In order for the selection of a pump for the water supply of a private house to be carried out correctly, it is necessary to approach this point "mathematically" - to choose according to a pre-compiled algorithm. What is this algorithm and why the selection of a pump for the water supply of a private house should be carried out according to it - see this material.

Before starting the selection of a pump for the water supply of a private house, we sit down at the table, take a pen and paper and begin to fill in the tables and draw diagrams. Further, moving in steps, from the very initial to the final, we can use the selection algorithm to choose a pump for the house.

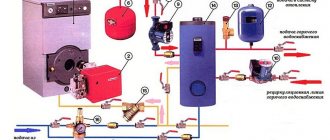

What is a pump in a heating system for?

Circulation pumps for heating private houses, designed to create forced movement of the coolant in the water circuit. After the installation of the equipment, the natural circulation of the liquid in the system becomes impossible, the pumps will operate in a constant mode. For this reason, high requirements are imposed on the circulation equipment regarding:

- Performance.

- Noise isolation.

- Reliability.

- Long service life.

A circulation pump is needed for "water floors", as well as two- and one-pipe heating systems. In large buildings, it is used for DHW systems.

As practice shows, if you install the station in any system with natural circulation of the coolant, the heating efficiency increases and uniform heating along the entire length of the water circuit.

The only drawback of this solution is the dependence of the pumping equipment on electricity, but the problem is usually solved by connecting an uninterruptible power supply.

Installing a pump in the heating system of a private house is justified both when creating a new and when modifying an existing heating system.

The principle of operation of the circulation pump

The operation of circulation pumps increases the energy efficiency of the heating system by 40-50%. The principle of operation of devices, regardless of type and design, is as follows:

- The liquid enters the shell-shaped cavity.

- An impeller, a flywheel that creates pressure is located inside the housing.

- The speed of the coolant increases and by means of centrifugal force, the liquid is discharged into a spiral channel connected to the water circuit.

- The heat carrier enters the water heating circuit at a predetermined speed. Due to the swirling of water flows, the hydraulic resistance during the circulation of the liquid is reduced.

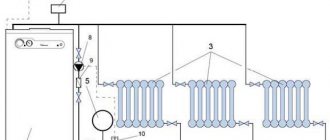

The principle of operation of a heating system with a circulation pump differs from circuits with natural circulation in that the movement of liquid is forced. The efficiency of heating is not affected by the observance of slopes, the number of installed radiators, as well as the diameter of the pipes.

The operation of circulation pumps may differ slightly, depending on the type of construction, but the principle of operation remains the same. Manufacturers offer more than a hundred models of equipment, with different performance and control parameters. According to the characteristics of the pumps, the stations can be divided into several groups:

- By the type of rotor - to enhance the circulation of the coolant, models with a dry and wet rotor can be used. The designs differ in the arrangement of the impeller and the moving mechanisms in the housing. For example, in models with a dry rotor, only the flywheel that creates pressure is in contact with the coolant fluid."Dry" models have high performance, but have several drawbacks: a high level of pump noise is generated, regular maintenance is required. For domestic use, it is better to use modules with a wet rotor. All moving parts, including bearings, are completely enclosed in a heat transfer medium that lubricates the most stressed parts. The service life of a "wet" type water pump in the heating system is at least 7 years. There is no need for maintenance.

- By the type of control - a traditional model of pumping equipment, most often installed in household premises of a small area, has a mechanical regulator with three fixed speeds. It is rather inconvenient to regulate the temperature in the house using a mechanical circulation pump. The modules are characterized by high energy consumption. The optimal pump has an electronic control unit. A room thermostat is built into the housing. Automation independently analyzes the temperature indicators in the room, automatically changing the selected mode. At the same time, electricity consumption is reduced by 2-3 times.

There are other parameters that distinguish circulation equipment. But to choose the right model, it will be enough to know about the nuances listed above.

Calculation of the head of a borehole pump

The calculation of the head is carried out according to the following formula:

Head = (distance from the point of installation of the pump in the well to the surface of the earth + horizontal distance from the well to the nearest point of draw-off * + the height of the highest draw-off point in the house) × coefficient of water-supply resistance **

If the borehole pump will be operated together with a storage tank, then the pressure value in the storage tank must be added to the above formula for calculating the head:

Head = (distance from the point of installation of the pump in the well to the surface of the earth + horizontal distance from the well to the nearest point of draw-off + height of the highest draw-off point in the house + pressure in the storage tank ***) × coefficient of water-supply resistance

Note * - when calculating, keep in mind that 1 vertical meter is equal to 10 horizontal; ** - coefficient of water supply resistance is always equal to 1.15; *** - each atmosphere is equal to 10 vertical meters.

Household Mathematics For clarity, let's simulate a situation in which a family of four needs to choose a pump for a well 80 meters deep. The dynamic level of the source does not fall below 62 meters, that is, the pump will be installed at a depth of 60 meters. The distance from the well to the house is 80 meters. The height of the highest tapping point is 7 meters. The water supply system has a storage tank with a capacity of 300 liters, that is, for the entire system to function inside the accumulator, it is necessary to create a pressure of 3.5 atmospheres. We consider:

Head = (60 + 80/10 + 3.5 × 10) × 1.15 = 126.5 meters.

