Home / Gas boilers

Back to

Published: 22.06.2019

Reading time: 4 minutes

0

808

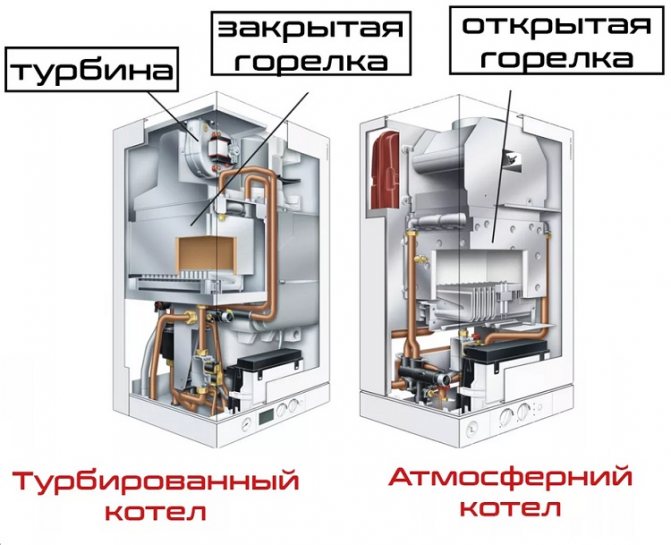

A turbocharged boiler by its design differs from the atmospheric one in the way that air enters the burner and the combustion products are removed. They can be placed on the floor and on the wall, there are single and double-circuit gas turbine boilers.

- 1 The principle of operation of a turbocharged boiler

- 2 Advantages of turbo boilers

- 3 Disadvantages

- 4 Turbocharged or naturally aspirated?

