Basement waterproofing is one of the most important activities that can be carried out both at the stage of building a house and after its completion. The basement part is a kind of connecting link between the foundation and the rest of the building. Therefore, its strength, stability and non-susceptibility to various influences will determine the durability and reliability of all structures of the house. During the operation of the building, in particular, with the help of the plinth, the interior rooms are protected from moisture penetration.

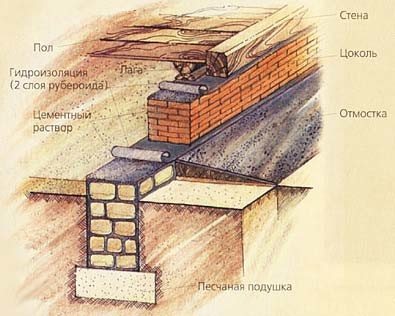

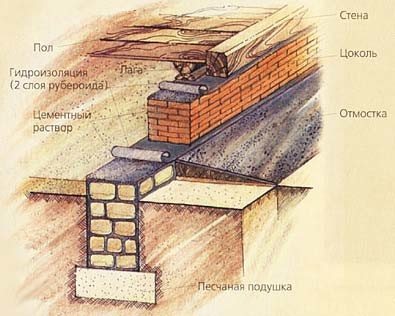

It should be noted that it is the outer part of the basement floor that is most exposed to moisture, therefore it is very vulnerable. The plinth takes on the influence of upstream water, groundwater, rain and other precipitation. There must be a reliable waterproofing and heat-insulating layer between the foundation and the upper structure of the building. This is how you need to make the basement of your house. Additionally, it is recommended to organize drainage of the site.

Insulation types

In order to reliably protect the base from moisture, it should be taken into account that the structures will have to be protected in two planes at once:

- Vertically. It is necessary to apply moisture-proof material on the outside of the walls.

- Horizontally. Moisture-proof materials are laid between the foundation and the outer part of the basement.

The horizontal waterproofing of the basement floor from the outside will exclude the penetration of moisture into the interior of the house. The waterproofing device in this case involves the use of roll materials, among which roofing material and roofing felt are more popular. It is best to choose roofing material, because roofing felt cannot provide long-term protection of the basement from moisture penetration.

The modern roofing material offered on the market is quite effective. It is made from bitumen, therefore it is perfect for waterproofing the outside of the building and between the foundation and the walls of the house.

Vertical waterproofing is more variable than horizontal, therefore (depending on operating conditions and other factors), you can choose a more suitable option:

- Bituminous mastics and analogues. The thick liquid mastic allows you to create on the outside (on the outside of the basement floor) powerful protection that will have excellent performance and operational characteristics. Of course, there is no need to talk about the strength of the material here, because the hardened mastic is easily exposed to mechanical stress. Experts recommend preferring liquid glass.

- To paint the base, you can use special protective varnishes, which are distinguished by an affordable price and ease of application. These varnishes have no more advantages.

- Using synthetic resin or liquid polymer waterproofing materials, you can create a more or less high-quality waterproofing layer. But if effective drainage of the site is not provided, these materials will remain useless.

- The plinth outside can also be pasted over with roll materials. In principle, the option is good, but again, a lot here will depend on the operating conditions.

When choosing the type of waterproofing, it is necessary to take into account what materials the basement is built from, as well as what building materials are supposed to be used in the future for finishing. The horizontal waterproofing of the basement deserves special attention.

Principles of protection of bases and foundations from freezing

The soil under the building is affected by the cold outside air and the heat from the building.

Insulation reduces the impact of low temperatures on the base of the building. It can be installed from the outside, from both sides, or as part of the basement structure - inside the foundation wall. The best result is obtained if the thermal insulation is on the outside of the foundation.

Under the recessed base, a base is made of a compacted layer of crushed stone to prevent damage to the foundation from frost swelling of the soil: 1 - soil; 2 - line of temperature equilibrium; 3 - heat-insulating layer; 4 - direction of action of negative temperatures; 5 - direction of heat input.

Thermal insulation is usually placed around the building within about 1 m of the foundation. It is laid at a depth of about 30 cm so that it slopes away from the walls of the building.

As insulation, various heat-insulating materials are used, if possible, with a minimum degree of hygroscopicity. The thickness of the protection depends on the material used.

The thermal insulation material must not only have good thermal insulation properties, but also meet the strength standards. Therefore, when choosing a thermal insulation material designed to protect the foundation from freezing, it is necessary to take into account the load it perceives.

Quite often, after the end of the winter season, cracks appear on the facades and basements of cottages, door frames warp or cracks appear in window frames. The cause of these troubles in most cases is the movement of the foundations of the foundations caused by the forces of frost heaving of the soil, which arise as a result of an increase in the volume of the soil when it freezes.

