Table of contents:

- Why is it wet in the basement

- Why do you need internal waterproofing

- Types of waterproofing

- What materials are used for waterproofing

- Penetrating insulation

- Cement-based waterproofing (cement mixtures)

- Roll insulation

- Liquid insulation (coating)

- Membrane waterproofing

- Liquid glass

- Polyurea

- How to order waterproofing on poliol.ru

80% of buildings without waterproofing begin to collapse in the first years. The foundation and basement of the building are in contact with the soil, which means with groundwater and moisture, as a result of which:

- Water corrodes metal and erodes support structures.

- If dampness enters the basement, the temperature regime is violated, mold, fungus, insects appear.

- With periodic flooding of the foundation, cracks and surface faults are formed.

Drainage and protection of the interior of the building from moisture ingress can extend the life of the house.

Basement waterproofing features

Basement after waterproofing

If moisture spots appear on the basement walls, it is necessary to check whether horizontal insulation has been installed under the wall.

Usually roofing paper is laid for her on a strip foundation. On closer inspection, you will see its edges sticking out. If the integrity of the waterproofing is violated, it is immediately corrected. When repairing waterproofing from bitumen, bituminous materials must be used, and when repairing such from a film, geotextiles or film are used.

It also happens that the vertical waterproofing needs to be replaced. Vertical waterproofing is always combined with horizontal insulation. Once the waterproofing has been fixed, it must be protected from damage. In this case, needle-punched geotextiles are used.

For high-quality protection of the basement from groundwater, it is necessary to provide for a drainage system.

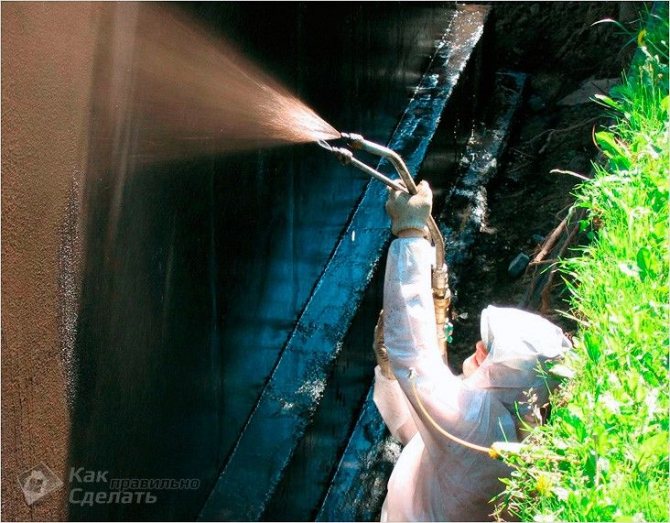

If the walls of the house are made of concrete, then the basement can be waterproofed from the inside. For such purposes, special substances are used. When they penetrate wet concrete, a reaction occurs with the formation of insoluble crystals. Such crystals fill pores and crevices, displacing water from them. Such substances are applied to concrete with a brush or spray.

Why is it wet in the basement

Heavy rainfall, wind, temperature changes - all this affects the foundation and basements in houses. Moisture is contained in the surface layers of the soil, melt and rainwater collects in the upper layer of the soil.

The reasons may be as follows:

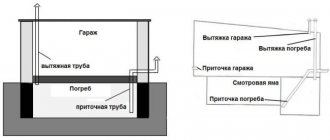

- poor ventilation;

- microcracks and faults in the foundation and supporting structures of the building;

- overload: the building presses on the soil, groundwater penetrates through loose joints and increases the amount of moisture.

Basement waterproofing from the inside from groundwater: methods of protecting a building from moisture in detail, with a photo

Waterproofing the basement inside will help to avoid mold and mildew, as well as the destruction of the foundation

The near-surface soil contains water. Its amount varies depending on external factors. The top layer of soil up to 1 m deep accumulates melt and rainwater. At the level from 1 to 2-3 m, soils occur, characterized by a variable amount of moisture. This area can be completely dry or filled with water from underground streams. The lower areas are fed with moisture from the aquifers.

Water can enter the basement of a building in several ways:

