When we start to insulate the facade, questions arise: which fastener to use for thermal insulation, which disc dowel to prefer with a metal or plastic nail, which fungus to choose for installing polystyrene, and which one for installing mineral wool?

To fasten the insulation to the wall, a dowel with an umbrella head is used. Dowels come in different lengths, the nail can be metal, plastic or with a thermal head. What is the difference? What kind of insulation do you need?

The main function of the dowel for thermal insulation is to reliably attach the insulation to the wall so that after applying the decorative coating, the insulation does not fall off under the weight of the finishing materials. Thus, the main characteristic of the fungus will be the force that must be applied in order to tear off the insulation from the wall.

Views

Insulation materials are made in the form of slabs. They come from mineral wool or glass wool, as well as from foam. If it is necessary to fasten the last material, then its installation should be carried out before applying the plaster and reinforcing layer.

Butterfly dowel for drywall load and other characterizing data can be found in the article.

The dowels, with which it is attached, mount it to the supporting base. Depending on the variety of these surfaces, different types of dowels are used. The planes to which it is attached are subdivided into three types:

- full-bodied porous, such as aerated concrete and gas silicate blocks;

- hollow solid (alkaline brick or hollow concrete block);

- solid solid materials (concrete, ceramic and sand-lime bricks).

You can learn how to use a self-tapping screw for metal with a drill from this article.

Therefore, when choosing a material, you need to focus on them. Usually, plastic varieties are used, and for fastening plastic heaters, products made of polypropylene or analogs made on the basis of nylon are used.

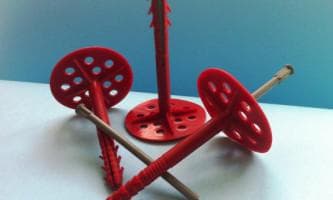

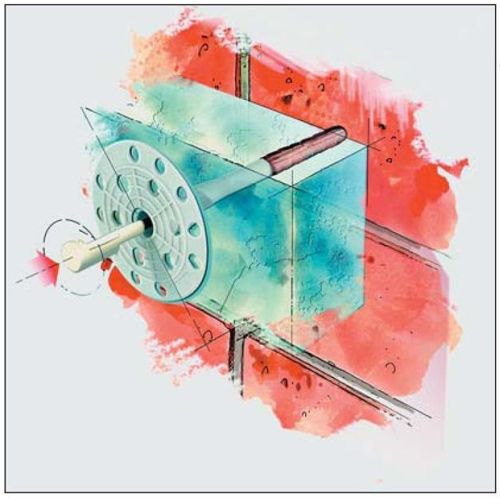

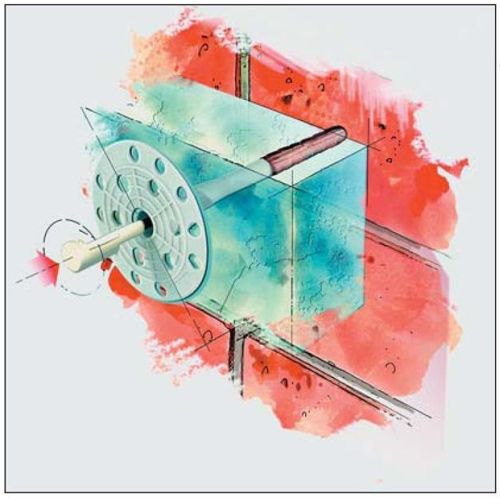

The dowel designed for thermal insulation is indispensable for installation due to its unusual design, consisting of three parts - a clamping component in the form of a cap, an internal strong core and an anchor element - a sleeve.

You can learn how to properly fasten the corrugated board to the roof with self-tapping screws from this article.

The connection of the cap, which is also called the fungus, with the core can have a straight joint or a transitional configuration. The core in the form of a nail can be plastic or metal. The first material is used for fastening light insulation, and the second for heavier bases, for example, basalt. When choosing it, you need to pay attention to its version with a thermal head, it is specially made to protect the fasteners from corrosion and cold.

