How is a boiler that serves two circuits at once

The main difference between a double-circuit boiler and a similar one with one circuit is the ability to simultaneously provide the room with heating and hot water. The primary heat exchanger, due to its location, heats the coolant so that the heating system in the entire room can function fully. The secondary one is responsible for providing the premises with hot water in the required volume.

The stability of the functioning of the principle of operation of a double-circuit boiler can only be ensured by complete serviceability and coordination of operation of each component.

Structurally, any double-circuit boiler includes such elements as:

- heat exchangers in the amount of two;

- combustion chamber, to which the burner block is mandatory;

- protective equipment;

- control system.

In order to understand exactly how a gas boiler of a double-circuit type is arranged and its principle of operation, each significant component of such a design should be considered in more detail separately.

How does a gas boiler work?

A double-circuit gas boiler is capable of operating in 2 modes:

- heating - along the circuit with the primary heat exchanger module;

- hot water supply - along the circuit with a plate heat exchanger module.

Switching between modes occurs special three-way valve.

Most often

space heating occurs according to the following scheme:

- when the temperature in the house drops below the set parameter, the automation gives a signal to the circular pump to operate the system;

- water begins its movement in the system, creating a vacuum in the return pipe;

- simultaneously with the beginning of the movement of water, the burner turns on;

- as water passes through the heat exchanger, it heats up, and then begins to carry heat;

- "Passing" through all the radiators, the coolant cools down - this causes it to return to the boiler inlet with a lowered temperature;

- then the water passing through the heat exchanger is reheated.

We recommend: Uninterruptible power supply for a gas heating boiler. Which one to choose for a boiler room of a private house?

When the selected temperature is reached (which is controlled by the temperature of the coolant or air), the burner turns off, and the water driven by the pump continues to circulate for a short time (post-circulation mode) until the heat exchanger cools down. After that, the boiler will be turned off until the temperature starts to decrease. When the temperature is reduced by 1 ° C, the boiler starts working again.

When heating water the operation of the unit is almost the same - the only change is considered burner switching on as a result of water consumption... In this operating mode (opening the tap causes the burner to ignite), the three-way valve closes the water inside the boiler. The hot water heats up the secondary heat exchanger module, and from it the running water is heated. The system turns off after closing the tap.

note

Most double-circuit models operate in only one mode - when the water is turned on, the heating of the room stops and continues only after the tap is closed.

Most often, the cessation of heating the house is almost imperceptible, since the heating pipes do not have time to cool down much during the time of using the hot water supply. If this option of work does not suit you, you can familiarize yourself with combined heat exchanger.

Installation method

Installation of gas boilers of a double-circuit type is:

- wall;

- outdoor.

The wall-mounted models are a compact unit, similar in size to a kitchen cabinet. They do not need to be installed in a separate room, so the device can be safely attached to the wall in any room. The maximum power of the wall-mounted model is 30-35 kW, which is enough to heat an area of 250-350 m².

Floor-standing boilers are more powerful, which means that they are larger and heavier. Some models are allowed to be installed in a residential area, while others require a separate room - boiler room.

Each boiler manufacturer prescribes in the instructions the requirements for the installation of its equipment, and it must be indicated the volume of the required room, the presence of a chimney and ventilationand the distance from the top of the boiler to the ceiling.

Attention! When choosing a boiler, its power must be taken into account. If it is enough, then take a wall model. If a boiler of increased power is required, then the floor-standing option will be the best choice.

Regardless of the boiler model and installation method, you first need to provide a certified project, one of the conditions of which is gas meter... All work on the installation of a gas boiler can be done independently, taking into account the mandatory conditions specified in the instructions.

After the installation work is completed, you need to contact the gas service, which has a license to put a gas boiler into operation. Company employees must connect the boiler to the gas supply system and carry out a test run of the equipment. If all work is carried out in compliance with safety rules, then the boiler can be used.

