The floor in the country house has its own characteristics regarding the arrangement of coverage in an ordinary private house, not to mention an apartment. How to make the floor of a country house better, how to level the rough covering, how to change the old floor and much more, you can find out right now.

The floor in the country has its own characteristics regarding the coating device

The floor for a summer cottage, as well as in a summer unheated wooden house, a wooden house should be:

- durable, tough enough;

- easy to install, with the ability to quickly replace damaged areas (this is especially important for a shower stall);

- waterproof;

- resistant to abrasion and various loads on it;

- environmentally friendly;

- thermo - and sound insulating;

- aesthetic.

Consider how to properly lay a wooden flooring in a house, on the first and second floors; what floor to arrange in a summer house or a shower room at a summer cottage.

Lags

Lags are a support for laying floorboards

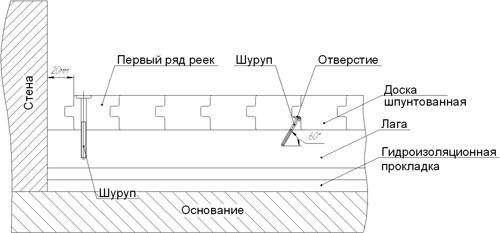

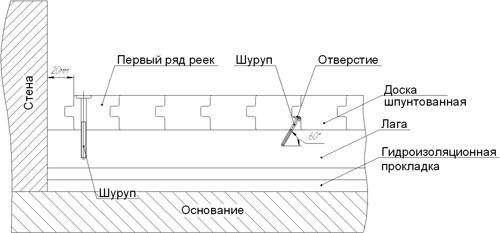

These requirements are met by timber floors mounted on logs. They are used as a support for laying floorboards (they can be placed directly on wooden beams).

Lags are usually made of timber. They are fixed with a certain step, which depends on the thickness of the boards to be laid. The logs can be laid on wooden beams, a concrete base or sunk into the ground. This design allows for quick replacement of boards that have rotted. This is especially important in a shower building.

Single plank floor

In light summer houses and in outbuildings (shower room, shed, etc.) simple single plank decks are made. In light summer houses and in outbuildings (shower room, shed, etc.), simple single plank decks are made. In case, the flooring is a single layer of planks, which is laid on the joists or directly on the beams. Boards are laid without gaps. An exception is the flooring in the shower room. You can even make such a floor from used wooden pallets (the material of such pallets has sufficient strength).

To protect the floor from decay and mold, they use antiseptics, varnishes, enamels. Consider the existing types of such single floors.

Floor arrangement schemes on the ground in a house, basement, garage or bathhouse

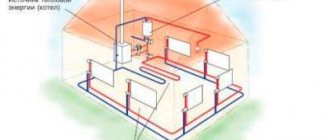

In houses without basements, the floor of the first floor can be made according to two schemes:

- based on the ground - with a screed on the ground or on logs;

- with support on the walls - like a ceiling over a ventilated underground.

Which of the two options would be better and easier?

In houses without a basement, ground flooring is a popular solution for all rooms on the ground floor. Ground floors are cheap, simple and lightweight; it is also beneficial to arrange in a basement, garage, bathhouse and other utility rooms. Simple design, use of modern materials, placement of a heating circuit in the floor (warm floor) make such floors comfortable and attractive in cost.

In winter, the backfill under the floor always has a positive temperature. For this reason, the soil at the base of the foundation freezes less - the risk of frost heaving of the soil is reduced. In addition, the thickness of the floor insulation on the ground may be less than that of the floor above the ventilated underground.

It is better to refuse from the floor on the ground if it is required to backfill with soil to a too high height, more than 0.6-1 m. The cost of backfilling and compaction of the soil in this case may be too large.

The floor on the ground is not suitable for buildings on a pile or columnar foundation with a grillage, which is located above the ground.

