In continental climatic conditions, winters are sometimes quite cold. That is why the owners of private houses prefer additional insulation of their home. Special coatings are intended not only for insulating the facade of a house or apartment, but also for ceilings, internal walls, roofs, floor surfaces and even for a sauna and a bath. Insulation by Rockwool is one of the leaders in the market for these products and occupies a leading position in the niche of materials for insulating facades with glass wool.

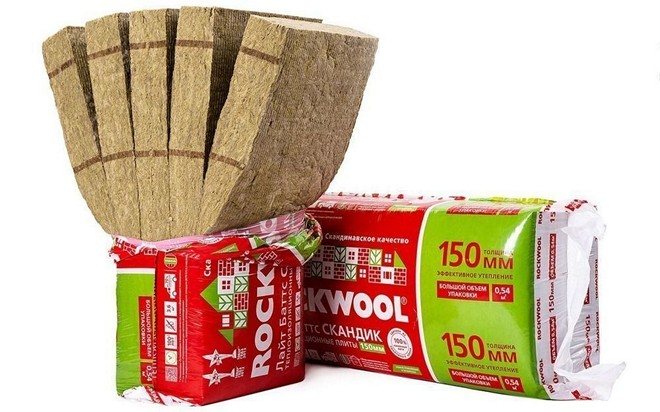

Socket Rockwool Lite BATS SCANDIC

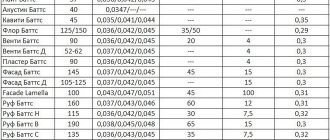

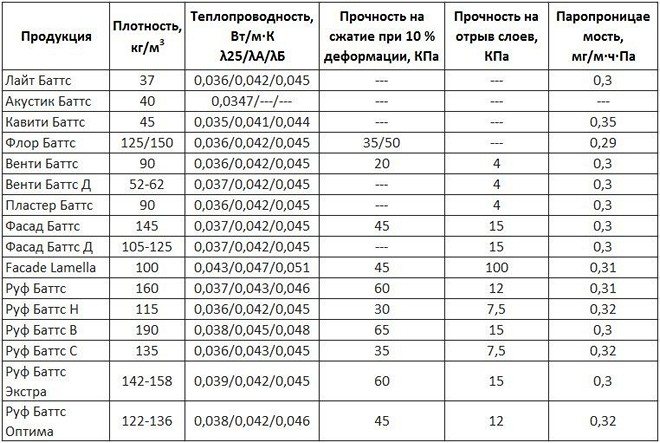

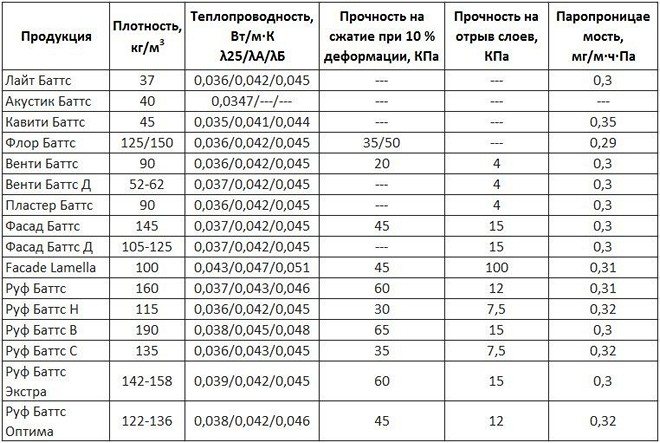

Rockwool specifications

Insulation Rockwool Butts has high performance, which once again confirms its popularity among thermal insulation boards.

Rockwool Specifications

In addition, all products are manufactured according to special technologies and have the EcoMaterialGreen quality certificate, which confirms complete environmental friendliness and safety.

Benefits

Thermal insulation with this material has its significant advantages:

- slabs do not form gaps and crevices due to increased density during installation;

- reliably protects against the formation of mold, fungus, rodent penetration due to its high biostability;

- incombustibility of the material;

- moisture resistance;

- high sound and heat insulation;

- a springy base, which is obtained as a result of the unique flexi technology, which makes installation quite easy and fast.

