A diaphragm tank for DHW is an extremely important element of the indirect heating boiler piping. It is important that it be in general, it is important to choose the right volume and initial pressure.

So that you are convinced of this, I want to tell you a story, then we will move on to the choice of tank parameters, and after that we will consider the main elements of the boiler piping.

The material will be very useful, so download my manual "Diaphragm expansion tank and the main elements of the boiler piping" for your reference.

History of finding water leaks.

Once I came to the site to the customer. It was necessary to make heating and water supply to the bathhouse - a guest house with a swimming pool. There are radiators and underfloor heating, ventilation and equipment for the pool. In short, if you add subcontractors as well, then the order is monetary. The customer is not stuffy and not stingy, great.

But at the beginning of the conversation, he asks: Sergey Nikolaevich, I have such a problem in my main house: the water consumption has always been 25-40 cubic meters, and for some reason more than a hundred for the last two months. Everywhere in the house is dry. Can you see what is the reason? And I understand: if I find a leak now, I will take the order; if I don’t find it, I will lose it in disgrace.

We checked all the taps for consumers - they were closed, the dishwasher and the washing machine were turned off, there was no murmur in the toilet bowls, all the taps in the garden were closed. And the counter is spinning. I went from the meter along the cold water pipe. Cold pipe, already with droplets. On the floors - collectors for water sockets - at room temperature.

Only the pipe to the boiler is cold, up to the safety valve. The valve itself is cold and you can hear the rustling of water in it. From the valve, a discharge tube is carefully directed into the drain. Also cold and wet. That is, the safety valve does not hold, and cold water flows through it directly into the sewer.

You ask, but where does the membrane tank of the boiler have to do with it? Yes, here's what: I unscrewed the nipple cap, pressed the stem, and silence. There is no air, it has leaked out. The tank must compensate for the thermal expansion of the hot water in the boiler during heating. When expanding, water goes into the tank, compressing its air part. If the pressure rises, then slowly, and will not exceed the pressure of the safety valve. And here the air has flowed out, there is nothing to compress. The entire tank is filled with water. When the doiler warms up, the pressure rises rapidly beyond 6 bar, and the valve is activated by dumping some of the water. After several dozen such discharges, the safety valves often begin to leak. And then the caring installers installed a discharge outlet into the sewer. The user does not understand what is happening at all, some miracles.

In general, the diagnosis was about fifteen minutes. I said that tomorrow our fitter would come up, replace the valve and pump up the tank. There will be no leaks. We received the order.

The customer also asked for an additional boiler to be supplied. This, 150 liters, was not enough to fill the jacuzzi. So there it is! the puzzle came together. This means that often it was necessary to heat the boiler from the minimum to the maximum, which means that the water expanding as much as possible when heated. When the air escaped, this inevitably caused an exorbitant excess of pressure and the actuation of the relief valve.

Do you understand how important it is that there is enough air in the tank for the smooth operation of the system?

Tying hot water storage tanks

Structurally, being a vertical or horizontal tank, the BAGV tank is completed with technological equipment for safe operation:

- automatic level controls to prevent overflow

- instrumentation for measuring liquid temperature, pressure, filling level, etc.

- blocking equipment, if necessary, turn off the water supply when the min level remains

- devices for measuring pressure in supply and discharge pipelines

- safety equipment

- drainage system to remove residues

- loading and unloading equipment

- overflow pipe at the maximum allowable level

- pipe for drainage of water from the overflow pipe

- a vestibule pipe, which prevents the formation of a vacuum during drainage due to the release of the steam-air mixture

- heat insulation from the outside

Specialists of the Saratov Reservoir Plant manufacture hot water storage tanks BAGV in any climatic design, of any design (horizontal / vertical, open or closed type), completing them with the necessary technological equipment.

What is the initial pressure to create in the tank.

The tanks come from the factory at 2.5 bars. Someone puts it right. I have a different approach and I will explain why.

Air must be pumped into the tank based on the pressure of cold water. For example, 4 bars come to the house from the central water supply. Create a little more air pressure in the tank, for example 4.2 bar. This is the opinion of at least one more respected author, I agree with him and explain why. If the air pressure was 2.5 bar, then after connecting the tank to water, it will compress the air in it to the same four, and the working volume of air will be significantly reduced, by almost half. If the pressure is set to 4.2, then the volume of air for compression will be consumed only with the beginning of the real expansion of water. Take a look:

Heat accumulator calculation

The calculation formula is very simple:

Q = mc (T2-T1), where:

Q is the accumulated heat;

m is the mass of water in the tank;

c is the specific heat capacity of the coolant in J / (kg * K), equal to 4200 for water;

T2 and T1 are the initial and final temperatures of the coolant.