What pump is needed for the well in this case? - an excellent option would be to purchase Grundfos SQ 3-105, the maximum head of which is 147 meters, with a capacity of 4.4 m³ / h.

In this material, we have discussed in detail how to calculate a pump for a well. We hope that after reading this article, you will be able to calculate and choose a borehole pump without outside help, which, thanks to a competent approach, will last for more than one year.

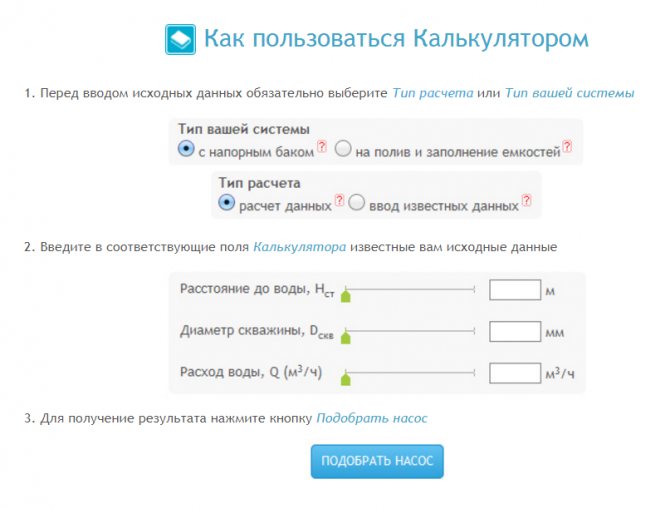

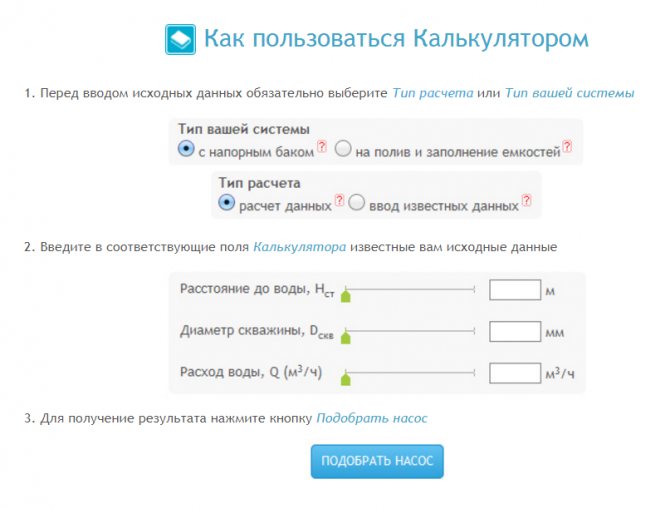

To organize the water supply of a private house before installing pumping equipment, first of all, it is necessary to calculate its parameters. In this case, it is necessary to take into account the technical characteristics of the source, the distance to the consumer and the volume of water intake.A homeowner who independently installs a water supply line to a house does not need to calculate a pump for a well using complex formulas - online calculators posted on the network are designed for this.

Fig. 1 Online calculator for determining the volume of delivery - appearance

Their significant drawback is the approximateness of the results obtained - many important parameters affecting the final result do not appear in the input data. Almost all online calculators calculate only one of the parameters: lift height, performance or the required pressure in the line, the rest of the data has to be determined in other ways. Another problem is choosing an accurate and reliable calculator from the many options available on the net. Therefore, the most correct solution to the question of how to calculate a pump for a well is to calculate its parameters using formulas using loss tables and use calculators as an aid to check the correctness of the calculations.

Fig. 2 Online calculator for calculating a pump for water supply

Compact pumps for summer cottages

If you have a problem with a slight increase in pressure in the system (no more than 1.5 atmospheres), you can solve it by installing a compact pump. The essence of the work is to insert equipment directly into the water pipe.

It should be remembered that such equipment may have different prices. The manufacturing plant and the characteristics of a particular model are of decisive importance here. According to experts, it is best to purchase a model that will provide standard feature set... And here it is completely superfluous to buy expensive equipment with a significant power reserve. The best option is a pump with a lower power, providing the possibility of optimizing the operation. Typically, these pumps are connected in front of pipe connections and next to household appliances.

Surface and submersible pumps: which one to choose

When choosing the type of equipment, not only the depth of the well is taken into account, but also the type of the bottom, the productivity of the source. Not every consumer can afford to buy expensive submersible equipment. In this case, you should pay attention to inexpensive surface pumps for water wells.

Surface pumps

These models are rarely installed without other elements of the water production system. The best borehole pumps are considered products of the brands "Dzhileks", Karcher, Gardena, Speroni. All devices have approximately the same performance indicators. Some models are equipped with ejectors that increase the height of the water rise.

Submersible pumps

The best in this category are the devices of the Danish brand Grundfos. Among the Russian brands are "Aquarius", "Whirlwind", "Dzhileks", Belamos. Most submersible models have a centrifugal mechanism of operation. When extracting clean liquid, it is allowed to use inexpensive Pedrollo Davis vortex devices.