15 years. Thanks to high-quality components, Keber gas boilers are also considered very economical.If necessary, this equipment may also be used for heating premises in the Far North.

Gas-burners

Efficiency and excellent operational characteristics of boilers of this brand are ensured primarily by the fact that the manufacturer has provided for very high-quality Danko burners in their design.

These elements are:

- provide stable fuel combustion;

- are distinguished by high anti-corrosion properties;

- provide the most complete combustion of fuel.

The use of high-quality gas burners allowed the manufacturer, among other things, to reduce the size of the fuel chambers in Keber boilers. The efficient work of Danko in terms of fuel combustion, in fact, made this equipment so economical.

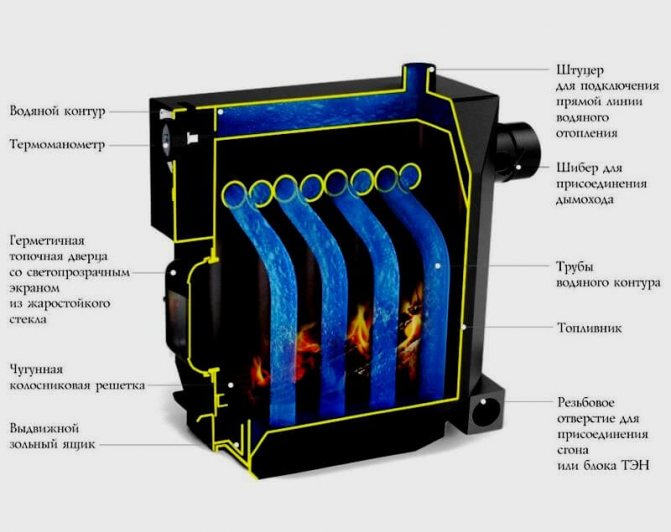

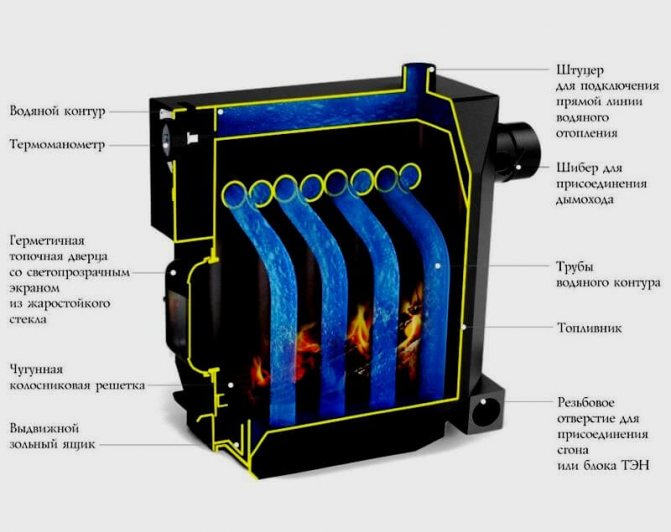

Components of a solid fuel heating boiler

- Firebox with a door for loading fuel;

- Water jacket with water circulation system;

- Smoke extraction system (chimney);

- Chimney damper;

- Temperature control and regulation system;

- Ash pan for the accumulation of coal from spent fuel;

- Curtain for primary air supply (ignition);

- Ash pan door;

- The grate is a shelf for holding fuel.

Firebox

Firebox, it is a fuel combustion chamber and at the same time a heat exchanger. The furnace includes: a portal for fuel supply, a zone for removing volatile fuel combustion products, a grate grate, containers for collecting ash and openings for air supply.

In the firebox, in the process of fuel combustion, its walls are heated, and the water that is around the firebox in the "water jacket" of the boiler is heated.

Note: For the pyrolysis (gas generating) boiler, an additional furnace compartment is provided for burning wood gas.

Water jacket

In a solid fuel boiler, double walls are arranged in the firebox, between which there is a coolant. This is a water jacket... In the process of burning fuel in the firebox, the coolant in the water jacket heats up, which is why convection (heat) flows are formed, which raise the hot coolant to the upper part of the jacket. From the water jacket, the hot coolant enters the heat pipe. After passing through the heating system and giving off heat to the house, the cooled coolant returns to the water jacket through the lower branch pipe. To speed up the circulation of water in the system, special circulation pumps are used.