Scope of application

Light Butts are modern pressed slabs made of stone wool. It is obtained as a result of processing basalt rocks, which makes the material strong and resistant to various damages and influences. So, the scope of their application is quite diverse:

- building's facade;

- internal walls;

- interior partitions, balconies, loggias, attic;

- roof;

- floor slabs;

- entrance doors, garage gates;

- external and internal walls of the apartment.

Insulation Rockwool due to its technical characteristics has a wide range of applications

Specification and dimensions

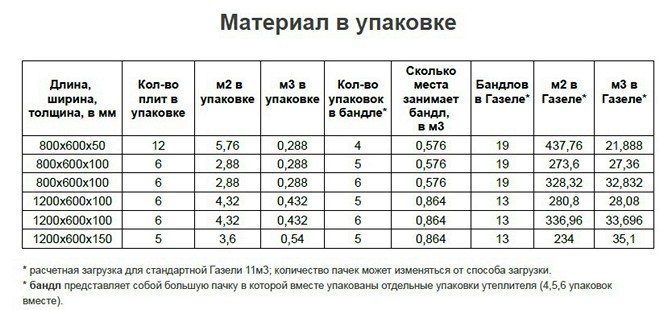

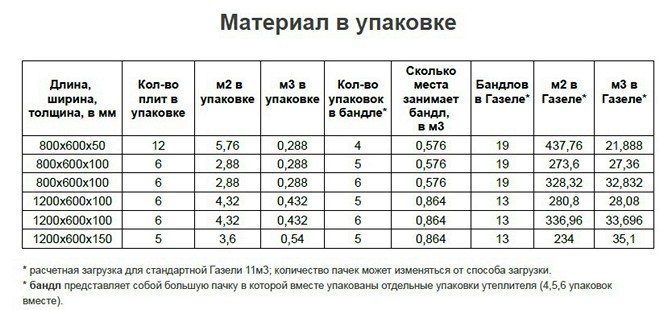

The manufacturer manufactures products in two types:

- standard - 60x80 cm (thickness - 5 or 10 cm) - this size is convenient for transportation by car;

- XL - 60x120 cm (thickness - 10 and 15 cm) - in case of transportation by trucks.

To roughly understand how much space one package takes and to facilitate the process of loading and delivering material, you can use the table:

Insulation size Rockwool

Insulation safety

Environmental certifications awarded to Rockwool

Stone-based cotton wool is considered one of the safest. The manufacturer was the first to receive the well-deserved EcoMaterial Green certificate of conformity. Therefore, the insulation is available for use in any children's, medical and public institutions. Such material is of exclusively natural origin; safe resins are used for the bond.

Due to the presence of a European certificate, it is acceptable to use Rockwool thermal insulation in a residential environment. There is no phenol in the structure. For this, the manufacturer used high-tech solid state binder resins.

Calculate your home's insulation

A cozy home is, of course, a warm home. The level of heat loss depends on the correctly calculated thermal insulation.To reduce it, it is necessary to correctly calculate the required amount of material for wall insulation and, in fact, calculate the optimal thickness of wool for insulation. Calculation of rockwool insulation for a facade can be determined in three ways:

- by contacting special construction organizations;

- on your own;

- using an online calculator.

Of course, the easiest way is to choose the first option and save a lot of time by getting just a number. But in this case, you will have to pay a considerable amount for such services, and this, as you know, is an extra expense during construction or repair, because you can calculate the amount of insulation yourself. It will certainly take some time, but the result will be just as accurate.

The calculation of the insulation (Scandic, Light Butts or any other) occurs according to a certain formula, and there is nothing complicated about it. It can be produced for absolutely any kind of material. But first, let's look at it with a specific example.