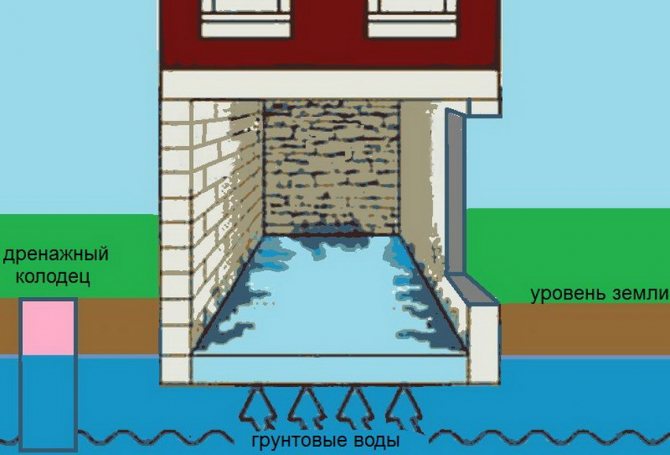

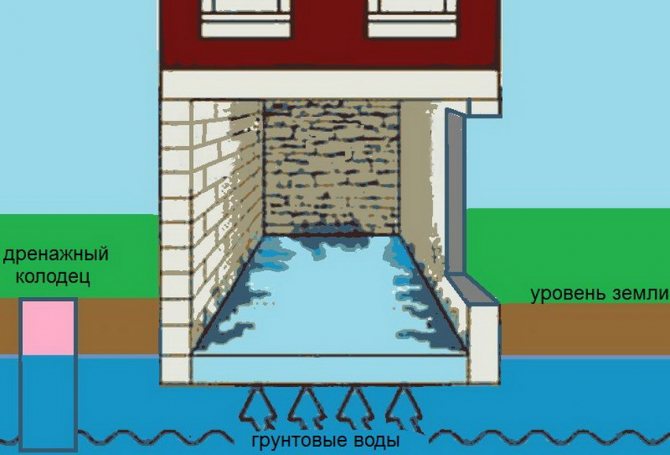

Squeezing groundwater is most dangerous for basements. Risks increase if moisture levels rise from precipitation. As a result, groundwater merges with surface streams, increasing the volume of liquid.

If the outer layer of waterproofing is broken, then a sharp increase in the amount of water will lead to the erosion of existing cracks. As a result, volley flooding of basements will occur. Despite this, there are effective ways to combat water pressure with the help of internal waterproofing, which copes with these consequences much easier than diffusion.

The scheme of raising groundwater and flooding the basement

The safest way to keep moisture out of your basement is to provide an exterior shielding. In this case, the liquid that rises will press the material against the building, providing the required level of insulation. Sometimes the outer protective layers, which are directed towards the concrete base, are not able to retain water.

There may be several reasons for this:

The vertical method of protection is used in cases where there is a need to waterproof the walls of the basement. This method is used if the liquid enters through cracks and joints between the elements of the foundation, while an aquifer of soil lies at the level of the walls.

Wall waterproofing is carried out by sealing cracks through which water can penetrate

The basement walls are waterproofed from the inside in several ways:

Experts recommend doing vertical waterproofing in cellars where there is no drainage system. Most often, this method is performed in conjunction with horizontal protection, which improves the effectiveness of the procedure.

Horizontal waterproofing is performed along the floor. This procedure eliminates the risk of groundwater rising into basements, and also prevents moisture seepage through the capillaries.

Horizontal protection is carried out in any case. Even if there is no urgent need for this procedure, the situation may change over time, for example, a large amount of precipitation will fall or soil movements will occur, which will increase the level of occurrence of the aquifer.

Several methods are used for protection:

Basement floor waterproofing is always performed, it is best to combine it with vertical wall waterproofing

Modern stores offer a wide range of materials for waterproofing basements. The foundation of the building suffers not only from groundwater, but also from leaking communication systems. When choosing waterproofing materials, it should be borne in mind that only penetrating protection can provide the necessary level of protection against melt and groundwater, as well as against capillary leakage. If a leak occurs in communication systems, it is advisable to use coating emulsions or mastics.

The most effective are the following waterproofing materials:

Rolled waterproofing products are used when it is necessary to protect the floors in the basement. Bitumen-based materials are glued with an overlap. The resulting seams must be melted with a blowtorch. Bitumen mastic can be used as an adhesive for fixing the material.

One of the most reliable waterproofing methods is the use of bitumen-based materials.

Roll-up protective materials include:

Further work is carried out taking into account the flood changes.If the rise of water is observed often, the surface is coated with bitumen in at least 4 layers. To protect the premises from rare floods, 2 layers are enough. After the material is completely dry, a concrete screed is made.

Unlike rubber, which has elastic properties, bitumen-based materials do not withstand the pressure of water so well. Under the influence of a pressure of more than 10 kPa, the waterproofing simply peels off. For this reason, bituminous materials and mastics are used as an addition to penetrating and other types of waterproofing.

This method provides effective protection of the cellar in cases where the groundwater is high on the site. Waterproofing from the inside of the room is carried out using a mixture of materials.

