Providing a private house with water is one of the main components of a comfortable life outside the city. During construction, engineering networks are laid at the stage of laying the foundation. However, it is possible to improve a long-erected object during its overhaul. The source can be a central backbone system, into which, with the permission of the organization that maintains it, an insert is made. Also, the water supply can be carried out from a well or a well located on the site. In any case, it is necessary to lay engineering communications using modern materials and equipment.

What equipment is needed

To conduct a water supply system to a private house from an autonomous source, you need to stock up on the following equipment:

- pumping station;

- hydroaccumulator (a special container into which a sufficient supply of water is pumped);

- a water treatment system installed on a pipe through which water for domestic needs is supplied;

- storage water heater.

Equipment for providing hot and cold water supply to a private house is compactly located in the basement or any utility room of the facility

Stop valves must be installed in front of all types of equipment used in the system. This will allow you to disconnect devices from the system to repair or replace them without disrupting the water supply to the entire house.

What about insulation?

But extra protection is often required when laying outside.

For this, for example, special cases are used. The existing water supply is laid inside another pipe with a small diameter. Which contributes to the formation of an air cushion between the walls of different products. Thanks to this, the warmth of the water is preserved.

Or the pipeline is simply poured using polystyrene concrete or foam concrete. It is a monolithic layer with a base in the form of lightweight concrete with a porous structure.

Or with a heating cable. The latter is laid both inside and outside the structure. The gasket is recommended to be carried out in two available ways:

- Two lines parallel to each other.

- Spiral around the water supply.

Not every system is designed so that pressure rises in it without problems. But this method of protection is capable of boasting efficiency.

When there is high pressure inside, the liquid does not freeze. Even if there is no physical insulation.

When installing external free-flow varieties of sewerage, a so-called socket connection is used. The main thing is the absence of contamination on the plastic, then the joints will acquire high tightness. Parts that need to be connected are lubricated with silicone or liquid soap.

Sealant treatment will provide additional protection during work such as laying polypropylene pipes in the ground.

Only compliance with all requirements and technologies will allow you to get a water supply system that will function for a long time. And will help reduce operating costs.

We are installing filters

If there is no scale or sand in the water, then such elements as fittings for toilet cisterns, washing machines with automatic controls, and ceramic faucets live much longer.

It is enough to install the simplest filters, with coarse cleaning. Without water treatment filters, it is not advisable to lay polypropylene pipes with your own hands.

You should not give preference to filters that are disassembled manually.Inside such structures are rubber seals, whose durability leaves much to be desired.

The preparation process depends on which type of pipe you have chosen. If it is galvanized, then we use a grinder to cut blanks of the sizes we need with our own hands. You can also do this with a hacksaw.

It is more convenient to cut metal-plastic or polypropylene products immediately in place. Even small slips in size will not be scary.