Smoke evacuation system

As a result of the burning of solid fuels, a large amount of smoke is generated in the boiler. An obligatory element of a solid fuel boiler is smoke exhaust system... The smoke is removed by heat-insulated pipes running from the boiler to the street. Some boilers are equipped with forced ventilation units.

Boiler automation

Of course, modern heating equipment should be not only economical and easy to use, but also safe. Natural gas is an explosive fuel, unfortunately. In this regard, Keber boilers have also earned relatively good reviews from consumers.

LLC "Trading House" Zvezda-Strela "" equips the boilers supplied to the market with the time-tested automatic equipment "Arbat". In total, the units of this brand provide five levels of protection. So, for example, in the event of a pressure drop in the gas pipeline, the Keber boilers are automatically turned off.

If desired, consumers can also order from the manufacturer of this equipment and its complete set with even more reliable expensive Italian EUROSIT automation. Units of this type can be operated practically without any intervention of the owners of the house or personnel in the workplace.

Filling a new heating boiler with water after preparation

The water in the boiler is a coolant that circulates through the pipes and carries heat to the premises. Modern models do not need special manual recharge. But the first launch is very important. This must be done very carefully so that in the future there will be no interruptions in the operation of heating equipment.The boiler is equipped with a pump and a special tap near the branch pipe through which cold water is supplied. When her fence goes, a characteristic sound is heard.

When first filling, keep a close eye on the pressure on the gauges and gauges.

At the level of 1.5–2 atmospheres, the boiler is full, you can turn off the water supply. These data are average. The maximum pressure depends on the manufacturer. You will find this information in the installation instructions for your particular boiler.

Then you need to remove the air pockets, which will slightly reduce the pressure. After this process is completed, the boiler will need to be refilled.

A schematic representation of the principle of operation of a gas boiler will help to understand the features of the operation of equipment

Video: filling the tank correctly with water

Technical characteristics on the example of model 12.5

Thus, using Keber boilers is quite safe and convenient. Excellent performance of this equipment is ensured, of course, first of all, by its well-thought-out design. The gas boiler "Keber 12.5", for example, has the following technical characteristics:

- power - 12.5 kW;

- Efficiency - at least 85%;

- control - mechanical;

- gas consumption - 1.62 m3 / h;

- total heating area - approximately 125 m2;

- maximum water pressure in the heating system - 3 bar;

- weight - 39 kg;

- guaranteed uptime - 22,000 hours

This floor-standing single-circuit boiler has an open combustion chamber. This modern model belongs to the group of non-volatile equipment.

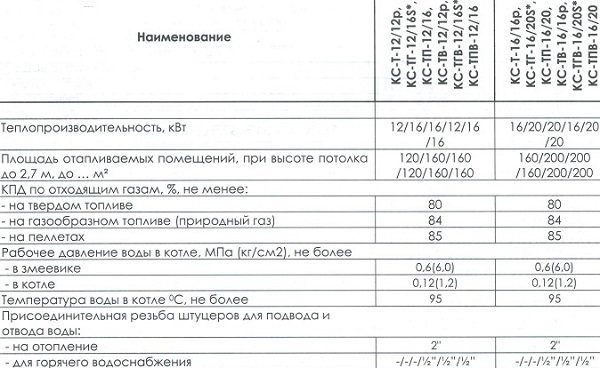

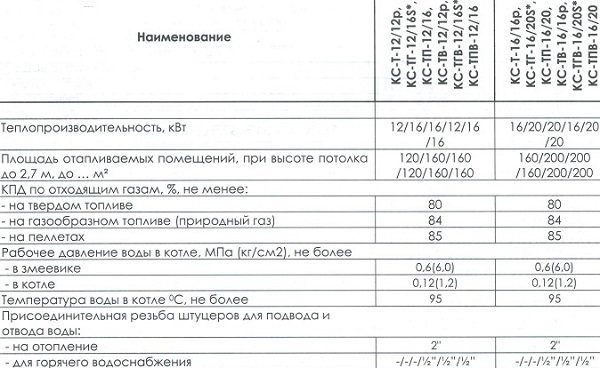

Specifications

Boiler characteristics

In some models, the temperature is regulated by a traction gear. The automation kit includes a supply fan and an operating mode controller.