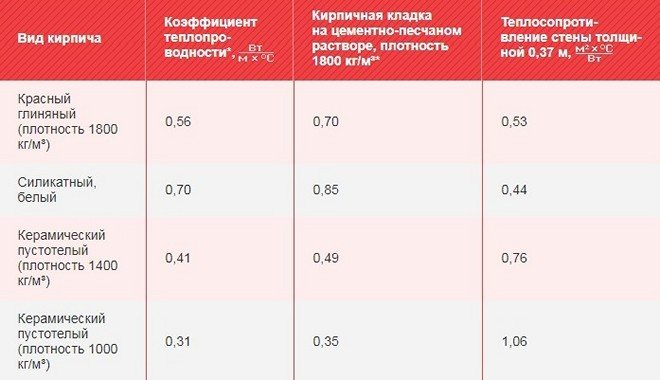

For example, we have a house made of bricks, the wall thickness is one and a half bricks. The work is planned to be done with the help of "Light Butts" or "Scandic". In order for thermal insulation to be effective and heat to be retained in the cold season, the wall must have a thermal resistance equal to at least 3.5 m2 * K / W. To determine the optimal thermal insulation, it is necessary to make certain calculations:

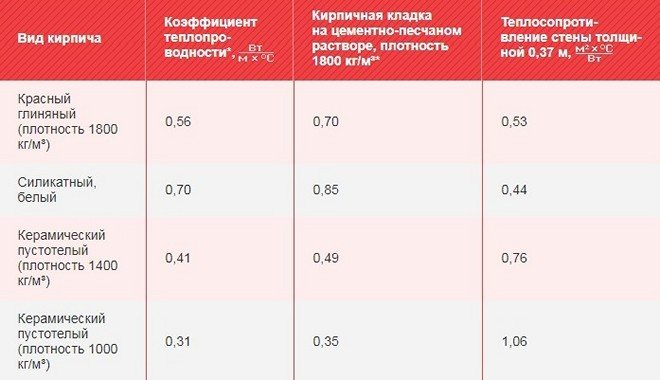

- To begin with, we determine the current thermal resistance of the existing wall. Its thickness is 37 cm, and the coefficient of thermal conductivity is 0.56. This applies to red clay bricks. So, for different types of material, thermal conductivity is usually different.

- We calculate the current thermal resistance. To do this, the wall thickness in meters must be divided by the thermal conductivity coefficient. As a result, we get: 0.37 / 0.56 = 0.66 m2 * K / W.

- We do not have enough up to the optimal value of 3.5 m2 * K / W: 3.5-0.66 = 2.84 m2 * K / W.

- Further, it became possible to calculate the required thickness of the stone wool layer: 2.84 * 0.045, where the second value is the coefficient of thermal conductivity of the insulation itself. Thus, we get the value in meters - 0.127. We find the value in millimeters - 127 mm. This is the required layer thickness for thermal insulation with Rockwool Light Butts and Scandic stone wool.

If you are still afraid of making a mistake in the calculations, you can use the online calculator, which are offered by many construction sites.

Mounting methods

To properly install the thermal insulation on the outer wall of the house, you can use special fixing dowels or a suitable adhesive base.

Application of special glue

Insulation adhesive

If high-quality and expensive cotton wool is used for facade insulation, it is necessary to use glue of the appropriate quality. There must be a sufficient amount of binder in this material. Depending on the weight of the insulation mats, it is necessary to select a fixing base. To fix the heat-insulating sheet to the surface, you must:

- pre-print the material and leave for a day;

- find the wrong side and mark the places for the location of the glue;

- stir the glue according to the recipe indicated on the package;

- make strokes around the perimeter with a spatula;

- gently lift the material and fix it in the right place on the wall.

It is better not to combine different adhesives with each other in order to save money. This will negatively affect the tightness of the heat insulator.

Fastening to construction dowels

First, you need to determine what structure the basalt wool has, since there are different types of dowels for solid and porous insulation. To calculate the number of fastening tools, you need to know the height of the building and the wind zone. Approximately 6 dowels are required to install one square meter of insulation.

There is always more wind force in the corners of buildings. Here you need to more reliably fix the insulation layer.Therefore, the number of fasteners must be increased.

A combination of glue and dowels is often practiced when installing insulation for Rockwool walls.