Almost all soils (except for rocky ones) can be subject to frost heaving, but to the greatest extent this disadvantage is inherent in clay soils (loams, clays, sandy loams, fine and silty sands), as well as sands containing silty clay particles. Sands are gravelly, large and medium, not containing silt-clay particles, are considered non-porous.

As already noted, soils containing the smallest dusty and clay particles are exposed to frost heaving. Compared to coarse and medium sands, these particles bind water very well. When freezing, the mass saturated with water significantly increases in volume, begins to put pressure on the structures in the ground and push them out of the ground.

Frost heaving deformations are the result of the impact on the structure of the so-called normal and tangential forces. The former arise under the base of the foundation as a result of freezing and an increase in the volume of heaving soil, the latter due to the vertical displacement of the soil frozen to the side surfaces of the foundation or to the walls of the basement. In addition, the frozen soil that has increased in volume begins to press perpendicular to the surface of the basement walls, causing deformation of the foundations in the horizontal direction.

The heaving process intensifies with an increase in the moisture content of heaving soils as a result of atmospheric precipitation (in particular, heavy autumn rains), with a capillary rise in moisture and an increase in the level of groundwater. In the Moscow region, 80% of all soils belong to the category of heaving, and the depth of their freezing in winter can reach 1.4 m.

Therefore, the protection of foundations, pipes laid underground, areas covered with asphalt or tiles, as well as entrances to garages from deformations caused by frost heaving forces is an absolute must. To reduce the impact of frost heaving forces on underground structures during construction and repair of a house, it is recommended to perform the following measures (Table 1).

Table 1

Causes causing deformation of structures Constructive solution The effect of normal forces of frost heaving on the base of the foundation Backfill device (1) 100-200 mm thick under the base of the foundation made of non-heaving soil: gravelly, coarse or medium-sized sand, gravel, crushed stone or sand-crushed stone mixture (sand 40% crushed stone 60%) Impact of tangential forces of frost heaving on the side surfaces of foundations and basement walls arrangement of coating (2) the side surface of foundations and basement walls, which reduces their roughness and adhesion forces with frozen heaving soil to the depth of freezing; backfilling (3) of the sinuses of the foundation to the entire depth of freezing with non-porous soil; the width of the backfill along the bottom of the excavation should be at least 0.5 m. Moistening of the heaving soil with atmospheric precipitation. The device of the blind area (4) with a slope of 3-5% to the side of the house, the width of which exceeds the width of the excavation for backfilling. Groundwater Drainage device (5) for lowering the level of groundwater and its removal from the foundation Silting of non-heaving soils with dusty-clay particles Protection of the sand bed from the penetration of particles of heaving soils into it with special filtering materials (6)

Penetrating waterproofing

The main advantage of penetrating waterproofing is that it penetrates deep enough into the concrete. The mixture will gradually move along miniature cracks into the concrete, clogging up all capillaries and pores through which moisture can flow. In addition, the penetrating waterproofing enters into a chemical reaction with the concrete itself, becoming a "single whole" with it.

Penetrating waterproofing will significantly increase the strength of concrete (the manufacturer notes that the strength increases by about 20-30%). In addition, concrete becomes inert to chemical attack.

The work technology is as follows:

- Penetrating insulation is presented in the form of a dry powder, which must be diluted in water and the resulting mixture is stirred to the required density.

- The mixture is applied to a damp concrete surface.

- Apply layer by layer. It is recommended to use special synthetic brushes for this.

- Processing the basement floor with these materials from the outside is allowed only at a positive temperature outside.

Insulation of foundations

Fig. 3

- basement wall; sand backfill 200 mm thick; extruded polystyrene foam; sand and gravel backfill 300 mm thick.

The measures considered make it possible to reduce the effect of frost heaving forces, but not to eliminate their cause. To exclude frosty heaving of soils allows the device of thermal insulation around the building. The essence of this method lies in the fact that the soil located near the building is protected from freezing by heat-insulating materials and thereby the cause of frost heaving is eliminated.

For the device of thermal insulation of the material, heaters are used that are able to maintain the necessary heat-shielding qualities in a humid environment and to perceive the loads from the structures located above them. Extruded polystyrene foam of various grades meets these requirements to the greatest extent.

Of no small importance is the fact that the proposed technology can be implemented both during the construction of new houses and during the operation of existing buildings, and the placement of heat-insulating material along the perimeter of the building allows not only to protect the soil from freezing, but also to insulate basements (Fig. 3 ).

