# 1. Briefly about the principles of work

It would seem that difficult in a solid fuel boiler? I threw wood or coal into the furnace, they burned out, heated the water, and the house was filled with warmth. In general, everything is true, but the principle of operation of the device is somewhat more complicated. In the design of a modern solid fuel boiler, the following main elements can be distinguished:

- firebox;

- coolant circulation system;

- smoke removal system;

- safety system;

- heat storage system.

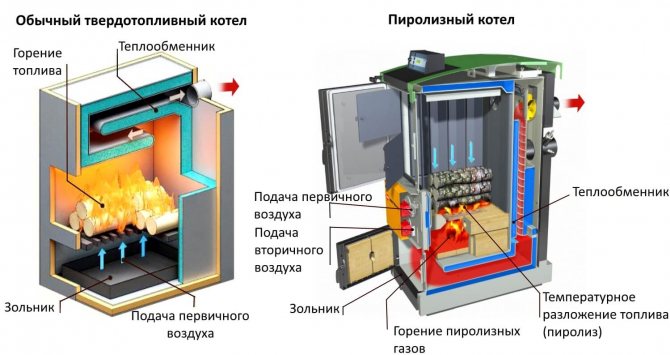

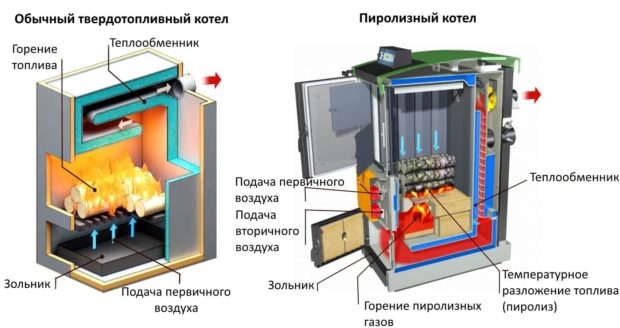

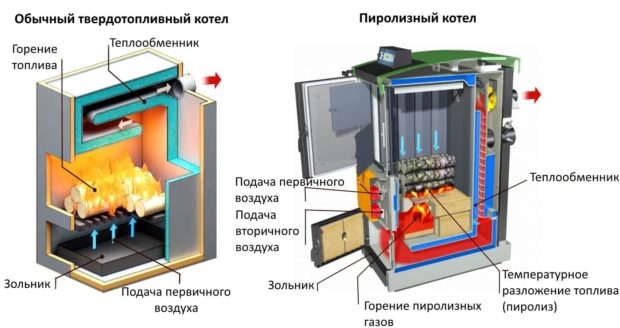

IN firebox fuel is supplied and burned to obtain heat. This is the classic version. There are pyrolysis boilers in which solid fuel (wood) smolders, releasing gas, which then burns, providing heat. At the same time, the efficiency increases somewhat, but we will deal with the peculiarities of the operation of classic and pyrolysis boilers later.

The firebox is a large container with double walls, between which there is coolant... In most cases, this is water, less often an antifreeze liquid or a mixture of water and antifreeze is used. The coolant receives heat from the burnt fuel, circulates through pipes and radiators, heating the air in the house. Cooling down, the water returns to the boiler and everything is repeated. Often special pumps are used to improve circulation.

When fuel is burned, not only heat is generated, but also gases that must be removed. The system is intended for this. smoke removal... The chimney removes gases from the boiler to the street, sometimes a forced ventilation system is used to increase the efficiency of this process.

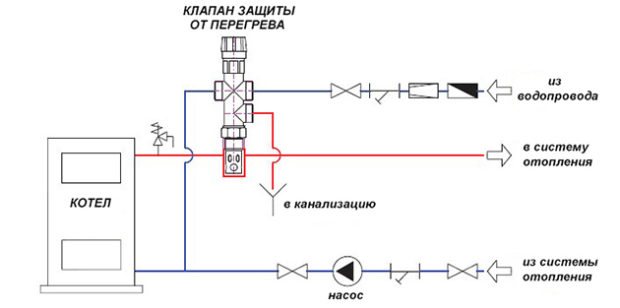

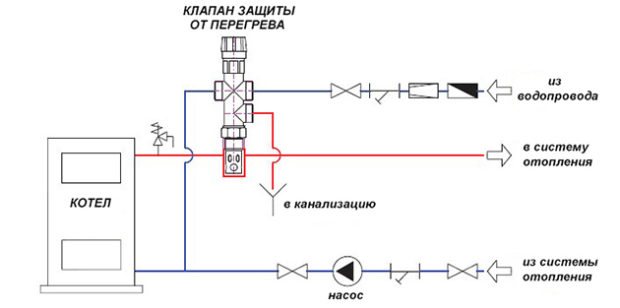

The most great dangerthat can happen when a solid fuel boiler is running is overheating of the coolant... The water may already be sufficiently heated and the boiler will continue to generate heat. If the water boils, the heating system may not be able to withstand it, especially if the house has metal-plastic pipes that are sufficiently sensitive to high temperatures. It is almost impossible to stop the combustion of firewood or coal - all that remains is to reduce the intensity, and so that the overheated coolant does not get into the system, they use cooling heat exchanger... It receives cold water from the water supply, but in case of a water cutoff, it is better to always have a sufficient supply of it.

