A boiler thermometer is a device that has a simple and at the same time reliable design. If, when buying modern boilers, the thermometer is already included, then for old ones it will have to be purchased additionally.

A thermometer, sometimes a temperature sensor, has two functions:

- Displays the reading of the operating temperature of the heat carrier inside the boiler or heating system. Thanks to this, the owner of the heating system determines the stability of the boiler and, if necessary, changes the operating mode. For example, if the thermometer shows a drop in the temperature level, this indicates a malfunction in the heating system, and it is turned off to find out the reasons;

- Modern boilers rely in their work on automation, and she rely on the operation of measuring sensors, including a temperature sensor. Thanks to the well-coordinated interaction between automation and sensors, it is not necessary to constantly go to the boiler and regulate it in order to ensure the desired temperature regime.

There are two types of thermometers: submersible and remote.

Thermometer installed in the heating system

Immersion thermometers

Designed to read information about the temperature of the heat carrier. They are installed on some segments of the system or on the boilers themselves. Depending on the working material, bimetallic and alcohol devices are distinguished.

- Bimetallic... A thermometer of this type consists of a metal plate, for the manufacture of which two different metals were used, and an indicator arrow with a scale. The work is based on the difference in the coefficients of thermal linear expansion, due to which, when heat is supplied, one of the metals is deformed and exerts pressure on the indicator arrow, which will show the temperature value on the scale.

Despite the simple operation scheme and simple design, this type of thermometer provides accurate readings.

Their only drawback is inertia. If the temperature of the heat carrier inside the boiler or in the system changes sharply, it will not become known immediately, but after a short period of time.

Bimetal thermometer

Bimetallic thermometers, in turn, are divided into axial and radial. The difference between these two types of products is the position of the dial axis. The axis of the radial thermometer is parallel to the sensor, and that of the axial thermometer is perpendicular.

The most reliable devices come from Watts, Dani and Introll.

- Alcohol... This type of thermometer is a vessel made of thermal insulating material with a degree scale, which is printed on the surface. The principle of operation is impossibly simple. When heated, alcohol or alcohol-containing liquid expands and moves through the vessel along the scale. The alcohol level shows the current temperature of the heat carrier inside the boiler.

There are few differences between this type of thermometer and a conventional thermometer, and hence a small drawback in working with it - visual inconvenience when taking readings.

And here the most reliable devices are manufactured by Watts.

Read the user manual first before installing the immersion thermometer. From it you will learn the upper limit of the temperature values of the product, the dimensions that are needed for connection, recommendations from the manufacturer regarding operation.

Alcohol thermometer

Control methods

Monitoring of pressure indicators in a closed system, together with the operation of an air vent and a safety valve (so-called.safety group) is a prerequisite for its safe and efficient operation.

Pressure gauge

To control the required values, a manometer is used - a device that shows the pressure of a liquid or gas in a closed loop on its scale. Typically, pressure gauges have 2 scales, showing values in kgf / cm2, bar or atmospheres. The manometer can be combined with a thermometer showing the temperature of the measured heat carrier.

Photo 1. Manometer for measuring pressure, shows values in bar and in pounds per square inch,.

For a private home, spring-loaded pressure gauges are commonly used because of their simplicity and reliability. The gauge scale has a wide range, but the more convenient zero to four atmospheres scale is usually used.

Important! The pressure gauge must have the necessary seals and stamps on the passage of verification, be intact, and the pressure gauge needle, in the absence of pressure in the system, must return to the zero position.

Usually, the pressure gauge cuts into the line at the outlet of the boiler, at the shortest possible distance from it, and is located so that it is convenient to take readings from it.

Air vent

An automatic or manual air vent is installed at the highest point of the heating system, and, if necessary, in other places, and is structurally designed for automatic or manual air venting without breaches of tightness and coolant leaks.

Safety valve

A safety valve is a special safety device designed to protect the system from exceeding the allowable pressure, usually about 2.5 atmospheres.

If the specified value is exceeded, the tightness of the system may break and an emergency situation may arise. Such a valve is called a bypass valve and is installed on the outlet pipe of the heating boiler.

Remote sensors

They are placed outside the heating system. Despite this, they are connected either directly to the boiler or to the programmer, which is responsible for regulating the parameters of the system. Recently, wireless sensors have gained popularity. With the help of auxiliary electronics, they transmit the temperature readings of the heat carrier to the automation, so that they are installed in the place where it is convenient.

In simple circuits, it is reasonable to install temperature sensors that transmit a signal to the control unit via electrical wires. Due to this, the likelihood of transmission failure or data loss is significantly reduced in comparison with wireless models.

What to consider when choosing

The operating parameters of the heating system influence the selection of a suitable thermometer. Pay attention to the following:

- Working range of measurements... Affects the accuracy of the readings. A temperature sensor that has an incorrectly selected upper limit of readings will display data with an error or stop working altogether;

- Connection method... When it is required to determine the level of heating of the heat carrier with a minimum error, choose among those models of thermometers that are immersed in the medium of the heat carrier. Their installation is carried out only in the heating system itself or on the boiler;

- Reading method... The method of measurement affects the speed of bringing the readings of the device to the real level (in other words, the inertia), the appearance and type of the indicator.