- 5 Floor standing turbocharged boilers

- 6 Wall mounted turbo boilers

- 7 Best manufacturers of turbocharged boilers

- 8 Installation rules

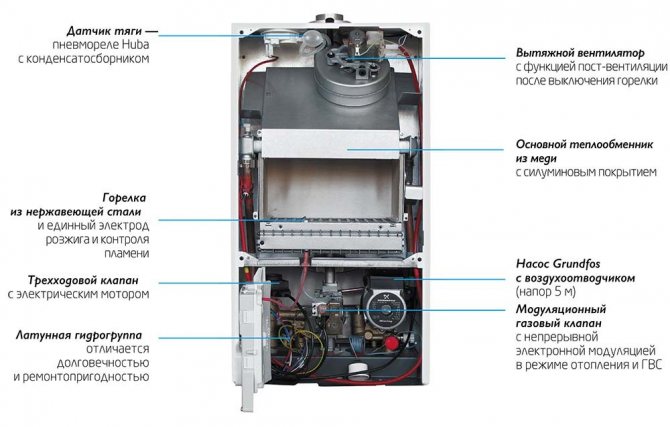

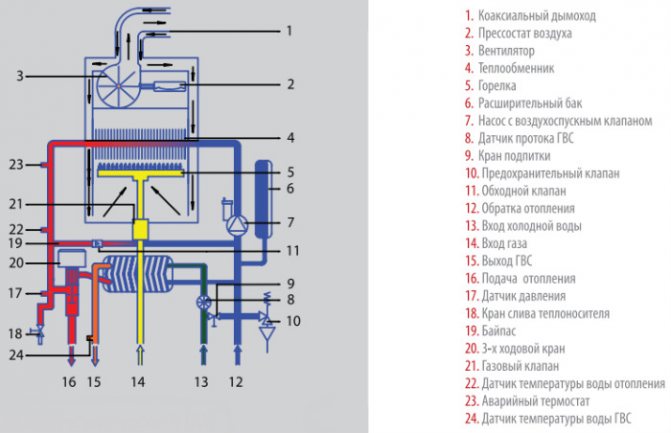

The principle of operation of a turbocharged boiler

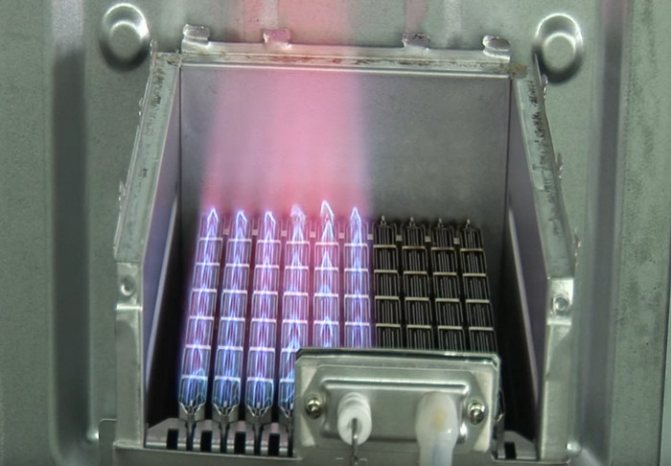

The name "turbocharged" means that the boiler has a turbine, that is, a fan that supplies air, maintains combustion and removes combustion products. The design assumes a closed type of combustion and a smoke exhaust system with several turns.

When the fuel burns, a certain amount of heated gases is released. To increase efficiency through increased heat transfer, the design provides for the passage of these gases through the channels where they give off their heat, increasing the efficiency. Thus, it is possible to reduce the temperature of the exhaust gases to 100-120 ° C. To understand how a turbocharged gas boiler works, you need to understand how equipment with a closed combustion type works.

Such units are connected to a coaxial chimney or to a pipe-in-pipe system: the inner pipe is used to remove gases, and the annular space is used to supply outdoor air. In equipment of this type, air circulation and smoke removal is carried out using a fan, the intensity of which depends on the gas pressure. It is connected to automation.

When the gas pressure changes in the system, the automation sends a signal to change the rotation speed. However, it should be understood that the system is characterized by noise and, in order to reduce its level, at the beginning of the boiler operation, it is necessary to set the minimum mode. The control of the turbine operating mode makes it possible to regulate the degree of heating.

Double-circuit gas boilers

Vaillant atmoTEC pro VUW 240 / 5-3

Compact inexpensive wall-hung boiler with excellent technical parameters

Expert rating: 95/100

The wall-mounted double-circuit boiler attracts with its conservative appearance and small dimensions inherent in the brand. This allows it to fit perfectly into the interior of the room. The model has proved to be excellent in operation with a critical drop in gas and water pressure.

The unit is distinguished by solid performance and a high degree of protection. The model is adapted for use in the residential area of the premises. The reliable chrome-nickel alloy burner is durable, and the flame modulation ensures economical fuel consumption.

Specifications:

- Power - 9-24 kW;

- Efficiency - 91.4%;

- Productivity at t-30 ° - 11.5 l / min;

- Installation option - wall-mounted;

- Weight - 35 kg;

- Dimensions - 800 × 338 × 440 mm.

The boiler has integrated software, with the help of which the parameter setting is controlled and the diagnostics of their implementation is carried out. In case of a malfunction, a self-diagnosis system of malfunctions is installed with an error code displayed on the display.

Dignity

- Separate heat exchangers

- Power adjustment

- Multistage circulation pump

- Resistant to voltage surges

- Electronic ignition

- Anti-jamming pump

- Built-in E-bus module

disadvantages

- Sensitive to voltage surges

- Volatility

- Lack of overheating protection

Lemax Premium-20B

Modern analogue to expensive imported boilers with a high level of protection

Expert rating: 89/100

Improved and modified model of a double-circuit floor boiler with simple mechanical control. The high degree of protection of the heat exchanger ensures long-term operation of the equipment. The boiler is installed in non-residential premises in natural circulation heating systems.

Despite the minimal set of functions and simple mechanical control, the boiler is characterized by a high degree of protection. Removable cladding parts ensure ease of maintenance.

