Metal-plastic on cold and hot water connections

It is believed that metal-plastic is not the best material for installing heating and distributing hot water: after a while, the pipe may leak at the connection with the fitting. Today we have to figure out whether metal-plastic pipes are suitable for heating and water supply and what are the reasons for numerous complaints about leaks.

What it is

What are metal-plastic pipes for water supply and heating?

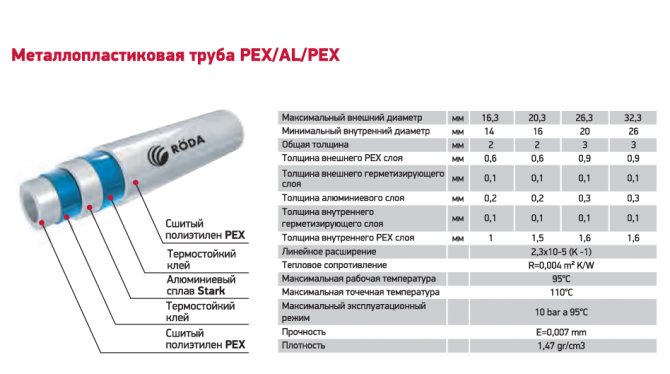

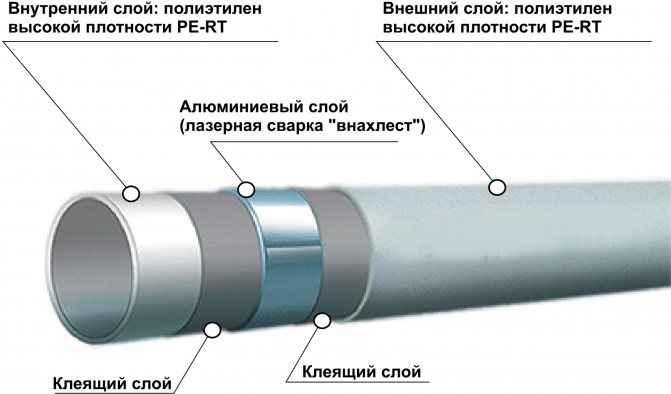

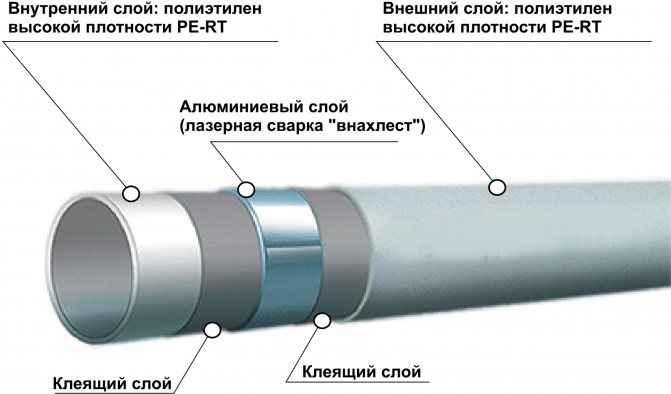

A multi-layer construction, usually consisting of three layers: two polyethylene shells (outer and inner) and an aluminum core. The core provides strength in relation to hydrostatic pressure, the shell - corrosion resistance and low hydraulic resistance.