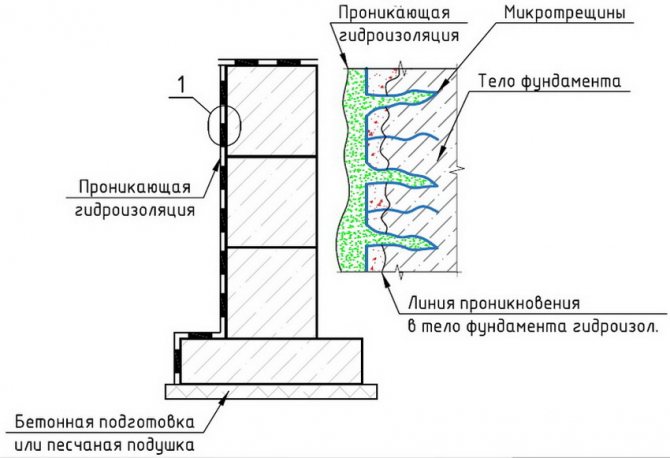

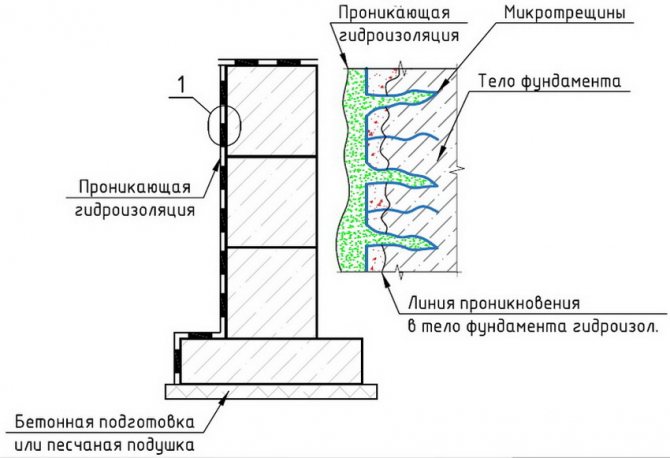

Features of penetrating waterproofing walls - scheme

This mixture consists of several components:

The viscous properties of the composition allow it to penetrate 5 mm deep into the surface. The mixture then solidifies and crystallizes.

Benefits of penetrating basement waterproofing:

In most cases, good penetrating agents are available as aqueous silicate solutions or mixtures of organic resins. Application is carried out with a roller or brush over a previously prepared and cleaned surface.

The application of the waterproofing mixture to the basement wall must be carried out on a cleaned and primed surface.

Before proceeding with waterproofing the inner walls of the basement, you should make sure that they are completely dry. Otherwise, the capillary moisture that has accumulated in the cracks will not allow the solution to penetrate into the concrete. Sometimes it is necessary to resort to a flushing procedure in order to remove ingrained concrete dust from the surfaces.

Processing is carried out in 2-3 layers. Dry the surface after each application. The penetrating waterproofing of the basement walls prevents the penetration of capillary water into the room, but this method does not in all cases help to cope with the filling of cracks.

A binary waterproofing system involves the use of calcium chloride and an aqueous solution of sodium silicate. When mixed, a calcium silicate gel is formed, the strength characteristics of which are several times higher than the parameters of concrete. Before application, the surface is cleaned and rubbed with a metal brush. Then processing is performed with an aqueous solution of liquid glass. After waiting 3-4 hours, you can start applying calcium chloride, after which the result is fixed by repeated processing with liquid glass.

This type of penetrating basement waterproofing from the inside from groundwater is 6-7 times more effective than conventional impregnation.

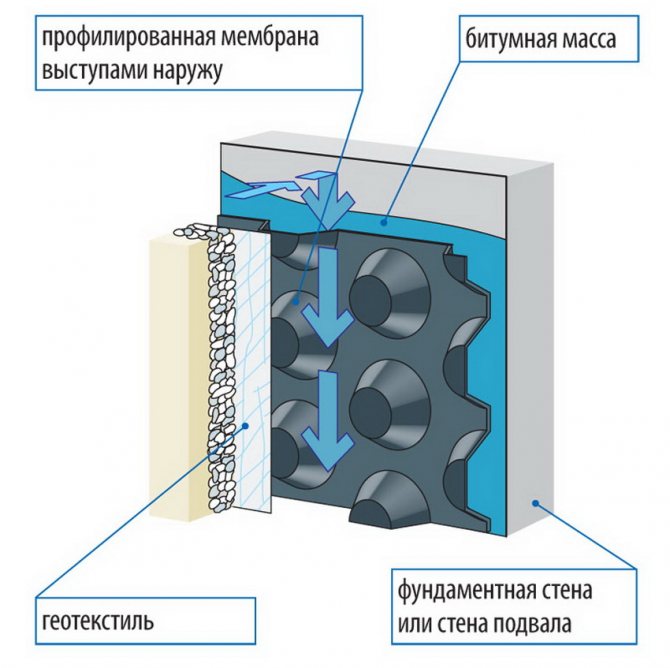

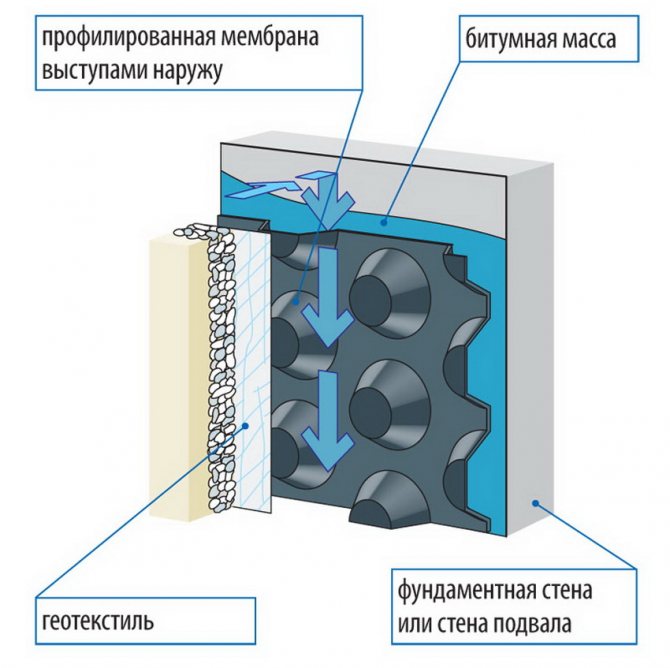

The membrane method is no less effective than other protection methods. This coating is in the form of a 2 mm thick film. It is so light that it does not overload the foundation part of the building at all. Due to the adhesive layer, the membrane insulation does not cause any difficulties during the application process.