It will be useful: Autonomous gasification of a private house

Combustion chamber type

The gas burner in the unit is located in the combustion chamber, which is of two types:

- atmospheric;

- forced (endowed with a turbine).

Important! A double-circuit boiler with an atmospheric chamber can only be installed in rooms with good ventilation.

The oxygen, which is required for combustion, is taken directly from the room, and the burnt food go out into the smokeetc.

In boilers with a closed combustion chamber, the outlet is a "pipe in a pipe", the design of which has a fan. This chimney must be brought out into the street or into the wall located at the back of the boiler. Through one pipe, air masses penetrate into the boiler, and through the other, waste products are removed from it.

We recommend: Heating with gas in a private house. Which gas is the best?

Although a closed chamber boiler works best because the air enters directly into the combustion area, it is endowed with some disadvantages:

- during a crosswind, the air can be of such force that it can easily blow out the burner - this will lead to the shutdown of the boiler;

- freezing and the appearance of ice during the cold season;

- work is possible only during power supply.

It is because of these negative qualities that boilers with an open chamber are often installed, the main thing is that there is a serviceable ventilation duct.

Boiler power

The main criterion that must be taken into account when choosing a gas boiler is its capacity. But before purchasing the equipment, it is worth calculating in advance how much power it should have... In this case, it is imperative to take into account the following factors:

- area of rooms required for heating;

- the height of the walls;

- wall thickness and material;

- number and area of windows and doors;

- insulation quality;

- geographical position;

- number of floors;

- roof type;

- finishing material of the building;

- the presence of a warm or cold attic.

It is required to add 20-30% to the results so that the boiler has a power reserve.

Due to this, in winter, the double-circuit gas boiler will not operate at the limit of its capacity, which will favorably affect its durability.

If it is not possible to accurately calculate the required boiler power, you need to take the area of all rooms and the resulting figure should be multiplied by 100-150.

This will result in the boiler power (expressed in watts) required for full heating and hot water supply.

Gas burners as part of a double-circuit boiler

The burner of a gas boiler is responsible for obtaining the required amount of heat, which can ensure the correct operation of the heating system in each room of the heated object. Also, the water is heated to the required temperature and already hot is supplied in the proper volume. Thermal energy can be obtained by burning appropriate volumes of fuel. For this, the burner is placed in the combustion chamber, where, in addition to gas, air is also injected, which helps to maintain the flame.

Depending on the selected mode, the burners can be conditionally divided into single-level, multi-level and simulated. In the first version, the equipment operates only in two modes - "start" and "stop", is highly economical, inexpensive and has a simple design. Double-deck burners can operate at full or partial power. Its advantages can be fully appreciated, starting in spring, when there is no need for heating, and therefore it makes no sense to operate the device at full capacity. The modulating burner is considered the most expensive, with its help you can adjust and regulate the power of the boiler. The latter is economical and lasts quite a long time.

Structurally, burners are open and closed. In the first case, the air, without which full combustion of fuel is impossible, is supplied from the room where the boiler is located. Such a system is equipped with a chimney, with its help natural draft is provided.

Atmospheric heating boilers are equipped with a conventional metal pipe, while turbocharged models are equipped with a coaxial chimney. They can be installed vertically, but often they are located at an angle - this option is connected to a common shaft, through which smoke and combustion products are fully removed.

Special attention should be paid to turbocharged models of gas boilers, in which closed-type combustion chambers are installed. Oxygen enters them forcibly, and therefore they are considered more reliable and do not pose any danger in the process of work, which makes them in demand in residential premises. In addition to the chimney, they need a special channel - it is through it that oxygen will be supplied to the chamber.

For turbo boilers, coaxial pipes are required in order to remove smoke and draw in fresh air from the street. In some models, there are two such elements, in addition they are equipped with a pipe for air supply.

All of the above models are necessarily equipped with fans that promote smoke, as well as automation and a multi-level protection system.