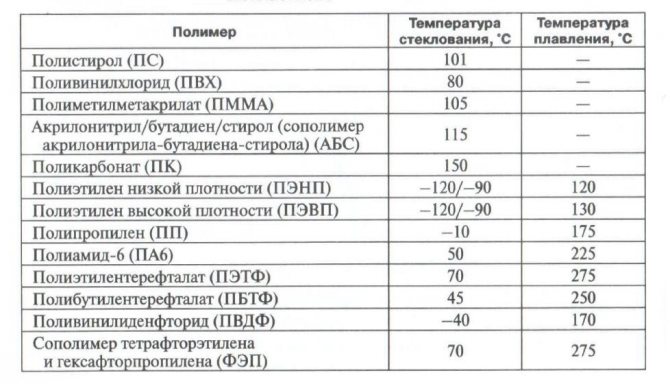

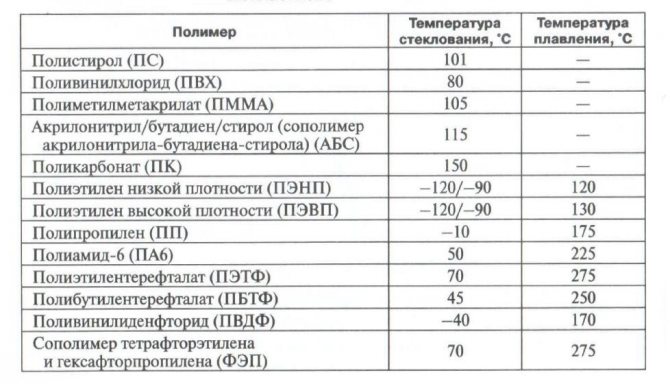

Modern metal-plastic pipes for cold and hot water supply are produced in several modifications:

- Not only ordinary PE-polyethylene, but also cross-linked PE-X or thermally modified PE-RT can be used as a shell material. The first provides greater tensile strength, the second - increased heat resistance (up to 110 ° C);

Pipe with sheaths made of heat-resistant polyethylene PE-RT

- The core can be not only solid, but also mesh.

Useful: in the Russian Federation, pipes are manufactured according to technical specifications TU 2290-001-12333095-96. There is no standard governing their production.

Origins

Metal-plastic began its triumphant march across the Russian expanses in the mid-90s. The reasons for its exceptional popularity boiled down to a striking contrast to the then massively used black steel pipes:

- The appearance of pipes and fittings allowed open installation and did not require painting or any other finishing. Snow-white pipes and shiny fittings did not spoil the appearance of the room or bathroom, but decorated the room;

Pipes and fittings are quite capable of becoming part of the design of the room.

- The pipes were not overgrown with rust and mineral deposits, maintaining their capacity throughout the entire period of operation;

- Manufacturers and sellers have promised an exorbitant life span of 50 years or more;

Reference: black steel serves no more than 25 years in cold water. The author came across the first leaks at the seams of water and gas supply (WGP) pipes 10 years after the commissioning of a new house.

- Finally, the main thing: the installation of water supply with metal-plastic pipes was within the power of, according to one seller from a plumbing store, "an eighth-grader with two adjustable wrenches." It did not require special skills, a complex instrument and took very little time.

A pair of adjustable wrenches is sufficient to assemble the connection.

Reinforced-plastic pipes for central heating: pros and cons

Currently, metal-plastic pipes are installed not only in apartments, but also in the premises of large shopping centers, although experts do not recommend this. After all, if possible, it is better to replace all the circuits with steel pipes. But in most cases, the operation of metal-plastic products does not cause problems; the latter can arise only due to some unforeseen factors. For example, with a sharp increase in pressure, such a pipe may simply burst. But let us consider in more detail all the pros and cons. Let's start with the merits:

- ease of installation. Reinforced-plastic structures can really be assembled with your own hands, and this does not even require any complex tool.But for the installation of steel pipes, you will need a welding machine and skills in handling it. Do not forget that steel pipes are not easy to cut and bend;

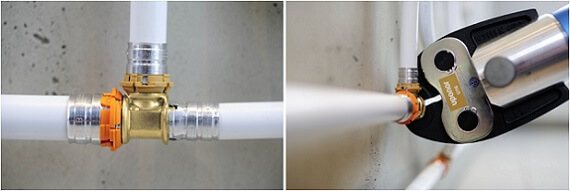

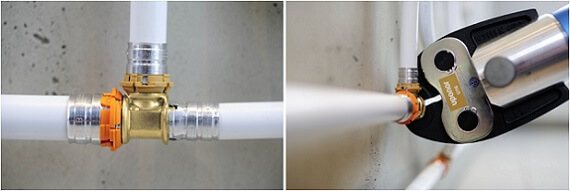

- even when using reliable press fittings, you only need special pliers, which cost several thousand rubles;

- service life of metal-plastic pipes. The declared service life of such products (with proper operation, of course) is 50 years. But the first leaks in steel central heating systems usually appear after ten years of operation;

- corrosion is not terrible for metal-plastic pipes, and various deposits, as a rule, do not appear in them.

Now let's move on to the disadvantages, of which there are actually only two:

- low tensile strength of pipes, which does not exceed twenty atmospheres;

- quite high cost. So, a water-gas pipe made of steel, which can also be used for gas and a water pipeline, costs about half the price.