Basement waterproofing scheme with a membrane method

There are several types of membrane coatings:

Despite the fact that membranes are classified as roll materials, they are more efficient and durable. These products look like a canvas with cone-shaped spikes, designed to drain water. The membrane coating is universal. It can be fixed to any surface. Can be used even on wet walls. Dowels are used for fixing.

Injection insulation is considered one of the most reliable, since it protects not only the treated surfaces from moisture, but also the foundation structure as a whole. The application process is quite laborious, it will be necessary to make a large number of holes in the wall and introduce the composition into them with the help of special injection devices.

The injection method is quite laborious, but also very effective.

For waterproofing the basement, the following types of mixtures are used:

Injection insulation belongs to the category of penetrating compounds. It has the form of a gel with a flowing consistency. This composition contains mastic:

The advantages of this method include cost-effectiveness (a small amount of gel is consumed), the ability to process hard-to-reach places, as well as the absence of the need for thorough preparation of the base. On the other hand, the application process is so complicated that it is almost impossible to do the job with your own hands.

Liquid rubber is preferred for horizontal waterproofing. This material is made on the basis of bitumen, it contains latex, due to which a strong film forms on the treated surface. This flexible coating can also be applied to walls and ceilings. To protect the room, a 2 mm thick layer is sufficient.

Silicate-based waterproofing mixtures can be used not only for walls, but also for floors.

How to waterproof a basement with liquid rubber:

Liquid glass is no less economical and easy to apply. To prepare the composition for work, it should be diluted with water. The resulting mixture fills the pores in the surface well, after which it crystallizes.

Benefits of using liquid glass:

Liquid glass is excellent for waterproofing walls already finished with plaster

Penetron is used when moisture appears on the walls of the basement. This product is in the form of a dry mix that is diluted with water and applied to the surface with a brush. Penetron penetrates deep into walls, preventing moisture from entering the room. At the same time, the throughput is maintained, so the treated surface is breathable.

Advantages of using Penetron system materials:

The solution is applied in 2 layers exclusively on a damp surface. This type of waterproofing can protect not only concrete walls, but also masonry as well as brickwork. The material is able to withstand any pressure exerted by the aquifer on the foundation.

To properly waterproof a room with your own hands, you must adhere to certain rules.

The general processing technology is as follows:

Most waterproofing methods can be done independently.

If you do the work yourself, then waterproofing the basement will be inexpensive, although in some cases it is better to resort to the services of specialists. When processing the premises using Penetron system materials, the service price will be 900-1400 rubles / m². Liquid rubber has practically the same price range - 900-1200 rubles / m². The cost of penetrating waterproofing varies between 1700-2100 rubles / m². Injection protection is considered the most expensive - 2200-2500 rubles / m².

Internal waterproofing provides excellent protection of the foundation against groundwater. All of these materials are effective in their own way, but they are used as a temporary measure. To achieve long-term results, it is advisable to eliminate the cause of the leak For this, external waterproofing is performed, as well as a drainage system and a blind area around the building.

Types of waterproofing

There are several ways to isolate the cellar from groundwater. To choose the best option, you need to take into account the climatic conditions of the region, the features of the structure and communications inside, the level of melt and ground waters.

- Vertical protection walls from the inside are required if the groundwater is very close or there are no drainage systems around the house. Waterproofing is arranged along the perimeter inside the building.

- Horizontal insulation it is necessary if we are talking about clay soil, which prevents steam exchange, and the base is adjacent to the places where groundwater is released. As a rule, vertical and horizontal foundation insulation is combined with each other. This helps to enhance the protective properties of the materials.

- Penetrating waterproofing relevant when it comes to the pressure of groundwater and the lack of drainage. The idea is to use water pressure, which pushes the protective material harder against the surface of the house. Penetrating waterproofing is designed to fill cavities that appear in walls and help stop moisture from entering. For example, concrete has a porous structure, if it is impregnated with a special hydrophobic solution, then it will repel water.