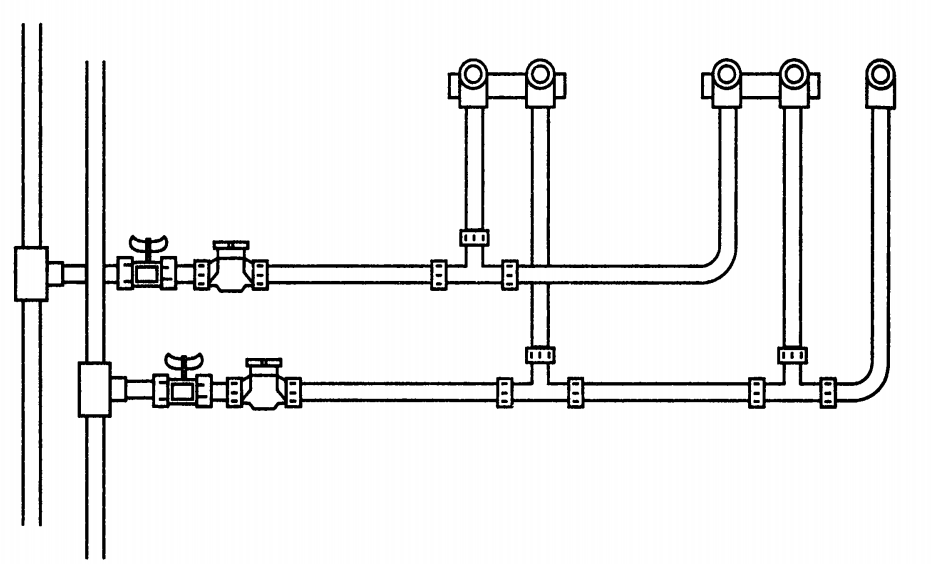

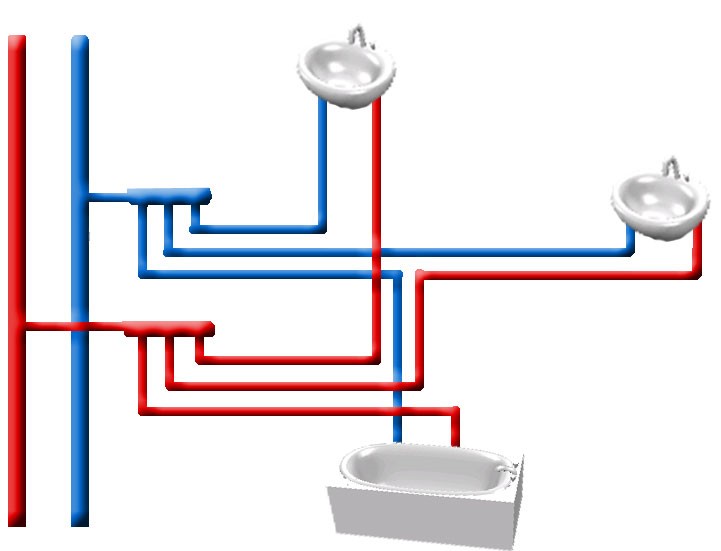

When connecting, two methods are preferred. For example, through the collector, which plays the role of wiring for individual devices, when each of them has its own fittings. Or through a simple tee.

We work with steel products

With the availability of appropriate tools at hand, such as welding, it is used to connect a metal structure.

Winter plumbing for a country house is the only way to ensure comfortable living all year round. To do this, in any case, it is necessary to lay water supply and sewerage on the street - external or yard. Despite the fact that the water supply system cannot be called a dangerous or complex engineering system, its installation also requires knowledge of certain rules and regulations. Only compliance with them guarantees a long service without gusts and freezing, as well as the purity of drinking water and the stability of the pressure declared in the project. But all of them do not require special equipment or technology, and it is quite possible to make such a pipeline on the site with your own hands.

How to make a plumbing in a private house with your own hands

Water supply can be organized using two types of pumps:

- surface models, not immersed in the water intake source, provide water rise from a depth of 8-9 meters, therefore they are used in wells;

- submersible models are placed directly in a borehole or well, while their power allows you to raise water to a height of more than 200 meters.

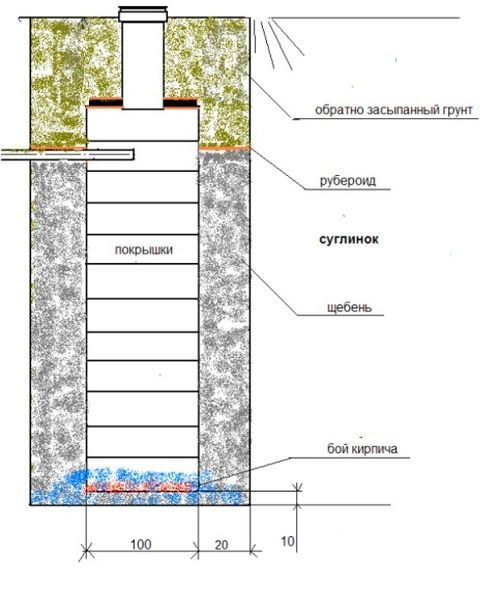

Conducting from the well

A trench is dug from an existing or newly built well to the house, the bottom of which should be below the freezing mark in the area. Further, a 32 mm pipe (copper, steel, polypropylene or metal-plastic) is laid at the bottom of the trench at a slight slope towards the source. The slope is necessary in order to prevent stagnation of water in the pipeline. The pipe is led into the basement through a hole in the foundation, which is insulated. Otherwise, in severe frosts, freezing may occur in this place.

The pipeline running from the well to the basement of a private house is laid in a trench dug taking into account the depth of soil freezing in a given area

From the well

It is also possible to provide water supply to the house from an autonomous source, which is usually a well or a well. It is recommended to use water from open reservoirs only for technical purposes; it is not suitable for drinking and cooking.