The cooling heat exchanger can be built into the boiler or between the boiler and the rest of the heating system. It can only be built into the structure of a steel boiler. It works in one of two possible ways:

- first option - cooling of the heated coolantwhich passes through a cooling heat exchanger. Cold water is supplied to the cooling heat exchanger through a thermal valve, which opens when the temperature of the coolant reaches + 950C. The process continues until the coolant cools down to a safe temperature;

- the second option provides for the presence shut-off valve... If the water temperature rises to critical values, the valve does not allow it to flow into the pipes. Cold water is supplied to the heat supply system from the water supply system, and the overheated coolant is drained into the sewer. True, the water pressure should be sufficient, and its composition should not contain an increased amount of salts, which will provoke the formation of scale.

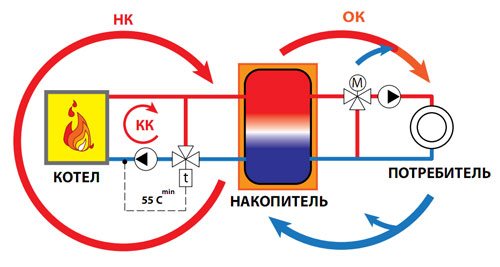

Dumping heated water into the sewer is not very smart and economical, therefore, it is better to supplement the design of a solid fuel boiler storage tank... This is a buffer between the boiler and the rest of the heating system, thanks to which a number of important functions:

- warm water accumulation for its further use, and this is fuel economy, comfort, stability in maintaining the temperature and a decrease in the number of trips to the firebox for tossing fuel;

- protection against accidents... In the tank, overheated water is mixed with warm water;

- the ability to use boilers of different types... The storage tank will be common for a solid fuel and, for example, a gas or electric boiler, will allow you to simply organize a single heat supply system at home and insure yourself with several heat sources.

Heat accumulators are made of cast iron or steel and receive powerful thermal insulation. Buffer volume, first of all, depends on the power of the boiler: for each 1 kW, it is necessary to provide 25 liters of tank volume. The quality of this element of the heating system must be of the highest, therefore it is better to trust the products of well-known manufacturers. The online store https://www.duim24.ru/ presents heat accumulators only from trusted companies, the assortment includes tanks of different volumes and materials of manufacture.

Design features and resource of work

When thinking about which solid fuel boiler to choose, one should not forget about the duration of its operation. The resource of the boiler plant depends primarily on the duration of the heat exchanger, which is made of cast iron or steel. Preference should be given to cast iron heat exchange units, which are characterized by increased durability, or heat exchangers made of boiler steel with a wall thickness of 4-6 mm.

You can order a hot water boiler in the Terem online store. The catalog contains a large selection of solid fuel boilers at very competitive prices. We also carry out delivery in Moscow and St. Petersburg. If you have any questions, our consultants will be happy to answer them.

# 2. Types of solid fuel boilers according to the principle of operation

With a similar general scheme of the device, different types of solid fuel boilers have some design nuances. The entire existing assortment can be divided into the following types:

- classic or traditional boilers;

- pyrolysis or gas generating boilers;

- long burning boilers;

- pellet boilers.

Classic solid fuel boilers

Such boilers are a lot like ordinary stoves. The heat is obtained here as a result flaming fuel... As a rule, firewood or coal is used as the latter. Fuel is supplied through one door, and through the other - the boiler is cleaned of ash and other products of incomplete combustion. Traditional boilers can have both cast iron and steel heat exchangers, usually used in natural circulation systems.

Although the efficiency of this type of device is not the highest, they are valued for reliability, because the design of the boiler has a minimum of electronic elements that can fail. The only automation element is a temperature controller, but it also works on a mechanical principle. Classic boilers are durable and rarely require repairs.