Groundwater is formed as a result of infiltration of sediments and surface waters. They accumulate in aquifers (sandy) layers located above the water-resistant (clay or rocky), and are found at different depths from the surface of the earth. Distinguish between groundwater flow and basin

... In the first case, the movement of groundwater is directed towards the depressions or along the slope of the aquiclude, and the speed of movement depends on the filtering properties of the soil and the slope of the flow. The groundwater level near water bodies (rivers, lakes, canals, etc.) is usually associated with fluctuations in the water level in them, and the movement of these groundwater usually occurs in the direction of the reservoir; in some cases, depending on the seasons, the movement of groundwater can be in the opposite direction - from the reservoir. It should be borne in mind that at high speeds of movement, groundwater captures and carries away with it small particles of the aquifer, thereby reducing its density and resistance to compression.

In the second case

the movement of groundwater does not take place, since the water is confined to the depression of the confining surface

... There are cases

when the aquifer is covered by a water-resistant layer. Under certain conditions, such interstratal waters create pressure on the upper water-resistant layer and the possibility of its breakthrough. Checking can be done according to the approximate formula:

| (3) |

Where Н0 -

ground water head;

h0 -

distance from the day surface of the pit to the bottom of the waterproof layer.

Groundwater can dissolve some rocks, salt, gypsum, anhydride, chalk, limestone, dolomite. The consequence of such groundwater activity is the formation of underground caves (karst phenomena). Groundwater also contributes to the formation of landslides, landslides, and so on. That is why, along with geological surveys, hydrogeological data should also be identified: the presence or absence of groundwater, their movement and chemical composition, since groundwater in many cases can be aggressive towards concrete and reinforced concrete underground parts of structures. In practice, cases are distinguished when groundwater is located below or above the base of the foundation. In the first case, when the groundwater level is below the base of the foundation and the speed of their movement is low, the groundwater does not have a significant effect on the strength of the foundation. In the second case, when the water table is above the foot of the foundation, the compression resistance of fine and silty sand of the foundation decreases. At the same time, if the groundwater has a large slope and a high speed of movement, then small soil particles, if present near ditches or trenches, can be carried out from under the sole, which reduces the density of the soil.

A decrease in the density of the foundation soils and a decrease in its resistance is also possible when the excavation of foundation pits is carried out with drainage. In this case, due to the one-sided pressure of ground water, small particles of the base soils are carried out from the bottom of the pit.Thus, if the basement soils contain fine particles (fine sand, silt), and the groundwater level at the site is higher than the basement of the projected structure, then the groundwater level should be artificially lowered beforehand. To lower the groundwater level, it is best to use wellpoints, which are placed along the contour at a certain distance from the structure. In many cases, groundwater is intercepted by a sheet pile fence or drainage system that blocks the flow of water and access to the construction site. With a favorable combination of geological structure and terrain relief, ground codes are assigned to, more, lower places - reservoirs, ravines.

Protection of pits from groundwater flooding is carried out using dewatering, installation of impervious curtains, or a combination of these methods. Water lowering is carried out using open drainage or deep water lowering. For the installation of impervious curtains, they choose to natural or artificial freezing or bituminization of the soil around the pit. An anti-seepage curtain can also be a sheet pile clogged up to a watertight seal. Protection methods are chosen depending on the type of groundwater, characteristics of strata and properties of soils, depth and shape of the pit in terms of plan and other factors. All applicable methods of protecting pits from groundwater should exclude the violation of the natural properties of soils at the base of the structure being erected, ensure the stability of the slopes of the development and the safety of nearby structures.

open drainage and deep dewatering

... The simplest way is open drainage, in which water is pumped out by pumps directly from the pit. Freezing, bitumizing. When protecting pits from flooding by freezing, the property of wet soils is used to transform into a solid state when frozen. Freezing can be natural or artificial.

The various methods of protecting structures and underground premises from the harmful effects of groundwater and dampness developed by construction practice can be divided into three main groups: the fight against the penetration of atmospheric precipitation into the ground by draining rain and melt water from the construction site; drainage device for its drainage; the use of various types of waterproofing. The choice of one or several methods of protection at the same time depends on the topographic and hydrogeological conditions of the construction site, seasonal fluctuations and possible changes in the level of groundwater, their aggressiveness, structural features and the purpose of buried premises. In all cases, water protection measures must ensure the specified mode of humidity in the designed premises and the protection of structures from aggressive waters for the entire period of their operation.

In more aggressive waters, before the installation of a clay castle, the surface of the protective wall and foundations is covered twice with bitumen or polymer mastic. Below the foundation, where the reinforcement is protected by only a small layer of concrete, the insulation should be more complex. To do this, preparation for the foundation is performed from a layer of crushed stone rammed into the ground and impregnated with bitumen, which is covered from above 2 ... 3 times with bitumen mastic or mastic from polymer resins. In case of highly aggressive waters, all underground structures are protected from the sides and bottom with glued insulation made of bitumen roll materials. Along with the device of anti-corrosion insulation, protection of foundations from destruction can be ensured through the use of cements that are more resistant to this type of aggressiveness (for example, sulfate-resistant cements with sulfate aggressiveness of water), as well as dense concrete.

What materials are used for waterproofing

Most often used:

- penetrating insulation - a mixture of sand, cement and polymers;

- cement mixtures - cement and polymer additives;

- roll insulation - bitumen, roofing felt, roofing material, brizol, waterproofing;

- liquid glass - an aqueous alkaline solution of sodium and potassium;

- membrane insulation - molding rubber for a snug fit to the surface;

- polyurea - sprayed two-component polymer.