Self-tapping screws for wood dimensions table weight and other characterizing data can be found in this article.

In the video - a dowel for thermal insulation with a plastic nail:

The dowel-nail is especially popular.... It is widely used for its galvanized coating, which resists corrosion and ensures the durability of fasteners. To achieve maximum strength, its version with a three-sided expansion is used.

Facade dowel often referred to as dish-shaped because of its hat, which resembles this flat dish. Its core has a thread, which ensures the perfect fastening of the insulation to the base.It can be used for the installation of ventilated thermal insulation systems.

Facade dowels are of three types:

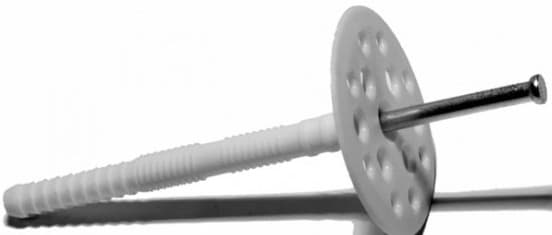

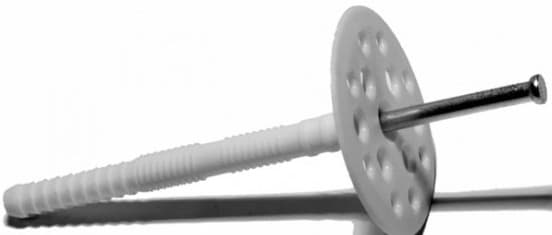

- With nail and thermal head... This is the preferred type of dowel. It consists of a fungus and a nail with a tip of a resistant material that provides thermal insulation to each point of the fastener. The fungus is made in the form of a perforated disk, which provides a reliable grip and retention of the insulation sheet. This kind of dowels can be used in any climatic conditions.

You can learn about what self-tapping screws to fix drywall from this article.

- With a plastic nail... This type can be used to fasten the heat-insulating material to both solid and hollow base. Its construction consists of a spacer nail and a retaining disc element.

- With a metal nail... Such dowels are very similar in design to the previous type, but are used for heavier materials.

Dowel dowels for thermal insulation differ not only in design, but also in the method of fastening.

They are:

- with a core;

- with threads, which, if necessary, can be driven into the base.

The dowel nail butterfly for drywall is used in the following cases listed in the article.

The principle of fastening the insulation with dowels consists in the created friction, which arises as a result of the operation of the expansion mechanism of the dowel. Thanks to this design, the required holding force is created. Therefore, when choosing a dowel, you must first carefully consider the core used. Make sure it is able to withstand the required load. You can use not only a nail, but also other threaded hardware. However, it is worth making sure that they fit in length and diameter.

How to use nails for a pneumatic gun can be found in the article.

In the video - a dowel for fastening thermal insulation:

The advantage of dowels for insulation:

- reliability of fastening and good fixation of thermal insulation foxes;

- facade fungi do not destroy, rot or corrode;

- their design allows them to withstand large bearing loads;

- the insulation remains intact for a long time, due to the fact that the plastic discs of the dowels smooth out changes in the material when it expands or contracts;

- due to the expansion mechanism of the dowels, their adhesion to the wall is improved;

- such an attachment does not create additional cold checkpoints;

- durability and strength.

How to use construction nails GOST 4028 80 can be found here from this article.