Pyrolysis boilers

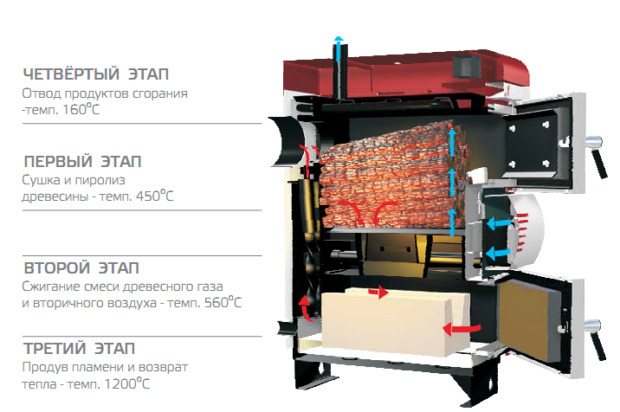

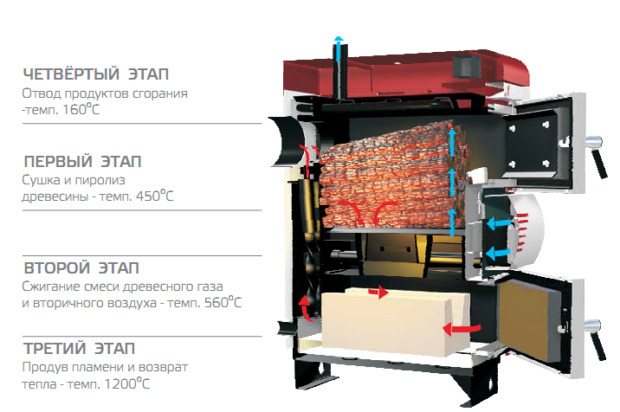

Pyrolysis (gas generating) boilers are somewhat more complicated. Their design contains two combustion chambers... Solid fuel (firewood) is put in the first, at high temperature and oxygen deficiency occurs pyrolysis process with the release of pyrolysis gas. It goes into the second chamber, where it burns and gives off heat to the coolant. Only charcoal remains from the firewood.

The combustion temperature of pyrolysis gas is higher than that of firewood, which increases the boiler efficiency by up to 90%. If we take into account the fact that the process of wood decay is slower than its combustion, then we can talk about another advantage - one fuel fill is enough for 10-13 hours (for classic boilers, this figure is 5-7 hours).The fuel used is hardwood and low moisture content (no more than 20%).

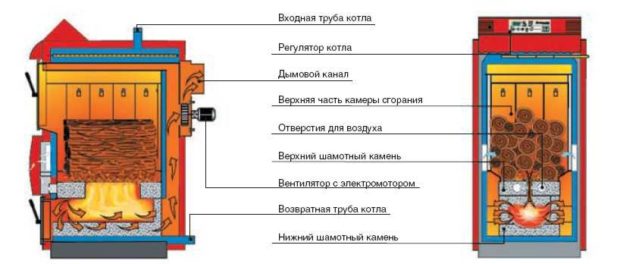

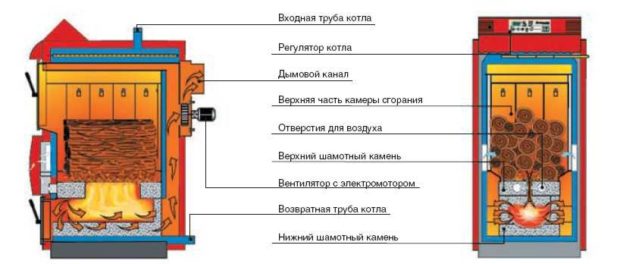

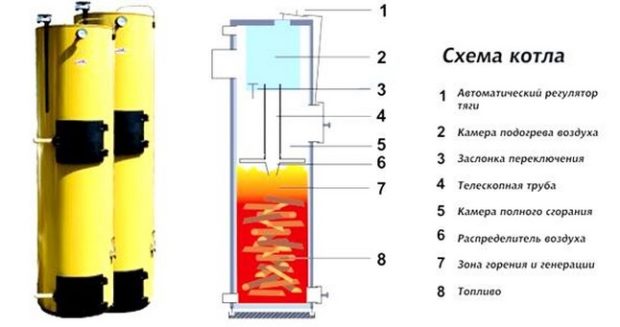

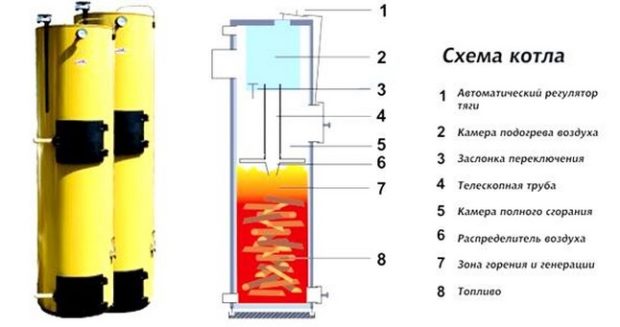

Long burning boilers

This type of boilers resembles pyrolysis boilers in many ways, but differs in some technical features. Solid fuel smolders in the first chamber, forms gases that burn out in the second furnace. In this case, only the upper part of the fuel is involved in the process of smoldering and combustion. Due to this, it has to be loaded less often, and the efficiency increases. One load of firewood is enough for the boiler to work two days... The main disadvantage is the high cost of the equipment.