The soil around the house is dug to a depth of 0.5-0.6 m. The dimensions of the recess should ensure that the insulation is laid at least 1.2 m wide.After that, a layer of washed sand with a thickness of at least 200 mm is poured onto the bottom of the trench, a small slope of the sand cushion is arranged away from the foundation and carefully tamped.

Heat-insulating plates made of extruded polystyrene foam are laid on the sand. The thickness of the slabs is taken depending on the thermal conductivity coefficient of the insulation (Table 2).

Table 2.

Thermal conductivity coefficient of the insulation, W / m ° С 0.030.0350.040.0450.05 Insulation thickness, not less than, mm 60708090100

It should not be forgotten that the heat loss through the outer corners of the building significantly exceeds the losses through the smooth surface of the wall, therefore, additional insulation must be provided in the corner zone. For this, at a distance of 1.5-2 m from the corner, a heater is laid with a thickness of 1.4-1.5 times greater than that shown in the table (Fig.

four). Then the insulation is covered with a layer of sand or gravel at least 300 mm thick to the ground surface. Such insulation will prevent the soil from freezing and the appearance of frost heaving forces.

Fig. 4

- exterior walls of the house; insulation from extruded polystyrene foam around the perimeter of the house; additional insulation with extruded polystyrene foam in the area of the outer corners;

Roll waterproofing

Roll waterproofing (aka bituminous, polymer, synthetic) is applied to all basement structures of the building. As a rule, the outer parts of the walls are covered with 2-3 layers of roll waterproofing for reliability. If the building is located on an area where there is a high level of groundwater or active perching, then it is recommended to make 4-5 layers of waterproofing in order to exclude the possibility of moisture penetration into the house.

The roll insulation for the plinth is glued with an overlap, therefore, the protection of the foundation from moisture in this case is at an extremely high level. Additionally, all joints can be covered with liquid waterproofing, which will provide a very high result.

Rolled waterproofing is not resistant to mechanical stress, therefore it is recommended to additionally protect it. Despite the use of waterproofing, good drainage of the site is necessary if the groundwater is located high enough.

Waterproofing rules

Each process that accompanies construction has its own characteristics. If you neglect them, you can spoil the whole idea and get unpleasant consequences. We will analyze the important points that require increased attention when performing actions aimed at protecting the basement of your house from moisture.

- To understand what type of insulation is right for your home, you need to establish the water table.

- If you are building your foundation on loose soil, then possible flooding or flooding due to heavy rainfall should be prevented.

- Pay attention to the factor that the soil tends to swell. This phenomenon occurs due to the constant change in weather conditions and the ability of water to expand or contract during the processes of freezing in winter and thawing in spring. Thus, the structure of the water changes, which causes deformation of the foundation.

- Consider the conditions under which the building will be used. If you are building an object for commercial purposes, for example, warehouses, then the level of waterproofing should be chosen the best.

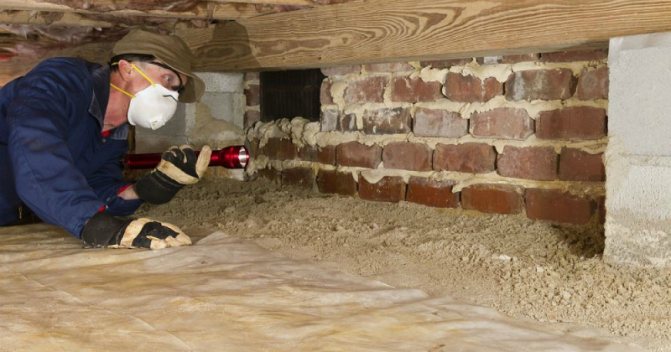

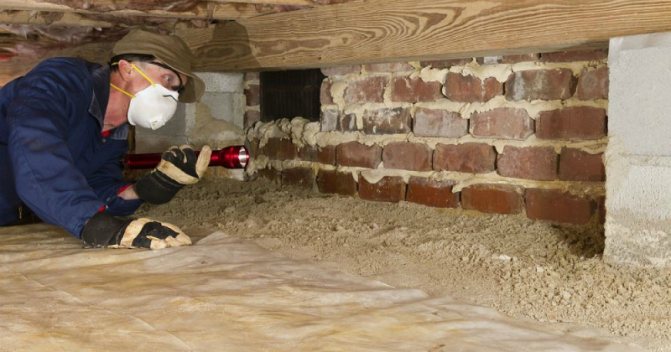

Protection of a brick base from water

The device of a brick basement is a traditional solution for many types of country houses. You can isolate it from moisture using the following simple technology:

- Before you start laying, you need to purchase a brick that has been pre-treated with special impregnations that protect the material from moisture (of course, such bricks are more expensive, but when operating the basement and the entire building, the costs pay off).