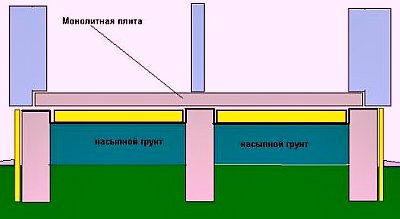

In the first variant, the concrete monolithic reinforced floor slab rests on the load-bearing walls, Fig. 1.

|

| Fig. 1. Monolithic overlap on the ground (suspended floor) |

After the concrete has hardened, the entire load is transferred to the walls. In this version, a monolithic reinforced concrete floor slab plays the role of a floor slab and must be calculated for the standard load of the floors, have the appropriate strength and reinforcement.

The soil is actually used here only as a temporary formwork when constructing a reinforced concrete floor slab. Such a floor is often referred to as a "suspended floor on the ground".

A suspended floor on the ground has to be done if there is a high risk of soil shrinkage under the floor. For example, when building a house on peat bogs or when the height of the filled soil is more than 600 mm. The thicker the backfill layer, the higher the risk over time of significant subsidence of the filled soil.

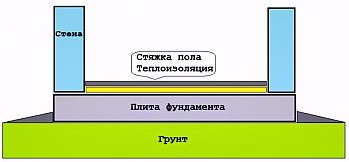

The second option is a floor on a foundation - a slab, when a reinforced concrete monolithic slab, poured onto the ground over the entire area of the building, serves as a support for the walls and a base for the floor, Fig. 2.

|

| Fig. 2. Floor on a slab foundation |

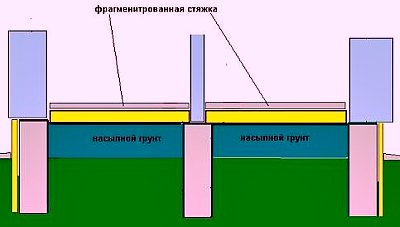

The third option provides for the installation of a monolithic concrete slab or the laying of wooden logs in the intervals between the load-bearing walls supported on bulk soil.

|

| Fig. 3. Ground floors |

Here, the slab or floor joists are not connected to the walls. The floor load is fully transferred to the fill soil, Fig. 3.

It is the last option that is correctly called the floor on the ground, which will be our story.

Ground floors should provide:

- thermal insulation of premises from the conditions of energy saving;

- comfortable hygienic conditions for people;

- protection against the penetration of soil moisture and gases into the premises - radioactive radon;

- prevent the accumulation of condensate water vapor inside the floor structure;

- reduce the transmission of impact noise to adjacent rooms along the building structure.

Cold plank floor on the ground

This is the simplest type of flooring in the country.

This is the simplest type of flooring in the country. In this case, the logs are sunk into the layer of calcined sand flush with the upper level of the layer.

Materials for arranging the floor on the balcony and loggia

Alternatively, they are embedded in a layer of compacted clay and slag. This better protects the wood from moisture. Such a layer is laid on a sand cushion. Its thickness should be 2.5-3 times the thickness of the used logs. The distance between them should be no more than 60 cm.

Another way of arranging this type of floor: from wooden dies coated with bitumen. The base for them is made of compacted sand, clay or concrete. The checkers are installed close to each other, and at the final stage of the flooring, they are all connected to each other. Such flooring should not be done in a shower stall.