Characteristics of coal-gas boilers:

- productivity - from 16 to 50 kW;

- heats the area of premises from 160 to 500 m2;

- The efficiency of gas models is 82 - 90%, for solid types - 75 - 80%;

- operating pressure of the energy carrier in the coil - 0.6 MPa, in the boiler - 0.12 MPa;

- the coolant is heated to + 95 ° С;

- internal dimensions of the smoke extractor - 202 x 96 and 252 x 97;

- the dimensions of the boilers are from 0.7 to 0.85 m in length, from 0.47 to 0.7 m in width, and from 1.18 to 1.43 m in height.

Gas units consume from 2 to 6 m3 / hour, depending on the capacity. The combustion products discharged contain carbon monoxide (not more than 119 mg / m3) and nitrogen oxide (less than 240 mg / m3).

Weight

The weight of the boilers ranges from 140 to 270 kg.

Weight of some models:

- KS-T-16 - 153 kg;

- KS-TVm-16 - 190 kg;

- KS-TG-16 N - 155 kg;

- KS-TGVm-16N - 188 kg;

- KS-TGVm-16 / 20N - 200 kg

- KS-TV-31.5 - 266 kg;

- KS-TGV-31.5 / 40 N - 259 kg;

- KS-GV-50 N - 266 kg

The weight of the boiler depends on the dimensions, the number of plates in the heat exchanger and the performance.

Consumer opinion

Despite the fact that Keber boilers are one of the cheapest brands of heating equipment in Russia today, they have earned quite good reviews from consumers. To the poles of these units, the owners of houses and apartments primarily refer to their impeccable work. For the first few years, boilers of this brand usually do not require any special maintenance at all. Some problems with their operation for the owners of country houses may begin to arise, judging by the reviews, only about 5-7 years after installation. At this time, it is recommended to clean the Keber boiler once purchased from limescale. This is primarily due to the fact that the water on the territory of Russia in most regions, unfortunately, is quite hard.

Thus, reviews of Keber gas boilers on the Web are mostly positive. The only thing is that sometimes the owners of country houses still criticize the work of the domestic automation of these models. It happens that after several years of operation, for example, the operation of the switch-on function deteriorates in Keber boilers.Burners are ignited in them only some time after pressing the "Start" button.

Types of devices

Solid fuel boilers are classified according to fuel combustion processes:

- Traditional boilers with a water circuit. This is a non-volatile class of equipment. In them, the combustion process proceeds from the bottom up, the fuel is loaded manually. It burns in a fixed bed on the grate, air enters the furnace in a natural way through the holes, the burnt gases are discharged into the atmosphere due to the vacuum created by the height of the chimney. Combustion on one fuel filling lasts from 2 to 6 hours, depending on the furnace volume, type of fuel and its calorific value.

- Long burning time. A distinctive feature of such units is the top loading of fuel. Combustion takes place at the bottom of the fuel on the grate, as it burns out, the fuel is released, which ensures a continuous combustion process on one tab during the day.

- Pyrolysis water boilers. The most promising and expensive boilers are equipped with two combustion chambers. In the first, the fuel smolders and the formation of pyrolysis gas, and in the second, the principle of afterburning is carried out, where a highly efficient pyrolysis gas burns out, releasing a significant amount of thermal energy. These boilers are with the highest efficiency and cost. They also require storage facilities for fuel storage, which must be taken into account before connecting the boiler.

- Universal water heating boiler - capable of operating on different types of fuel from electric to gas, after the appropriate replacement of the burner device. However, they achieve their design efficiency only when using the main type of fuel. In other types, it will be significantly lower with a drop to 10%. This is due to the fact that the smoke ventilation system is designed for solid fuel and the corresponding speed of movement of flue gases, as well as the possibility of heat removal of the "water jacket" of the boiler.

Gas boilers "Keber": instruction

Heating equipment of this brand, like any other similar one, can only be installed by licensed specialists. Before starting up in the boiler, all connections must be checked for tightness.