Specifications:

- Power - 20 kW;

- Efficiency - 90%;

- Productivity at t-30 ° - 6 l / min;

- Installation option - floor-standing;

- Weight - 83 kg;

- Dimensions - 961 × 470 × 556 mm.

The Lemax Premium-20B boiler is non-volatile, ideal for areas where there are problems with power grids. There is a removable top panel which makes it easy to clean the boiler.

Dignity

- Injection low-flame burner

- Overheating and attenuation protection

- Increased air flow

- Mechanical control

- Energy independence

disadvantages

- Low quality automation

- Flame extinction

- Frequent breakdowns

Advantages of turbo boilers

The use of turbocharged gas boilers is associated with both positive and negative aspects.

The advantages of the equipment include:

- easy installation in any convenient place;

- air intake from the street, which does not affect the violation of the indoor climate;

- the presence of a modulation burner device adapted to operate at low fuel pressure;

- transition to liquefied gas is possible;

- the presence of automation that regulates the combustion mode depending on the weather;

- smoke exhaust without the likelihood of harmful gases entering the home.

In general, turbocharged gas installations have no analogues in terms of economy and efficiency.

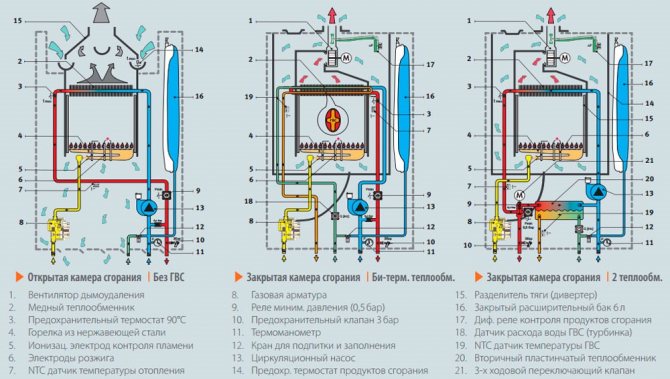

Combustion chambers of gas boilers and their features

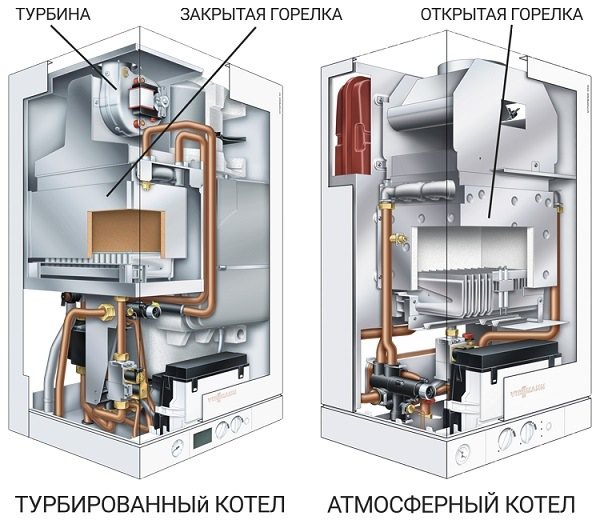

The combustion chambers of these types of boilers have significant differences in their design. This determines the way carbon monoxide is removed from them.

Turbocharged gas boilers

Here, "closed" combustion chambers are used to burn gas. Their peculiarity is that the chamber cavity does not communicate with the air of the room in which the boiler is installed. What does it do? The fact is that for normal gas combustion, air oxygen is needed in the required amount (for normal combustion of 1m3 of gas, 10m3 of air is needed) and it must be taken somewhere. So in this case, it is taken forcibly not from the room, but directly from the street is sucked in by the fan. This makes it possible not to arrange an inflow of fresh air for the boiler and not to place it in a specially allocated and ventilated room. That is, in accordance with the technical requirements, such a gas boiler has more possibilities at the place of its installation in a house or apartment.

