Why do you need to make a vapor barrier when insulating with mineral wool

Mineral wool insulation is an effective type of thermal insulation that contributes to high heat saving at home, but has one significant drawback: when wet, mineral wool almost completely loses its insulating ability, freezes and gradually collapses. At the same time, moisture accumulating in the thickness of the heat insulator penetrates into the decorative finish of the interior of the house, deforms it and contributes to the formation of fungus, mold, and rot. To prevent such negative consequences, vapor barrier membranes are laid in the "cake" of floors, roofs and walls of the house - films that shield moisture, but allow air to pass through.

Do I need a membrane over mineral wool

When the walls are insulated according to the "ventilated facade" system, the insulation is constantly washed with a stream of air. Therefore, the most important characteristic of the applied insulation is its breathability. You need to know how freely the air can move inside the insulation itself. This means that the thermal insulation characteristics of the layer should be reduced, or even “its disappearance” may be created. Depending on the breathability of the mineral wool, it may be necessary to use windproof membranes.

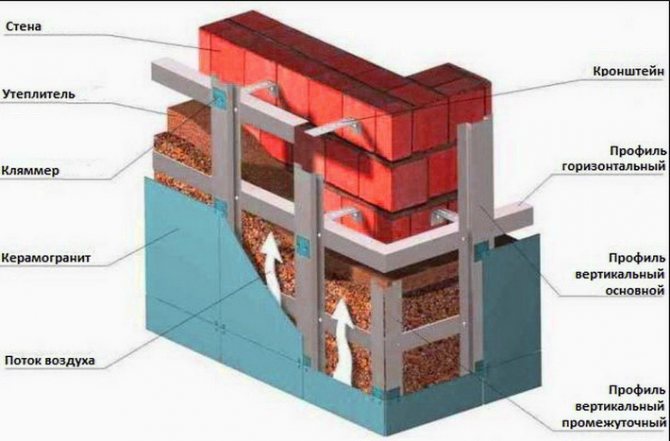

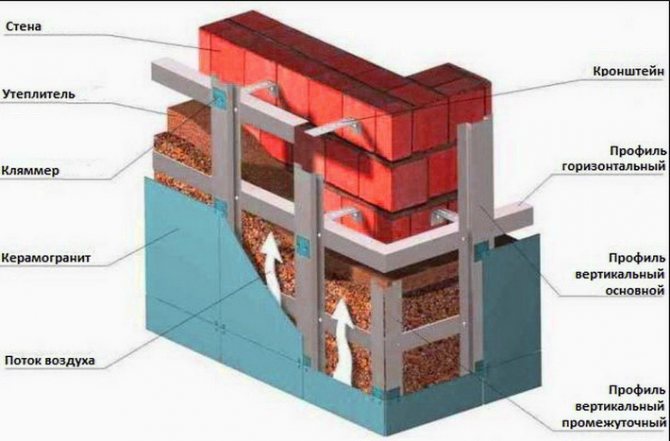

In a ventilated facade

When insulating according to the "ventilated facade" system, the insulation is pressed against the wall with the help of anchors, slats hung on the wall, etc. A ventilation gap is left between the insulation and the external finish.

If the system is assembled correctly, then under the influence of heat passing through the heat insulator, as well as due to wind pressure, a natural stable air draft from the bottom up occurs in the ventilation gap.

In a curtain wall system with a ventilation gap, air is constantly exposed to the insulation, moving along the ventilation gap. But the air moves from bottom to top and through the insulation layer, i.e. directly on the insulation. And the more air permeability of this material, the more air will pass through it.

The heat escapes with the air

This movement of air through the insulation is, in fact, a direct leakage of heat from the building, reducing the effect of insulation. This, the so-called convection heat transfer by air, is a phenomenon that reduces the resistance to heat transfer of the enclosing structure through the "ventilated facade" system by 20% or more.

If during installation the tight contact of the insulation with the wall was not ensured, then the convection heat loss increases significantly, and the effect of the insulation decreases by 40 - 60%. This is a very serious problem when insulating buildings using this technology.

