When changing plumbing or heating means, pipes have a strong influence on the quality of work. In hardware stores, you can see a huge selection of products: copper, steel, plastic. Therefore, it is necessary to decide on the necessary and effective accessories. For example, metal-plastic pipes are a popular element for repair. These attributes are used in many areas of activity, they are functional and practical.

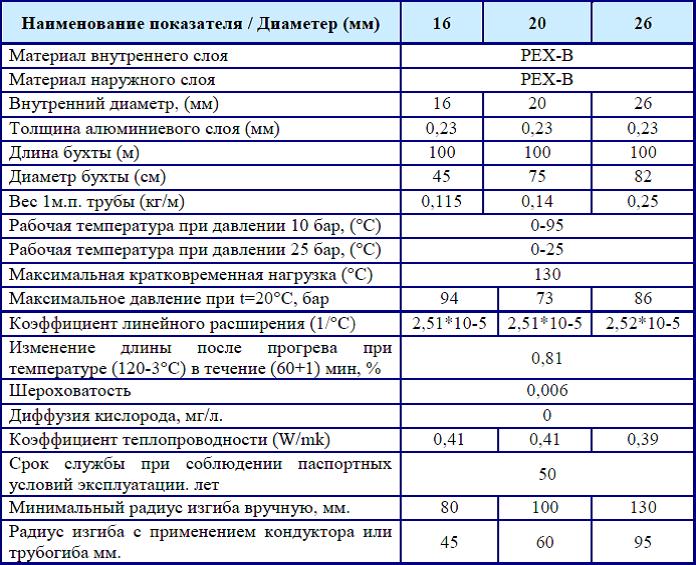

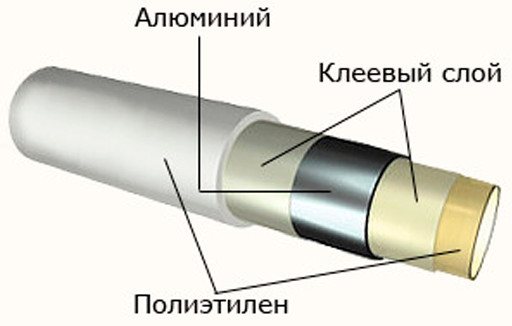

Diagram of the device of metal-plastic pipes.

The defining criterion when choosing structures is the service life of reinforced-plastic pipes. They are durable. Therefore, modern specialists purchase them more often than other plumbing items.

Combination of metal and plastic

The metal-plastic wall is made of an aluminum base covered with high-density polyethylene. A special adhesive layer is applied to it using the extrusion method from the inside and outside. The outer layer of polyethylene protects the product from atmospheric corrosion and mechanical damage.

Aluminum

The middle aluminum layer gives the pipe mechanical and hydraulic strength and makes it oxygen-tight. The thermal deformability of polyethylene is reduced by more than 7 times due to the presence of aluminum.

The edges of the aluminum base can be joined by laser butt welding or ultrasonic overlap welding. Laser welding gives a more durable option.

Polyethylene

The inner layer is made of heat-resistant polyethylene. It forms a smooth surface and corrosion protection of the metal. Polyethylene, which is used in production, does not contain harmful chemicals. This suggests that the metal-plastic pipelines are suitable for drinking water supply. Polyethylene prevents the multiplication and spread of microorganisms in the water.

To provide thermal insulation and reduce heat loss, pipelines with closed pores and concentric insulation are used.

Features of the choice of pipes made of metal-plastic for the heating network

The main problem arises with poor quality products. The metal foil leaves during operation, a leak, rust forms, and the contour changes shape.

To avoid trouble, you should heed the advice of the masters:

- buy products directly from the manufacturer or in a good store;

- require a certificate - no papers, obvious fake;

- there should be no chips, bends, stains on the pipe;

- the dimensions correspond to those stated in the passport, there are markings, the coating is smooth;

- errors in letters and letters are fake;

- if the aluminum foil is butt-welded - this is a factory production, the overlap seam is an artisanal fake;

- different thickness of aluminum is not allowed.

When ordering a pipe of a certain shape, you need to find out the thickness of the outer layer of the polymer, measure the parameter. Violations will say that this is a fake and it is better to refuse the product.

Life time

Manufacturers declare the service life of metal-plastic heating pipes at 50 years. But here it all depends on the conditions of use - excessive aggressive exposure reduces the period of use by 15 years. However, this indicator is higher than that of any other products, therefore composite pipes are deservedly popular.