Additional requirements

So, the principle of operation of a double-circuit gas boiler for heating and hot water supply is clear to us. And we think that to the question that worries many consumers, how a two-circuit gas boiler works, we have answered completely. But there are several additional parameters that we cannot ignore.

Let's start with one very important node - the chimney. Since there are two types in our model line: with an open and a closed combustion chamber, you can use different chimneys for each of them. For a closed chamber, coaxial pipes are well suited, for an open chamber - ordinary ones.An important point is the dimensions of the chimney for a gas boiler. First of all, you should be interested in its diameter or section. It is very important here to accurately correlate the power of the unit - the diameter and length of the outlet pipe. Usually the manufacturer shows this ratio in the product passport, where the dimensional parameters of the gas boiler itself are indicated.

Attention! The diameter of the outlet pipe must be less than the inner diameter of the flue. This is the backbone of a well-chosen design. If you stick to it, then it will be difficult to make a mistake with the selection of the pipe.

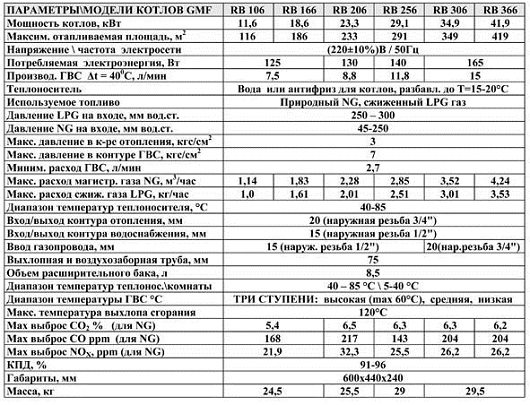

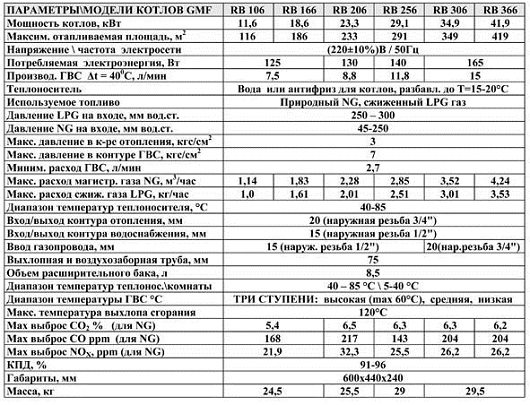

Fuel consumption specifications

Fuel consumption

How to correctly determine the gas flow rate in a gas boiler? Many might say that this is a very strange question.

- Firstly, such indicators are usually indicated by the manufacturer in the accompanying technical documents.

- Secondly, this can be determined in a purely practical way by installing a gas meter on the boiler.

But we are interested in a completely different question. After all, it is not uncommon at the present time that gas equipment is purchased by the owners of private houses, where there is no main gas in sight. They use bottled gas. And here our question will be very relevant. Let's just say that the consumption of propane in a gas boiler is usually less than that of a main boiler. Why?

- Balloon liquefied gas is always supplied to the burner with the same pressure. No jumps and drops.

- It is purified at the factory to the maximum, so that when it is burned, the amount of non-combustible particles is minimal. And this is a high efficiency of the heating equipment itself.

Perhaps enough to give a high assessment to this type of fuel. By the way, anyone who has decided to install gas equipment in his home that will run on liquefied gas must definitely understand how a gas heating boiler works on this particular fuel. The principle of operation is the same, but the maintenance becomes more complicated. It's all about the cylinders, which will have to be manually changed. And this is the most difficult thing, everything else is done by automation.

Pipe connection diagram

Power consumption

In the device of volatile gas heating boilers of a double-circuit type, an automation system is used. This has already been mentioned above. So many are interested in the question: how much does the gas boiler consume electricity, will this greatly affect the financial situation of the family?