- On the surface of the masonry, after cleaning it, it is necessary to apply bituminous mastic in 3-4 layers (or any other analogue of coating waterproofing).

- Further, the surface is necessarily covered with roll waterproofing (you can take a regular roofing material or any modern material).

- Penetrating waterproofing can also be applied if desired.

It is recommended to consult with specialists about the use of certain materials in specific climatic conditions.

Once again, we note that in any case, when installing high-quality waterproofing, effective drainage of the site is required. It is drainage and its entire system that guarantee the absence of large volumes of water on the site around the house.

Roll, coating and penetrating waterproofing, drainage and high-quality performance of all work - these are the main components of high-quality protection of the basement from moisture penetration.

Chief editor of the site, civil engineer. Graduated from SibSTRIN in 1994, since then he has worked for more than 14 years in construction companies, after which he started his own business. The owner of a company engaged in suburban construction.

The importance of protecting the foundation from water

The foundation is the main barrier between the groundwater and the basement. Poor insulation from moisture, an ill-conceived version of the material used cause the formation of dampness, fungus and mold. The porous structure of concrete, even the most durable concrete, is well impregnated with water and subsequently:

- cracks form in the foundation;

- the room loses its warmth;

- the building structure is gradually deteriorating.

Ideally, when waterproofing is carried out by specialists who will take into account the characteristics of the foundation, soil, climatic conditions and other important factors. This is the only way to achieve 100% effectiveness of protection against water.

Polyurethane mastics for foundation protection

From time to time, TV channels tell us how a whole house or part of it suddenly collapsed somewhere. We do not want to scare you, as idle TV people do. But let's say that there is no "sudden" in the case of the destruction of a building. Any structure starts from the foundation and rests on it. If it is not strong enough and moisture resistant, then the house will not stand for a long time. The most common causes of foundation destruction are dampness, moisture, loose and water-saturated soil, heterogeneous soil, the beginning of the construction of a new house or a road nearby. It only seems that the foundation is heavy and will withstand everything. No, it is, first of all, a movable structure that is sensitive to any load and changes in the environment. Polyurethane mastic will help protect the foundation from destruction.

Foundation protection methods

The first and only effective remedy against freezing of foundations is their insulation. There are several proposed protection of foundations from freezing - mineral insulation, polymer foil material and cement-sand plastering. Each of the options has the right to life, but first it would be very nice to dry the foundation - the drier it is, the better.

The foundation below the depth of soil freezing is dangerous only in the block version - freezing blocks can move them relative to the total masonry, reducing the adhesion of the solution. Or completely tear them off, which will force the homeowner to seriously fork out for the creation of an armored belt, a pulling bracket, or replacing an entire block.

How to understand that your foundation is in danger

There are several signs that can help you identify the problem in the first step. Usually, thin cracks, spots, mold on the walls inside the house, distortions of door and window structures appear on the foundation, then the external finish begins to collapse, the floor deforms, some parts of the building collapse, the soil falls along the structure.If you notice cracks, it is worth checking the stability of the base.

The most common problem in Russian latitudes is excess moisture. Usually concrete is used for the foundation. It is a porous material that can take in some water. But if there is too much of it, then the concrete will not cope. In addition, moisture can linger inside, freeze and thus destroy the material.

Which waterproofing to choose

There are several main types of waterproofing. To choose the best option for you, you need to understand what type of soil you are dealing with, how deep the groundwater goes, at what depth the foundation is located, what it is made of, what size the building is.

There is one simple way to check how deep the groundwater goes. In the spring or fall, dig small holes where you plan to build your house. And look to what level the water reaches in them. This will determine how deep the foundation can be set.

If you notice that there are many marsh plants and sedges near the site, then the water is close.

We decided to arrange a basement or basement, which means that waterproofing is needed for sure.

Very often in such cases, vertical insulation is used together with roll materials based on bitumen. Another option is coating insulation. In this case, polymer compositions are applied to the surface of the foundation. Some recommend using both for maximum protection.

Protection of foundations and basement walls from frost heaving deformations

When erecting buildings on heaving soils, it is necessary to arrange a cushion of washed sand, gravel or gravel-crushed stone bedding under the base of the foundation.

A base of these non-heaving materials will prevent the normal (buoyancy) forces of frost heaving from acting on the base of the base. It should be noted that with an increase in the level of groundwater (in the autumn period, as well as during the melting of the snow cover), the filling is surrounded by water saturated with particles of silty clay soil. Migrating along with water, these particles penetrate into the bedding and clog it, gradually turning the non-heaving soil into heaving.