Remote temperature sensor

When choosing among immersion thermometers, be sure to consider the length of the well, which is from 120 to 160 mm. And when choosing among wireless sensors, pay attention to the signal transmission range, measurement error and the possibility of autonomous operation from batteries.

Water pressure rate in heating systems of a private house

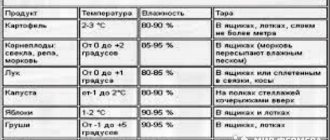

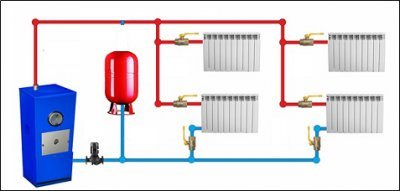

Hot water heating systems are:

- Open... The system communicates with atmospheric pressure through open expansion tankinstalled at the very top of it, and the boiler is installed at the very bottom.

In this case, water circulates through the pipes according to the laws of natural convection - the lower layers of water heat up and rise up, and the colder and heavier ones go down, where they are heated up again.

- Closed... In closed systems, water pressure is isolated from atmospheric, and water moves through the pipes of the circuit a special water pump.

What should be the operating parameters in an open circuit

The pressure in an open circuit is determined by the hydrostatic pressure of its water column. Column of water high 1 meter creates an increase in pressure per unit surface area at its lowest point, equal to 0.1 kgf / cm2, or 0.09 atmospheres.

Reference! To calculate the pressure at the selected point of the open system, it is necessary to measure the height from the measuring point to the water level in the expansion tank, adding 0.1 kgf / cm2 for each meter of water column.

The pressure in the open circuits is self-regulating and does not require balancing, their arrangement is less complicated and requires less maintenance.

However, the laws of heat exchange establish height restrictions such a system associated with uneven heating of the coolant and, as a result, a decrease in its overall efficiency.

Partially solves this problem installation of a circulation pump, increasing the flow of the coolant, however, an open heating circuit, due to its limitations, is only suitable for single-storey houses.

Normal performance in a closed system

In practice, closed systems are more often used due to the wider possibilities of their application. In particular, if the house has two or three floors, and one pump cannot cope with maintaining the water flow, additional circulation pumps can be installed at various points in the circuit, connected in series or in parallel, which reduces the load on the boiler.

The working pressure of a closed heating system is usually considered to be in 1.5-2 atmospheres... The maximum allowable operating value, usually controlled by a safety valve, is 2.5 kgf / cm2.

How is the adjustment

The pressure in the closed heating system is regulated by pumping water into the heating circuit through its connection to the cold water supply system, and membrane steel expansion tank.

One half a tank separated by a membrane filled with air with t. n. overpressure charging, and the other with circulating water.

As in open heating circuits, the membrane tank serves to contain the expanding water during its operating heating, and also reduces pressure fluctuations (water hammer) when the movement of water suddenly stops.

The charging pressure of the diaphragm tank when the circuit is not working is equal to the pressure of the water column. The standard factory value of the expansion tank charging is 1.5 kgf / cm2, and the maximum value for which the equipment is designed is up to 3 atmospheres.

What you need to find out before purchasing

Before purchasing a thermometer, find out some points:

- Find a place on the boiler drum for mounting the thermometer and determine the mounting method. Make sure that the selected device matches the received data and that the installation is available.

- Determine if a pressure gauge is installed in the system. If it is not in the original package, either purchase it separately, or purchase a thermometer with a pressure gauge in one case.

- Determine the required temperature measurement range. Do not take devices with a higher boundary temperature than necessary, since with a higher division value, the result is a large error. This will reduce the reliability of the purchased device.

Temperature norms for heating the coolant

Of course, the standards specified in SNiP largely depend on the region, and sometimes on the time of day, but in general, they are a benchmark that the management company adheres to. If, due to some circumstances, it is cold in the apartment, and it is not possible to install the thermostat, then these parameters make it possible to determine whether there is a reason for a complaint to the appropriate service. As a rule, the temperature of the water in the radiator (standard for apartment buildings) should not be higher than + 95 ° C if a two-pipe heating system is installed in the building and 105 ° C if it is a one-pipe heating system.

In order for the coolant to reach the desired temperature, it has to walk a considerable distance from the boiler room, where it is heated, and under a pressure of 7-9 atmospheres, it reaches + 160 ° C, to the heat exchanger in the house, which is most often located in the basement. It is here that it cools down so that the temperature norm in the central heating batteries corresponds to the safe parameters of SNiP.

Thanks to such processes, the water heats up the radiators, and they, in turn, must ensure the temperature in the apartment is at least + 18 ° C, and in the northern regions - + 20 ° C. If the indicators are below the established norm in the daytime, then you should check the heating system for air jams, find out how warm the neighbors are, and only then decide who to call to complain to, and how to adjust the heating batteries.

Heat loss plays a significant role in the quality of housing heating. They arise if:

- Frequent ventilation of the premises is carried out.