Floor structural elements

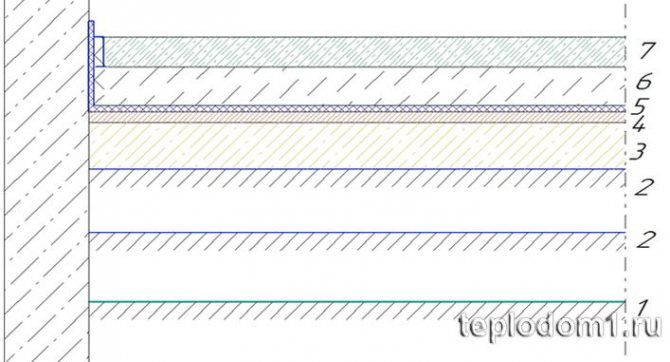

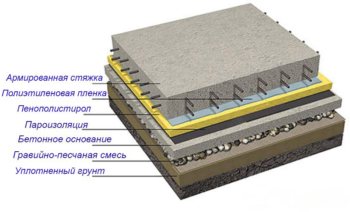

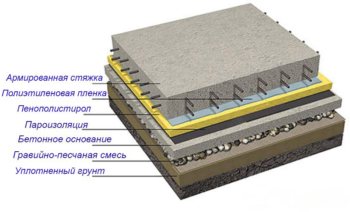

If the flooring is arranged on the ground, then its cake should look like this:

- The ground must be planned, leveled and compacted.

- Next, an underlying layer of crushed stone, slag, gravel is arranged, sand (10 cm thick) can be laid. The layer is leveled and compacted with rollers.

- The waterproofing layer prevents water from reaching the structural elements. It protects the structure of the above deck from rising groundwater levels. It can be two layers of roofing material, all kinds of waterproofing films, membranes.

- If the base is insulated, then the next layer is heat insulating. If this is a summer residence only for summer vacations, then you can do without it. Thermal insulation, as a rule, is made of expanded clay, slag with a thickness of approximately 150 mm.

- Concrete preparation device of grade 100 - 150, thickness 100mm.

- Leveling screed made of 100-150 grade mortar, 25-30mm thick.

When arranging the base on the floor slabs, the cake will be slightly different. As a rule, this is the attic floor:

- The soundproofing layer is not always performed, since this is a summer residence and there are no neighbors above. But if you decide to arrange a bedroom for relaxation there, then, if you wish, you can also make a sound-insulating layer.

- Leveling layer made of cement, polymer-cement or other compounds with a thickness of 20 -25 mm.

We took a tour of the basic elements of preparing a subfloor. According to the project, some of the structural elements can be added or absent - everything is individual.

The base is ready, we proceed to the choice of the finishing floor covering.

Insulated single plank floor on the ground

In contrast to the cold floor, warming layers are arranged here under the sand cushion.

In contrast to the cold floor, warming layers are arranged here under the sand cushion. For this, after removing the fertile layer, the site under the future building is rammed. Then the first thermal insulation layer is laid. The material for it can be the packing bags left over from the cement mixture. They need to be laid in 2 layers and covered with a layer of crushed stone 8-10 cm thick. Crushed stone is rammed and poured with milk of lime.

Then the remaining layers are laid: roofing material, fiberboard and expanded clay (thickness 8-10 cm). They are poured with "lean" concrete (with a high content of filler (gravel and crushed stone)).

Cold single floor with subfloor.

The logs or beams of this floor covering are installed on the support poles made of bricks or blocks of foam concrete.

The logs or beams of this flooring are installed on the support posts made of bricks or foam concrete blocks. You need to do this kind of floor if the beams are not built into the frame of the house. This type of floor is also called "floating".

The poles are mounted on foundations, various fillings or compacted soil. The section of the posts depends on their height. Such supports can be made along the entire floor grid or only along the perimeter of the building.

On top of them, you need to lay layers of waterproofing (roofing material or its modern replacements) and 2-5 mm wedge gaskets. Then lags or beams are fixed on them. To prevent wood floors from decaying quickly, they must be treated with an antiseptic, varnishes must be used to cover the surface.

Tip: It is better to use a two-component, water-based polyurethane varnish. These varnishes are expensive, but the flooring will be durable. It requires less maintenance. Acrylic and epoxy varnishes are very popular.

Floating floors are not recommended for light summer houses. Due to the lack of heating, in winter, due to freezing of the soil, there is an uneven "walking" of the pillars, and, therefore, the floor covering. To prevent this, the bottom of the underground is insulated with a layer of expanded clay, crushed stone or gravel.