Everything will depend on how complex the automation is, and how many additional devices and units operating from the AC network will be included in the heating unit. Of course, a circulating pump will raise this bar a lot. It is the most energy-consuming element in the boiler design. All other nodes are low-power, so they will not bring high costs.

What are the heat exchangers of gas boilers

A heat exchanger in a gas boiler is responsible for receiving heat in order to transfer it to water later. If we are talking about a double-circuit boiler and its principle of operation, then there is a primary and secondary heat exchanger. The first is located above the burner and is represented by a tube with ribs, a curved snake. The water heated to the required temperature in the heat exchanger moves into the three-way valve, after which it enters the heating system. The secondary heat exchanger is represented by a whole system of plates curved by waves, all of them are combined in a single block, on which 4 holes are also located. Through 2 of them, the flow of water is carried out, 2 more are responsible for the movement of the coolant, which is supplied to the heating circuit.

The system of two heat exchangers is called double. There are heating devices on the market that use a bithermal heat exchanger. It is characterized by a complicated configuration.For its manufacture, copper is used, the element itself is represented by tubes located in each other: the heat carrier moves along the outer one, the inner one serves for the movement of water, with the help of which the supply of hot water is ensured.

Gas boilers equipped with such heat exchangers are difficult to operate, the latter being difficult to descale. However, such heating devices are in demand, since they are small in size and heat water very quickly.

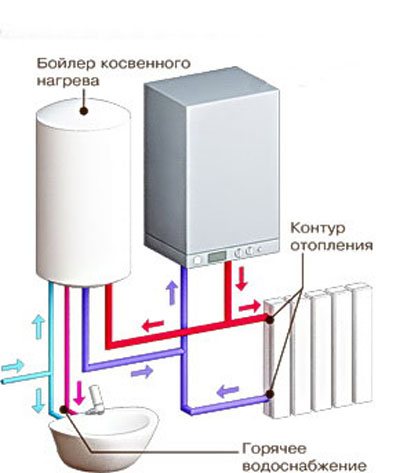

The device of a double-circuit gas boiler

The device of a double-circuit wall-mounted gas boiler is shown in the diagram:

1 - main heat exchanger; 2 - gas burner; 3 - expansion tank; 4 - circulation pump; 5 - heat exchanger for heating water; 6 - thermostatic valve.

The diagram shows that the double-circuit boiler has another heat exchanger (5) - for heating water. There are two circuits in this heat exchanger: the tap water circuit and the heating medium circuit of the heating system, but they move towards each other, but through different tubes, are separated by the tube walls and do not mix with each other. But these walls are so thin that heat is easily transferred from the coolant to tap water.

The heat exchanger is designed in the form of an "accordion" to improve heat transfer:

Water (through pipe 2) and coolant (through pipe 4) flow towards each other, as a result heat exchange occurs, and the water heats up and leaves the boiler through pipe 3.

The purpose of the outgoing pipes is as follows:

As a rule, the end pipes are for connection to heating, the second at the end - for connection to a cold water supply and a hot outlet. But check the passport of your boiler model as well.

How the boiler is controlled

In order to ensure the stable and safe operation of such heating equipment, it is better to choose automation. It controls the temperature of the water in individual components, maintains the temperature of the coolant at the proper level and is responsible for the competent principle of operation of the double-circuit boiler. In the event of potentially dangerous situations, the boiler automatically turns off - a similar manifestation is shown if:

- decrease in pressure in the gas system;

- maximum heating of the coolant;

- lack of traction.

In those gas boilers that are on the market today, mainly "smart" control is used, the software of which allows you to select one of the available operating modes.