As a result, after several years of operation, the foundation again turns out to be standing on the ground, which deforms during freezing. The use of special filtering materials (fiberglass, "Taipar", etc.) that allow water to pass through well, but prevent the penetration of the smallest dusty-clay particles into the sand cushion, allows to prevent siltation of the bedding.

Fig. 1

- foundation; backfill from non-heaving soil; filter material; existing heaving soil.

To reduce the effect of tangential forces on the foundation, heaving soil in contact with the vertical surfaces of the foundation or with the walls of the basement is recommended to be replaced with non-heaving soil. Backfilling, which is carried out along the entire perimeter of the building, must (as in the previous case) be protected with a layer of filter material (Fig. 1).

Significant moistening of heaving soils leads to the fact that when they freeze, they increase in volume much more than soils with less moisture. This entails an increase in the level of deformations, and, as a consequence, the need for more serious protection of foundations from the effects of frost heaving forces. One of the ways to reduce the activity of heaving soils is a drainage device that allows you to lower soil moisture by lowering the level of groundwater.

The traditional design is a system of drainage pipes placed in a layer of washed gravel to trap soil particles. The pipes are laid with a slight slope, which ensures the flow of water into a special well or sewer.Despite the presence of a gravel pack, during the operation of the drainage system, there is a gradual clogging of the drainage holes with soil particles.

Drainage cleaning is a rather laborious process, requiring the construction of special wells. To prevent clogging of the system, it is possible to lay around the drainage pipes filtering material ("Taipar" or fiberglass), which does not allow the smallest particles to pass through and ensures the efficient operation of the drainage system for a long time (Fig. 2).

Fig. 2

- existing foundation; drainage pipes; filter material; washed gravel

If filter media is available, it is not necessary to lay a layer of gravel around the drain pipes.

Polyurethane mastic or bitumen?

There are many types of waterproofing compounds on the market. With the development of the chemical industry, these products are becoming more and more perfect. Whereas previously it was possible to rely only on bitumen, now it has more durable alternatives.

What is the difference between bitumen and polyurethane mastic? Bitumen is one of the oldest building materials available and cheap. Polyurethane mastics appeared on the market not so long ago, but they are distinguished by their strength and elasticity, which persists for many years. Bitumen loses these properties very quickly. Its strength is enough for several years, then the physical and chemical properties of the material weaken. Polyurethane mastics can last more than 40 years.

Polyurethane mastic from "Khimtrast"

has developed its own polyurethane mastic, which can be used not only for waterproofing foundations, but also for roofs, swimming pools, tanks, basements, terraces, balconies, tunnels, as well as under screeds and tiles, for repairing old bituminous insulation.

Mastic "Chemtrast PUMA (1k)" is available for purchase in wholesale and retail volumes. If the surface for waterproofing is not so large and you need to make minor repairs, then you can buy a liter or three-liter jar of mastic. You pay for the purchase through the online store on the company's website, then the product arrives at your home. You save your time on trips to hardware stores, markets and queuing.

You can also order the color of the mastic that best matches the color of your home. In this case, the indicator of moisture resistance will remain unchanged. High adhesion allows you to protect almost any surface from external influences.

How to insulate the foundation from the inside of the house

As mentioned above, this type of work is performed from the inside of a basement or underground room.

What to do first

But before proceeding with thermal protection, it is worth taking care of waterproofing. Everyone knows that moisture contributes to the destruction of the foundation. The temperature difference (cold-heat) can lead to deformation of the erected structure.

There are some helpful tips.

As a waterproofing, you can apply treatment in several layers with acrylic waterproof paint of walls and foundation surfaces. When using this type of waterproofing, both pros and cons can be noted.

The advantages include: ease of use of paint or bitumen (bitumen can be used as an alternative to paint). The material can be applied with a paint brush or roller. To make the waterproofing, it is enough to remove the remains of cement and sand. Then apply layer by layer of paint or bitumen until the foundation has acquired the appropriate color.

This method of protection against water hammer is able to protect the foundation and wall surfaces from getting wet and moldy.

The downside is the high consumption of paint or mastic. Because when it dries, the paint (mastic) evaporates by more than thirty percent. Which, accordingly, hits the pocket.

What materials are suitable for insulation. There are many types of insulation.From the simplest and most budgetary, to the most expensive with the use of innovative materials. Consider affordable and not requiring special skills, but quite effective.

Polymer materials

Easily assembled thermal insulation boards can be found in hardware stores.

- Polyurethane can be used to create a reliable thermal insulation layer. This heterochain polymer possesses, in its properties, excellent thermal breakdown and resistance to external natural factors. The material is quite affordable in terms of price characteristics and can be purchased at any hardware store.