- There are several windows in the room with inappropriate sealing.

- The outer walls are not insulated.

- There is an unheated basement under the non-insulated floor.

Since any complaints must be justified, the heat leaks should be eliminated first, after which the temperature in the rooms should be measured again, and if it is still far from normal, then contact the management service.

Post-purchase check

If a submersible device was purchased from one of the above companies, feel free to install it on the boiler or in the heating system. If not, then first check it for accuracy. What for? The low accuracy of readings inherent in cheap products will lead to an inaccurate display of the real picture of the boiler operation, to a decrease in the efficiency and reliability of operation.

This verification process is shown in detail in the video:

How to check? Take a purchased thermometer and a probe with an external spike for water. Bring the purchased thermometer and then the control probe to an open fire for 10 seconds. Given the inertness of the readings, allow a little time for the thermometer to display the actual temperature reading. Then compare the reading of the thermometer with the control sensor. The lower the difference, the more accurate the temperature measurement and display is.

What does the regulation of the temperature of the radiators give

Since the centralized heating system, with all its attractive concern for the needs of the population for warmth in winter, has significant disadvantages, the consumers of this very heat have to eliminate them. Pressure drops, large contamination of water with various suspensions, airiness in pipes, all this affects the fact that the temperature of the coolant in the central heating batteries is far from normal. In order to control the heating process of an apartment and save money on utility bills, an increasing number of residents of apartment buildings are installing special temperature regulators.

This gives them the following benefits:

- Air does not accumulate in the heating circuit, which interferes with the free circulation of water.

- The cost of heating housing is reduced, which is especially noticeable in houses with an autonomous type of heating.

- Adjusting heating radiators allows you to reduce the temperature in the room if it gets warmer outside the window, and vice versa.This is especially true in the case of a sharp warming in spring, when the heating season is not over yet, and the batteries continue to operate at full capacity. If there is no regulator, then people have to open balconies and vents to cool the apartment.

- Knowing how to adjust the heating batteries in an apartment, you can create a different microclimate in each separate room, for example, by slightly increasing the amount of heat in the nursery or reducing it for a time when no one is at home.

You can think about how to regulate heating batteries with a regulator only after heat loss has been eliminated in the premises. Typically, heat “leaks” are windows, doors, exterior walls, an unheated overhead attic, or a basement underfoot.

It is unlikely that even the most economical thermostat will help save money on heating, if the heat simply escapes through the cracks in the window or is spent on heating the outer wall.

The knowledge of what temperature should be in the radiators will help to navigate the quality of the service of the management company in charge of heat.

Pressure sensors as a complement to thermometers

In a diagram of a heating system with forced circulation, pressure sensors indicate the level of expansion of the heat carrier from heating. For this reason, experts recommend installing pressure meters in the heating system together with thermometers.

Appearance of the spring pressure gauge

The limiting value of pressure is the main indicator for pressure gauges and can in no way be lower than the maximum pressure reading in the system. As practice shows, it is better to install devices with a maximum pressure of 6 MPa.

Pressure sensors are of two types: spring-loaded and electro-contact.

Spring loaded... The role of the sensing element is played by a tube of round or oval cross-section. When a heat carrier is supplied, it shifts, and from this the arrow on the dial starts to move.

The visible advantages of this type of sensors are high operational reliability and reasonable price.

No special skills are required to mount this type of sensor.

The video will tell you about the operation of the minimum pressure sensor:

Electrical contact... Upgraded version of spring type sensors. In addition to the arrow, which indicates the main readings, there are two additional ones, they are set to the lower and upper pressure limits. When the pointer reaches one of the additional readings, the contact closes, and then an electrical signal is sent to the control device. It is advisable to install devices of this type only in autonomous systems of large objects.

Electrical contact pressure sensor

As you can see, there is a choice among the devices for monitoring the operation of the heating system, which depends on a number of factors, such as the place of installation, the operating range, the accuracy of determining the temperature or pressure of the heat carrier. Remember: a properly selected device will allow you to accurately control the operation of the heating system and ensure the durability of its operation.

Causes of pressure drop

The operating pressure of the system is not always at the required level and may drop or increase.

The main reasons for its decline:

- Coolant leaks. Leaks can appear in all elements of the heating circuit - in pipes, radiators, and are usually associated with a defect in their manufacture.

Leaks at joints are often caused by loose fasteners or damage to the joint during assembly.

- Deterioration of the structure. Usually caused by improper installation of the circuit or violations of operating standards - too high pressure or its significant differences, high water temperature or its high "hardness". Individual elements of the system, incl.circulating pump, have a warranty period, and after its expiration, they can reduce performance, requiring them to be adjusted or replaced.

- Scale. It appears when water is heated to too high temperatures. Scale is solid salt deposits that form on the heating surfaces of a heat exchanger. Accumulating in the heat exchanger, scale blocks the water flow and lowers the operating pressure.

Important! Water that is too "hard" contains an increased amount of oxygen, chemical impurities and salts that form rust deposits. Hard water can be present in the system due to frequent replenishment of fresh water, including due to thermal fluid leaks.