Types of insulation and its application

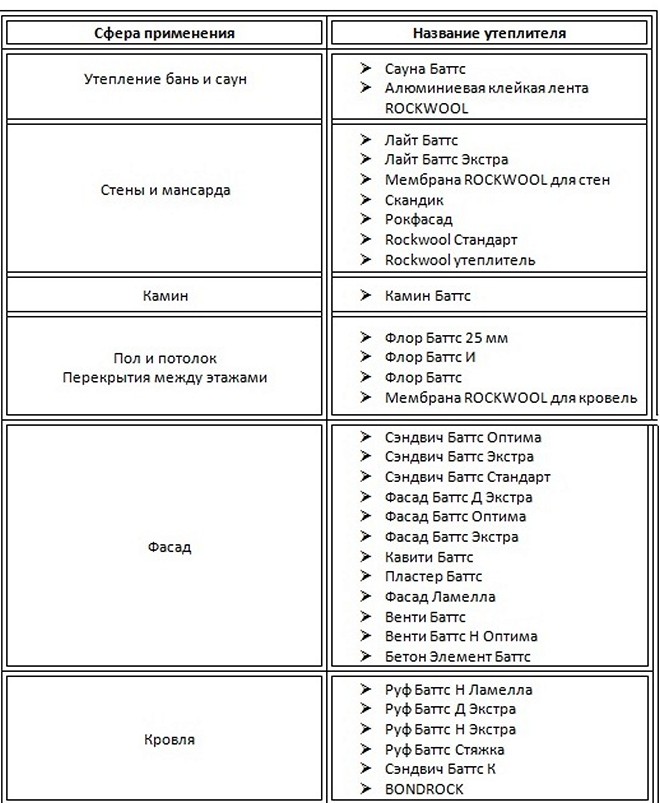

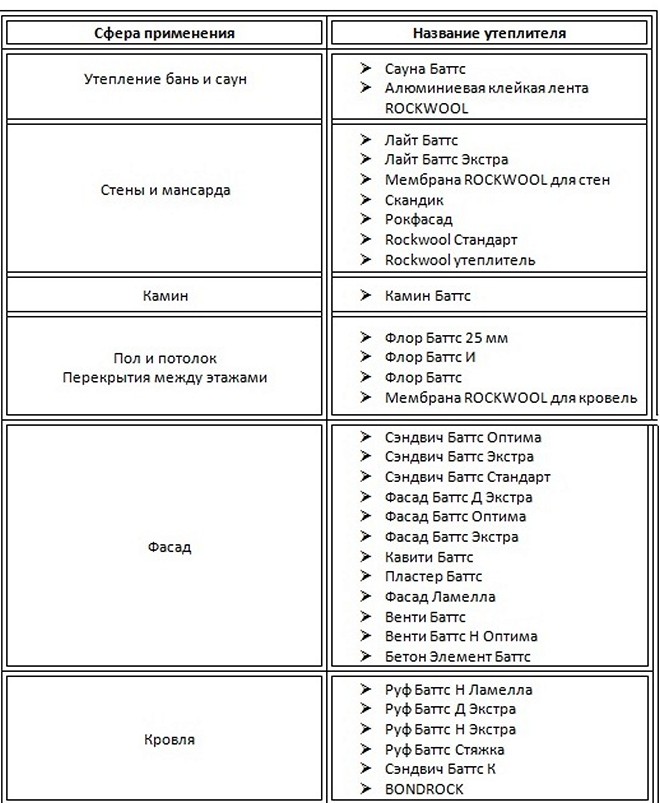

Rockwool manufactures a wide range of insulation products. So, each of the heaters can be applied to different parts of a house or apartment, and all products can be divided into blocks, taking into account the scope of its use:

This is not a complete list of manufactured stone wool for thermal insulation of premises. Among other things, there are special membranes, aluminum tapes, vapor barrier plates, which are also aimed at retaining heat. Also, some types can be used in different fields. For example, Light Butts, Light Butts Extra, Scandic, Floor Butts can be used to insulate balconies and loggias, as well as for floors and storey ceilings. And, for example, Light Butts is perfectly practiced as a second thermal layer for steam rooms.

Wet Facade Walls

This method of insulating facades is the most common and has its own advantages:

- maximum heat savings;

- reduction of financial costs.

A variant of the "wet" method of insulation

So, after all the preparations for the facade, a basement profile is installed, which serves to balance the load distribution from the insulation. Next, the installation of the Rockwool Butts thermal insulation layer is carried out:

- Along the edges of the insulation, at a distance of 3-4 cm, an adhesive mortar is applied in a wide strip.

- Then it is pressed tightly against the wall, but the excess glue is removed immediately. The second layer of insulation is pressed against the first with the same effort.

- Move from the basement profile - up.