Instructions for turning on the Keber ignition head are as follows:

- turn the control handle counterclockwise to the ignition icon;

- without releasing the handle, press the piezo ignition button (a torch should appear);

- release the handle 20-30 seconds after pressing the button;

- check for the presence of a flame on the ignition head.

As you can see, the operating instructions for Keber gas boilers are quite simple. If there is no flame after performing the above steps, all four operations simply need to be repeated. In this case, it is necessary to increase the holding time of the handle.

How to troubleshoot the Keber gas boiler

_______________________________________________________________________________

_______________________________________________________________________________

Explain to me how to fix this problem. At the dacha, a floor-standing Keber KSG boiler with an Arbat automation unit was installed. If the ignition is carried out, the main burner starts to burn intensively, but after 16-20 seconds it turns off. Repeated action does not bring any changes. Has anyone met this? First, check the functionality of the draft sensor and thermocouple. Diagnose the circuit contacts. Disassemble the pilot burner carefully and clean. Adjust the ignition burner to a lower gas pressure. Apparently, the thrust has decreased, so the pilot burner does not have enough air during the ignition of the main burner. The torch smokes thoroughly and the burner always burns, does not extinguish. The temperature does not rise above the set level, while the torch continues to burn. A lot of burning. Local gasmen said that the traction was weak. How to fix it? It looks like there is a lack of air. You must perform a comprehensive prophylaxis. Dismantle the burner device, clean and rinse the burner and nozzles. The heat exchanger must be cleaned from the outside.Can you tell us why the boiler unit smokes? What needs to be done in order to resolve this issue? Apparently, there is a weakening of draft in the firebox. We advise you to clean the smoke exhaust duct. What to do, tell me if the KSGV Keber boiler does not want to ignite? I hold the control handle, press the ignition button, then hold it for about 10 minutes, start to squeeze it, and the device goes out. The pilot tube may be dirty. In this situation, complete maintenance is required. Another problem is the oxidation of the terminals on the draft sensor. It is recommended to remove the terminals and strip them from oxides. Disruption of the heating boiler KSG 12.5 with Arbat automatic equipment. When you press the ignition key, there is no gas flow to the burner mechanism. What could be the reason? When you press the button, gas fuel enters only the igniter, its entrance is not allowed to the main burner. You have completed the installation of this unit. It's a little annoying to cycle from the wick to the main burner. Three claps are heard all the time. It should be? Apparently, it is required to adjust the automation for gas pressure. I use the same device complete with the Sit 820 Nova automation, which turns off when the temperature rises to about 70 degrees. Tell me how you can fix such a malfunction? Apparently, the thrust sensor is turned on. You should examine the chimney. A similar unit was installed at the dacha. The heating stopped at fifty degrees that week, but the flame continues to burn incessantly. What could be the reason? We assume that there has been a clogging of the gas supply pipe from the automatics on the burner, as well as the burner jet. The house has a Keber 10 gas boiler equipped with Eurosit 630 automatic equipment. A week ago, a breakdown happened to it. It began to extinguish when a wind stream hits the pilot burner. I have recently replaced the thermocouple, but there are no changes. How to fix it? At the moment of starting the main burner, this serves to reduce the entry of fuel to the ignition device, that is, the automation is triggered. You definitely need to increase the fuel supply to the pilot burner. This can occur intermittently due to low pressure in the heating system. Another reason may be a weakening of the chimney draft if it is installed with errors. Tell me what the problem is if this unit stops with us, mainly if there is a strong wind and bad weather outside. How should the problem be corrected? When the pilot burner is turned on, the EMC is forcibly triggered in twenty seconds. When the ignition device goes out, the EMC valve stops working after 10 seconds, 0 You will hear a click. Once upon a time, a Keber 12.5 boiler was installed in the country. The house is small, the space is no more than thirty square meters. As if the consumption is small, and the heating of water does not happen more than 55 degrees. The house has 2 batteries for 12 sections. Can't figure out how to raise the heating temperature? Installing a circulation pump can help you. There is often a decrease in pressure in the gas line. Why does the boiler overheat often during use? An essential reason is the lack of circulation in the heating circuit. Clogged filters or excess air in the heating system is also possible. There was a problem yesterday. If we close the cold water tap and start opening the hot water supply, all water disappears from the heating circuit. Why is this happening? Most likely, the make-up valve of the heating system is malfunctioning. It allows water to pass through both lines. When there is a pressure of the coolant in the system, then transmission in the opposite direction cannot happen. What is the reason that the device makes noise, gurgles, and sometimes howls and claps loudly? The