Boiler working principle: part 2

But it doesn't end there. After switching on, the boiler starts to work on an increasing basis. First, at minimum power, and eventually it reaches its maximum. When a wall-mounted double-circuit gas boiler at some stage heats the carrier to a predetermined temperature, the unit goes into modulation mode. If at the first start-up the power exceeds the permissible, the microprocessor sends a signal to turn off the burner. Re-activation is carried out after three minutes. The combustion chamber is metal and has a special heat-resistant winding. There is a heat exchanger above it, a burner below it. The latter lights up exactly at the moment when the temperature of the carrier in the system drops and the water needs to be heated. Together with it, a circulation pump is also included in the work, designed to drive water through a closed system. When the set temperature is reached, the double-circuit gas wall boiler goes into standby mode. In some models, the burner burns, but at a minimum, in others it goes out and lights up when gas is supplied.

The specifics of the operation of boilers with two circuits

Those who think that both circuits in such a system heat up immediately at the same time are mistaken, in fact, everything works completely differently.In normal operation, such equipment operates on an ongoing basis only in order to heat the coolant circulating in the system. How often it will turn on and how intense the flame seems during the operation depends on the temperature sensor that monitors these processes. Together with the burner, the pump starts, but only if the circulation of the coolant naturally does not have any effect on the operation of the heating system. After the temperature of the latter reaches the desired level, a signal is sent from the sensor that the activity of the burner should be reduced. After that, the boiler works only in passive mode until the temperature indicator reaches the programmed level. Next, the sensor sends a signal to the automation, which, in turn, starts the valve, which is responsible for supplying fuel.

It is enough to first familiarize yourself with certain subtleties of the functioning of gas boilers equipped with two circuits in order to understand what advantages can be obtained from their operation. Moreover, the purchase of such heating systems allows you not to purchase additional equipment, which may be required in any other case in order to provide the house with hot water. Even if one circuit fails, the second can be operated further, replacing one circuit will still be much cheaper than repairing an entire heating installation.

A double-circuit boiler may well be operated in the summer, when there is no need for heating and it is only necessary to provide heating of water intended for domestic needs. In this way, you can really save money, since buying two units at the same time, each of which functions autonomously, will cost much more.

Device, structure and characteristics of equipment

A double-circuit gas boiler is a device in which heat energy is generated as a result of the combustion of gas. The received energy is directed to heating the water used for heating the house, and is also supplied to the hot water supply system.

What does such a unit consist of:

- gas-burner;

- heat exchanger;

- igniter;

- heating circuit;

- hot water supply;

- expansion tank;

- liquid circulation pump;

- chimney required to remove combustion products;

- automation - allows you to control the boiler, as well as control the temperature.

When choosing a gas unit of a double-circuit type, it is important to know exactly what you need to pay attention to in the first place. That is why it is worthwhile to familiarize yourself with its device in more detail.

Heat exchanger types

The main difference between a two-circuit device is that it is capable of heating water for heating a room, as well as for hot water supply.

Attention! Both functions cannot work at the same time.

That is why the device contains special heat exchangers, which are of the following types.

Doubled

It includes 2 modules, each of which is presented separately - primary and plate. In the primary, the water required for heating the house is heated, and in the secondary, water intended for household needs is heated.

If you look at the structure of a double heat exchanger, then the first type of module is comparable to a tube with fins, and the secondary one looks like a set of plates. Both of these modules are connected to each other, therefore they represent a single part, however, structures are located in two different boiler parts - on top of the primary, and on the bottom of the plate.

Bithermal

In appearance, it looks like 2 tubes made of metal, which are inserted into one another. In the inner part of the 1st tube, the water used for household needs is heated, and the 2nd tube (outer) is needed for heating.

Dual heat exchanger system considered the highest quality and most durable... The fact is that when heating water for domestic use, running water is taken, which leads to a large amount of scale in the pipes.

This situation contributes to the frequent repair of the unit or requires its complete replacement, which is not always easy to do.

And if only some parts of the hot water supply can be replaced in a double heat exchanger, then in the case of bithermic separation, it will be necessary to install a new device, which will cost the owner twice as much.