- The second type of insulation recommended by experienced builders is expanded polystyrene. This material is a type of foam. However, in its manufacture, manufacturers have introduced innovative technologies. Thanks to them, expanded polystyrene, also produced in the form of wall panels, has become much stronger and more reliable. In addition, rodents do not like it at all, and mold and fungus do not settle on it.

How to insulate walls with heat-insulating plates

First you need to level the walls with gypsum plaster. For this, the "Volma-layer" is usually used. This type of plaster allows you to remove irregularities and waterproof joints.

On buildings built on damp soils, it is necessary to apply waterproofing with a special solution. Experts recommend using TechnoNIKOL. This material penetrates deeply into the cracks and reliably protects the foundation from moisture.

Polystyrene boards are glued with a special glue (Dragon brand glue is recommended). Apply the glue, at least eight to ten drops per square meter of the sheet.

After the glue dries, the polystyrene sheets must be reinforced with dowel nails. For this, holes are drilled so that the depth is at least fifty millimeters deep into the foundation. After that, insert a plastic dowel and, using a screwdriver or screwdriver, screw in a steel screw. The screw cap must be flush with the insulation.

One and, let's say, an important drawback of this type of insulation is its susceptibility to rodent attacks. In order to avoid this misfortune, the following is proposed. On the layer of insulation already glued and fixed with dowels, on the mixture of glue and cement, a reinforced mesh is attached. After that, putty is made and decor is applied to your taste.

Budget options for warming the foundation

Another time-tested method. By the way, one of the most budgetary is expanded clay. In order to insulate the foundation with expanded clay "fur coat", you do not need to have seven spans in the forehead. It is enough to make the formwork along the entire foundation, and fill in a mixture of expanded clay and cement mortar with water and sand. This insulation will definitely not be attacked by either rats or mice. It will also resist mosses, lichens and all kinds of mold.

Perhaps the cheapest option is to use sawdust as a heater. Wood waste in the form of shavings or fine wood dust is an excellent thermal insulation material. But it is important to properly prepare it for use. Because in its pure form, sawdust is fire hazardous, and mice and rats like to settle in them. As a heater, you can use a mixture of shavings with cement, gypsum or lime, which is moistened with an antiseptic solution. In this form, sawdust is not flammable, and they are not afraid of either rodents or mold.

The ratio of sawdust and lime is 10: 1, sawdust and gypsum is 8: 1. A proven and reliable composition: for 10 buckets of small shavings, they take a bucket of lime and cement. You can pre-moisten the sawdust with liquid glass. But be sure to add an antiseptic solution.

By the way, wood concrete, a relatively new material, is based on sawdust. Thanks to them, it not only has high thermal insulation properties.Arbolite is strong, capable of bearing serious loads, refractory, and due to its fibrous structure, it is resistant to bending.

How to work with polyurethane mastic

The concrete foundation on which you plan to apply the mastic must be clean, without tears or cracks, without sharp joints. If you notice bubbles on the concrete, then its surface must be sanded and then cleaned of dust and dirt. It is also necessary to get rid of moisture from the foundation. The best time for work is a sunny dry day without precipitation.

How to check if the surface is dry enough? A few hours before applying the mastic, place a small piece of polyethylene on the surface of the concrete and check for condensation. If it is not there, then you can start work.

For better adhesion, the company's specialists recommend applying a primer to the concrete - "Chemtrast Primer-PM (1k)". One coat of primer should be sufficient. An hour after that, you can start applying the mastic. Before use, the material must be mixed using a mixer with a spiral nozzle.

Then take a roller or paint brush and apply the first coat of polyurethane mastic from top to bottom. The layer should not be thick, literally 1-2 millimeters. After a day, you can add a second layer of thicker mastic. Use aliphatic mastic to protect the surface from UV rays.

When working with polyurethane mastic, observe safety precautions, work in a gas mask or protective mask, in special clothing that will cover all parts of your body.

After work, rinse all brushes with acetone, and store the mastic in a tightly closed container so that polymerization does not occur.

Experts are always ready to tell you which polymer is best for your purposes. Our warehouses can be found in Novosibirsk, Irkutsk, Yekaterinburg, Krasnoyarsk, Voronezh, Yaroslavl, Nizhny Novgorod, Moscow, St. Petersburg, Samara and Ufa.

The plinth protects the walls of the building from the penetration of ground moisture into them and, as a result, their destruction. But what will the base itself protect? Surely this is done correctly. finishing the basement of the house, which only in the second place performs decorative functions, and in the first place - a protective role. It is this issue that we will deal with in the current article, in which, together with the site stroisovety.org, we will deal in detail with how to properly veneer the basement of a building so that it is completely protected from aggressive environmental influences and, moreover, has an attractive appearance.