For example, penetrating insulation is suitable for concrete surfaces; for buildings in regions with frequent and heavy precipitation, a bitumen-based coating mixture is used.

Let's consider in more detail in what conditions and how to use each material.

Penetrating waterproofing

Such basement waterproofing is used if the groundwater is high enough. Penetrating insulation is an umbrella term for a mixture of several components. It includes sand, cement and polymers. As a rule, such mixtures are diluted in water and then applied to the surface to be protected from moisture. It is also a concrete or brick building. The liquid composition penetrates into cracks and capillaries, fills the concrete structure and crystallizes, leaving no chance for moisture to penetrate inside. At the same time, the ability to transmit steam at the concrete remains, which avoids the appearance of condensation.

How to apply penetrating waterproofing

Remove grease and dirt from concrete. If there are cracks on the surface, they must be repaired with a putty and a homogeneous structure of the material should be achieved. This will help to avoid the formation of fractures and premature deterioration of the concrete. Then rinse the surface with water, prepare a waterproofing mixture and apply it on damp concrete in 2-3 layers. It is worth starting work from the corners and joints of the joints. After completion, we recommend moisturizing the treated surface for several days, this will promote uniform hardening.

What are the ways to protect the foundation

To protect the foundations of a house or basement from soil moisture, you can choose any of their variety.

It can be:

- The device of a special drainage system, which consists of perforated pipes through which groundwater is discharged from the base into special wells. After cleansing them, moisture can be used for technical needs.

- Foundation protection can be performed using a cement-sand mortar, while its layer should be at least 25 millimeters. The surface is covered with the mixture, leveled, then thoroughly dried. After that, a layer of roofing material or ordinary roofing material is fixed on top. The photo shows the filling of the floor with cement-sand mortar.

Basement floor protection with sand-cement mortar

- To isolate the base walls from excessive moisture, mastic made from fluff lime and heated bitumen in a two to one ratio allows. Lime, if necessary, can be replaced with dry sieved chalk mixed with normal resin in a one-to-one ratio. Such molten mastic is applied to the surface in two layers, with a total thickness of over 8 millimeters.

- The easiest way to isolate the foundation is to lay two layers of roofing material or roofing felt. The price of such coverage is lower. In this case, it is necessary to ensure that one layer overlaps another at least 15 centimeters.

Tip: When laying, make sure that there are no damages or defects in the roll material.

- Often, surfaces are cemented in several ways.

Cement-based waterproofing

This type of protective coating is also called plastering insulation. It adheres well to the surface, is durable and is applicable not only to concrete surfaces, but also to wood and metal. There are many options for cement-based waterproofing mixes, but the most resistant are those containing polymers. Chemical elements add elasticity to classic cement.

How to apply the cement mixture

Remove dust, soil residues, grease from the basement surface, brush with a steel brush or water. This is necessary in order to open the pores of the concrete for the mixture to penetrate inside. After that, prepare the cement mixture, mix thoroughly until it begins to resemble sour cream in consistency. Apply the solution to the surface with a brush in two layers, first lay it horizontally, after two hours - vertically. The composition will completely harden after 24 hours.

Choosing a basement waterproofing system

So, oddly enough, the choice of one or another foundation waterproofing begins already at the design stage of your future home. Digging out the foundation every year for the purpose of repair is not a very promising and rather expensive occupation. Remains the option of repairing from the inside. The cost of such work can significantly affect the family budget.

Therefore, it is necessary to choose the right waterproofing system at the design stage. Foundation waterproofing is not just two layers of bitumen. This is a whole complex of measures aimed at preventing water from getting inside a house or other building and eliminating the causes of dampness.

The elements of the waterproofing system can be:

- concrete (or reinforced concrete) of the foundation;

- primers and primers;

- waterproofing membrane;

- protection of the waterproofing membrane from damage;

- insulation of the foundation;

- drainages.

To say that water enters the basement mainly from the ground is not original, therefore, before starting the construction of your house, you need to study a little hydrogeology. First of all, we analyze the situational plan of the land plot.

If your future home is located on a hill, you are in luck, regardless of all other criteria. The cost of waterproofing will be minimal, since, in most cases, you only need to protect yourself from the temporary effects of groundwater, which may appear from heavy precipitation.

If it is on a plain, then additional factors will have to be analyzed, such as: the type of soil, the presence of water in the soil, the presence of natural or artificial watercourses nearby (river, ravine, etc.). Let's talk about this below.

If in a lowland, you will have to seriously invest in waterproofing, since your future home will be located next to a watercourse (river, ravine, etc.). Usually, in such a place, the groundwater is close to the surface of the earth and will have a strong impact on your foundation. You can stop at this and not analyze the rest of the factors. Despite such a gloomy picture, of course, you should not be upset.