fluid in the system is heavily oxygenated. During the heating process, air evaporates, so a noise is heard. If the unit is configured incorrectly, then the gas valve or bypass valve howls.A popping sound on start-up indicates a malfunction with ignition. In October of that year, I installed the Keber 20 floor-standing gas boiler. About a few months later, there was a malfunction. I am trying to adjust the temperature cycle, but it does not hold it. Explain what could be? Apparently, there was an automatic failure, and at the moment the temperature rises by 70 degrees, the nozzles are turned off. It is necessary to adjust the automation for correct operation. Another factor may be that the wrong power of the device is selected in proportion to the heating area. Launched the same device in the middle of this year. It operates on liquefied gas. Almost nine cubic meters were spent in three months. Currently, there is a lot of soot inside the apparatus, and the main burner also smokes. What is the reason for this phenomenon? Too much soot deposits in the furnace indicates that the gas burner is not adjusted, and this does not completely burn the fuel. An unsatisfactory gas mixture is also likely. To prevent the burner from smoking, it is necessary to systematically clean it with water. The same device is connected to the system. At the moment of start, the gas burner ignites and immediately goes out. I believe the pilot is out of order. Can you help fix this accident? It is necessary to check whether the sound of a spark from the ignition mechanism is heard when the ignition cable is disconnected. If there is no sound, it is recommended to change the ignition transformer. If there is sound, replace the ignition electrode or ignition burner. Just yesterday, a malfunction was revealed with the Keber KS-GV 12.5 boiler. Water flows from it. He was at work no more than 3 weeks. Perhaps someone will tell you why the water is dripping? Apparently dripping due to the high pressure in the heating system. Probably the burnout of the walls of the heat exchanger. Water hammer also causes leaks in the boiler. At the dacha, I want to implement the connection of this device. Explain what is the standard gas / methane / propane / gas supply pressure for these models? In this type of apparatus, the nominal gas supply pressure for methane / propane is 150.0 / 300.0 Pascal. This unit was put into operation. Not so long ago, there was a malfunction. The device turns on, but does not heat up in heating mode. What can happen? There may be an airlock in the batteries or a lot of scale in the heat exchanger. You need to wash it. We use this unit indoors. Until yesterday evening I worked without question. But now there is a problem with him. It overheats intensely. How do I fix this problem? Probably, there is a blockage with scale, due to which the duct is clogged. You need to clean the device. Just yesterday there was a problem with the boiler. Was in operation for only 2 weeks. Then he abruptly stopped raising the regulated temperature. Maybe someone can tell you why this happened? In your system, the gas pressure is weaker than necessary. It is necessary to inspect the gas valve. Most likely, there is an abundance of lubricants inside. You want to remove the extra. Explain how you can pump up the expansion tank? The expander tank can be pumped up with any car pump to the pressure required according to the instructions. Most often, the approximate range is from 0.8 to 1.5 bar. Before pumping up the tank, according to the regulations, you need to drain the water from the boiler device. This is done through the drain connection or through the tap, shutting off the hot water supply. The Keber 31.5 heating boiler cannot start up. As long as you keep the start button pressed, the burner ignites. But if you press the key, the device goes out. Explain the cause of the problem? The thermoelectric converter or gas valve is probably faulty. There is also a decrease in gas pressure in the supply pipeline. In some cases, there is a shortage of voltage on the electronic board. Remind us what operations need to be carried out in order to switch from liquefied gas to natural gas? For this, it is recommended to replace the nozzles of the main burner.Next, change the voltage of the modulator supply. Finally, adjust the range of minimum and maximum pressure. How does a safety valve work in a heating system? This valve, adjusted to the operating pressure, protects the heating system. Do not use a safety valve to drain the system. The pressure in the heating system rises constantly. I decrease the pressure of the expansion tank to 2.1-2.3 atm. Can the heating water come from hot water pipes? The increase in pressure in the heating system can be attributed to the following main reasons. Incorrect expansion tank pressure settings. The make-up valve is leaking. A malfunction has occurred. The start is very difficult. The pilot burner ignites and there is no fire on the main burner. I just can't understand what is the reason? Possibly a malfunction of the ignition mechanism. We recommend checking the boiler and cleaning the ignition unit. Can anyone please help fix the problem with the chimney? Soon for three days, reverse thrust was observed, because of which the smoke began to pour straight into the room. I made the chimney myself. It consists of a metal tube. Perhaps something was wrong. The main factor may be an incorrectly executed chimney design. Contamination of the pipe with combustion products is possible, which significantly limits its capabilities. In addition, it is recommended to check the ventilation in the living quarters.