Disappointment

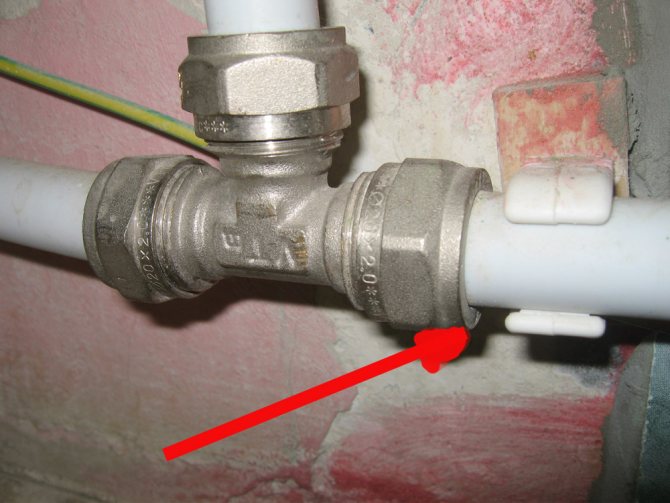

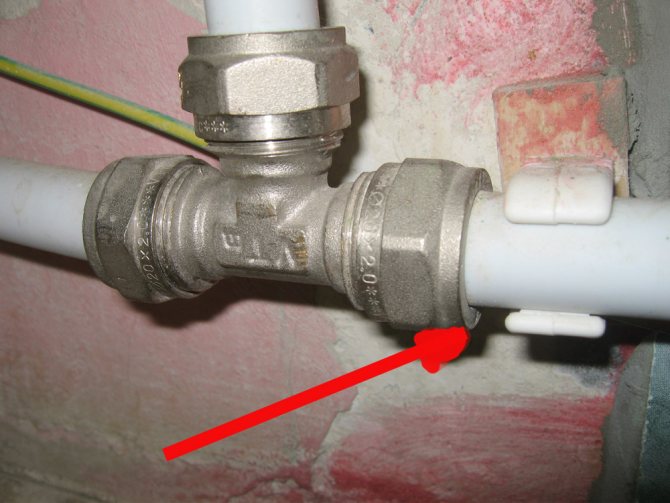

Just 2-3 years after the massive appearance of new material on store shelves, the first negative reviews began to appear about it. They boiled down to complaints about leaks of compression (with union nuts and split rings) fittings on hot water and heating (see. Fittings for water supply of a private house). Usually the leak could be eliminated by tightening the nut; but often after a while it appeared again.

Typical Leak Location - Pipe-to-Fitting Connection

Note: multilayer metal-polymer pipes for cold water supply did not cause the slightest criticism from anyone and never. At a constant temperature of the working environment, no leaks occur, the water supply system serves the owner for a long time and flawlessly.

Metal-plastic pipe for cold water supply: there is no need to be afraid of leaks

The attitude towards metal-plastic has changed. Experienced plumbers began to recommend their customers to use steel pipes - black steel and more difficult to install galvanized.

Note: galvanized pipe should only be mounted on threaded connections. When welding in the seam area, the anti-corrosion coating completely burns out: steel melts at 1400 degrees, while zinc already evaporates at 900 degrees.

Decline

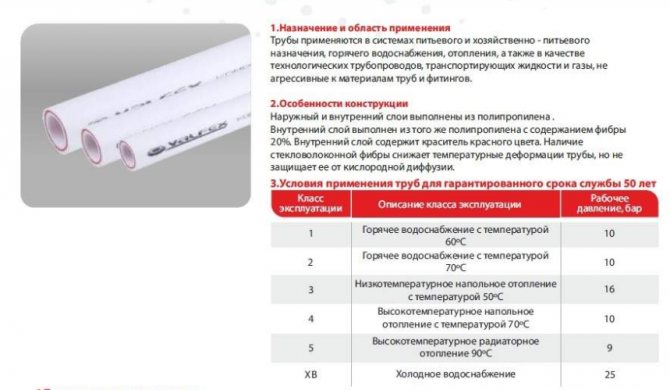

Almost completely metal-plastic pipes for hot water supply and heating have ceased to be used with the advent of polypropylene on the Russian market.