Roll insulation

Roofing material, roofing felt, waterproofing - all these are roll materials. They are used when it is necessary to protect the floors and walls in basements from the inside from moisture. The easiest way is to lay the rolls on the floor using an adhesive or bitumen mastic. If the house is located in a region with abundant floods, waterproofing should consist of 4 layers, if not, 2 is enough. Roll insulation is chosen because it is affordable and you can install it yourself. However, at low temperatures, it becomes brittle and cracks.

The blind area is the protection of the foundation from rain

The blind area is being built around the perimeter of the house. This is a concrete strip 1-1.5 m wide. The construction of the blind area is carried out according to certain rules:

- there must be a drainage layer;

- insulation is necessary;

- the waterproofing film is laid.

It is advisable to use Polynor sprayed insulation only in small areas, as it is expensive.

Dense basalt insulation Park can be placed even under the screed.

The blind area protects the foundation from rain, and this is the lion's share of all the moisture that affects concrete. The groundwater level is not always high. The blind area is erected when the house is already completely ready. It must be borne in mind that it does not protect the upper part of the foundation (plinth).

What is the best protection of the foundation from moisture

The best way to protect the foundation from moisture is to lay bitumen rolls outside. If for some reason this cannot be done, then it will be optimal to process the concrete from the inside with penetrating compounds, and build a blind area around the perimeter of the house. In addition, during the construction process, waterproofing is mandatory at the junction of the foundation and the wall. Roofing material is usually used. If this layer is not there, then problems with wet walls are guaranteed to you, and it will be very difficult to solve them.

Liquid insulation (coating)

Protective coatings are varied in composition. The mixture can be bitumen-based, bitumen-polymer, polymer and polymer-cement. Such formulations are suitable for concrete, stone and brick surfaces. They are easy to apply and protect basements from temperature extremes, moisture and salt. The most durable are polymer and polymer-cement. By adding active chemical elements, their lifespan is extended. Bituminous mixtures lose their elasticity at low temperatures, so cracking is highly likely.

How to apply liquid insulation

Clean the surface of dust and dirt, level if it is uneven and contains cracks. Then prime the walls of the cellar to increase the adhesive force. Moisten non-primed walls with water. After that, prepare the coating mixture according to the instructions and apply in two layers. The second coat can be applied when the first coat has hardened but not completely dry.

Foundation protection from the outside

Ideally, moisture protection of the foundation should be applied externally. This is usually done during the construction of a building. If the house has already been built, then outdoor work is possible only after the foundation has been dug around the perimeter.

It is imperative to put waterproofing between the foundation and the wall.

Before protecting the foundation from moisture, consider which materials are suitable for outdoor use:

- bituminous rolls;

- polyurea;

- bituminous mastics;

- PVC membranes.

It must be borne in mind that the hydro-barrier will be covered with earth. It contains stones that, under high pressure, can damage the protective layer. The material used must be strong, therefore liquid rubber, acrylic mastics and thin polymer films are not suitable for these purposes.

Bituminous rolls are the most common form of foundation protection against water.

Black bitumen mastic is used as a primer (preparatory layer). It is applied to the work surface with a brush or roller in one layer. Then bitumen rolls are fused onto the mastic. It is a self-adhesive material that becomes sticky when heated with an open flame. Rolls are laid in at least two layers with overlapping seams.

Polyurea is applied by spraying. Beforehand, the working surface must be cleaned of dust. A protective liquid polyurethane compound creates a strong, waterproof film that adheres securely to concrete. It is advisable to apply in several layers.

For installation outside the foundation, do not use thin PVC film. A special PVC membrane with pimples is suitable for these tasks. Hemispherical pads protect from stress and serve to connect the sheets. The waterproofing is attached to the walls of the foundation mechanically (by means of studs).

Membrane waterproofing

The membrane-type protective material is similar in principle to roll insulation. But it is lighter, produced in the form of a film with a thickness of two millimeters. To protect the interior of the house from moisture, a PVC (polyvinyl chloride) membrane is often used. It is fire resistant. Membrane coatings are available in the form of a web with cone-shaped spikes, this helps to drain water. They are also easily attached to any surface due to the adhesive backing.

How to apply membrane insulation

The walls and floor in the basement or cellar need to be cleaned.If there are cracks and chips on them, putty and prime. Apply bituminous mastic, for better adhesion, fix the membrane to the surface with dowels, install an insulating material.

How to protect the foundation and basement of a house from groundwater. Foundation waterproofing, drainage

Any building must be reliably protected from the level of groundwater, and it is best to do this even during the construction process. The complex of protective measures may include various methods of waterproofing, drainage, etc. Protective measures should be planned with the calculation of 50-60 cm higher than the groundwater can rise in spring. Even if the groundwater level in the area where the building is being built is not too high, it is necessary to block the surface water from access to its foundation and plinth. For this, a blind area or sidewalk is arranged around the building under construction.

The options for protecting the foundation from groundwater may vary. So, if the building does not have a basement, or the groundwater is located below it, it will be enough to arrange waterproofing against capillary moisture. In this case, it is necessary to isolate the walls of the basement and make sure that moisture from the soil cannot rise up through them.