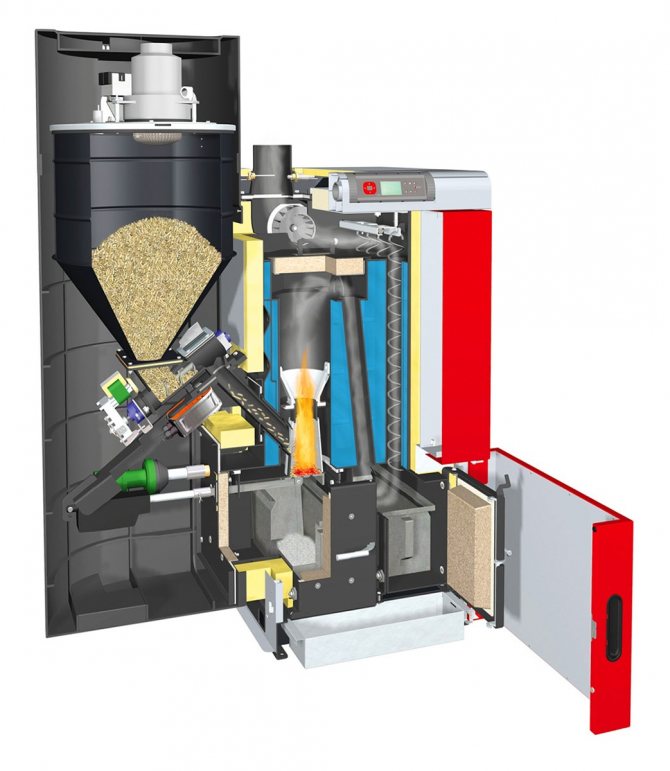

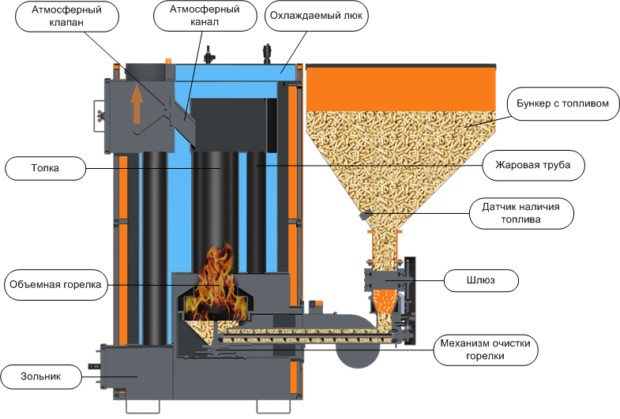

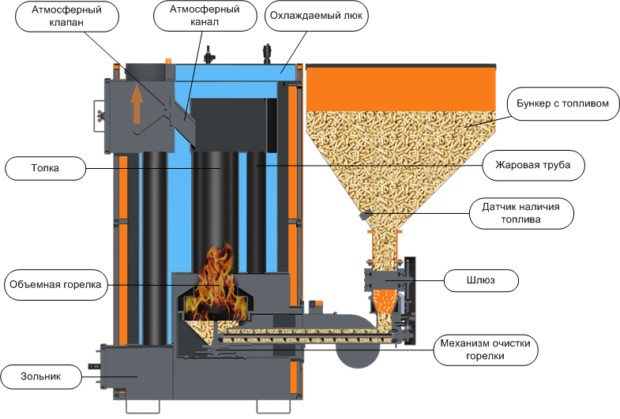

Pellet boilers

They are also often referred to as automatic boilers. According to the principle of operation, they differ little from traditional ones, but besides the firebox, they have bunker for storing a stock of fuel. This means that it will not be necessary to often come up and pour fuel into the furnace manually - everything will be done by automatic equipment. Approximately 7 days... In addition, such a system can be very precisely adjusted for yourself. Fuel is considered one of the most environmentally friendly at the moment. Pellets are granules that are produced from wood waste (sawdust, shavings, etc.). The efficiency of such systems is 91-95%, the only drawback is the high price of boilers.

Boiler types

To understand how to choose the right heating equipment, it is important to take into account the features of boiler installations. There are several types of boilers for private houses with different operating principles, automation levels, and efficiency.