Air speed and wind zones

Also, losses will increase with an increase in the speed of air movement along the ventilation gap. There is a significant increase in convection heat losses in the insulation layer in areas where there are frequent winds (6 - 7 wind zones) or for high-rise buildings (70 m from ground level) in any wind zone.

In which basalt wool heaters there are significant convection heat losses?

Density of mineral wool

For basalt fiber slabs with a density of 80 kg / m3 and more, this problem practically ceases to exist.Its manifestations can only be if the insulation is not completely pressed against the wall, then an increase in heat loss of up to 5% is possible, but due to the movement of air in the cracks between the insulation and the wall.

Now it can be argued that when using mineral wool boards with a density of 80 kg / m3 or more for insulation, convection heat losses will not be more than 2.5%.

Thus, the indicated density of basalt slabs is the boundary for trouble-free operation in a ventilated facade system. And such plates can be used without additional wind protection - without a superdiffusion membrane.

Whether to use a membrane

Sufficient resistance to air permeability can be achieved either by using a high-density heat insulator, or by increasing the resistance of the layer to air movement by installing an additional windproof membrane.

What is the best way to solve the problem?

To use a denser, and therefore more expensive insulation with a thicker layer, or to hang an additional element of the system, which, by the way, can become unusable and at least create fire problems?

It is believed that it is still better to use denser mineral wool, without an additional membrane, while, if required, in areas with significant wind load, install basalt fiber insulation with a density of 180 kg / m3.

The problem of reducing heat loss from air convection should be solved by using heaters with appropriate characteristics.

What is more expensive, more effective - a membrane or….

The insulation itself will, of course, be more expensive, but taking into account the absence of a membrane, the rise in price will not exceed 2% of the cost of the entire ventilated facade system. In this case, the reliability of the system is significantly increased.

It should be noted that two-layer insulation can also be used, in which a cheaper and warmer layer is covered with a wind-resistant dense layer. But this option requires a higher culture of construction, the absence of gaps between the slabs during installation, which is difficult to ensure in practice.

At the same time, the use of single-layer insulation is more technologically advanced, and the rise in the cost of the entire system at the level of 2% should not affect the feasibility of just such a "ventilated facade" insulation technology.

To date, there are no construction standards and rules that would determine when it is possible to do without a windproof membrane in a ventilated facade system, and when not.

The above recommendations are based only on scientific research carried out recently in the field of construction and insulation technologies.

Vapor barrier for insulation with mineral wool inside the house

The warm air circulating in the interior of the house is saturated with humid vapors that people, animals, plants, and household appliances evaporate. Warm air masses tend upward and accumulate under the ceiling of the premises, therefore it is extremely important to combine mineral wool with a vapor barrier when insulating the ceilings of Manasard and rooms adjacent to the unheated attic.

A certain amount of warm air seeps outside the house through walls and floors - in order to avoid swelling of floor coverings and destruction of wall cladding, vapor barrier films are placed between the mineral wool layer and the finishing layer.

We answer the question why a ventilation gap is needed

The gap is necessary for air convection, which is able to dry out excess moisture, and have a positive effect on the safety of building materials. The very idea of this procedure is based on the laws of physics. Ever since school, we know that warm air always rises up, and cold air goes down. Consequently, it is always in a circulating state, which prevents the liquid from settling on surfaces.In the upper part, for example, of the siding sheathing, perforation is always made through which the steam comes out and does not stagnate. Everything is very simple!

The use of mineral wool in the process of building a house is most often associated with the implementation of a number of measures designed to protect the insulation from getting wet.

Sometimes this is completely justified and necessary, and sometimes it will be an unnecessary transfer of funds.

In each specific case, depending on the expected operating conditions and the type of structures to be insulated, it is necessary to clearly determine whether a vapor barrier is needed when insulating with mineral wool?

Melts of rocks (basalts, dolomites) are used as raw materials for production. Industrial slags are sometimes added. From the molten mass, fibers are formed, which are then pressed into plates or rolls.

The strength of the final products is determined by the compression ratio during pressing and binders, which are phenol-formaldehyde or urea resins.

The more force is applied during the forming step and the higher the concentration of binders, the more dense and rigid the material will be.