Polypropylene risers and water supply lines

Metal-polymer pipelines lost to him literally in everything:

- In the price of fittings and pipes;

- In the speed of installation;

- In the reliability of the joints (socket welding of polypropylene guaranteed strength, at least not losing out to the strength of a single piece of pipe). At the same time, maintenance-free connections could fit into grooves or screeds.

Metal-plastic has moved to the distant windows of plumbing stores and is gradually disappearing into oblivion. According to the author, it is absolutely undeserved.

Installation errors

Let's think about why a metal-plastic pipe for water supply leaks. The reason is only and exclusively in the gross errors of installation.

How to

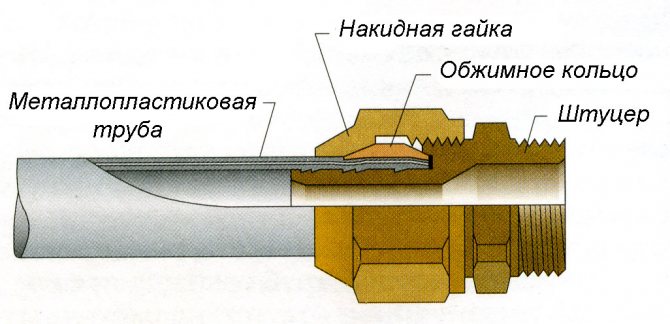

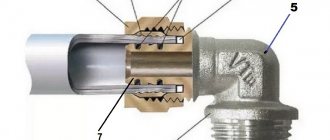

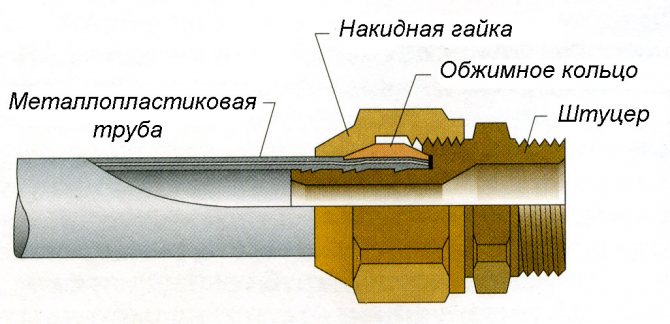

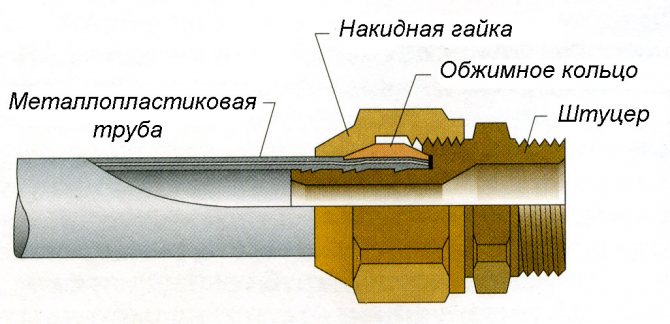

Compression fitting for metal-reinforced plastic is a herringbone fitting with one or two rubber o-rings seated in the grooves. It is these rubber rings that must ensure the sealing of the joint. The shape of the fitting is designed only to ensure reliable fixation of the pipe crimped with a split ring.

Compression fitting device

Rubber sealing rings are responsible for sealing.

Here is a step-by-step instruction on how to install a connection with your own hands:

| Picture | Description of the stage of work |

| Cut the pipe to size with a pipe cutter. A specialized tool for metal-plastic makes the cut perfectly straight and strictly perpendicular to the longitudinal axis of the pipe. |

| Calibrate the end of the pipe with a hand-held calibrator. Small diameter pipes are usually supplied in coils and after being unwound they retain an oval cross-section. Calibration makes it perfectly round. |

| Remove the inner chamfer at the end of the pipe. The chamfer will allow it to enter the fitting without moving the O-ring on its fitting. Calibrators for metal-plastic are often equipped with knives for chamfering. |