Product characteristics

The polypropylene plastic dowel is in wide demand, it is profitable to buy it in large quantities for resale, so it will cost much less. It is widely used by construction companies and crews who, by making bulk purchases of this product, can ensure the smooth operation of their workers. It is always bad for any employer when, due to a lack of material, builders are idle. A propylene dowel, a nail for insulation, is especially valued for its corrosion resistance, you can be one hundred percent sure that it will not rust, which is why stains usually appear on the facade, which spoil all the work done. Products have different lengths and diameters, which allows them to be used to fix a particular material. They come in the following sizes, which are especially in demand:

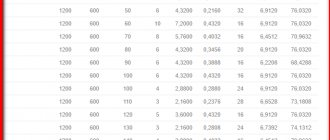

- Dowel nail for insulation 80 millimeters, 10 millimeters in diameter, there are 1000 of them in a pack;

- 90 millimeters, 10 millimeters in diameter, 1,000 pieces per pack;

- 100 millimeters, 10 millimeters in diameter, 800 pieces per pack;

- 110 millimeters, 10 millimeters in diameter, 700 pieces per pack;

- 120 millimeters, 10 millimeters in diameter, 700 pieces per pack;

- 140 millimeters, 10 millimeters in diameter, 600 pieces per pack;

- 160 millimeters, 10 millimeters in diameter, put 500 pieces of such products as a dowel for thermal insulation in one pack;

- 180 millimeters, 10 millimeters in diameter, 500 pieces per pack;

- 200 millimeters, 10 millimeters in diameter, 500 pieces per pack;

- 220 millimeters, 10 millimeters in diameter, 400 pieces per pack;

- 260 millimeters, 10 millimeters in diameter, 400 pieces per pack;

- 300 millimeters, 10 millimeters in diameter, 400 pieces per pack.

What functions do they perform, application features

For reliable fastening of the insulation, the fastening element must meet several requirements:

- during installation, hold the thermal insulation plates, prevent their displacement;

- in windy weather, protect the structure and promote an even distribution of the load;

- prevent the formation of surface stresses in the decorative layer applied to the insulation;

- provide a strong attachment of two surfaces - the decorative layer and the base.

How to use fasteners for a terrace board can be found in the article.

In the video - a disc dowel for thermal insulation:

Disc dowels are used mainly for insulating building facades, and nail dowels are used to improve the thermal insulation of ceilings and roofs.

Fasteners with plastic nails are suitable for slabs and rolls of glass wool, foam, plastic, mineral wool and other materials. The disc dowel can securely fix them on concrete, brick and aerated concrete surfaces.

The type of dowels used depends on the base on which the attachment is made:

- for expanded polystyrene and lightweight materials, a dowel with a plastic core and reinforced fiberglass is used;

- compression collars are best suited to wooden surfaces, in the design of which there is a hole for a nail or screw and a propylene cap;

- denser materials require the use of dowels with a galvanized metal nail;

- its analogue with a thermal head is used for lightweight heaters that cannot be secured with a plastic nail.

How the fastening takes place and how the panels to the ceiling can be found in this article.