Density, depending on the form of release, can fluctuate in a very significant range:

- Rolls - 20-50 kg / m3;

- Mats - 50-80 kg / m3;

- Lightweight slabs - 80-120 kg / m3;

- Plates of medium hardness - 120-200 kg / m3;

- Rigid slabs - over 200 kg / m3.

Vapor barrier when insulating with mineral wool outside the house

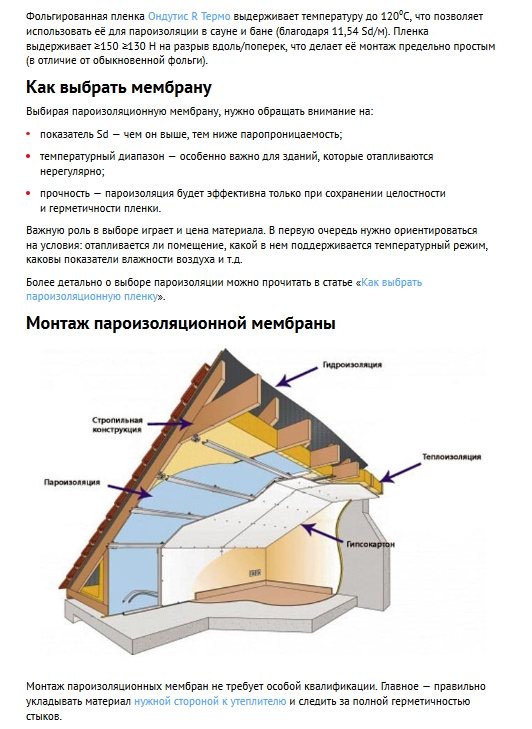

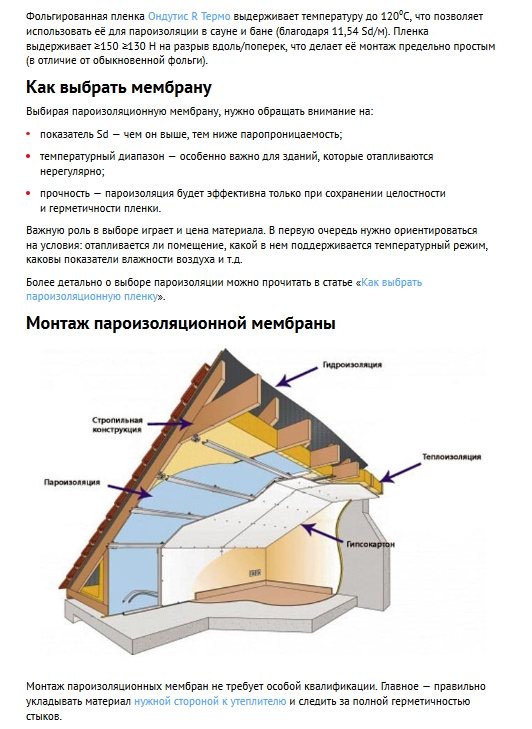

It is recommended to lay hydro-, wind- and vapor-insulating films when insulating the outer walls of brick, frame and log houses when arranging ventilated facades. Multifunctional protective membranes are mounted under siding, clapboard, blockhouse and other facade cladding - the film reliably shields moisture and condensation, but allows air to pass through and allows the walls to "breathe".