- After 2-3 days, when the glue solution is completely dry, the insulation is additionally fixed with dowels. The length of the fasteners must match - in addition to the rock wool layer, they must fit into the wall.

After all the fortifications are completed, a reinforcing layer is installed:

- building glue is applied to the insulation layer, in which the fiberglass mesh is recessed;

- the same adhesive is applied over the mesh.

It should be remembered that the total layer should not be more than 6-7 mm. After the glue is completely dry, plaster is applied on top for external use.

Two-layer masonry

Layout of two-layer brickwork with insulation inside

Warming using the home method is the easiest way to insulate a room using Scandic or Light Butts slabs. In this case, the insulation is mounted between two rows of masonry. For example, a wall is built using bricks (silicate, ceramic). Further, stone wool is fixed to it using the same method as with the wet facade technology. And then another layer of wall masonry is erected. It can also be made of bricks or other building materials - foam block, slag concrete and others. Rockwool Venti Butts are often used to insulate suspended systems with an air gap.

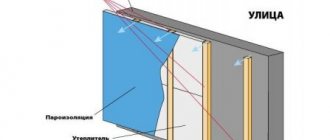

Frame walls

Rockwool Light Butts is the ideal insulation for frame walls

Any house consists of two walls - internal and external. In this method, both are insulated. For this, the ideal choice would be Rockwool Caviti Butts or Rockwood Facade Butts:

- outside, the facade of the house is sheathed with wood planks;

- a waterproofing membrane is strengthened on them, which protects the insulation from moisture, also from the outside;

- from the inside of the house, Rockwool is installed in the frame racks for the walls;

- all gaps and voids are filled with polyurethane foam;

- the inner walls should be covered with a vapor barrier membrane and wood-based panels should be reinforced over it.

Walls from the inside

Insulation of the wall of the house from the inside with Rockwool insulation

Not all insulation materials are suitable for interior decoration, as some have very low environmental performance.So, the insulation must meet the following requirements:

- durability;

- high fire safety;

- low heat loss;

- complete environmental friendliness.

All these requirements are met:

- Rockwool Light Butts Extra;

- Light Butts Scandic XL.

Work from the inside takes place in several stages:

- To prevent the appearance of mold and mildew, the surface is treated with a deep-penetrating primer.

- The crate is installed in the form of a metal frame or wooden bars.

- Insulation is laid;

- The waterproofing or vapor barrier membrane is stretched.

- Drywall is attached.

Screed floors

Insulation of the floor under the screed with Rockwool insulation

Thermal insulation wool is laid on the floor slabs. For greater efficiency of heat preservation, it is recommended to lay in several layers in a checkerboard pattern, i.e. when the edge of the top plate is in the middle of the bottom. As soon as the insulation is tightly mounted, they begin to level the floor - with cement mortar or using wood planks. This is followed by laying the flooring - linoleum, parquet, laminate, wood.

The most popular floor insulation materials are:

- Floor Butts 25 mm;

- Flor Butts I;

- Flor Butts.

Floor on logs

Thermal insulation of the floor along the logs

At the first stage, a Rockwool membrane is laid on the floor, intended for waterproofing. Its joints must be glued with tape. Then lag bars are laid, in the intervals of which thermal insulation is laid. It is recommended to strengthen the vapor barrier membrane from above and only then the floor covering is laid.

Flat roof

Expanding a flat roof with Rockwool Roof insulation

Insulation of a flat roof should be carried out only from the outside. Initially, Rockwool slabs are laid on the base - Roof Butts, Bondrock, Butts K. Sandwich. Then the cement screed is poured and the roofing material itself is laid.

Mansards and roofs with rockwool slabs

The attic is insulated only from the inside. So, the insulation is inserted between the rafters and covered with drywall or thin sheathing board. In this case, it is advisable to lay the insulation in several layers.

Pitched roof structures and attics

Insulation of the roof over the mansandra

These works are carried out only after the roofing has been installed. This will prevent the insulation from getting wet in case of rain or snow. The inner side of the counter-lattice is sheathed with a ROCKWOOL hydro-windproof roofing membrane. Further, the finished frame of the attic or pitched roof structure is filled with insulation. Then it is covered with a vapor barrier membrane and reinforced with a construction stapler. To create an air gap, a crate is installed in the form of drywall, sheathing board or wood-based panels.