Drainage is arranged when the groundwater level is above the basement floor level. The goal is to ensure that the water table is below floor level. Drainage is easy enough to arrange if there are reservoirs or collectors nearby, into which water can be diverted from the building. However, it so happens that a drainage device is impossible (for example, due to the features of the relief), then the basement should be protected by arranging a special waterproofing. Waterproofing options, as already mentioned, you can choose different: it depends on whether the building has a basement or not.

In buildings that do not have a basement, waterproofing is laid in the basement 1-1.5 cm below the floor structures and 2 cm above the level of the sidewalks. The building is insulated from soil moisture with concrete floor preparation. The concrete preparation and the insulation layer must be bonded together. If the preparation is located lower than the insulation, then a double layer of bitumen is used as a connecting link, applied to the surface of the base from the inside.

Installation of an insulating layer: 1.2 cm thick asphalt or a layer of cement mortar with ceresite or hydrosite. The solution is prepared in a ratio of 1: 1.5 and applied in a layer 1.5 cm thick. You can also use roofing material, laying it in 2 layers and smearing it with a bituminous mass between them.

With a basement height of more than 60 cm, 2 layers of insulation are laid: the first - 10-15 cm below the floor structures, the second - 15-20 cm above the sidewalk level. In addition to this, the inner surface of the wall, which is in contact with the ground between the concrete preparation and the insulation, is coated with 2 layers of hot bitumen. If the building has a basement, waterproofing against capillary moisture is arranged at the level of the basement floor, as well as 15-20 cm above the surface of the sidewalk. To protect the walls of the basement from dampness, use a double coating on dried plaster with hot bitumen or resin. A cement mortar with the addition of hydrosite is also used.

If the building is experiencing groundwater pressure, then it is better to arrange drainage, but a waterproof continuous basement shell on the outside of its walls and floor is also suitable.

If the pressure of groundwater is not too large (0.1-0.2 m), crumpled clay is placed in a free pit above the concrete preparation. Layer thickness - 25cm. From above, everything is lubricated with cement mortar with hydrosite (1: 3) and an asphalt or cement floor is made.

After smearing the outer surface with a solution with the addition of liquid glass, it is plastering. Plaster in 2 layers of 1.5 cm with cement mortar with hydrosite, 50 cm above the groundwater level. Then, behind this wall, in layers of 25 cm, fatty crumpled clay is stuffed, so that its top layer is 25 cm below the insulating layer.The weight of the concrete preparation dampens the groundwater pressure. In order to ensure the continuity of wall and floor insulation, the basement floor should be installed after the walls have been erected, especially in sandy soil. If the soil is clayey, then the sedimentation takes longer, and the continuity of insulation can be ensured with a bitumen and tow lock.

With a stronger head of groundwater (0.2-0.8 m), additional loading of the floor structure may be required. Usually, heavy concrete is used for this, the volumetric weight of which is 2200 kg / m3. In this case, the thickness of the load will be 2 times less than the excess of the groundwater level above the basement floor.

If the pressure of groundwater is even more powerful, from 0.8 to 2 m, then more roll layers (3-4 layers) are added to the main waterproofing, and the reinforced concrete slab is reinforced with steel (reinforced concrete) beams

Liquid glass

This component contains an alkaline solution of sodium and potassium silicate. It is produced in the form of a powder, which must be mixed with water to obtain a waterproofing mixture. Outwardly, it resembles transparent rubber, which is why it got its name - liquid glass.

The composition can be prepared independently and applied too. Liquid glass protects the surface from corrosion. If the integrity of the coating is suddenly broken, it is easy to repair it. Most often, this material is used to protect concrete walls with metal inserts from moisture.

How to apply liquid glass

Clean the surface of dirt, degrease and level with a putty or primer if it is uneven. Then prepare a solution and apply to the entire surface, without bypassing joints, corners and crevices. The process should not be delayed, as the mixture hardens quickly. When the surface is dry, apply a layer of plaster.

Polyurea

The polymer has high physical and mechanical properties, does not leave seams, unlike roll materials, dries quickly and serves for more than 30 years. It also easily adheres to concrete, metal, ceramic tiles, which makes it very versatile in many ways. It is polyurea that is used for waterproofing pipelines and swimming pools. It consists of two components that must be mixed together to obtain a spray mixture. The mixture is applied using a special installation.

How to spray polyurea

The material can be applied to the surface with a roller, brush or using a high pressure unit. It is better to use the latter method, this will allow you to spray the polymer in an even layer and avoid the appearance of bubbles. Before applying, mix components A and B from a two-component high-pressure unit, then the mixture is heated and sprayed with a gun. The surface on which the polyurea will be must be prepared in advance: clean, close the cracks and prime.

How to order basement waterproofing from groundwater on poliol.ru

More than 550 teams of performers are registered on the site poliol.ru, ready to help you. To use the service, leave a request on the website for free. A waterproofing consultant will contact you by phone or chat on the website. He will advise on the materials and help you choose the performers.

You can also describe the task and post it on the site. All contractors in your region will receive notifications and send preliminary quotations - you choose the one that suits you. Our service is completely free.