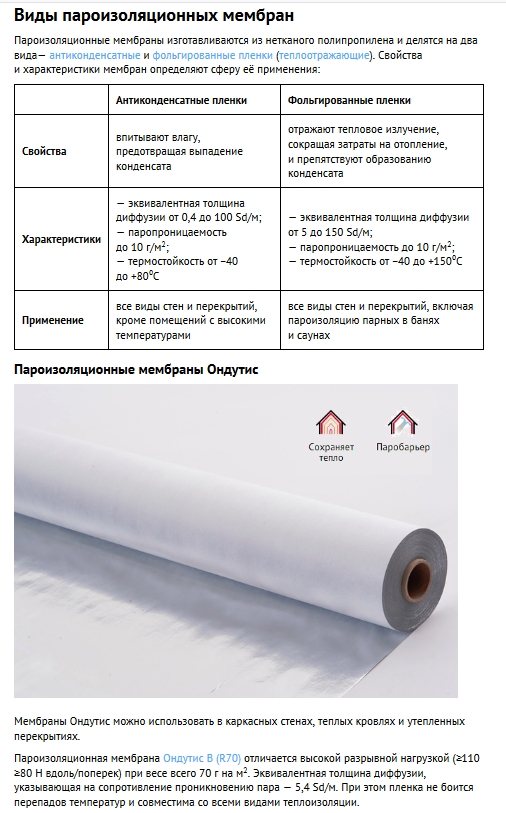

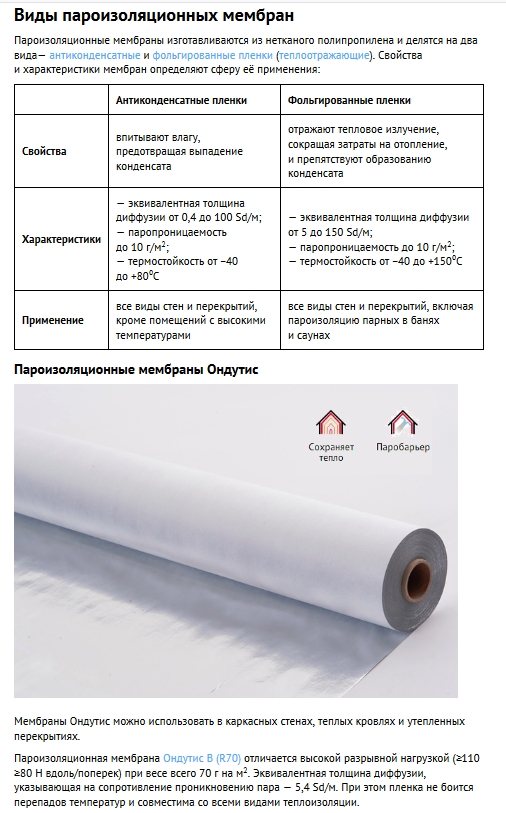

Modern types of vapor barrier films are superdiffuse and anti-condensation membranes, vapor barriers with a metallized layer - such innovative materials are produced under the Ondutis brand.

When you need a ventilation gap (ventilation gap) in a frame house

So, if you are thinking about whether you need a ventilation gap in the facade of your red house, pay attention to the following list:

- When wet If the insulation material loses its own properties when wet, then the gap is necessary, otherwise all work, for example, on the insulation of the home will be completely in vain

- Passing steam The material from which the walls of your house are made allows steam to pass into the outer layer. Here, without the organization of free space between the surface of the walls and insulation is simply necessary.

- Preventing excess moisture One of the most common questions is: Is there a need for a ventilation gap between the vapor barrier? In the case when the finish is a vapor-insulating or moisture-condensing material, then it must be constantly ventilated so that excess water is not retained in its structure.

As for the last point, the list of similar models includes the following types of cladding: vinyl and metal siding, profiled sheet. If they are tightly sewn onto a flat wall, then the remnants of the accumulating water will have nowhere to go. As a result, materials quickly lose their properties, and also begin to deteriorate externally.

Do I need a ventilation gap between siding and OSB (OSB)

Answering the question of whether a ventilation gap between siding and OSB is needed (from English - OSB), it is also necessary to mention its need. As already mentioned, siding is a product that insulates steam, and the OSB board consists of wood chips, which easily accumulates moisture residues, and can quickly deteriorate under its influence.

Additional reasons to use a ventilation gap

Let's look at a few more mandatory points when the clearance is a necessary aspect:

- Preventing the formation of rot and cracks The wall material under the decorative layer is prone to deformation and deterioration under the influence of moisture. To prevent rot and cracks from forming, it is enough to ventilate the surface, and everything will be in order.

- Preventing the formation of condensation The material of the decorative layer can contribute to the formation of condensation. This excess water must be removed immediately.

For example, if the walls of your house are made of wood, then the increased level of moisture will negatively affect the condition of the material. The wood swells, begins to rot, and microorganisms and bacteria can easily settle inside it. Of course, a small amount of moisture will collect inside, but not on the wall, but on a special metal layer, from which the liquid begins to evaporate and be carried away with the wind.