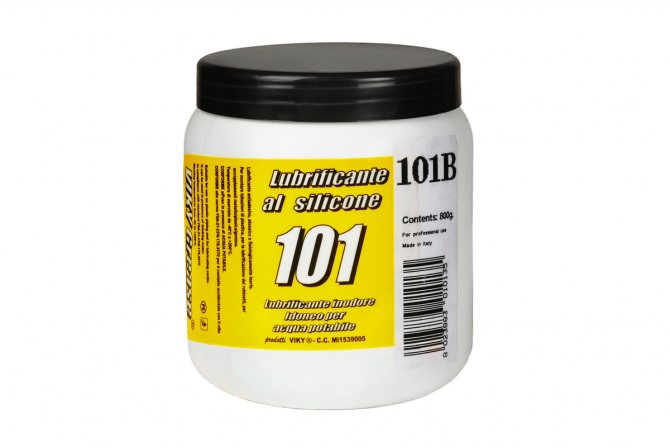

| Apply some neutral grease (silicone, liquid soap, etc.) to the fitting. Do not use petroleum-based fuels and lubricants as a lubricant: O-rings may crack over time. |

| Slide the pipe with the union nut and split ring onto the fitting nipple in a forward motion and tighten the nut moderately. At the same time, the body of the fitting must be held with a second key, which will not allow it to turn. |

How do

Now let's remember how newcomers in the field of installing these pipes collect heating and water supply from metal-plastic.

- For cutting, a hacksaw for metal is usually used. The cut is only very approximately perpendicular to the pipe axis;

- Nobody removes the chamfer at the end. Moreover: even burrs from cutting are not always removed from the inner surface of the pipe;

- Calibration? No, you haven't heard. There is definitely no calibrator in the arsenal of a novice master. The oval pipe is pulled over the fitting with force and tightened to the stop with a split ring nut.

The result is fully consistent with the effort expended:

- An oval pipe with an oblique cut and an unclean chamfer pulled over the fitting pulls the O-rings out of the grooves and pushes them towards the fitting body. In this case, the O-rings often break (the edge of the pipe, as we remember, is uneven and with burrs);

- When tightening the union nut, the split ring squeezes the pipe on the fitting, ensuring the sealing of the connection due to the deformation of its inner shell;

- When heated to 70-80 degrees or more, softened polyethylene is squeezed out of the gap between the fitting and the core;

Polyethylene melts at +120 degrees, but it begins to soften already at 80 ° C

- Upon subsequent cooling and concomitant compression of all parts involved in the connection, the fitting leaks.

Sometimes, after two or three tightening of the union nut, the connection can be sealed by pressing the fitting with a soft aluminum core. At the same time, polyethylene is completely squeezed out from under the core, leaving it defenseless against electrochemical corrosion. Much more often, small irregularities on the surface of the core and the union interfere with the sealing, and the connection continues to flow.

Irregularities and scratches in the fitting may interfere with the seal.

Preparation and assembly of connections on fittings

First of all, we should mention calibration - a procedure that is sometimes neglected even by professionals. Meanwhile, metal-plastic pipes come from the factory in coils, and therefore, without calibration, they retain some ovality, which can then come out sideways. After all, when a fitting is inserted into a bent pipe, its O-rings are simply pulled out of the grooves, shifting towards the fitting body.

We recommend: How to install a heat meter for a house with central heating?

All this leads to a decrease in the tightness of the connection, since the polyethylene sheath must be pressed with rings directly to the fitting. Moreover, polyethylene will inevitably soften when heated and partially displaced from the area under the split ring. This means that if the O-rings are not in place, leaks can occur. The latter is usually easy to remove by tightening the nut, but sometimes not.

Installation of metal-plastic pipes

We add that with mandatory calibration, pipes with compression fittings can be laid openly.However, when such pipes are walled up in a screed or grooves, it is better to use press fittings.

If we talk about the assembly of heating systems, then, of course, there are few subtleties in this matter. When installing steel pipes, threads are usually used, which are wound with plumbing flax. Such products are cut with a grinder or a hacksaw for metal. The need for calibration and deburring and chamfering is not canceled. In addition, a jumper is required directly in front of the ball valves that cut off the radiator. Otherwise, the throttle or valve will regulate the passage of the entire riser.