Installation

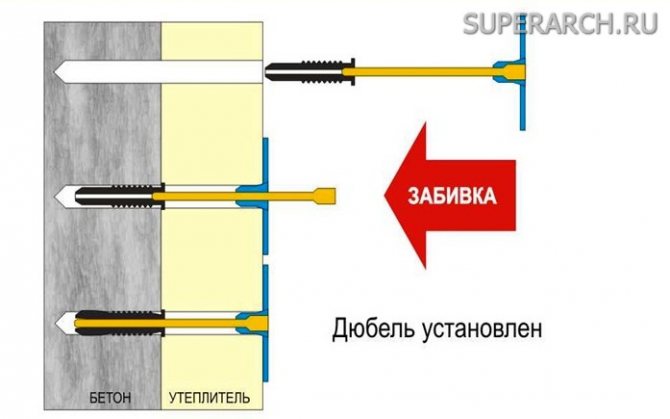

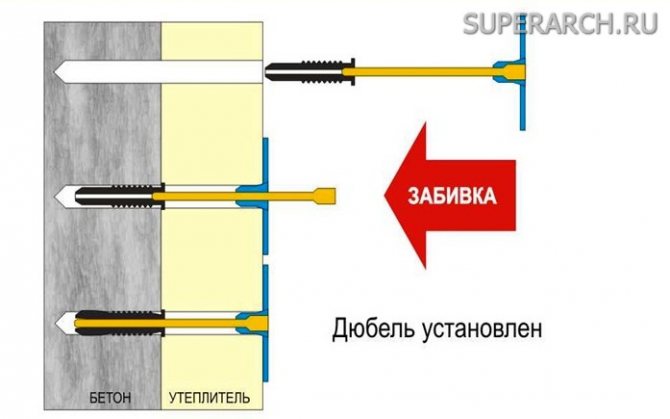

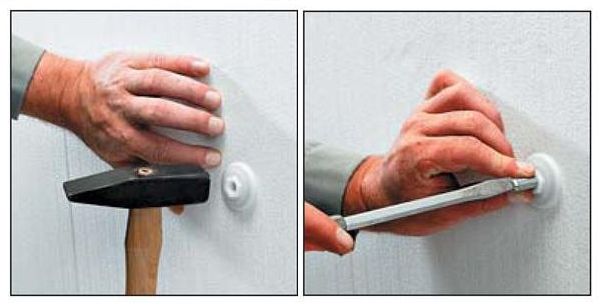

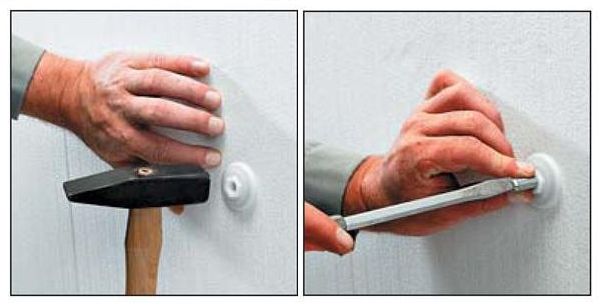

The installation of the insulation must be started with the marking of the fastening points. For clarity, you can mark them with a marker for construction work. Then you need to:

- Drill a Ø 10 hole through the insulation and the main surface, its depth should be ten centimeters longer than the dowel rod.

- Fill the resulting voids with dish-shaped products, which must be manually pressed with effort until their caps sit close to the insulation.

- Then the selected nail is driven into their core. If there is a thermal head, it is put on the protruding part of the rod.

The video shows more information about the dowels for fixing thermal insulation:

The principle of operation of fastening dowels for insulation

Despite the fact that there are different technological processes and materials are constantly being improved, the physical law, thanks to which the dowel fixes the thermal insulation, remains unchanged - this is the holding force of friction. In this process, it is so large that the fastener can be used only once - when removed from the hole, it will simply collapse. You can spoil the mount in one more way - pull it out under the pressure of the insulation. Such troubles can be avoided if the seat is carefully prepared.

The hole for the installation of the disc dowel must correspond to the required diameter and depth of the fastener. Inside it, the presence of cracks, chips, sand or dust remains is unacceptable. Due to their shapes and the presence of various spacer zones, the thermal insulation fasteners are securely fixed on almost all types of surfaces.At the same time, external factors practically do not affect the strength of such an attachment during the subsequent operation of thermal insulation systems.

Dowels for monolithic bases have a spacer fastening principle, and for hollow anchor

Traditionally, the calculation of the required length of the dowel for insulation is carried out according to the following formula: L = H + K + I + W, where:

- L is the required length of the dowel;

- H is the thickness of the insulation layer obtained on the basis of a heat engineering calculation;

- K is the thickness of the adhesive for gluing the insulation;

- I - the length of the expansion part of the dowel (it must be at least 45 mm);

- W is the sum of the actually determined deviations of the base of the building from the vertical and the deviation of the facade plane at the points of installation of the dowels for thermal insulation (a kind of safety factor along the length of the fastener).