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Elimination of malfunctions in boilers

- Gas water heaters

- Malfunctions and repair of gas water heaters

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Elimination of malfunctions in electric convectors

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Features. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and check. Maintenance.

- BAXI SLIM

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAXI - REPAIR

After starting, a malfunction appeared. He does not want to turn on, he worked for two years, now the entire display is on fire, as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but it gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

- BAXI - OPERATION

The Baxi main four 240 boiler is in operation, it turns off with an error E35 (parasitic flame). Tell me what to do? The first season is in operation.

- BAXI - SETTINGS

We installed and connected a Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW unit?

- BOSCH - REPAIR

Bosch 6000 24 kw boiler, single-circuit with built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

- BOSCH - ADJUSTMENTS

If you turn off the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

- ARDERIA - REPAIR

Installed the Arderia esr 2.13 ffcd boiler. If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for the malfunction of the three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed and so on. Is it possible to really reduce the power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems.Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

- BUDERUS WALL

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on the DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation of turboTEC plus VU / 5-5 compared to / 3-5?

- VAILLANT - ADJUSTMENTS

Malfunction in the operation of the boiler, the green LED (power supply) flashes, the instructions say that the thermal protection has worked, the green indicator flashes, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

- DAEWOO

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation. When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The wall-mounted boiler Electrolux Basic Xi is installed and connected. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

- KOREA STAR

Malfunction of the Koreastar boiler. Heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the ferroli domiproject 24 boiler - I adjust 60-70 degrees, it goes to minimum combustion, does not turn on, does not turn off. Restarting is unstable. No pattern is revealed. What to do?

- JUNKERS

In operation, the gas boiler Junkers euroline, when hot water is turned on, ignites the gas, then goes out and so on several times. If you turn it on while the heating is running, then the water heating turns on immediately. Can you please tell me what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. The fan run-out cannot be set. I bet 30 seconds, but still 2 minutes. twists.

- OASIS

Malfunction of the boiler Oasis ZRT18. The unit starts up, the gas is ignited, then it goes out. It lights up again, goes out (three times it happens). Then it flares up and works fine. It does not give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the gas boiler Senor Duval - the water pressure sensor shows 0.0, the indicator flashes red, hot water does not heat up, but the water pressure in the apartment is good. How do I fix the problem?

- VIESSMANN

Where should a condensate drain be installed in the coaxial flue? Boiler wh1d with a closed combustion chamber, located at a distance of 1m from the wall.

- WESTEN

The problem of starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, after a crackling error E01. Rearranged the fork in places.

- BERETTA

The Novella floor-standing gas boiler has blocked - the green lights on the panel are on, and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler was installed and connected, which does not hold pressure at all: during the cooling of heated water, the pressure drops to zero, although water is regularly drawn. What's with the pressure?

- SIME

Malfunction of the metropolis dgt 25 bf boiler. The hot water supply stopped working, the heating is working, it does not give an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, with any attempt to turn it on or hot water, gives a GS error.

- WOLF

The Wolf boiler is in operation. Recently, he began to behave strangely: in the pause between starts, he turns on the burner for one second five times, and 70 degrees jumps out on the display. Where to look for a malfunction?

- ACV

ACV Wester Line works very unstable: it often goes into an accident, at startup it emits a characteristic knock and stalls, and at times everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, gas is no longer supplied to the burner. The piezo element clicks, but there is no ignition. Everything is in order with the gas stove, there is gas. What is the reason?