Baths or saunas

Insulation for baths and saunas Rockwool

Rockwool produces special materials for thermal insulation of baths and saunas, which have high properties for keeping warm in steam rooms. They effectively store heat, which helps save on electricity or wood. Of particular importance is the aluminum coating on one side of the Butts insulation, which significantly increases the vapor barrier properties.

The insulation is installed in two layers from the inside of the room with the aluminum side inward in a checkerboard pattern, that is, in a staggered manner. This provides excellent thermal protection. For greater efficiency, the joints are glued with 100 or 50 mm Rockwool aluminum adhesive tape. Next, a crate is installed, which provides an air gap between the insulation and the external finish. The slabs themselves are mounted against the frame racks. The most common types of insulation for steam rooms are Rockwool Sauna Butts and the second layer of Rockwool Light Butts Scandic 100 and 50 mm.

Overview of the qualities of wall insulation

Basalt insulation in the form of mats is considered the best option for arranging a wall cake of frame walls... The material combines the main properties: heat capacity, vapor permeability, resistance to deformation and fire.

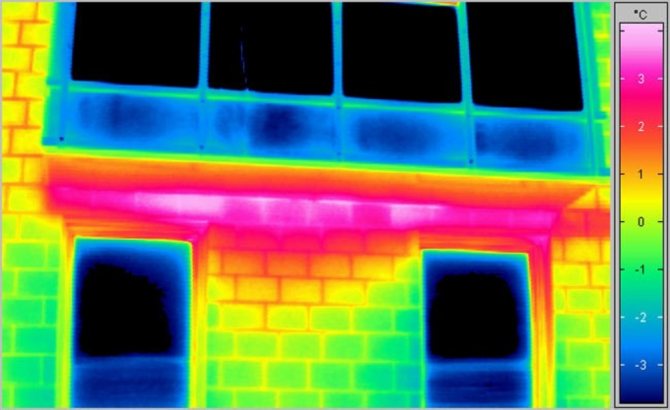

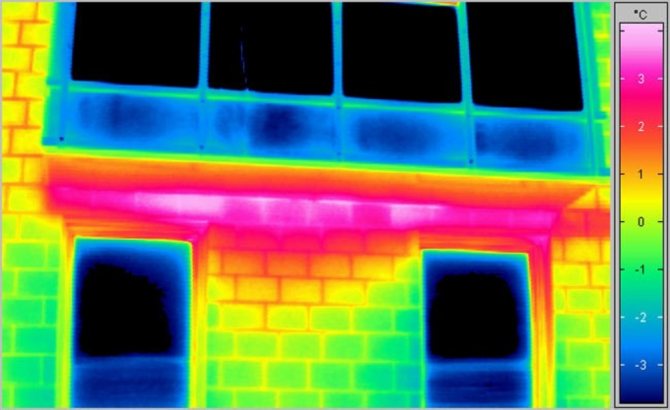

Heat saving effect and steam permeability

The main advantage of "stone" mats, which determines their field of application, is their high heat-insulating ability. Rockwool basalt wool does an excellent job of regulating the temperature inside the house. In winter, the insulation protects the room from frosty air, and in summer it keeps it cool and does not allow the heat to penetrate inside. Insulating mats fit tightly together. This technology prevents the appearance of cracks - cold bridges.

Elastic stone wool canvases are easy to mount, no additional fasteners are needed - the layers are installed in a previously prepared frame.