Methods for waterproofing the foundation of a house from the outside

In order to prevent destruction, waterproofing the foundation of the house from the outside can be done in the following ways:

- surface treatment with penetrating compounds;

- coating the foundation from the outside with bituminous mastics;

- covering the outer walls of the foundation with roll types of waterproofing: roofing material, glass insulation, rubemast and other materials.

There are cases when it is necessary to use two types of waterproofing at the same time in order to increase the level of protection against the effects of groundwater and precipitation. It all depends on the type of soil, the characteristics of the site on which the house is being built and other factors that specialists take into account before carrying out work.

Penetrating waterproofing

Penetrating waterproofing is a fairly new material that quickly won the trust of specialists in the construction industry. The market offers a wide range of penetrating compounds with excellent plasticity, high adhesion and excellent hydrophobic properties.

Waterproofing the foundation from the outside begins with cleaning the surfaces from dirt, dust, mortar residues, etc. After that, the outer walls of the foundation are thoroughly moistened with water, the cracks are embroidered and also well moistened.

The penetrating composition is applied with a wide brush in two layers, with a time interval between them 2-4 hours, carefully sealing seams and cracks. Having performed such a waterproofing of the foundation, you can be sure that all the pores of the concrete will be closed, without giving the slightest chance for capillary penetration of moisture.

Roll waterproofing

Waterproofing the foundation using roll materials is the most common method, as the most budgetary and quite reliable. Pasting with roofing felt or a more modern product based on fiberglass allows you to achieve effective protection of the structure from moisture.

Foundation waterproofing is done as follows:

- the surface is cleaned, primed with a bituminous primer;

- installation of roll insulation - melting the lower edge of the material and gluing it to the walls of the foundation, gradually unrolling the roll.

It is imperative that such waterproofing of the outer surfaces of the foundation is performed with an overlap of sheets of at least 100 mm. Particular attention should be paid to the outer corners, when moving from a vertical surface to a horizontal one, reinforcing the area with an additional 300 mm strip of material. If the depth of the structure exceeds 3 meters, then the waterproofing of the foundation with roll materials is carried out in several layers in order to achieve perfect sealing. When backfilling the foundation, it is necessary to make a drainage layer close to the walls: sand with gravel, and on top to equip a clay castle with a slope from the surface of the foundation.

Coating waterproofing

How to waterproof the foundation from the outside, if the budget is limited and you have to do the work on your own? In this case, the ideal option would be a coating method of protection, using bituminous mastic. Foundation waterproofing is carried out as follows:

- walls are thoroughly cleaned of dust and dirt, sharp protrusions are removed, porous areas are filled with cement mortar;

- a bituminous primer is applied to a dry surface in one thick layer, avoiding gaps;

- after the primer has dried, bituminous mastic is applied using a roller or brush, keeping the stripes parallel and moving up / down;

- the second layer is applied after the previous one has completely dried, repeating the process until the coating thickness is at least 3-4 mm.

When waterproofing the foundation, in order to save money, it is not recommended to use pure bitumen, since without special additives, such a coating will quickly begin to crack. Bituminous mastics, with plasticizers, increase the strength, elasticity and durability of the material, making it possible to make effective waterproofing of the foundation from the outside.

Finishing the basement of the house: how to make waterproofing

Oddly enough, but before proceeding with the immediate finishing plinth foundation at home, you need to execute it waterproofing... For what? The answer is still the same - protection from moisture, which can seep not only through the soil, but also through the seams of the facing material. In general, the waterproofing of the basement should be carried out at the stage of building the foundation, but, as a rule, everything is limited to insulating only its underground part, which is mainly performed with roofing material or bitumen mastic. In fact, these materials interfere with further finishing the basement of the house, and they seem to be ignored, or, at best, released 10-15 cm above ground level. In principle, this is quite enough to protect the foundation from destruction, but not the basement of the structure.

Finishing the basement of the house do-it-yourself stone photo

FROM waterproofing the basement of the house things are a little different - roofing material, bituminous mastic and similar materials will not work here. Almost all materials for finishing the basement of the house require a different type of base - therefore, the requirements for waterproofing the basement of the building are slightly different.

Horizontal waterproofing

Horizontal waterproofing scheme.

Horizontal foundation treatment for waterproofing is optimal for strip or monolithic slab foundation. When erecting a foundation, a clay or sand pillow is first laid, the first elephant of concrete is poured on top, and after 10-12 days, when the concrete hardens, its surface is covered with bituminous mastic, and roofing material is laid on it.