Features of mounting a windproof membrane

If the building has mineral wool insulation, the windproof membrane is attached from the outside directly to the insulation. If there is insulation only indoors, the material is mounted from the inside.

Membranes have a front and a back, which is very difficult to distinguish. Nowadays, many manufacturers have solved the problem by labeling the sides.

When using a conventional membrane, it is necessary to leave a gap for ventilation, and when installing diffusion materials, there is no need to.

When installing roll membranes, you will have to overlap the canvases. Manufacturers usually indicate the required distance, an average of 10-20 centimeters.

Protection of basalt insulation after installation

And, of course, immediately after the installation of a section of basalt insulation on the wall, this section is closed. This protects the already installed cotton wool on the walls from slanting rain.

The membrane itself does not tolerate ultraviolet light very well, so you must not hesitate with the subsequent decorative coating - siding or whatever you have chosen.

If you are not doing a ventilation facade, but, then you shouldn't worry too much here. The plaster layer will calmly cover the cotton wool, it will still get a little wet during the installation process.

- The question is asked by Andrey Sukhorukov, Perm: Hello, dear colleagues! Would you like to clarify how you can protect vinyl siding from the sun and frost? I look at the neighbors ...

- Do you personally think that the rising prices for electricity and gas make you think about saving energy resources? Try to answer this question honestly. If yes, then this material ...

Mansard roof insulation offers three benefits in one solution. Firstly, it becomes noticeably warmer in the house. Secondly, heating costs are reduced by 30-50%. Well, and third: a residential floor appears. We trimmed the walls - and instead of a cluttered attic we got cozy rooms under the roof.

Popular roofing insulation is mineral wool. Excellent performance material, non-flammable and affordable.

Thin-layer sound insulation: features

You can often find the statement that the thicker the sound insulation layer, the better the sound insulation properties. You can stumble upon recommendations for the use of board material with a thickness of 50 - 100 mm. It is difficult to argue with such a thesis, but what about the residents of city apartments, where the area of the room does not boggle the imagination anyway.

Laying the soundproof membrane on the floor

In old buildings with dilapidated ceilings, the construction of a floor with a thickness of 100 mm will create a serious load. Under these conditions, soundproof membranes have become widespread, which are made on the basis of synthetic binders and mineral components. This type of noise isolator has its own characteristics and advantages.

- Thickness - the main feature of soundproof membranes is their thickness.The use of the material allows you to reduce the noise level in the room with minimal loss of the usable volume of the room. At the same time, a 4-6 cm thick membrane layer makes it possible to double the sound insulation of the room, which corresponds to a 30 cm thick concrete wall.

- Density - the products have a dense structure, due to which the noise is extinguished not only as a result of sound absorption, but also as a result of sound insulation. The membrane has a sound insulation index of 25 - 35 dB.

Sound insulators reflect sound waves, they are heavy and dense, so their molecules simply do not vibrate with the sound wave. Sound absorption is a gradual decay of the intensity of noise, which is achieved due to the fibrous or porous structure of the material. A classic example of a sound insulating material is a concrete wall, and a sound absorbing material is mineral wool.

- Versatility - soundproof membranes can be used for different surfaces: walls, ceilings, partitions, floors, pipes, etc. Different mounting methods are allowed: frame and frameless.

Membranes are supplied in rolls, so they are easy to store and transport

The frameless installation method is simpler, since it does not require lathing. Frame installation requires the construction of a structure from metal profiles. The frame installation method allows you to level and insulate the wall surface.

- Combination with other materials - Membranes can be used with other types of soundproofing materials. For example, a combination with mineral wool can improve sound insulation.

- Elasticity - synthetic binders provide high flexibility of the material, even at low temperatures soundproof membranes do not become brittle. Elasticity allows them to be used for coatings of complex shapes.

- Temperature resistance - the sound insulator retains its characteristics over a wide temperature range. The material can be used in rooms with high humidity.

- Environmental friendliness - the material does not contain harmful impurities and does not emit substances into the air that negatively affect human health.

- Fire resistance - the indicators depend on the specific manufacturer, but some types of materials demonstrate high fire protection indicators, do not support combustion and fade out. According to the classes, individual developments are classified as low-flammable (G1), hardly flammable (B1), with moderate smoke emission (D2).