Video: how to provide yourself with clean water

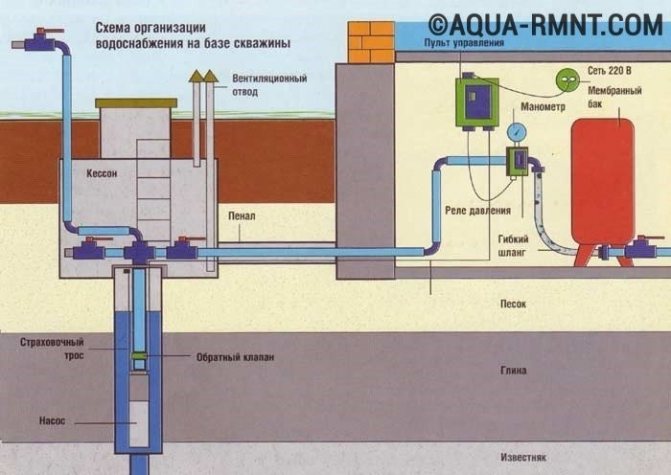

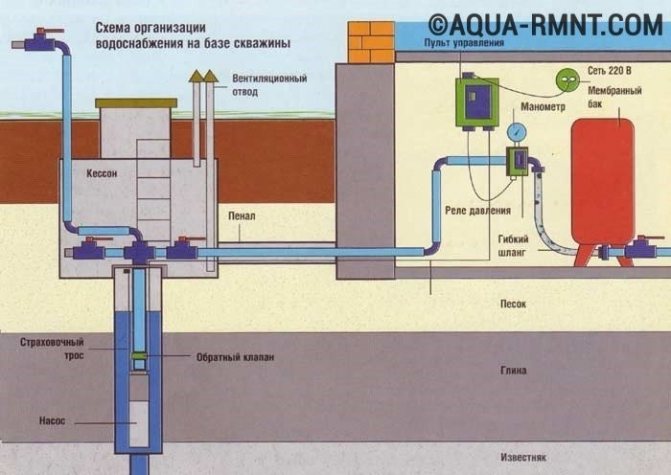

The laying of communications from the well, protected from freezing and the ingress of contaminated wastewater by a caisson (metal container), begins with assembling a bundle of cable, a safety cable and a water supply pipe glued with aluminum tape. Then a submersible pump is attached to them and lowered into the well. On the surface, the cord is wrapped with insulation, after which they begin to lay it on the bottom of a one and a half meter trench dug from the well to the house.

Important! The depth of the trench may be different, depending on the degree of freezing of the soil in the area.

Installation diagram of a private house water supply from a well drilled to the aquifer by a licensed company using a powerful rotary drilling rig

They bring a pipe and cable into the house, then they put:

- a tank that will allow you to turn on the pump as needed;

- control unit designed to protect the system from voltage surges in the network, as well as from overheating.

Central water supply system

The central sewerage and plumbing system has a lot of advantages. You do not need to spend money on the pumping station and the units themselves. There is also no need for a fluid storage tank. As for the purity of the supplied water and its pressure, then the organization that provides the water resource for the facilities will take care of these indicators. Also, an enterprise can be of a state type, in simple words - a housing office. In this case, the sewerage and water supply system may be unstable: additional bills for pipe repairs, the presence of rust, low pressure.

The photo shows a large-scale system that provides water to an entire microdistrict.

When choosing a centralized sewage system, you do not have to deal with digging trenches for pipes, creating a well, etc. You need to send an application to an organization that works in your sector. After obtaining permission, work begins: special equipment prepares trenches for pipes, laying is performed, meters are installed.

Important: before contacting such an organization, you need to study the reviews. If the water is supplied to other houses clean, without pressure drops, then you should choose a centralized network, in other cases you will have to lay pipes and create a sewage system with your own hands.

Features of connection to the central highway

If there is a central water supply in the village, it is not difficult to equip a water supply system in a private house. Especially if the highway runs close to the facility. After obtaining permission to connect from the organization serving the water supply system, an insert is made within a couple of days in accordance with the technical conditions and estimate documentation. Digging trenches to the required depth is carried out with the help of special equipment, so excavation takes only a few hours.

Important! The work can be delayed if you have to dig by hand. In some cases, special equipment cannot be used, otherwise the previously laid communications may be damaged.

Next, a pipeline is laid from steel or polypropylene pipes, shut-off equipment is installed in the inspection well and in the house. After the completion of the external work, they proceed to the wiring inside the room according to the scheme.