Let's say we have a radiator heating system. Radiators are matched to a temperature regime of 70/50/20. Those. when the temperature in the battery tank drops below 70C, we will begin to experience a lack of heat, that is, we will simply freeze. Let's calculate when this will happen.

90 are our T1

70 is T2

20 - room temperature. We will not need it in the calculation.

Let's say we have a heat accumulator for 1000 liters (1m3)

We count the heat supply.

Q = 1000 * 4200 * (90-70) = 84,000,000 J or 84,000 kJ

1 kWh = 3600 kJ

84000/3600 = 23.3 kW of heat

If the heat loss at home is 5 kW on a cold five-day period, then the stored heat will be enough for us for almost 5 hours. Accordingly, if the temperature is higher than the calculated one for a cold five-day period, then the heat accumulator will be sufficient for a longer time.

The selection of the volume of the heat accumulator depends on your tasks. If it is necessary to smooth out the temperature, set a small volume. If you need to accumulate heat in the evening in order to wake up in a warm house in the morning, you need a large unit. Let the second challenge stand. From 2300 to 0700 - there must be a supply of heat.

Suppose that the heat loss is 6 kW, and the temperature regime of the heating system is 40/30/20. The heat carrier in the heat accumulator can heat up to 90C

The stock time is 8 hours. 6 * 8 = 48 kW

M = Q / 4200 * (T2-T1)

48 * 3600 = 172800 kJ

V = 172800/4200 * 50 = 0.822 m3

A heat accumulator from 800 to 1000 liters will meet our requirements.

Tank service.

If the safety valve has worked, it means that air has escaped from the tank, or the diaphragm has leaked. Unscrew the tank nipple cap and push the stem. If water comes out, then the membrane is torn and the tank needs to be replaced. If nothing went wrong, or the air hissed, then you need to pump it up: • give the union nut on the squeegee - cutoff, • open the drain cock (red handle) and drain the water, • pump up pressure, for example, with a car pump, • close the drain clan.• attach and tighten the union nut.