Arrangement of the floor in the country or in a private house

Then, floor boards are fastened to the beams, or logs laid on them, with the help of nails. Tip: Drive nails into floorboards correctly at an angle of 45 degrees to their surface.

How to install floors in a cold house in winter

Question:

Hello Semyonitch! Tell me, is it possible to lay a floor from a floor slat in an unheated room in winter?

Vladimir, Tomsk.

Answer:

Hello Vladimir from Tomsk!

Not quite familiar with the term sex slats. All these names such as tongue and groove, floor slat, tongue-and-groove board in construction are better known simply by the name floor board.

A floorboard is a board of various sections with 4-sided processing. The upper surface is smooth, the lower one with a pair of projections. And the sides - one with a spike, the other with a groove.

It is always more comfortable to lay floors in warm weather, but you have to do it in cold seasons as well.

And here everything depends more on the quality of the board itself than on the ambient temperature.

If the board is dry, then everything is fine. If it has a moisture content of more than the standards, then after you lay it, even with careful tamping with wedges, then after the onset of a warm time or good heating of the premises of the house with heating devices or stoves, the possibility of cracks formation is extremely high.

In the old days, the owners usually did the following when installing floors.

They laid the boards, nailed them from above, but did not finish off the heads of the nails all the way, but left them above the floor surface to such a height that they could then be picked up with a nail puller and pulled out.

After that, the floor boards were left in this position for two to three years. During this time, the floorboard has dried to condition. Then we looked at what the floor looked like. If cracks appear, then the original floor board was not dry enough. The nails were taken out, and the floors were covered again, but now they were hammering in the nails all the way, pushing their caps down. If the gaps did not appear, then they simply nailed the boards, finishing the nails all the way.

So look at the place. If the board is dry, then even in an unheated room it can be nailed (or screwed in) completely. If the board is wet, then it is better to do as our predecessors did. And finally fix the boards after a while.

But in any case, try to use the wedges as much as possible to keep the boards together. It doesn't hurt anyway.

Everything. Good luck!

Construction in Moscow and Moscow region

We work with a guarantee! A wide range of construction services. Foundation, walls, ceilings, roof, turnkey!

+7 (905) 797-20-34

luxurykomfort.ru

Other questions on the topic of floors:

- Lags thickness - table of sections of wooden logs

- The cost of replacing the floors in the bath - Estimate

- The beams of the floor of the country house sagged

- Thermal insulation of interfloor floors made of wood

- What film is needed for a floor cake on the ground

- To increase the ceilings in the extension to the house made of sleepers

- Pillar under the floor beams of the attic floor

- Wooden floors in the garage

- Open beam ceiling

- Leveling floors in a log house

- Insulation of the attic floor

- Replacing the kitchen floor with an old wooden floor

- Interfloor overlap in a log house

- Extension to a panel one-story house

- How to fill up the underground

- Why apartments have always had wooden floors

- Thermal insulation of wooden interfloor floors

- Coating with bituminous mastic of a concrete floor in a bath

- Reinforcement of ceiling lags for the attic floor

- Floor beams for the ceiling in the garage 7 by 7 m

- Workers to replace the floor in the country

- Harmful substances from furniture

- Sagging of the slab between the first and second floors

- Replacement of joists and floors under a partition with a door

- Overlapping a house from an aerated block with a channel

- Support for the log and shrinkage of the log house

- Make a floor hatch to access the subfloor

- Finishing the old concrete floor on the balcony

- Replacing rotten ceiling beams

- Floor screed device

- Insulation of old floors on the balcony without removing

- Floor cake on the ground

- Replacement of support pillars for lag

- Overlap between the steam room and the residential floor

- Waterproofing the floor in a wooden house on the ground

- Fighting mice in insulated wood floors

- Ceiling uterus in the garage

- House with mezzanine under the wards for children

- How to insulate wooden floors in a gas block house

- Replacing a rotten floor in a Finnish house

- Calculation of floor beams

- New floor on top of old wood

- How to insulate floors in a bath

- Round log floors

- Concrete floors in a log house

- Floors without insulation in a black bath

- The price of replacing a wooden floor in a brick house

- Replacing the ceiling with an increase in its height

- Sagging unsupported beam alignment

- How to fix sagging wood floor

- Warm water floors in a log house

- Pie floor in the bathroom of a log house

- Replacement of wooden floors in a house of 1906

- Wooden floors in the house from SIP panels

- The floor sinks in the frame on piles

- Strengthening the wood floor

- Leveling the deflection of wooden floors

- Bloated wood floors

- How to change beams built into walls from a block

- Sheathing of the ceiling of an adobe house with euro clapboard

- Change of sex in a cinder house

- Floor on the ground in an old wooden house

- Tiled floors in a wooden bath

- Thermal insulation of a wooden floor

- Plywood floors on logs

- How to level a subfloor under a laminate

- How to reinforce a trimmed timber joist

- Coating the log floor with a bituminous primer

- How to restore old beams

- Porcelain stoneware on wood floors

- Replacement of logs and subfloors in a house from a bar

- Sagging ceiling beam

- Repair of sagging floors in a wooden house

- Lower the floor in an old log house

- Laminate flooring in an old village house

- Compatibility of polystyrene foam and wood in construction

- Bulkhead flooring in a brick house due to squeak

- Logs from a bar 150 by 4 meters of span

- How to level a sagging ceiling in a house

- Replacing rotten floor logs in a log house

- Replacement of floors on the ground in the bath

- Waterproofing the subfloor of the house

- Beamed ceiling

- Blackened ceiling in the bath

- 12mm plywood flooring in two layers

- New floors to old

- Aligning beams in a house from a bar

- Strengthening the interfloor timber floor

- Hardwood ceiling-to-floor pie

- How to raise a lag without opening the floor

- Option for arranging the floor in a log house from OCB

- Is it possible to replace the beams

- Interfloor wooden floors

- How to cut a block diagonally with a circular saw

- Glassine in the house slab pie

- The floors are dry - what to do?