Soundproof membranes also have disadvantages, for example, they are not as effective in industrial premises with a large area.

Types of soundproof membranes

The market for soundproof membranes is rich in various product names, but it is difficult to single out any specific varieties among them. Manufacturers often assign brand names to their products. By and large, membranes differ in the method of installation and composition. According to the method of installation, there are products with and without a self-adhesive base. The first option is convenient from the point of view that there is no need to apply glue, but this is where the differences end.

By composition, materials are of the following types:

- Rubber membranes are made of synthetic rubber, have good elasticity if the air temperature does not drop below -20 degrees. The high density provides good sound insulation performance for this material. In most cases, the material is used for soundproofing walls.

The rubber membrane is elastic and has a high density

- Rubber membranes with mineral components - universal sound insulation suitable for ceilings, walls and even when constructing floating flooring.It is used with most coatings, such as drywall, gypsum fiber board, plywood, etc. Operation is allowed in a wide temperature range from -60 to +180 degrees.

- Diaphragms without synthetic rubber contain only mineral components. For example, such sound insulators include aragonite, a mineral rock that is part of chalk, marble and limestone. Avoiding the use of synthetic additives makes the material more environmentally friendly. Aragonite-based membranes are used in offices, private construction and industrial plants.

How additional floor insulation should function

So, when and why do you need to insulate an already existing floor insulation? The main purpose of additional insulation is to improve its performance, as well as to make sure that the available heat dissipates over the floor more evenly and for a long time. In all cases, when floor insulation works without additional thermal insulation, over time, the floor heating system does not start working at full strength and, as a result, breaks down in the future.

In order for the underfloor heating system to function correctly and serve for many years, it must be organized wisely. For the arrangement of warm floors, you can use only such insulation that has a low level of thermal conductivity. What problems can be solved by floor insulation?

Types of membrane for floor insulation:

Types of membrane for insulation

How to choose an insulating membrane

Special equipment is used for the installation of a warm floor.

Floor device

A properly laid floor in a wooden house is a multi-layer structure that provides reliable waterproofing, protection from cold and overheating, insects and fungi, as well as providing strength and durability to the entire house. Also, in the correct design, a ventilation gap is needed to ensure air circulation. Depending on the floor of a wooden house, the floor arrangement may be different.

The floor on which the room is located, the degree of humidity, as well as the purpose of the entire structure also dictate its requirements for the floors: the requirements for floors in the country, for example, are not as strict as for the coating in a private country wooden house. The attic floor is also different from the ground floor. The floor of the second floor is arranged differently from the floor of the first floor or attic. Most often, the floors are arranged in the form of a so-called cake, by analogy with the well-known puff pastry. One of the layers of the floor pie is the thermal insulation layer, along with wood flooring, screed and other types of insulation.

Types of wind protection

Glassine. Has a low resistance to weathering, short service life. A budget option.

Plates. The windscreen is made of coniferous wood. The surface layer is covered with paraffin. Good protection from side winds.

Polyethylene film. Protects structures from wind and moisture, but does not allow steam to pass through. Which leads to decay of the insulation.

Non-woven film. Serves as a barrier to precipitation. The surface has a slight roughness, which prevents the accumulation of condensation.

Super diffusion membrane

One of the best windproof materials to look out for.

Super diffusion membrane

Has a dense protective layer that provides resistance to mechanical damage. Complies with all technical characteristics: does not allow moisture to pass through, withstands frequent changes in temperature conditions.

The superdiffusion membrane is used for roofing, floor or wall coverings. The main functions of the product are to protect the insulation from water, steam and strong winds.

The main advantages of the material:

- long-term operation;

- ease of installation;

- strength;

- environmental friendliness.

The main advantage of the product is that it prevents the accumulation of water in a certain place.The material consists of several protective layers, which provides not only good vapor permeability, but also protects the insulation from adverse external conditions.

Therefore, when buying this product, no one should have any doubts about the correctness of the choice. In order for the product to justify the desired result, and to show its best qualities, it is necessary to carry out the installation responsibly.

Interesting: Terrace with a transparent roof - let's take a closer look