Traditional

They work according to the classic scheme of burning wood or coal in the lower part of the combustion chamber. They are distinguished by simplicity of design, energy independence. The air supply to the heating boiler is regulated manually by opening or closing the ash chamber damper. They require regular manual loading of fuel every 3-4 hours and constant monitoring of the combustion process. They have an efficiency of no higher than 75%, they are intended for houses of a small area with seasonal living.

Pellet

Solid fuel hot water boilers for autonomous heating are equipped with a spacious hopper and a mechanism for automatic fuel supply to the burner. They are characterized by good efficiency at the level of 86-93%, forced air supply, autonomous operation lasting up to 7 days. Equipment and fuel are expensive, but the price of environmentally friendly pellets tends to decrease due to the increase in the number of manufacturers and the improvement of technology.

Pyrolysis

Heating boilers with a sequential combustion process in two chambers. In the first, smoldering occurs without oxygen, during which gas is formed, which is afterburned in the next chamber. This technology provides an efficiency of over 90%, the duration of the combustion cycle on one load of firewood up to 12-24 hours. The process control is fully automated. The equipment is optimal for private houses with autonomous heating, non-residential premises, garages.

Number 3. Heat exchanger material

There are few options. Heat exchangers can be:

- steel;

- cast iron.

It is difficult to say unequivocally which solid fuel boiler is better to choose - it all depends on the budget, operating conditions and personal requirements. Manufacturers produce both boilers.

Cast iron heat exchangers have the following advantages:

- they are going to from separate sections, therefore, their transportation and installation is easier. Moreover, if one of the sections is damaged, can be replaced, so durability such boilers at a height - up to 20 years or more;

- cast iron during operation is covered with a film of iron oxide. This is a dry rust that hardly progresses, protecting the rest of the material from negative effects. Cast iron more resistant to corrosion, therefore, the heat exchanger will have to be cleaned less often;

- cast iron keeps warm longer, that's a plus.The downside is that it warms up more slowly.

Among cons high weight, higher brittleness than steel, and low resistance to thermal shock. With a sharp change in temperature, the cast-iron heat exchanger can easily crack, so avoid getting cold water into the still-hot heat exchanger.

The advantages of a steel heat exchanger include:

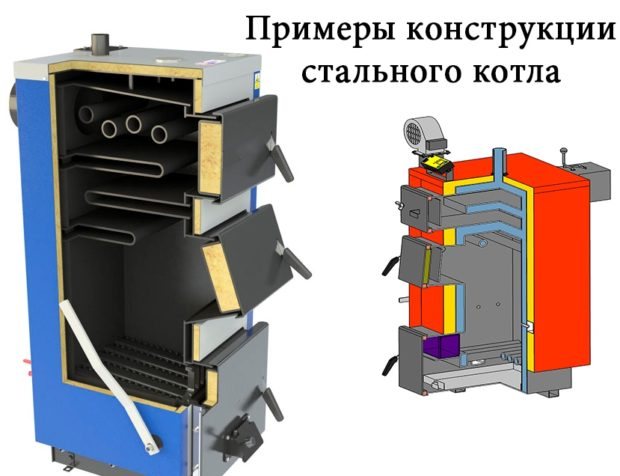

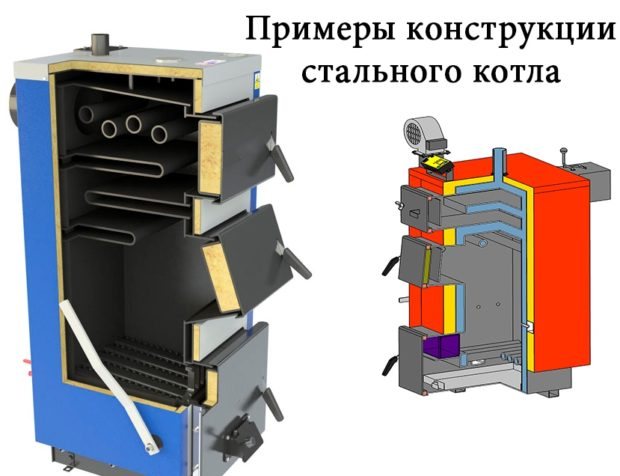

- higher strength, and since such a heat exchanger is cooked in the factory and comes out in one piece, it becomes possible to manufacture combustion chambers of complex configurations, due to which the efficiency increases;

- high resistance to sudden temperature changes... Boilers with such heat exchangers, as a rule, receive more advanced automation, since the temperature can be controlled freely without fear of damaging the structure;

- not as high weight as cast iron;

- faster heating, but also faster cooling.