- Repair of the ceiling of an old wooden house

- How and what to paint OSB

- Fastening the lag to the foundation

- Floor waterproofing on the ground

- Floating floor on the ground

- Floor pie over floor beams

- Strengthening the ceiling lag

- New overlap without touching the old one

- Floor insulation in a village house

- How to strengthen the floor joists 150x50 span 6 meters

- Arrangement of floors in the annex to the house

- Wooden floors on the ground

- Cement screed to the ground

- Cold floors in the house

- Can logs be installed after assembling a log house

- Section and spacing of beams for a span of 5 meters

- Overlap the floors in the cinder building

- Fastening of sex lags in a log house

- Attic floor in an old cinder block house

- Channel or I-beam for floor beams

- The smell of floor polish - how to get rid of

- Floor on rotten crowns

- Gouged out the floors in the country house

- How to decorate a wooden ceiling over a gas stove

- Replacing a rotten floor - the cost of work and material

- Floating wooden floor in the country

- Metal I-beam as a ceiling beam

- Fc plywood floors on an open terrace

- What is the best way to lay wood floors on a concrete slab

- Film faced plywood for sub-floor

- Rotted floors what to do

- How to change a subfloor without analyzing the final one

- Ventilation of the floor in a log house on a slab

- The mushroom is eating our home

- Installation of logs to the walls of the log house

- Country house made of blocks and wood

- Beam 8 meters what is the section

- Replacing the subfloor and floor in a log house

- Insulation with polyurethane foam of a floor in a log house on piles

- The thickness of the lag for the ceiling

- The floor rots and molds

- Subfloor made of cement-bonded particle board and insulation

- Plakhi for attic overlap 5 m

- Replacing a beam under a brick wall

- Reconstruction of an old floor in an old house

- Open beam ceiling

- What to support the floor beams

- Sandwich panel floors

- Log floor beams

- How to remove part of the floor beam

- Insulation of the floor from the subfloor

- Cold floors in a warm brick house

- Floor arrangement in an old brick house

- Insulation of the floor of the 1st floor in a log house

- Soundproofing the floor of the 2nd floor in a wooden house

- I-beam joist

- Insulation of the floor in the house on stilts

- The choice of the section of the log with a span of 5 m

- Repair of the ceiling of an old house

- Laminate flooring on the second floor in a log house

- Floor insulation in an old wooden house

- The worm wears away the wooden floors

- Overlapping in a wooden house

- Distance from ground to floor

- Protection of the log floor from moisture

- Wood floor to laminate

- Reinforcement of wooden floors

- How to install floors in a cold house in winter

- How to replace a rotten floor

- Floor insulation

- How to strengthen floor joists

- Second floor floor beams

- Floor insulation with foam

- Laying the floorboard

- Channel bars as interfloor overlap

- Interfloor overlap in a silicate brick house

- Chicken coop floor

- How to strengthen the overlap of a garage basement

- Support beam 6 meters

- Moldy subfloor

- Raise floors over the old floor

- Mastic for covering subfloors and logs

- How to lay plywood on floor logs

- Squeaky floors in the apartment

- Bath floors and drainage

- The logs and the rough floor of the country house have rotted

- Lags of 9 meters

- How to block the first floor of a log house of 8 meters

- Rotting sub floor

- What ceiling logs to choose

- How to put ceiling beams in a bath

- Transfer of beams in a log house in height

- Strengthening old timber beams

- Overlapping the first floor of a house without a basement

- Thermal insulation of wooden floors with moss

- About lumber for floor and roof

- Strengthening or replacing the ceiling lath

- Ground floors

- Tiles on the floor in the bath

- Laminate floor in the country

- Subfloor and roofing material

- Replacing the Support Structural Beam

- Finishing floor on an old floor with insulation

- Tiled floor in a wooden house

- How to insulate the subfloor

- Laying parquet boards in the apartment

- What to put on the veranda floor boards

- Renovation of an old sub-floor

- Fixing the log floor

- Sub-floor repair

- Waterproofing a floor from a board

- Floor beams - reinforcement

- Plywood thickness on logs

- Squeaky wooden floors how to clean

- Strengthening the interfloor overlap

- Film faced plywood for repairing wooden floors

- Leveling floors when shrinking at home

- Thermal insulation of wooden floors

- Installation of floor slabs

- Fastening beams to a vertical concrete wall

- How to join three skirting boards in a corner

- Floor log supports

- Floor beams for a span of 7 m

- The device of the floor in the house from a bar

- How to make a floor in an extension from a foam block

- Which timber to choose for a beam floor

- Bath floor repair

- Second floor terrace floor

- Round timber floors

- How to strengthen hardwood floors

- How to change a decayed beam

- Replacing floor beams in an adobe house

- Support for strengthening the beam

- Ceiling logs

- Laminate concrete floor

- Maximum distance between floor beams

- The middle of a wooden house sank

- Repair of floors in an adobe house

- Heated floors in a wooden house

- Raise the floor in an old house above ground level

- Replacing sex lags in an old house

- Attic floor repair

- Floors - asbestos-cement pipes for poles under logs

- Fastening the lag to the slabs

- Strengthening the log in a log house of 7 meters

- Bath floor device

- Warming of floors using Izospan V film

- Floor ventilation below ground level

- The floors in a log house are rotting

- Floor insulation on a concrete screed under linoleum

- How to make garage floors

- Types of flooring for the home

- What thickness of the floor board should be 28, 36, 40 ...