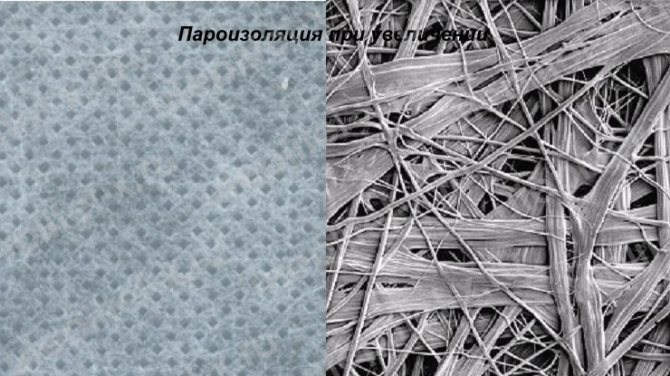

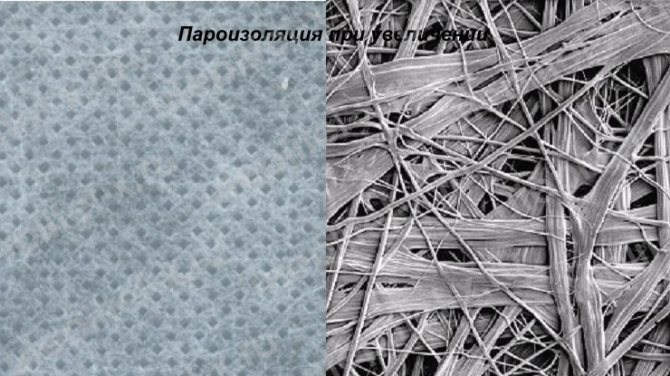

An indisputable plus of basalt insulation is its "breathing" ability. Unlike foam insulators, natural wool is breathable... In the frame, the effect of a thermos is not created, and the excess of accumulated moisture is removed through the micropores of the insulation.

Moisture resistance and sound insulation

As testimonials show, stone wool used for walls or floors, delays the propagation of shock and airborne noise... By choosing the optimal insulation layer, you can achieve a decrease in the sound effect in the range of 43-62 dB.

An indisputable plus of basalt insulation is its hydrophobicity. Rock does not get wet - drops do not linger on the surface, but roll down. The material does not absorb water, which means it retains its thermal insulation qualities. This property of insulation is very important for outdoor installation, the use of cotton wool for arranging "wet" areas: saunas, baths.

The inability to accumulate water and the mineral base of the heat insulator exclude the appearance of a favorable environment for the development of parasitic microflora, the appearance of rodents and insects. For stony composition processes of decay, decomposition, mold formation are not characteristic... Rockwool basalt mats can be reused - their characteristics and qualities are practically unchanged over time.

Useful: Choosing a material for building a house

Fire safety and environmental friendliness

The key factor in the use of insulation in residential buildings is operational safety. In this regard, stone wool has succeeded.

Basalt withstands high temperatures and does not ignite, the heat insulator begins to melt when heated from + 1000 ° C. Rockwool insulation complies with the following safety classes:

- KM0 - completely safe;

- NG - non-combustible materials.

Due to its fire resistance, stone wool insulation often used as effective fire barriers.

The Rockwool heat insulator is considered an environmentally friendly product. In its production, no harmful components are involved - only a natural mineral and a water repellent that provides moisture resistance. Stone wool, regardless of operating conditions, does not emit hazardous substances into the environment. In terms of environmental friendliness, Rockwool basalt insulation is ahead of most alternative polymer-based insulation. Its use is permissible inside the house..

Reviews and purpose of mineral wool cylinders

Thermal insulating cylinders made of Rockwool mineral wool are quite popular among consumers today. They are manufactured according to technical specifications and represent the most effective insulation, which has found its application in the protection of cold and hot water supply systems.

Basalt rocks are the main raw materials for production. Cylinders are obtained by gluing together insulation material and aluminum foil. Consumers emphasize that thermal insulation has a wide range of uses.It can be used to isolate technological objects in various industries, including food.

According to users, the material has a chemical resistance to oils, has effective thermal insulation properties, durability and ease of installation. If you decide to purchase this material, then the price of Rockwool mineral wool should interest you. By purchasing a cylinder, the thickness of which is 30 mm, you will pay 68.1 rubles per square meter.

If the thickness increases to 40 mm, then 74 rubles will have to be paid for the same volume of material. This is true if the pipe diameter is 18 mm.

The slabs are used for the unloaded thermal insulation layer, in partitions, mansard rooms, light roof structures, walls of low-rise buildings, interfloor ceilings, including inclined and vertical walls. The material is intended for surfaces that will not be subjected to significant loads during operation. With the help of insulation, you can ensure its tight abutment to the surface, while no gaps will form. With the help of the material, you will be able to maintain a comfortable temperature in the room, excluding drafts.