When installing a heat-insulating layer consisting of materials with high deformability (semi-rigid mineral wool boards), it is best to choose dowels with an expansion washer with a diameter of 100 mm

Manufacturers and prices of their products

For the convenience of choosing dowels for insulation, the approximate cost of products from popular manufacturers is given.

| Company | Dowel type | Size, mm | Quantity in one package, pcs. | Price, in rubles |

| Koelner | with metal nail | from 10 × (90 ... 220) | 250 | from 800 to 1500 |

| Technics | with plastic core | 10×(70, 80) | 100 | 320350 |

| Wkret-Met | with galvanized nail | 10×120 | -//- | 820 |

| Strezzar | with polyamide core | 10 × (140, 160, 180 and 220) | 50 | from 400 |

| Pan Insulate | with plastic nail | 10×(70…160) | 100 | from 340 to 450 |

| with metal core and thermal head | 10×(90…200) | 50 | from 650 |

Read about where self-tapping screws are used for metal with a drill.

The use of a facade dowel is very widespread, since it not only firmly holds the insulation on the main wall, but also serves as a fuse for the entire appearance of the house from external negative influences. It is also an additional support for the heat-insulating material, and does not make the weight of the structure heavier, especially if a dowel with a plastic rod is chosen.

Insulation installation process

The technology for attaching the insulation is quite simple and can be done by hand.

The process consists of the following steps:

- Foundation preparation;

- Bonding insulation to mortar;

- Fastening to disc dowels;

- Sealing joints;

- Fastening of steam and waterproofing;

- If necessary, plaster using fiberglass mesh;

- Finishing cladding \ finishing.

Insulation of the loggia: to reduce heat loss, the caps are sealed with reflective tape

Before insulation, old plaster is removed, irregularities are removed. First, you need to glue the insulation on a special mixture for gluing the plates. If the walls are level enough, it can be applied with a notched trowel, but usually it is simply thrown in piles on the surface of the sheet.

So that the first row does not slide under the weight of the others, a starting bar from a profile or rail is attached downward, on which the sheet will rest.

After the solution dries (after 2-3 days), you additionally need to fix the sheets on the fungus for insulation. To do this, you first need to make holes with a puncher.

The thickness of the drill should be equal to the thickness of the fungus stem. The depth of the hole should be 5-7 mm deeper so that the dowel is driven tightly regardless of the construction dust inside.

The number of attachment points per sheet depends on their location and the height of the walls.

- In ordinary areas, it is customary to fix the insulation at 5 points in each square meter.

- In corner areas, you need to increase the number to 6.

- If the height of the building is from 8 to 20 meters, then 7 umbrellas are required for each square.

- For high walls over 20 meters in the corners, you need to fix the insulation at 9 points.

It is better to place the fixation points at the joints of the sheets. This will save you from additional "ventilation" holes, and after installation, the edges of the sheets will not bulge. In the photo you can see several ways to position the dowels.

Insulation fixing scheme

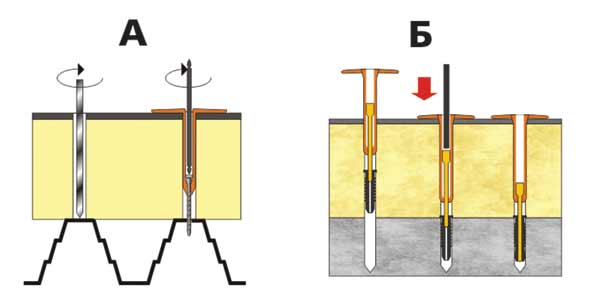

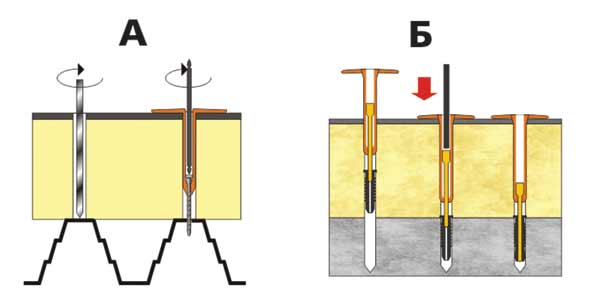

If it is necessary to fasten to a metal surface or corrugated board, first a self-tapping screw and a screwdriver tip are inserted into the disc element. Then the dowel pushes the insulation to the base.