- KITURAMI

Malfunction of the Kiturami world boiler, stops periodically. I wipe the flame sensor and the apparatus works well for a while, but soon everything repeats itself. He also began to smoke heavily. Maybe it's a short chimney, and you need to lengthen it?

_____________________________________________________________

- IMMERGAS - ERRORS

Errors of boilers Nike Star, Eolo Star / Mini, Mythos. Boiler malfunctions with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler in winter mode systematically raises the temperature to 80 degrees. I summoned the master three times. He said that this is for many imergaz models, and offered to install a programmer, but not the fact that it would help. Tell me how to solve this problem and will this programmer help?

- AOGV

Model 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The gas boiler AOGV was installed and put into operation. Hot water dispensing problem. The heat exchanger has been flushed. Less than a month has passed, and the water does not flow again. We put the filter on the water, but time has passed, and again hot water does not flow. What could be the breakdown?

- AGV

Assembly and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and work order. Automation adjustments.

- NEVA LUX

Malfunction of the boiler Neva lux 7023. With a frequency of 2 times a month, it gives an error E7. But after a reboot it still works. Now it gives an error E6. It will work for 15 minutes, and it turns off. What could it be?

- ROSS

Construction and automation unit. Firing up procedure. Malfunctions and repairs.

- ATEM ZHITOMIR

Tell me if the Atem Zhitomir boiler goes out because of the weak gas pressure, it clicks and goes out. What is the problem? Is it possible to turn off the automation for a while and how?

- LEMAX

A gas boiler Lemax KSG-12.5 Premium was installed. After turning off the main burner, a click occurs after a couple of minutes, what is the reason, tell me?

- KEBER

A gas boiler KS-G was installed and connected, for 250 sq. m. When firing up, it does not turn off, the temperature rises, if I am not mistaken, the automatic Arbat 1. The flame is not regulated - too large. What to do?

- LIGHTHOUSE

I installed a gas boiler Mayak and connected it. It works fine. But the reason is this. When it works on a unit, it beeps strongly, if the regulator is turned 2-7, the squeak disappears. Tell me what could be?

- DANKO

We installed and connected the Danko gas boiler with the Kare automatics, it works fine on the igniter, but it is worth adding the power on the burner, it completely fades, yesterday it faded out for 5 minutes, today it works for 20 minutes and completely goes out. Who faced this problem?

- GAZLUX

The boiler gazeko 18 is in operation. When hot water is turned on, the pressure in the system drops after make-up, the pressure reaches 3 bar. Have to dump. What's the matter, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, while it goes into an overheating accident. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Malfunction of the Rinnai 167 RMF boiler. Recently started showing error 14. How can you fix the breakage?

- CELTIC

The Celtic ds boiler heats up to 45 degrees and costs the whole day it does not turn off and does not heat up the batteries, sometimes it shows an a3 error. How can this problem be resolved?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

Seoul wall mounted gas boiler stopped turning on due to no ignition error. How can it be eliminated? What exactly is out of order?

Possible equipment malfunctions

Like any other technique, floor-standing gas boilers "Keber", of course, can sometimes break down. Most often, owners of country houses with this equipment have the following problems:

- unstable operation of the igniter;

- shutdown of the burner some time after the start of work;

- lack of fuel supply to the injectors.

In the first case, the cause of a malfunction in the Keber gas boiler may be a clogged nozzle. Also, sometimes the igniter is unstable simply due to the fact that the meter does not allow a sufficient amount of gas into the system. To remedy the situation, the owner of a country house, respectively, needs to either clean the jet, or properly adjust the operation of the monitoring equipment.

There can be many reasons for the shutdown of the burner after starting work. But most often this happens due to the failure of the thrust sensor. It is unlikely that you will be able to eliminate such a malfunction yourself. Only a specialist called to the house can cope with it.

If the gas supply to the injectors in the model equipped with the Arbat security system has stopped, then, most likely, the stem is jammed in the middle part of its structure. In order to eliminate this malfunction in the Keber gas boiler, in this case, you should drip a little machine oil into the device. After that, be sure to check the unit for gas leaks.