On the other hand, steel is more prone to development corrosion processes... Despite the resistance to temperature extremes, with frequent such fluctuations, cracks may appear at the weld points. In which case it will be impossible to repair the steel boiler - you will have to buy a new one, therefore, the durability of such structures is lower.

Performance characteristics of solid fuel boilers

And finally, after choosing the material of manufacture, the type of work and fuel to provide heating, in order to understand which solid fuel boiler to choose for heating a house, let's look at the rest of the work parameters.

- Safety. Where it comes to heating a home and burning materials in the process, the first step is to take care of the safety of the system. There must be an alarm function for a failure or an emergency situation, as well as an automatic shutdown of the boiler.

- The volume of the chamber for loading consumables. This affects the convenience of use, the frequency of feeding a new portion of fuel, and ease of installation. If you are not limited in the room, then it is better to choose larger cameras.

- The degree of automation of work processes. Today, most of the boilers on the market have their own systems for automating work and diagnostics, and notifying the user about the progress of processes. If they are not there, then you can check with the manufacturer if there is a possibility of their introduction into the design.

- Electricity consumption. Most often, solid fuel boilers are self-contained devices, without the need to connect to an electric current source. But there are also models with the need to connect to the mains for the ignition system to work. In such boilers, energy consumption indicators are very important and the most economical option should be chosen.

After the final selection and purchase of a solid fuel boiler, it remains to introduce it into the heating system of your home. There are separate recommendations on this score, it would be better to adhere to them so that everything is safe, and the heating system has the best thermal efficiency.

No. 4. Traction and energy consumption

Solid fuel boilers can be divided into two types:

- non-volatile natural draft... They do without special pumps, so they do not consume electricity. Classic boilers and some long-burning boilers function in a similar design. Well suited for areas with frequent power outages, can be used as a backup heat source;

- volatile with additional thrust... The design provides for a fan that helps air flow into the combustion chamber. In this version, most long-term combustion boilers, pellet and pyrolysis boilers are produced. Some settings can be made using the control panel.

No. 5. Number of contours

Single-circuit boilers responsible only for the heating system. There is also double-circuit boilers, which allow you to provide a hot water supply system for a private house.This is very convenient, but when calculating the required power, you should definitely take this feature into account. In addition, there are boilers equipped with hob.

Please note that solid fuel boilers are floor-mounted - there are no wall-mounted models.

No. 6. Calculation of the power of a solid fuel boiler

One of the main indicators that you should first of all pay attention to when choosing a solid fuel boiler is its power, on which it depends on what area it can provide with heat. One should proceed precisely from the area of the heated room. You can use the generally accepted rule: for every 10 m2 of area, 1 kW of boiler power is needed. This is subject to normal thermal insulation and a ceiling height of no more than 3 m.

It turns out that a 15 kW boiler will be enough to heat a house with an area of 150 m2. Even at an external temperature of -360C, it will maintain the temperature in the house + 180C With insufficient thermal insulation at home, as well as in a harsh climate, it is better to take a boiler with a small power reserve.

If the boiler is to be used in a hot water supply system, then this must be taken into account when calculating the power of the heat exchanger. Experts say that in order to ensure comfort in the house, the power of a double-circuit boiler should in any case not be lower than 24 kW. It is better to entrust more accurate calculations to professionals who will take into account all the features of a particular house and heating system.

Power

Of course, it is advisable to perform accurate power calculations so as not to be the loser after purchasing heating equipment. However, there are averages that will help simplify the task. It is believed that 1 kW of power of a solid fuel boiler is enough to maintain a comfortable temperature for 10 m2 of a private house. Therefore, having a building of 100 m2, it is worth taking care of purchasing equipment with a capacity of 10 kW. With this indicator, rapid heating is provided, if necessary.

Models of solid fuel boilers, differing in power

Since pellet heating devices have maximum efficiency, the power of such a device may be different. Therefore, when choosing this parameter, it is necessary to take into account how the heating is carried out: with wood, coal or another type of fuel.

No. 7. Fuel type

You can throw into the firebox of a solid fuel boiler firewood, coal, pellets and sawdust... It is a mistake to believe that the power of the boiler will remain unchanged, no matter what fuel is used. Many models of boilers can work with different types of fuel, but at the same time, the maximum power will be achieved only when using the fuel that the manufacturer indicated as the main one. When using less high-calorie fuel, the power will drop by 25-30%, and if it is too wet, then the power drop can be up to 40%.

Average parameters of heat transfer for different types of fuel:

- firewood - 2500 kcal / kg. Logs of wood are usually 25-30 cm long and can be sawn or chopped. It is important that the wood is dry;

- anthracite coal - 7400 kcal / kg;

- hard coal - 7000 kcal / kg;

- brown coal - 3500 kcal / kg;

- pellets - 4500 kcal / kg.