When tightening the nut on the compression fitting, hold its body with another wrench, otherwise you can accidentally break the tightness of the previously made connections. Do not forget that the turns of the heating line are made using special corner fittings, and not by pipe bends. With a small radius, you can simply break the aluminum core, and too large a radius will look sloppy. When connecting the eyeliner to the radiator, it is better to use special nuts - American. This connection allows, if necessary, to quickly disconnect the heater.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- How to choose a microprocessor controller for two central heating pump pumps?

- How to install a heat meter for a house with central heating?

How to repair

What to do if multilayer metal-polymer pipes for hot water supply have leaked at the fitting connection due to installation errors?

Fortunately, this type of connection is serviceable and can be dismantled:

- Unscrew the union nut and slide the split ring;

- Forcibly remove the pipe from the fitting;

- Calibrate it and remove the inner chamfer;

- Install the o-rings in the original grooves. If they are torn, replace the seals (or, if they are missing, the whole fitting);

- Lubricate the fitting and reassemble the connection.

Installation of metal-plastic pipes

Step-by-step instructions with a photo

- Prepare pipes and tools - cut metal-plastic according to the water supply diagram, select fittings. Compression or press fittings are ideal for joining. Installation tool:

- a hacksaw for metal or special pipe scissors;

- a calibrator for cleaning sections;

- measuring tape or tape measure;

- knife;

- wrench.

- Process the pipe sections with a calibrator.

- Remove the nut and the ring from the fitting, put it on the processed pipe cut. After processing, the cut should be even, smooth, without burrs. For this, a round file is used.

- Slide the fitting onto the pipe and align with the squeegee on the fitting.

- Install the previously removed nut and clamping ring on the fitting, tighten until a specific crackling sound. Control the tension of the nut - too much load can break the thread and then a complete replacement of the connection will be required.

Springs and other ways of bending the pipe

Often times, pipes are bent to get the most out of the surface that conducts heat.

Here are some methods: Hand bending.

- Bending with a pipe bender.

- Spring for bending.

Bending the pipes with your hands is the most affordable method, which involves the following actions:

Gently bend the pipe to a bend radius of no more than 20 degrees.

- Bend it a little higher again.

- Make such bends several times (about 15) until the pipe turns to the desired angle.

With the same smooth and accurate movements, you can straighten the pipe.

Smoothly and easily, you can bend a metolloplastic pipe using a pipe bender. This method is safer and allows you to work with different pipes (both profiled and metal-plastic).

Maria Korol, expert

With the help of a spring or wire, the metal-plastic pipe is bent quite evenly and neatly:

Place the spring or wire inside the pipe.

- Bend the pipe with your hands at the required angle.

- Pull out the spring or wire carefully.

Typical errors in the installation of metal-plastic pipes

The consequence of incorrect actions during installation is leakage or leakage at the joints. The most common mistake is overtightening the fitting nut, which leads to thread stripping or pipe rupture. Another common mistake is saving on a specialized fixture such as a chamfer and calibrator. This often leads to damage to the O-rings, which does not improve the quality of the connection. At the same time, check the level of tightness and strength of the connection, detect leaks and deficiencies by pressing.

Pressure testing of water supply pipes

The main part of the pressure operator is the hydraulic pump, which sets the pressure required for a correct test. There are two types of pressure operators:

- Manual - used to test short water pipes.

- An electric tool is easy to operate, reliable, durable, but expensive. Therefore, it is used only for professional installation.

Do you use metal-plastic pipes on the farm? Describe in the comments how you install the products, what fittings you use, how you bend the pipes.

Press fittings

Metal-plastic pipes for water supply can be mounted not only on compression, but also on press fittings. What it is?

Structurally, such a fitting is distinguished by the absence of a thread, a split ring and a union nut. Their functions are performed by a stainless sleeve, which is crimped at the connection with mechanical or electrical pliers.

Let me introduce you: crimped press fittings

It is believed that this type of connections is much more reliable than compression ones and can be safely used for hot water supply and heating. And this is true, but not because of the magical properties of the cartridge case.

The fact is that crimping pliers are a rather expensive tool, and therefore they fall exclusively into the arsenal of professionals. Which, of course, do not save on buying much cheaper pipe cutters and calibrators.