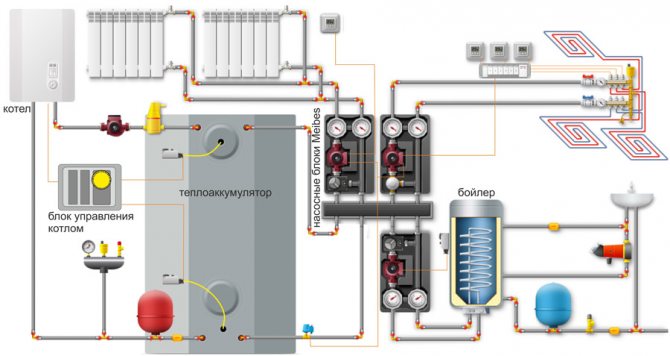

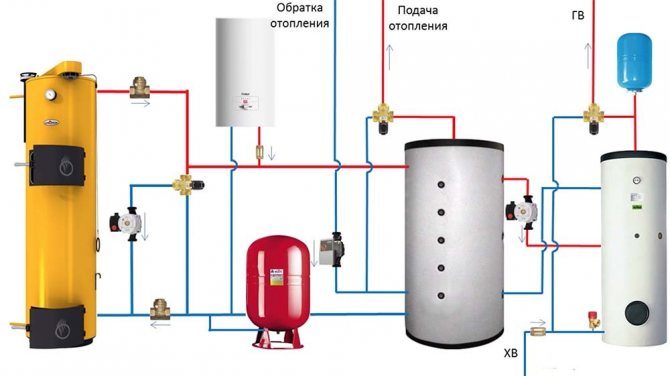

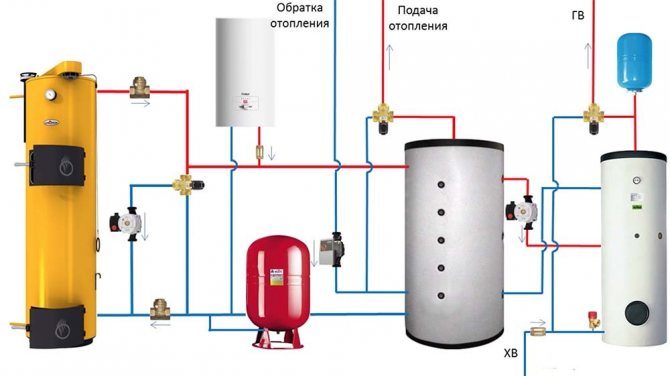

Connection diagram with a boiler

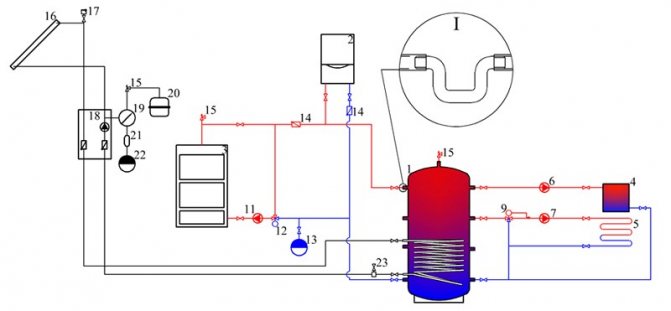

Consider another scheme for piping a solid fuel boiler, in which, in addition to a heat accumulator, there is a boiler. We will not redo the boiler part, we will leave it unchanged. Similarly to the previous diagram, we will connect the entire heating system. Only the indirect heating boiler added to the planned circuit will be new. Inside the model we have chosen is a coil through which the heated coolant passes. Thanks to this, the water is heated directly and pumped using a special pump. Based on the experience of previously used circuits, I recommend using the leads connected to the boiler away from those connected to the boiler itself and heating radiators.

Another expansion tank must be installed at the outlet of the prepared hot water from the boiler. After that, we cut in a petal safety valve at the inlet to the cold water system. According to this scheme, it is permissible to supply hot water without additional inserts directly to the bathrooms. The pipes will not be too hot - the boiler automatically controls the temperature of the coolant inside itself.

It may be useful to put an additional mixer at the outlet, since it is periodically required to do preventive disinfection of the internal cavity with a high temperature in the boiler. When the system heats up, there is a chance of scalding with steam if at this moment someone opens hot water. In addition, the mixer will allow you to leave an increased supply of hot water in the boiler. For this, the electric boiler must be connected to the boiler, but the circuit will be built directly according to a different scheme.

The recirculation line in the boiler is connected through a special additional outlet. We connect the reinforcement to the circuit according to the scheme discussed above. Please note that in the above diagrams, only the hydraulic part is disassembled in detail, without installation of insulation.

What's in the know Installation of an indirect heating boiler:

• Device and principle of operation. • How to choose the volume of the boiler. • Simplified wiring diagram for floor and wall boilers. • Detailed diagram of the boiler piping. • Detailed equipment. • How to heat a boiler with a wall-mounted single-circuit gas boiler. • Connection of a wall-mounted single-circuit gas boiler with a boiler. • How to heat a boiler with a floor-standing boiler. • Scheme of piping of the pump manifold for multi-circuit boiler houses with a boiler. • Boiler heating control from its own thermostat. • Control of boiler heating with a separate immersion thermostat. • Scheme of boiler priority over other consumers. • Application of heating elements and night tariff. • Additional materials.

Other articles about diaphragm tanks:

1. Where in the boiler room should the expansion tank be installed for heating.

2. How to choose a membrane accumulator tank and set up a water supply system. Sergey Volkov.

When is it profitable to install a heat accumulator:

- you have a solid fuel boiler;

- you are heated by electricity;

- solar collectors added to help with heating;

- it is possible to recover heat from units and machines.

The most common use of a heat accumulator, when a solid fuel boiler is used as a heat source. Anyone who has used a solid fuel boiler to heat his home knows what comfort can be achieved with such a heating system. Flooded - undressed, burned out - dressed. In the morning in a house with such a source of heat, you don't want to crawl out from under the blanket. It is very difficult to regulate the combustion process in a solid fuel boiler. It is necessary to heat both at + 10C and at -40C. Combustion and the amount of heat generated will be the same, only this very heat is needed in completely different ways. What to do? What kind of efficiency can we talk about when you have to open windows at positive temperatures. There can be no question of any comfort.

The installation diagram of a solid fuel boiler with a heat accumulator is an ideal solution for a private house when you want both comfort and savings. With such a layout, you heat up a solid fuel boiler, heat water in a heat accumulator and get as much heat as you need. In this case, the boiler will operate at maximum power and with the highest efficiency. How much heat will be given by firewood or coal, so much will be stored.

Second option. Installation of a heat accumulator with an electric boiler. This solution will work if you have a two-tariff electricity meter. We store heat at a nightly rate, spend it both day and night. If you decide to use such a heating system, it is better to look for a heat accumulator with the ability to install an electric heater directly into the barrel. An electric heater is cheaper than an electric boiler, and no material is required for piping the boiler. Minus the work of installing an electric boiler. Can you imagine how much you can save?

The third option is when there is a solar collector. All excess heat can be dumped into the heat accumulator. In the demi-season, excellent savings are obtained.

Vertical tanks for refrigeration

Carbon steel

- Series V

- VK series

- VKG series

- VKT series

Series V includes a range of non-insulated galvanized chilled water tanks typically used to increase the thermal inertia of an air conditioning system.