Traditional chimney gas boilers

Open chamber boiler

These designs have an "open" (sometimes called "atmospheric") combustion chamber. It communicates with the air in the room where the gas boiler is located and the required amount of air for gas combustion will be absorbed naturally during the operation of the gas burner of the boiler. That is, the oxygen in the air will gradually be consumed and its constant replenishment is necessary. For this, supply and exhaust ventilation is needed. Its device must solve this problem, otherwise the normal operation of the gas boiler is both impossible and dangerous.

With a lack of oxygen, the following occurs:

1) the gas stops completely burning, and we do not receive the amount of heat that we should receive during the normal process;

2) carbon monoxide (CO) is formed, which in certain concentrations is life-threatening (the presence of only 1% carbon monoxide in the air when inhaled can lead to poisoning of the body with a fatal outcome).

Therefore, the operation of such gas boilers is considered more dangerous and, even with automatic protection, requires periodic monitoring of the process.

disadvantages

Among the disadvantages of turbocharged gas boilers are:

- use of electricity. Boiler automation and turbine depend on electricity;

- with regular power surges in the network, the automation may fail;

- condensation is present. Since the temperature of the flue gases does not exceed 120 ° C, condensation forms in coaxial chimneys, which can block the duct when freezing.

To solve the latter problem, the chimney is usually insulated and a condensate collector is installed.

Turbocharged or naturally aspirated?

When the buyer is faced with the choice of which boiler is better to choose: turbocharged or atmospheric, all the features of their design and operation should be considered. The main difference is that in an atmospheric boiler, the process of fuel combustion occurs in an open manner with natural air exchange, therefore such equipment is often called convection. Such boilers are connected to a standard chimney, and air for the combustion process is taken from the boiler room.

When using atmospheric boilers, there is an increased gas consumption and strict installation requirements, regulated by SNiP. Also, atmospheric equipment must not be used in multi-storey buildings and during installation, the cabinet must not be covered with decor. In a turbocharged boiler, the combustion chamber is closed. Forced air exchange and flue gas removal by means of a turbine are applied. During operation, the air from the furnace is not used for fuel combustion.

Therefore, the norms are allowed to install such equipment in small rooms, decorating the case, near the counter. Turbocharged gas boilers are connected to a coaxial chimney, which serves both for the intake of outside air and for the removal of combustion products.

Therefore, the main difference in comparison with atmospheric boilers is forced air exchange and smoke removal.

Distinctive features

Their most important difference from other types of heating devices is that they do not require a chimney. Therefore, they are allowed to be installed not only in private houses, but also in multi-storey buildings. All other functions are similar to those of atmospheric boilers.

The main advantage of turbocharged devices is their high efficiency. It is achieved by the presence of a fan in the design of the apparatus, which sucks in only the required amount of air.

Moreover, control over its work is carried out using a sensor that analyzes the flow of gas and allows you to economically consume energy.

Closed-loop gas boilers differ in the method of removing decay products into:

- coaxial vertical

- horizontal

- vertical of a pair of pipes

- connected to a pipe with a flue duct

The advantages of this type of technology include the possibility of their installation with gas channels from water heaters. This became possible due to the separate exhaust and intake, incorporated in the design features of the device. In this case, the hole from the coaxial pipe is closed with a plug.

The wall-mounted turbocharged gas boiler has a high performance. It is capable of producing up to 12 liters of hot water per minute, which is enough for the needs of people living in the house.

In this case, heating is provided in line mode, for this the boiler is equipped with an additional burner.

Also, the advantages include the presence of an electronic control system for this type of equipment.It provides automatic maintenance of the set temperature in the room, and is a protection against emergency situations, such as short interruptions in the gas supply.

Floor standing turbo boilers

Floor standing turbo boilers generally have high power and are reliable in operation.

When choosing a floor-standing option, the following characteristics should be analyzed:

- heat exchanger material (cast iron or steel). Cast iron is more reliable and durable (up to 35 years), but steel is cheaper;

- number of circuits: can be single-circuit and double-circuit. Some models have a built-in container for preparing hot water. If there is no need for DHW, then a single-circuit floor boiler can be used, which copes well with heating large rooms, since there is no energy consumption for DHW.