Selection of suitable pipes for plumbing

Before proceeding with the construction of a water supply system in private housing construction with your own hands, you need to choose high-quality pipes, which may differ not only in length and cross-section, but also in the material used for their manufacture:

- The copper product of the pipe rolling industry is considered the most expensive segment on the construction market. The copper pipe does not corrode, is not afraid of ultraviolet radiation, is indifferent to microorganisms, withstands high pressure and is not afraid of temperature extremes. There is no better piping product.

- Reinforced plastic plumbing is a good alternative to the copper analogue. A pipe made of aluminum, protected both outside and inside with plastic, in addition to having an attractive appearance, is not subject to accumulation of scale or other sediments contained in the water on the walls.

- A standard steel pipe is a product that has been used for decades for arranging a water supply system in high-rise buildings and private housing buildings during the Soviet era. It has a long service life, has a large margin of safety, but at the same time it is afraid of rust. Also, the installation of such products requires certain knowledge and tools.

- Polypropylene products are gaining more and more popularity for the construction of cold water supply systems in private homes.Such a product is not afraid of corrosion, has a long service life and a relatively low cost. However, a special soldering iron is required to connect the individual elements of the pipeline.

When laying a pipeline with your own hands it is important to consider the material, from which the pipes are made, since the quality of the wiring of the water supply system and the final cost of the work carried out will depend on this.

How to choose a cross-section of pipes for an in-house pipeline

An equally important role in the construction of an autonomous water supply system is played by diameter of pipes used... First of all, a pipeline with a small cross-section will lead to turbulization of water flows and, as a result, the movement of water with a characteristic noise.

Water resources should move through pipes with a maximum speed of no more than 2 m / s. Also, the cross-section of products of the pipe rolling industry depends on the length of the water supply system:

- for pipes of the water supply system with a total length of up to 30 m, a pipeline with a diameter of 2.5 cm is used;

- if the total length of the pipeline exceeds 30 m length, the cross-section of the pipes increases to 3.2 cm;

- in the case of a very small pipeline, the length of which does not exceed 10 m, pipes with a cross section of 2 cm are suitable.

The quality of the water supply pipeline depends on the correct selection of the diameters of the pipes of the collector system to determine which, there are simple calculations.

On average, the shut-off valves on the manifold are capable of passing up to 6 liters of water per minute. From this it is possible to determine the number of consumers in the house that can be used at the same time. You also need to pay attention to the inlet pipe of the collector:

- Pipes with a cross section of 2.5 cm are capable of passing up to 30 l / min.

- The product with a diameter of 3.2 cm has a flow rate of 50 l / min.

- In turn, a pipeline with a cross section of 3.8 cm will freely pass 75 l / min.

If a large family lives in a private house, then even with a small number of water intake points, they can often work simultaneously. Therefore, when designing a water supply system, you need proceed from totals simultaneous consumption of water resources in 1 minute.

If, on the contrary, a small family of three or four people lives in a large house, and there are many water intake points: a washing machine, a dishwasher, a bathroom, a shower and other water consumers, then all calculations are performed according to a different algorithm. In such a situation, the total consumption of water resources decreases by 25–40%.

How to ensure good water pressure

For the normal operation of plumbing and household appliances, a certain water pressure must be maintained in the pipeline. To achieve a sufficient pressure level in the pipeline, a water tank or a hydraulic accumulator is installed in the attic. A water intake is installed in the well, equipped with a filter mesh and a check valve. The water supply to the system is organized using a pump that can automatically turn on when the pressure drops and turn off when the value of this parameter is restored.

When calculating the volume of a water tank, it is assumed that for each person permanently living in a private house, 50 liters per day are required. In addition, a supply of water is laid to extinguish a possible fire. When choosing a hydraulic accumulator, the volume is calculated taking into account the fact that each valve should have 20 liters of flow per day.

The nature of the soil

- Sandy, clayey soils are rather light and loose and do not exert significant pressure on the pipeline. Plastic and metal-plastic water pipes of the appropriate diameter and with the required wall thickness do an excellent job.

If it is necessary to install a water supply system of a relatively large diameter, then it is better to choose corrugated products. Stiffeners increase the strength of the material without losing elasticity.

- Rocky ground is much more demanding.It is rare, but soils prone to movement is a common problem. Steel water conduits are required here, since plastic ones will not withstand such strong pressure.

Depth of occurrence

Plastic water pipes are available in different stiffness classes, which allows you to choose the best solution.

- SN 2 - laying underground at a depth of up to 2 m is allowed. At the dacha, this option is most often implemented.

- SN 4 - installation is supposed to be at a depth of 3 m. Both smooth and corrugated conduits are used.