Criterias of choice

It is necessary to decide which solid fuel boiler to choose for the house based on the basic characteristics:

- thermal power;

- the type of fuel to be loaded;

- the principle of work;

- duration of the combustion cycle;

- energy efficiency;

- degree of automation.

But do not lose sight of the ease of use and resource of boiler equipment.

Fuel

The running costs of heating are primarily based on the cost of energy carriers. Which one is better to use is determined by the ratio of the cost and calorific value of the fuel. Taking into account the availability and regional characteristics for a private house, choose one of the following types of fuel:

- hard coal or brown coal;

- firewood;

- pellets;

- sawdust, shavings, branches;

- briquettes;

- peat;

- agricultural waste.

It is recommended to load coal of that fraction and firewood of such importance into the boiler, which are indicated in the equipment passport.

Power

With the standard calculation scheme, it is assumed that 1 kW of thermal power is sufficient to heat 10 square meters of dwelling. In practice, more factors are taken into account:

- ceiling height;

- glazing;

- wall thickness;

- orientation of the building to the cardinal points.

For boilers with a hot water circuit, the calculated value increases by 20%, with additional insulation of the house, it decreases by the same amount.

No. 8. Combustion chamber volume

The larger the volume of the combustion chamber, the more fuel you can load, and the less often you run to the firebox and throw in a new portion. In the characteristics of the boiler, it is customary to indicate such an indicator as the ratio of the volume of fuel loading to the power of the boiler, measured in l / kW. Since a steel boiler with the same power as a cast iron boiler will have slightly more compact parameters, for it this ratio is 1.6-2.6 l / kW. For cast iron boilers - 1.1-1.4 l / kW. The higher this indicator, the less often you will have to run to the boiler.

For boilers with top loading fuel the useful volume is greater, and in this case the fuel is distributed more evenly. With front loading, especially when it comes to a cast iron multi-section heat exchanger, some effort will be needed to evenly distribute the fuel.

No. 9. What else to consider when choosing a solid fuel boiler?

Obviously, even before the purchase of the boiler, it is worth deciding whether the boiler will be the main source of heat or a backup one. In the latter case, it will be necessary to install an expansion tank or a heat accumulator - it is easier to do this right away than to upgrade the existing system later.

If in the future there is an opportunity switch to gaseous fuel, when choosing, you should pay attention to the possibility of transforming the boiler. Many traditional boilers can switch to gas by installing an inflatable burner. It is convenient, but it should be borne in mind that the efficiency of the converted boiler will be lower than that which was originally designed for gas.

No. 10. Solid fuel boiler manufacturers

We will not open America if we say that quality largely depends on the reputation of the manufacturer. Large companies will not spoil their name with products of inadequate quality, so when choosing a solid fuel cat, it is better to pay attention to models from trusted manufacturers. This is the case when it is better not to save.

You can mark boilers of the following brands:

- Buderus Is a German company that specializes in the production of boilers for various types and purposes. Solid fuel models run on different types of fuel, there are classic and pyrolysis boilers, the power is enough to heat large private houses;

- Bosch produces traditional non-volatile boilers;

- Ferroli Is a large Italian company that produces household and private boilers. Among the solid fuel boilers there are coal, wood and pellet boilers. The assortment is wide, the quality is high;

- SIME Is another Italian company that has made a name in just 35 years. Products are exported to 50 countries around the world, the range is represented by coal and wood-fired boilers;

- VIADRUS - Czech boilers. They are presented in a fairly wide range, reliable, safe, and have a pleasant cost;

- Stropuva Is a Lithuanian manufacturer that often introduces new solutions in the field. The latest development is a 40 kW boiler with the ability to work from one load for 30 hours;

- Protherm - high quality Slovak cast iron boilers with high efficiency.

You can also note the products of domestic enterprises produced under the brands "Prometheus" (for houses up to 450 m2), "Hearth" (there are double-circuit boilers), "Zota" and "Smoke".

What types of solid fuel boilers are on the market today

The decision about which solid fuel boiler is better depends on a number of factors that are decisive in each case. Depending on the selected fuel, the power of the equipment and the type of heating unit on solid combustible material depend.

Today, solid fuel boilers for heating of the following types are presented on the domestic market:

- traditional (steel or cast iron) heating devices;

- pyrolysis (gas generating) boilers;

- long burning solid fuel heating devices;

- pellet heating units.

All devices have their own specific advantages and disadvantages, therefore, to assess the most acceptable type of equipment, it is necessary to take into account a number of nuances.

With traditional models of solid fuel devices, it is not particularly difficult. Appliances of this type resemble an oven. And the method of fuel supply, and the design of the furnace itself, and the device of the chimney, all these elements are similar to the device of a conventional furnace. For such a heating device, coal or wood is usually used. The devices are traditionally produced in two versions - steel and cast iron.