The disadvantage of floor-standing turbocharged boilers is the size. This is important when placing it in a small area. The advantage is reliability, all units and parts of the boiler are made of durable materials due to the absence of weight restrictions. Such boilers are used for about 5 years longer than wall-mounted ones.

Criteria for choosing an atmospheric and turbocharged gas boiler

The equipment differs in the type of installation, power, dimensions and weight. An important parameter for operation is the boiler efficiency, it will depend on it how costly the heating season will be.

Power

The main characteristic that determines the boiler's ability to heat the room. To calculate it, take into account:

- the area of the room and its volume;

- type of home insulation;

- type of heated object (apartment or private house);

- climatic region.

Features of atmospheric boilers – lower efficiency, which must also be taken into account when choosing the power of the equipment.

Weight and dimensions

For wall-mounted models, the weight ranges from 25 to 50 kg. Most boilers have standard dimensions 70 * 40 * 25 cm. The weight depends on the power of the boiler and the availability of additional equipment: sensors, touch panel, additional cameras.

| It's important to know! More modern models are lighter and lighter. |

Efficiency

During the operation of the boiler, part of the energy is lost, therefore each model has such a parameter as efficiency. It shows how much of the resource will be used profitably.

The efficiency of atmospheric boilers varies within 80-90%, for turbocharged versions this parameter is 90-97%. The difference is formed due to the temperature of the outgoing gases: in the first group it is 110 degrees, in the second - 55.

Main characteristics

By the type of installation, floor and wall structures are distinguished. Boilers are single-circuit (provide only room heating) and double-circuit (provide hot water supply).

By the type of connection to the mains, volatile and autonomous models are distinguished.

| It's important to know! All turbocharged boilers are volatile, since the air flow into the chamber is provided by a pump. |