Manual pliers for crimping press fittings on metal-plastic Valtec (16-32 mm). Retail price - 9500 rubles

How to choose pipes for use in a centralized heating system

Now on sale there are many brands of metal-plastic pipes intended for space heating systems. However, choosing to advise a specific brand is not always correct, you should always pay attention to the technical characteristics of the product, that is, to the declared operating parameters of pressure and temperature in the system. It goes without saying that the higher the latter, the better.

We recommend: How to choose a microprocessor controller for two central heating pump pumps?

The next question is what pipe diameter to choose. Let's say right away that it should be larger than that of the same steel pipe that could have been installed in this place. So, pipes with a diameter of 32 or 26 millimeters are taken for risers, but 26 mm products can also be used for the piping to the radiators. The thing is that the marking of a steel pipe (DN) is a conditional bore, which usually corresponds to the inner diameter. While for metal-plastic pipes, the outer diameter is taken into account. This means that the useful section of the latter is reduced taking into account the wall thickness.

The useful section also decreases on the fittings. After all, the main element of the latter is a fitting inserted into the pipe.

Limitations

We have convincingly proved that with proper installation, metal-plastic can be used for heating and hot water supply. However, a number of limitations still exist. Some of them are directly mentioned in the construction rules of SP 41-102-98, which regulate the installation and design of metal-plastic pipelines.

- The laying of metal-polymer heating pipes, if possible, is done hidden - in grooves, baseboards and niches;

Commentary: the requirement is related to the vulnerability of the shell and core of the metal-plastic to mechanical damage. A strong blow can crush the pipe, or even break its tightness.

In the photo - the installation of an underfloor water heating system (underfloor heating) with metal-plastic. The pipe is laid in a heat-insulated screed

- With hidden laying, free access to connections and fittings must be maintained;

- Polymer-metal pipes cannot be used in systems with elevator units (that is, in most apartment buildings);

Commentary: in some operating modes, the elevator unit provides a direct supply of service water from a straight line of the heating main to the DHW and heating systems. The temperature in it at the peak of cold weather, according to the temperature schedule, reaches +150 degrees, which far exceeds the capabilities of metal-plastic.

Temperature regime of the heating main and its dependence on weather conditions

- In front of the metal-plastic pipeline for heating and hot water supply, shut-off valves should be installed (see Valves for water supply: types, purpose, nuances of selection), which allows you to quickly stop the supply of water or coolant in the event of an accident;

- If the coil of a metal-plastic pipe was stored at a negative temperature, then before rolling it must be kept in a heated room for at least a day;

Commentary: polyethylene remains elastic at low temperatures. However, water trapped in the pipes and crystallized there can damage the inner jacket or core during unwinding.

Small-diameter metal-plastic is supplied in coils, for which storage in cold warehouses is permissible

- The bending radius of the pipe should not be less than five of its diameters. When bending the walls should not be allowed to "fold": it adversely affects the strength of the pipeline and reduces its throughput;

Commentary: at small bending radii, the pipe is bent in a steel spring put on it.

The spring allows you to bend the pipe with a small radius without damaging its core

- Reinforced-plastic is laid through building structures in a sleeve filled with an elastic material with a low friction coefficient (for example, foamed polyethylene);

With horizontal laying of liners and spills, the fixing step should not exceed:

| Outer pipe diameter, mm | Mounting step, mm |

| 16 | 500 |

| 20 | 500 |

| 25 | 750 |

| 32 | 1000 |

| 40 | 1000 |

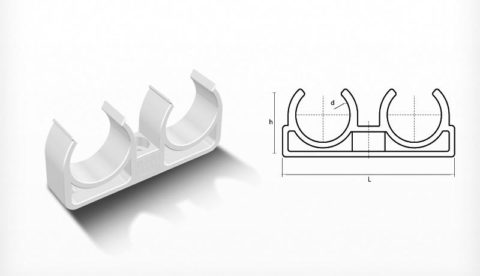

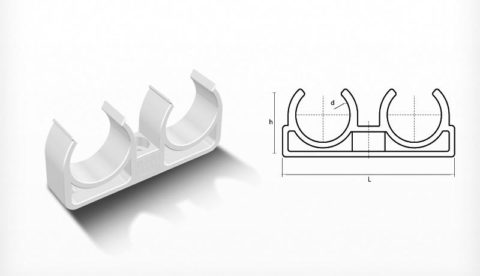

Clip for attaching paired metal-plastic water supply pipes to the wall