After that, the screw is screwed into the metal so that the cap fits snugly against the insulation. The self-tapping screw must enter the base by at least 15 mm. Mounting instructions are shown in the diagram.

A - fastening to corrugated board, B - to concrete

If you decide to make a ventilated facade, then it is imperative to cover the mineral wool on top with a hydro and vapor barrier membrane. The only exceptions are materials with low moisture absorption (expanded polystyrene, polyurethane foam, etc.).

When plastering from above with a layer of 3-4 mm, an adhesive mixture is applied, intended for a protective layer. The layer must be even, therefore it must be applied with a notched trowel.

A reinforcing alkali-resistant mesh is pressed into the mixture. You need to fasten it with an overlap of 10 centimeters.

In order to finally level the surface under the facade plaster, the walls are treated with another layer of mortar on top, and leveled with the rule.

The video in this article shows the process of installing insulation on dowels:

The structure of the dowel fungus

Such a fastener consists of a wide head and a long leg that expands and securely fixes the insulation in a vertical or suspended position. This type of fasteners is completely immersed in the depth of the wall, the size of the sleeve is selected depending on the thickness of the insulation material, it varies from 80 to 300 millimeters, the cap has a standard indicator of 59.

The fastening is obtained reliable due to the sharp notches of the spacer type, which are located in the extreme part of the body. Such a part is turned towards the plate, thanks to this, the dowel does not fall out after fixing. The fastening is obtained of high quality thanks to the holes on the cap, when pressed, they are immersed in the insulation material.

A mushroom dowel with a poppet-shaped head is used to fix various materials, they are resistant to corrosion, thermal effects, and fire. The cap is made of low pressure polyethylene, and the wedge is made of galvanized steel. To fix the insulation of a soft structure, elements made of nylon are used, but plastic, which is resistant to impacts, is more durable.

Varieties and use of the mushroom dowel

To fix a different type of insulation, it is necessary to select a specific fastener. A universal fastener is a disc-shaped dowel, that is, a fungus, it is used to fix heat-insulating material. The rod can be made of plastic or metal, there is a combined type of element. Let's consider in detail the types of dowels.

- Plastic dowels are made of nylon, polyethylene or polypropylene, they have a number of advantages. Such elements do not corrode, are lightweight, and easy to fasten. Fasteners are resilient, so they are securely fixed inside the wall. Plastic items are classified into nylon and polypropylene types.

- Fungi of nylon and polyethylene type are used to fix the material to wood, brick, concrete or hollow-type surfaces.

- Polypropylene parts are used for aerated concrete surfaces, hollow bricks or concrete. Such parts are made of polypropylene material, there are cone-shaped holes on the head, this helps to perform high-quality fastening. Products of this type have a low thermal conductivity, prevent cold bridges, and can withstand temperatures from -40 to +80 degrees. The price is affordable, but such elements are not used for heavy insulation material.

- Dowels with a metal nail are used for buildings with thin walls, and are capable of withstanding significant loads. Due to the rapid freezing of metal, fasteners can form cold bridges, this affects thermal conductivity.

- A rod made of metal material with a thermal head is more durable, such a fastener consists of a steel nail and a plastic plug, it is used to fix the insulation. At the same time, cold bridges are not formed, and the appearance of corrosion is prevented, such dowels are applied to wooden-type walls, they are able to withstand a significant load, are resistant to chemicals.

- The anchor dowel is placed in the wall using a special pistol, this helps to reduce the working time. Mushrooms with a metal anchor consist of a steel-type nail, the spacer part, and the head are made of polypropylene, which is resistant to impact. The size of such an element is the largest in comparison with the rest of the fasteners. Dowels are able to withstand temperatures from -55 to +60 degrees, the main disadvantage is the creation of cold bridges. But this element is able to withstand significant loads, this makes it possible to fix heavy insulation.