It is also worth considering the fact that if the hot water supply system fails in a double-circuit gas boiler, the double heat exchanger will continue to successfully heat the room, while the bithermic one will have to be repaired, since it will be completely unusable.

Heat exchanger material

When choosing a gas boiler of a double-circuit type, it is worth paying special attention to the material for the manufacture of the heat exchanger:

- Cink Steel - the cheapest and fastest "out of order" material;

- stainless steel - this is a more durable material, which is distinguished by a considerable price, however, the efficiency of such a boiler is rather low;

- copper - this durable material is characterized by good efficiency, so the high cost of a device with a copper heat exchanger does not scare many people who prefer to pay less for gas in the future.

We recommend: Where can a gas boiler be installed in a private house? Equipment rules and requirements

Copper is considered the best option, therefore most modern and high-quality boilers have heat exchangers made of this material.

The boiler automation helps to prevent overheating, and it is possible to reduce excessive chemical activity by using chemically neutral materials such as polymer pipes.

Burner types

Depending on the type of flame control, burners can be divided into the following types:

- Single stage - there are no intermediate positions, the burner is either working or in a switched off state. This is not the best mode of operation, since the unit is turned on / off.

- Two-stage - there are 2 modes of operation of the device - 50-60% and 100% power. The required power is maintained automatically. Based on the reduction in the number of on / off switching, these types of burners operate in a more economical mode and maintain the required temperature well.

- Modulated - these are the most expensive, but also the most economical types of burners. They are controlled by automation, and they have the ability to set exactly the power that is required at a certain time - from 10 to 100%. Since the double-circuit boiler, equipped with a modulating burner, has a minimum number of on / off cycles during operation, it has increased durability. On the positive side, such boilers have significantly lower fuel consumption than other models.

The most economical choice is a boiler equipped with a modulating burner. It allows you to set the required room temperature, as well as heat the water to the required values.

Automation

To ensure the safe operation of the boiler and to facilitate its performance, gas boilers must must be equipped with automation... Parameters that are tracked using it:

- flame control;

- gas pressure;

- the presence of draft in the chimney.

If one or more of the above parameters does not correspond to the norm, the boiler will not turn on.

But in order to increase comfortable living conditions, as well as to simplify operation, it is worth choosing models that have extensive customization optionsand. Additional functions of gas boilers include:

- Opportunity setting a stable temperature for space heating and water heating. This function can be achieved thanks to two types of automation. In one case, the water temperature is controlled, and in the second, the air temperature.

- Opportunity heating liquid for the heating system with different temperature conditions... This may be required, for example, if heated floors are made. In pipes laid under the floor, a higher temperature can be given, while in radiators it can be reduced.

- Combustion control - flame modulation, electronic ignition, soft start.

- On timer hot water supply at a given time. This function will allow you to set the heating of the water for a certain time, so that in the morning, before going to work, it was possible to take a shower and not wait for the boiler to heat up.

- Post-circulation pump - after the liquid reaches the set temperature and the burner turns off, the pump continues to work for a certain time, which will allow the circulating water to “remove” energy from the cooling down heat exchangers.

Also, do not forget about automatic security systems that will prevent the occurrence of various emergencies and notify when equipment fails.

Double-circuit boiler diagram

Let's talk about how to properly connect the device. Often professionals are engaged in this, but if you decide to do it yourself, then nothing will come of it without some knowledge. Firstly, a double-circuit gas boiler, the principle of operation of which we have already examined, must provide for a mechanical filter at the inlet. It is advisable to pre-install a shut-off valve on the boiler return. This is done so that it is not necessary to air the system in the event of a unit breakdown. After that, the boiler is mounted directly, then communications are supplied, that is, water supply, gas, and coaxial pipes are installed to remove combustion products and supply oxygen. In any case, the start-up of the system is carried out under the control of the gas service. Do not forget that the double-circuit gas boiler, floor or wall, must be installed strictly at the level.