If you want to have a simple and reliable heating device at home, the traditional models are just for you. Here you will find neither complex automation nor electronic devices, which usually affect the cost of heating equipment and often cause the failure of heating equipment. Traditional type heaters are equipped with a mechanical heating temperature controller. The entire system is designed for long-term and trouble-free operation.

Which boiler is better if you have a limited amount of fuel, but at the same time it is desirable to have powerful equipment with high efficiency. The answer is simple, get a pyrolysis type apparatus. Using a similar heating device with the same volume of combustible material as for traditional units, you can get a significant increase in thermal energy.

In pyrolysis boilers, the whole process is divided into three phases: fuel drying, synthesis of combustible materials into a gaseous state, and combustion of a gaseous substance. Fuel is synthesized by 85%, giving an air-gas combustible mixture. Combustion results in a huge amount of thermal energy. Fan operation provides a constant supply of fresh air, thereby regulating the direction of the flame. Moreover, the pyrolysis-type devices are equipped with a secondary heated air supply system, which increases the intensity of combustion.

A good heating device that will be fired with wood or coal is a long-burning boiler. The main thing to distinguish this heating technology from other designs is that these models are not whimsical to maintain. The high efficiency of this equipment is achieved due to a fundamentally different method of combustion of combustible material. The combustion chamber is devoid of an open flame; the thermal effect is achieved due to the smoldering of the fuel layer.

The figure shows a diagram of the device device using wood briquettes for long burning.

In conclusion, a few words can be said about this type of heating device as a pellet boiler. Granulated wood - pellets are used as fuel. For that category of consumers who live in areas rich in forest resources and have woodworking products constantly at hand, pellet heating units are an ideal option for heating equipment.

Models of this type are equipped with a mechanism for automatically feeding combustible material into the combustion chamber, making them competitive products.

Net volume of the loading chamber and boiler output

What you need to pay attention to when evaluating a solid fuel boiler for heating a house is what is the ratio of the useful volume of the loading chamber to the power of the units.For different heating devices, this ratio is different. The best solid fuel boilers have an optimal ratio in this case. The higher the number, the better for you.

On a note: useful volume is the amount of fuel that can be put into the combustion chamber at one time to operate the heating unit. The maximum values of the useful volume have models of fuel apparatus with top loading. Such front-loading devices also have high usable volumes. However, it will take more time and effort to load the combustion chamber with the combustible material of such a device.

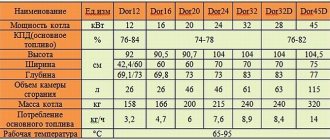

For traditional models of solid fuel equipment, the table gives an idea of the ratio of useful volume to power.

| Steel boilers 26l / 13kW = 2l / kW |

| Steel boilers 61l / 32kW = 1.9 |

| Cast iron boilers 21l / 12 kW = 1.75 |

| Cast iron boilers 73l / 35 kW = 2 |

With pyrolysis units, the situation looks different: one refueling is enough to get heat in 6-10 hours of combustion. The efficiency of the heating device is 90%. The main and distinctive feature of mechanisms of this type is two combustion chambers. The loading chamber is large in size and volume when compared with the furnace of traditional types of apparatus.

The first chamber is used for primary combustion. It is here, due to the lack of oxygen, that pyrolysis occurs - a process that generates combustible material into a gaseous state. In the second chamber, the afterburning of the synthesized gaseous fuel is already taking place. This technique is designed to be used for kindling hardwood. The table shows the data of pyrolysis devices.

| 86l / 25 kW = 3.44 |

| 138l / 36 kW = 3.8 |

| 110l / 25 kW = 4.4 |

| 294l / 60 kW = 4.9 |

The next type is solid fuel pellet heaters. Here the fuel is loaded mechanically. Burning time directly depends on the volume of the loading chamber. Some models are equipped with pneumatic fuel supply devices. The ratio for boilers of this type is shown in the table below.

| 725l / 24 kW = 30 l / kW |

| 725l / 45 kW = 16 l / kW |

A separate place in this list is occupied by long-burning heaters. The burning time in the combustion chamber from one load in such units is significant, reaching 12 hours, 24 or 48 hours. The peculiarity of the equipment lies in the fact that combustion in the combustion chamber does not take place from the bottom up, but, on the contrary, from top to bottom. As a result, firewood, coke or coal smolder. The parameters of the ratio of useful volume to power for devices of this type are given in the table

| 200l / 10 kW = 20 |

| 350l / 20 kW = 17.5 |

| 500l / 40 kW = 12.5 |