Then the surface of the roofing material is again treated with bitumen mastic, and the roll material is again laid on it. On top of the second layer of roofing material, another concrete screed with a thickness of 5-8 cm is made. After that, they proceed directly to the construction of the foundation. Additionally, you can use vertical methods of protection from moisture, this will increase its effectiveness.

How to decorate the basement of the house: materials for finishing the protruding part of the foundation

Materials with which modern builders can perform finishing the basement of the house, quite a lot - they include natural and artificial stone, siding, special facade panels, tiles, clinker bricks, bassoon and even ordinary or decorative plaster. In principle, this list can be continued and continued, but there is little sense in this - all the same, the decoration of the basement with these materials is almost identical.

By technology finishing the basement of the house all materials can be divided into two groups - which require a frame for their installation and which do not need it. Frame materials include all kinds of siding, fiber cement and other panels, for the installation of which you will need to arrange a metal frame. If we talk about such materials in more detail and consider their installation technology, then we can note one feature concerning the preliminary stage of waterproofing - here the choice of insulating materials is not limited. Bitumen, roofing material, and similar materials are suitable.

The disadvantage of this option finishing the basement of the house is the high cost of the materials themselves and the work associated with their installation. For example, fiber cement panels are one of the most expensive materials today, and their main advantage is durability.

Finishing the basement of the house Photo

In financial terms, the most profitable material for a basement is all kinds of tiles, clinker bricks and stone of artificial or natural origin. The advantage of these materials lies in a fairly simple installation technology - for example, finishing the basement of the house with artificial or even natural stone, it is quite simple to do it yourself. The same can be said about tiles and clinker bricks - knowing the technology of working with tile material, revealing the foundation with any such products will not be difficult.

Materials for finishing the basement of the house

Additional protection for the tiled basement of the house

As the saying goes, every cloud has a silver lining - having protected the basement of the building, it is also necessary to protect the cladding itself from the ubiquitous moisture. No matter how ridiculous it may seem, but such a situation really takes place. The fact is that rain and melt water, flowing down the walls of the house, can flow and be absorbed into the solution or adhesive composition, with the help of which the basement was finished with natural stone or something else.

As a rule, either the same finishing material or special cornices made of painted galvanized steel are used as such protection. If you deal with the quality of such protection, then it is better to give preference to galvanized steel - it is more reliable. If moisture can still seep into the seams between the finishing material, then, in principle, it is not able to penetrate under the cornices.

Cornice on the basement of the house photo

The eaves are attached as follows - first, a slot is made in the wall 1.5–2 cm deep to the width of the grinder's disk, into which the bend of the eaves is inserted. After that, the cornice itself is attached to the wall with dowels, and the cut slot is sealed with a sealant. If you correctly do the docking of individual cornices, then finishing the basement of the house artificial stone (or whatever you use there for these purposes) will be reliably protected from rain and melt water.

In general, be that as it may, but finishing the basement of the house is a necessary construction activity that must be carried out in conjunction with other means of protection of the foundation (drainage of the foundation, its waterproofing and the device of the drainage system).

Basic concepts and definitions

Freezing of the foundation is a decrease in the temperature of the concrete monolith below the zero mark in a volume of at least 25% (observations show that fixation of freezing can be carried out even at 20% cold penetration, if only the thickness of the concrete itself is taken as a measurement indicator).

If we abstract from the type of foundation and its dimensions, the signs of freezing are as follows: - a change in the color of the concrete surface from traditional gray to a darker one with a bluish tint (in rare cases, there are pronounced spots of a light blue color, as evidence of the formation of crystals inside the concrete ice); - the appearance of frost on the concrete surface (an indicator of the initial stage of freezing, or the presence of a large amount of water in the outer layers of the solution); - stringiness - the appearance of a clearly visible network of "wrinkles" on the concrete indicates that the surface has already cooled, and freezing has passed into denser deep layers.

Here we come to one of the most important characteristics of the problem - the depth of freezing of the foundation. It is necessary to understand that the depth value itself can have several criteria: - normal freezing depth assumes the inevitable penetration of cold into the surface layers of the foundation at significant negative temperatures; - the dangerous depth of freezing shows that it is necessary to carry out measures to insulate the foundation and the basement (in the absence of changes over several seasons, the problem will move to the next stage); - critical depth of freezing - that rare case of improper construction of the foundation, in which its operation is extremely undesirable or even impossible.

There is another equally important aspect of the problem that needs to be correlated with the depth of the device - freezing of the foundation relative to the depth of freezing of the soil. In this particular issue, freezing of the soil is a normal natural phenomenon, and freezing of the foundation is a consequence.