- SN 6 - maximum depth 8 m.

- SN 8 - water supply is allowed to be collected underground at a depth of 10 m.

Steel water pipes are not limited in depth. You just need to pick up a product with a sufficient wall thickness.

Buyers are increasingly choosing polypropylene-based pipes. The products are in high demand, which ensures operational characteristics, no problems during installation, and an affordable cost indicator.

Manufacturers say they last at least 50 years. There will be enough minimal skills in order to perform such work as laying a water supply system from polypropylene pipes in the ground.

The first stage in any installation of a water supply system is to dismantle sections of the old pipeline. Steel products most often require replacement completely.

Installation with a grinder is the most convenient and simple solution. After that, we proceed to laying the polypropylene pipes of the new water supply system.

How to properly lay a water supply pipe

The most important condition is that the water supply pipe must be laid below the freezing level of the soil. For the Moscow region, this value is 1.4 m, which means the trench should be 30-40 cm deeper. Why is such a stock needed? In order to equip a gravel-sand cushion, thanks to which small movements and heaving of the soil will not lead to deformation of the pipe.

Insulation of the pipe

If it is impossible to go deep below the freezing point of the soil (rocks, stone), I always insulate the pipe. For this I use:

- insulation (glass or mineral wool);

- fasteners (metal clamps, mounting wire or plastic tape);

- folgoizol

First, I unfold a roll of insulation in length and cut a strip that will completely wrap the pipe. Then I fix it with fasteners. After that, I wrap the insulated pipe with a hydro-barrier and foil and fix them with tape. I do such manipulations along the entire length.

To facilitate the work, in building materials stores you can purchase ready-made heaters for pipes of various thicknesses and for any diameter.

Plumbing installation tools

In order to carry out high-quality installation work on laying water pipes in the ground, it is far from always necessary to resort to the help of special equipment. Many of the spacers are found on the farm in most homes. You will need the following set of tools:

- pipe cutter, sharp pipe scissors, knife or hacksaw;

- drill or hammer drill;

- sandpaper;

- construction pencil;

- roulette;

- a set of gas and wrenches (for tightly tightening the fittings);

- soldering iron (if the installation will be carried out by hot welding);

- earthmoving tools: shovel, compact scrap.

For even and accurate cutting of pipes, you need to use special scissors

Pipeline installation methods

Polyethylene pipes can be connected to each other using a special soldering iron by welding or crimp fittings. The soldering iron guarantees a reliable connection and after assembly, all pipes will be one single piece. Most often, welding is carried out on the surface. The pipes are combined into sections, which are then lowered into the trench and welded using the same method. This is done because it is more convenient to carry out welding work on the surface.

Laying of polypropylene analogs can also be done by welding. But unlike polyethylene, in order to connect polypropylene pipes, the soldering iron must be heated to a temperature of 260-270 degrees. When performing welding work, the heating time must be observed. If the pipe diameter is 25 millimeters, then the joint must be heated for about 9-10 seconds. If the diameter is 32 millimeters, you need to heat for a few seconds longer. It is necessary to observe temperature loads, overheating contributes to damage to the surface of plastic products.

Low heating of the connecting parts is also considered a gross mistake, the connection will not be strong and leaks may form in these places. The inner surface of the connecting fittings and the outer surface of the pipes must be free from dust and moisture, otherwise the quality of the soldering may deteriorate. During operation, plastic sags appear, which do not need to be removed immediately, since you can accidentally deform a heated pipe. Even with the observance of the soldering technology, the constructed pipeline should not be backfilled immediately. First you need to test it under pressure for several days. If during this time no leaks have appeared, then everything is securely connected to each other and the trench can be filled up.

How to choose the right pipe for water supply

I always recommend using a 32mm polyethylene pipe. It can withstand fairly high mechanical loads, is resistant to adverse environmental influences and is relatively cheap. Various fittings and connectors can be found without any problems at any hardware store. In addition, you can make one-piece couplings or solder joints, but I use this option only in extreme cases.

CHARACTERISTICS OF HDPE PIPES

| Parameter | unit of measurement | Value |

| Service life, not less | years | 50 |

| Operating temperature | ºС | -20…+40 |

| Extreme temperatures | ºС | -70…+80 |

| Operating pressure | bar | 4…16 |

| Average weight 1m.p. | Kg | 0,17…0,25 |

Instead of HDPE, metal pipes can be used. In this case, be prepared for a significant increase in the estimate, difficulties in laying and connecting the elements of the water supply system to each other.