- Fastening the floor log in a panel house

- Concrete floor in a wooden house

- Repair of the wooden floor on the balcony

- Installation of logs in a log house

- Concrete floor screed on top of a Sip floor

- Strengthening and warming the floor from wood blocks

- How to align floor joists

- Strengthening timber beams

- Whether to tie the concrete floor to the house

- Insulation of a regularly flooded floor

- Insulation of the floor of the house on sleepers

- How to fix floor joists on top of a round log

- Replacing rotten floors

- Glassine in the underground of a log house

- Film blows up over the subfloor

- Questions about the floors in the garage 2nd floor

- Arrangement of a rough floor in a rounded log house

- Monolithic floors on the ground

- The better to sheathe the walls and floor of the garden house

- How to level a concrete floor in a panel house

- How to level the floor in the kitchen

- Bath floor

- What to support the floor logs on

- How to strengthen interfloor logs in a brick house

- Economical floor slabs

- Insulation of concrete floor slabs

- What is better to put under linoleum

- Sub-floor repair

- Floor arrangement with gas silicate

- Replacing floors in a country house

- Moisture resistant slabs floors

- How to put linoleum on an old floor in an apartment

- Leveling floors in an old house

- Genital lag processing

- Choosing a floorboard in the house

- Heat and vapor insulation in the floor pie

- Raise sagging floors without dismantling

- Heat and sound insulation of a floor in a panel house

- The floor in the hallway of a private house is rotting

- Rotten floor in a wooden house

- How to change the floor under the fireplace

- Concrete floor in the garage

- How to wax a floorboard

- How to make a wooden garage floor

- Repair of the concrete floor on the balcony

- Replacing subfloors

- Moisture resistant laminate for wooden floors

- How to cheaply remodel the floor in an apartment

- Bath floors

- Arrangement of subfloors

- Sagging logs and floor

- How to change a rotten floor

- How to properly lay the floor on the loggia

- Wooden floor device in more detail

- Larch sub-floors for the 2nd floor

- Second floor subfloor

- How to hide air conditioner pipes in a tile floor

- Replacing a rotten floor

- Floor repair in a panel house

- Lay the floors on the attic loggia

- The new wood floor has started to rot

- Repair of a wooden floor in a country house

- How to insulate a wooden floor

- Again about floor insulation

- Larch floors on the loggia

- Foundation and floors of an adobe house

- Floor in a ready-made (transportable) bath

- How to arrange a floor on an open balcony

- Underfloor insulation

- Connecting the ends of the floor board

- Concrete floor in the garage

- How to level the subfloor

- How to put a new floor on an old one

- How to lay a subfloor

- How to raise floors in a house

- How beautiful to lay the floors

- Underground ventilation

- How to align log beams under flooring

- The subfloor beams began to rot

- Laying the floor with a board without a thorn

- Floors in a country house

- Floor on the balcony-loggia

- Floors - leveling log logs

- Asbestos cement pipes for lightening concrete floor

- Insulation of the underground space

- Preparing the base for the laminate when laying the floor

Construction in Moscow and Moscow region

We work with a guarantee!A wide range of construction services. Foundation, walls, ceilings, roof, turnkey!

+7 (905) 797-20-34

luxurykomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee!A wide range of construction services. Foundation, walls, ceilings, roof, turnkey!

+7 (905) 797-20-34

luxurykomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee!A wide range of construction services. Foundation, walls, ceilings, roof, turnkey!

+7 (905) 797-20-34

luxurykomfort.ru

Floors

All questions to Semyonich about construction

Semyonich (author of materials)

Our site is regularly updated with interesting and unique materials and articles on the topic of lumber, building materials and works, the author's opinion and knowledge of a real shabashnik with more than 15 years of experience is given. There is a section - funny stories of shabashniki. If you would like to receive information about this, subscribe to the newsletter of our website. It is guaranteed that your address will not be passed on to third parties.

Apartment renovation in Moscow and Moscow region

We work with a guarantee! A wide range of renovation works. Professional craftsmen.