- Fiorini industries series V 100-5000

VK series The VK series comprises a range of galvanized chilled water tanks fitted with thermal insulation, typically used to increase the thermal inertia of an air conditioning system. The zinc coating protects the tank from corrosion.

- Fiorini industries series VK 100-1000

- Fiorini industries series VK 1500-5000

VKG series includes a range of galvanized carbon steel tanks for chilled water or water / glycol mixtures, equipped with thermal insulation. VKG-HC series includes hot / cold tanks equipped with thermal insulation, typically used to increase the thermal inertia of an air conditioning system.

- Fiorini industries series VKG 100-1000

- Fiorini industries series VKG-HC 100-5000

VKT series includes a range of internally enameled and insulated chilled water tanks typically used to increase the thermal inertia of air conditioning systems. Internal enamel coating provides anti-corrosion protection for the tank.

- Fiorini industries series VKT 100-1000

- Fiorini industries series VKT 1500-5000

Stainless steel

- VKX series

VKX series includes stainless steel chilled water tanks typically used to increase the thermal inertia of air conditioning systems. Stainless steel provides excellent corrosion protection for the tank, making it particularly suitable for use in corrosive environments and for industrial applications.

- Fiorini industries series VKX 100-5000

Dividing

- VKS series

- VKR series

- VKD series

VKS series includes chilled water tanks typically used to increase the thermal inertia of a single ring air conditioning system. Equipped with dividing baffles that avoid the formation of selective flows inside the tank, thereby creating conditions for optimal temperature distribution. They are especially suitable for use with medium and high flow rates, as well as for special designs where the tank provides for the possibility of connecting to more than two circuits.

- Fiorini industries series VKS 100-1000

- Fiorini industries series VKS 1500-5000

VKR series VKR insulated tanks are generally used to increase the thermal inertia of a two-circuit air conditioning system. Equipped with outgoing pipes that create a priority circuit inside the tank.

- Fiorini industries series VKR 100-1000

- Fiorini industries series VKR 1500-5000

VKD series VKD chilled water tanks equipped with thermal insulation are generally used to increase the thermal inertia of a two-circuit air conditioning system. Equipped with diffuser pipes that directly connect the two circuits connected to the tank. Energy enters or exits the storage tanks through the circular openings of the diffuser. This minimizes mixing in the tank.

- Fiorini industries series VKD 100-1000

- Fiorini industries series VKD 1500-5000

Volume of the tank.

If there were no tank, the pressure in the system would drop immediately when the tap was opened and the pump would immediately turn on. It would just as quickly build up high pressure and stop. That is, when filling, for example, a bucket of water, the pump would constantly start and stop. The tap jet would also pulsate. The tank helps to make starts and stops much less frequently, which increases the pump resource and the comfort of the system. The larger the tank, the less often the pump will turn on. The pumps have a passport value for the number of starts per hour. This value is given in the documentation for the pumps, and is often about 50

... But be sure to see the instructions. For example, this rate for Grundfos with MS 402 and MS 4000 engines is 100 times per hour. Tank manufacturers indicate that this is usually

12 – 15

.

The volume of the tank is proposed to be calculated using the formula:

Fig. 2. The formula for calculating the volume of the accumulator tank. The formula is complex, it is easy to make mistakes, so I made a small Exel file for you. You just have to substitute your values. Download it for yourself along with the training manual.

n

- the number of pump starts per hour, 1 / hour - we take from the pump passport;

Pmax

- set pressure

shutdown of the pump,

bar;

Types of heat accumulators

Depending on the manufacturing characteristics, there are several types of such tanks:

- steam;

- liquid;

- thermochemical;

- solid state;

- with auxiliary heating elements.

In water supply and heating systems of private houses, accumulators with hot water are more often used, since this coolant has a high specific heat capacity. Any type of tank has an outlet and an inlet branch pipes coming from the boiler and from the heating system. In some heating systems, a special heating antifreeze is used instead of water.

Types of safety valves with pressure control for the heating system

A modern storage-type water heater can serve as an example of a water heat accumulator, equipped with an additional heating element. It is used in hot water systems.

What is a storage tank for a heating system

An accumulation tank is a device for storing and storing heat. Outwardly, the structure resembles a thermos, because its walls are insulated with heat-resistant foam rubber, which retains heat well. In fact, it is a sealed container with a large volume, in which heat accumulates during the operation of the heating boiler. After all the fuel in the boiler has burned out, the storage tank gradually transfers heat energy to the heating system.

Important! The accumulator tank increases the efficiency of the heater and reduces the frequency of fuel loading.

Such a buffer in heating systems is a necessary element, because it allows you to accumulate heat energy from different sources, and then evenly distribute it throughout the system. The main element of this product is a heat insulator.