Analogues of insulation Rockwool Sauna Butts

Insulation Isover saunas have similar thermal conductivity and vapor permeability.

Due to the nature of the room, a rather narrow range of materials is used to insulate the steam room in the bath. Instead of thermal insulation from Rockwool, you can use analogs similar in properties.

Building insulation Green Planet "Bath-Sauna" is a fairly new moisture-resistant breathable material that perfectly tolerates temperature extremes. The insulation is made of polyester fiber, therefore it is not subject to decay, environmentally friendly, hypoallergenic. Differs in ease of installation and increased service life. Supplied in the form of slabs packed in boxes. It allows you to keep warm in the cold season and prevents the room from heating up in summer.

Isover "Sauna" with foil is a fiberglass-based heat-insulating material. Marketed as lightweight air mats packed in rolls. Possesses high moisture resistance, low flammability. Thanks to the foil, it is not necessary to lay a vapor barrier film during installation. In addition, the foil layer reflects heat, which increases the indicators of thermal insulation properties. Isover "Sauna" is completely safe for the health of people and animals, in addition to its heat-insulating properties, it is soundproof. Has a long service life. Manufactured in accordance with European quality standards.

Foil thermal insulation Ursa is available for sale in the form of rolled mats. On one side, the material is covered with a foil layer. Produced on the basis of mineral fiberglass. Possesses not only heat, but also sound insulation properties. The most effective for horizontal placement, for insulation of ceilings, basements, attics, floors. Ursa is not flammable, the temperature of its application is from -60 to +270 C. It is completely safe for people and animals. Also, thanks to the foil coating, it does not require the use of additional vapor barrier.

Which side to lay the vapor barrier to the insulation

At first glance, it seems that there is nothing complicated - fix the waterproofing film on top of the insulation from the side of the warm room and you're done. However, in this case, there are some important nuances that you need to know about. It is also important to consider which side of the vapor barrier is laid to the insulation on the ceiling and what are the installation features. This is where the previous knowledge about the types of film used will come in handy.

How to distinguish the inside from the outside

If the manufacturer's instructions are absent or does not contain the necessary information about which side of the film is considered internal, then you should independently determine this by external factors. You should pay attention to the following points:

1... If the waterproofing film has different colors on both sides, then bright side isospana fits to the insulation; 2. Side waterproofing, which when rolling facing the floor, considered internal and should look towards the insulation; 3. The outer side is made fleecyto keep moisture out, and the inner side is smooth and fits in the direction of the insulation.

Which side to put the vapor barrier on the insulation

The polyethylene film is laid on either side, because they are not different from each other. The diffusion membrane (steam condensate film) is correctly laid with the smooth side on the insulation, and the rough side in the direction of the warm room. Thus, it prevents the insulation on the ceiling or wall from getting wet, and excess moisture from the material can freely pass through the smooth side.

Also, diffusion membranes are mounted with the smooth side to the insulation on the floor or wall. Foil-sided vapor barriers are attached with the reflective side outward, as it reflects heat back towards the warm room. And it should be remembered that laying vapor-proof materials, for example, isospan c, requires a ventilation gap to remove excess moisture.

If the inner lining (false wall) is made close to each other without a gap, then it will be exposed to the influence of moisture deposited on the film. If there is a gap, the movement of air will facilitate the unhindered evaporation of excess condensate from the surface of the film. It is important not only to know isospan in which side to put the insulation, but also to preserve the integrity of the vapor barrier itself.

Application area

The material can be used for balconies

Despite the fact that the bath or sauna room is not constantly heated throughout the year, it must be insulated. This has its advantages. The supporting structure and interior decoration will be less susceptible to sudden temperature changes, which do not affect them in the best way. In addition, the steam room will warm up faster and cool down more slowly, which will save money on heating.

Thermal insulation of such a specific room has its own characteristics and requirements for materials due to high temperatures and humidity. Due to its operational properties, Rockwool for baths are widely used in thermal insulation of steam rooms. They can insulate load-bearing walls, partitions and even the ceiling. Due to its incombustibility, stone wool can be used where there is a high risk of fire.

In addition to thermal insulation of steam rooms, Rockwool insulation is used in other rooms. It is used for thermal insulation of roofs and attics, floors and basements. The material can be used not only on private premises, but also on production sites.