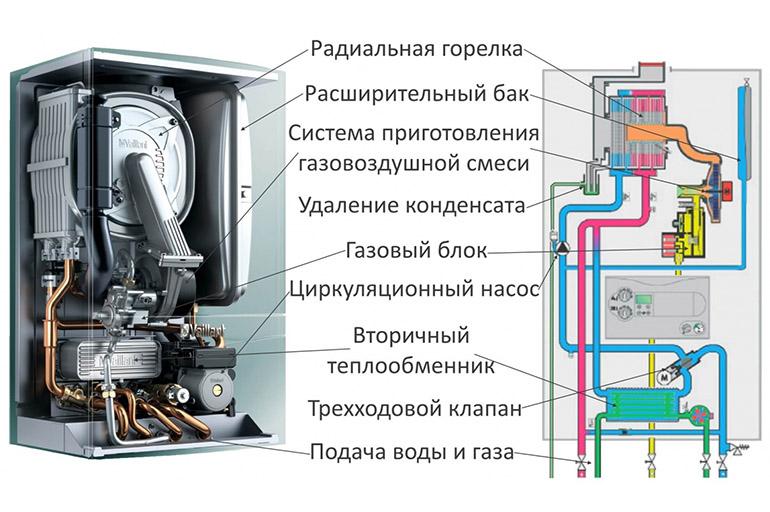

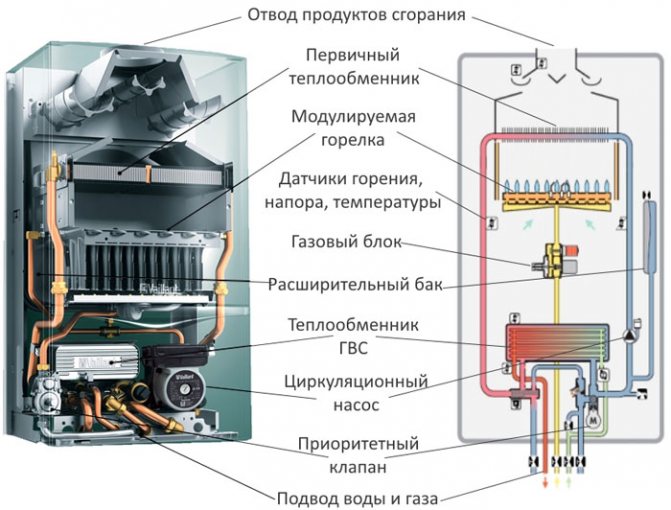

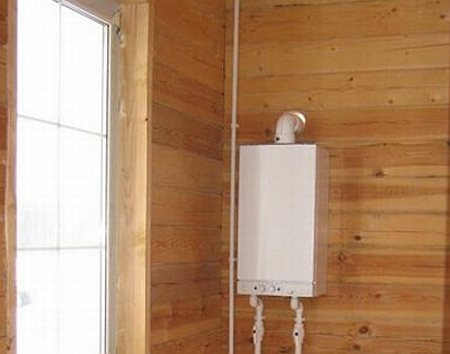

Wall mounted turbo boilers

Photo: idroclimaterm.it

Wall-mounted turbocharged boilers are very common, as they are compact, have a beautiful design and are easy to install.

Wall-hung boilers have the following features:

- simple installation and connection;

- fast heating. Despite the fact that water heating is carried out in a flowing manner, it occurs instantly;

- weather-dependent automation, modulating burner.

The most popular are double-circuit turbocharged boilers, since single-circuit boilers are convenient for use only for heating non-residential buildings.

Principle of operation

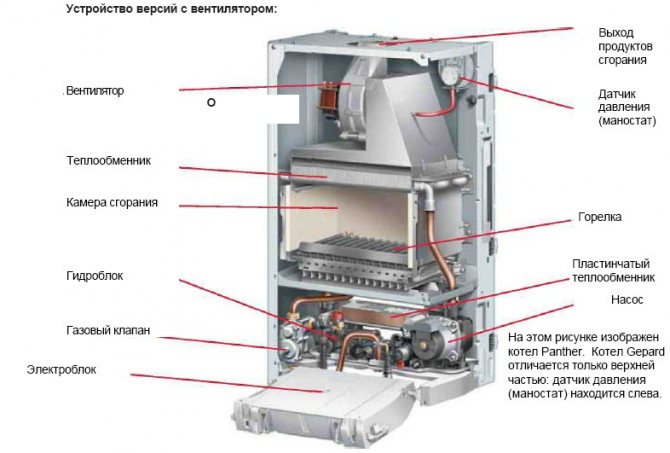

Gas turbocharged boilers are used both for organizing hot water supply and for heating. Heating of the coolant in wall-mounted equipment of the bithermic type is carried out by heating water from the heat generated by the combustion of gas.Gas double-circuit boilers with a plate heat exchanger heat the coolant using an internal circuit.

Fig. 3 Wall hung gas boiler

Well-known manufacturers produce wall models of various types, among which you can always choose the appropriate option. The choice of a gas turbo boiler primarily depends on the quality and hardness of the water, the available budget and individual requirements. When purchasing turbocharged wall-mounted units with a bithermal heat exchanger, it should be borne in mind that filters may need to be installed. If this is not possible, it is better to buy a double-circuit model with a plate.

For domestic heating systems, the second option with a wall installation is considered more reliable. With improper installation and operation of bithermal turbocharged gas units, the coolant in the main heat exchanger boils up, which negatively affects their functionality.

Double-circuit turbo boilers with a plate heat exchanger are currently the bestsellers due to the fact that they are less demanding on water quality and are easier to install and maintain.

The best manufacturers of turbocharged boilers

The most popular and high-quality equipment is produced by German firms. Italian and French companies follow. A number of Russian enterprises have mastered the production of turbocharged boilers, and their quality is approaching the level of world brands.

The first in the quality rating is the products of the companies: Buderus, Bosch Gas, Protherm, Vaillant... Slightly inferior to them: Baxi, Neva Lux, Arderia.

Next are the slightly inferior Korean brands: Navien, Daewoo, Kiturami, Hydrosta.