+7 (905) 797-20-34

luxurykomfort.ru

| Country house | Bath |

| For giving | Tool |

| Materials (edit) | Bikes |

| Foundation | Log cabins |

| Roofs | Warming |

| Walls | Siding |

| Floors | Cellars |

| Attic | Window doors |

| Stairs | Outbuildings |

| Wells | Toilets |

| Balconies | Loggias |

| Condensate | Flooding |

| Fences | Kennels |

| Sidewalk | Birdhouse |

| Adobe | Carts |

| Garages | Barn |

| Greenhouses | Bath |

| Swing | Brazier |

| Shower |

| Horizontal bar |

Double plank floor with subfloor

It differs from single ones in that the lower, draft layer is attached to the bottom of the laid lags or beams, with the help of rails

It differs from single ones in that the lower, draft layer is attached to the bottom of the laid lags or beams, with the help of rails. Insulation plates and vapor barrier material are laid on the rough boards. As rough boards, boards with wane, rough boards, parts of wooden pallets, etc. can be used.

To prevent the floor boards from rotting, you need to make an air gap between the finishing layer of the boards and the insulation for ventilation. Sometimes a simplified, budgetary version of such a double floor is made - without laying insulation plates.

Laying options for floorboards

The methods of laying wooden flooring depend on the type of finishing base, which can be:

- cement-sand screed or concrete slabs;

- plywood;

- lags;

- old floor.

Figure 1. To give the structure reliability, adjacent bars are fastened together with transverse elements.

If the boards need to be laid on a concrete base, then it should be as flat as possible, because even the slightest defects will eventually lead to deformation of the lumber and an unpleasant creak. To level the floor, you can make a screed with a cement-sand mortar or a self-leveling mixture, which is poured with a thickness of about 30 mm.

To protect the wood from moisture, a waterproofing layer is mounted on top of the screed. It can be foamed polyethylene, plastic wrap or liquid mastic. Rolled waterproofing is rolled out over the entire base with small allowances on the walls. In this case, adjacent pieces should overlap. It is recommended to glue the joints with construction tape.

Instead of waterproofing, moisture-resistant plywood with a thickness of more than 18 mm is allowed. To simplify installation work, a sheet of plywood is cut into several pieces, after which they are attached to the floor using dowels or an adhesive mixture.

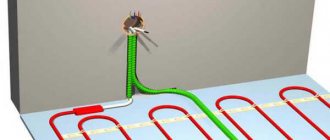

The methods of laying the floorboard can be different, but the most popular and convenient option is installation on a lag system. In this case, you do not need to achieve perfect evenness of the base, since the logs allow you to hide even significant irregularities in the floor. Another advantage of this method is the possibility of insulating the floor and laying electrical wiring inside it.

Figure 2. Diagram of laying boards with your own hands.

As a lag, wooden blocks with dimensions of 50x100 or 50x70 mm are used. The step of their installation is 40-70 cm. It all depends on the thickness of the board. The lag is fastened with screws or dowels. The horizontal evenness of their laying is controlled by the building level. To adjust the evenness of the base under the logs, wooden pads are mounted in the required places.

To give the structure rigidity, adjacent bars are fastened together with transverse elements (Fig. 1). To increase the thermal insulation properties of the floor, the space between the logs is filled with insulation, which is used as foam, mineral wool, expanded clay, etc.

It is possible to lay the floorboard not only on the concrete base, but also on the existing surface. The main condition for this installation method is the sufficient strength of the old finish. The process of preparing such a floor is no different from the methods described above.

Pallet floor

One of the cheapest flooring options for a small summer house or shower room

One of the most inexpensive options for flooring a small summer house or shower room is to use wooden pallet boards. Pallet boards are neatly, without damaging the wood, separated from the pallets, impregnated with an antiseptic and stacked on logs. Then they can be cleaned and used for ennobling varnishes, or they can be leveled with plywood and covered with linoleum.

Tip: you can only make the flooring from the boards of only those pallets. The origin and terms of use of which are known to you.

The floor covering on the second floor does not need insulation. This overlap is performed single. Floor boards are attached to floor beams, and from below (like the ceiling of the first floor) they are covered with plywood, fiberboard sheets or panels.