Advice! If aluminum foil reinforcement is not suitable, fiberglass reinforced models are available.They are more expensive, do not delaminate, but have a slightly greater linear expansion than aluminum ones.

Characteristics and properties

Reinforced-plastic pipes are bent and cut without much effort. They are transported and stored in bays. Pieces of the required length are cut from the bay. Due to the low weight density of plastic and aluminum, a low weight of the finished product is ensured. At the same time, its transportation is facilitated.

Such pipes have a fairly long service life. In practice, it exceeds the periods between planned capital repairs of premises. If water freezes in a metal-plastic pipe, then an accident will not occur. The pipe will swell locally and retain its functionality.

The flexibility of this type of pipes allows them to be used for underfloor heating.

Before proceeding with the installation of the heating system, you need to determine which pipelines are best suited for a particular room. To do this, you need to take into account not only the technical characteristics, but also the positive and negative aspects of the selected material.

Main advantages

- reliability and durability;

- pronounced resistance to salt deposition, aggressive environments;

- resistance to silting and overgrowing;

- high throughput rate;

- light weight and high ductility;

- easy to do it yourself;

- good maintainability;

- high coefficient of noise absorption capacity;

- low thermal conductivity.

Negative sides

- it is forbidden to use in fire safety systems;

- cannot be installed near heat sources, the temperature of which is more than 1500 ° С;

- unreliability of fittings;

- high sensitivity to defrosting.

It is not recommended to use metal-plastic products outdoors. They can burst if you start defrosting the heating system. As a result, an emergency shutdown of the boiler from electricity will occur, which leads to the replacement of all pipes and dismantling of the system.

Taking into account all the characteristic features, it can be noted that the use of metal-plastic pipes for heating residential buildings is most justified.

"Warm" floor using metal-plastic pipes

The technical characteristics of metal-plastic pipes made it possible to establish the production of cost-effective and with a sufficient degree of heat transfer additional heating systems for floor coverings in apartments.

Underfloor heating installation

No deformation of pipes under the influence of high temperatures of the heat carrier (up to 95º), flexibility, smooth inner surface allows the installation of a reliable heating system.

The service life of underfloor heating made of metal-plastic pipes is 25 years. According to consumer reviews, a well-installed heating system allows you to create additional comfort in the room.

The reason for reducing the service life of "warm" floors is the use of low-quality heat carrier (water), which leads to the deposition of insoluble compounds (scale) at the joints of pipes using fittings.

Types and features

Knowing the structure of the product and its labeling will help determine which pipelines are best suited for a private house and apartment.

The most popular metal for the production of elements of any diameter is aluminum, but polymers differ significantly. Any metal-plastic pipe used for heating must withstand well a temperature of 95 ° C and a pressure of up to 7 atmospheres.

Unlike hot water supply, heating involves the transfer of a heat carrier at a higher temperature and at a lower speed, which causes increased pressure on the pipe walls. Such conditions can lead to rapid aging of the polymer, which will significantly reduce the life of the product.

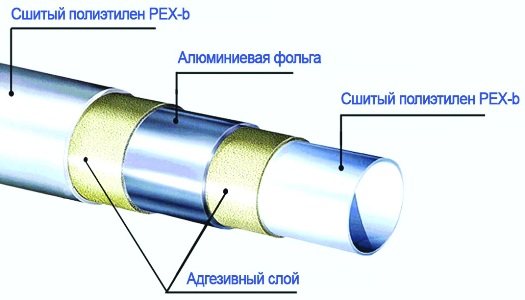

That is why it is better to choose pipelines for heating with cross-linked or heat-resistant polyethylene piping. Crosslinking and three-dimensional structure increases strength and resistance to thermal deformation. Such pipes are marked with the letter designation PE-X and PE-RT. Polypropylene (PP-R) and common polyethylene (PE-R) are well suited for cold water applications.

Given the presence of a metal core and a polymer sheath, the service life of such a product is highly dependent on the properties of these materials.

Service life of steel pipes

Steel products are used not only in everyday life, but also in many other fields of activity. They are used for the construction of irrigation systems, oil pipelines, gas and heating mains. In many apartments of the old fund, steel communications were laid, which still serve today.

For the organization of heating systems, it is recommended to use products made of black steel, while galvanized products are more suitable for the plumbing. To protect steel pipes from corrosion, which becomes the root cause of communication failures, manufacturers apply zinc coating inside and out.

The service life of a steel riser or piping in a cold water supply system is 30 years, a hot one - 20 years.

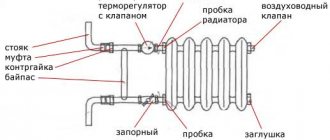

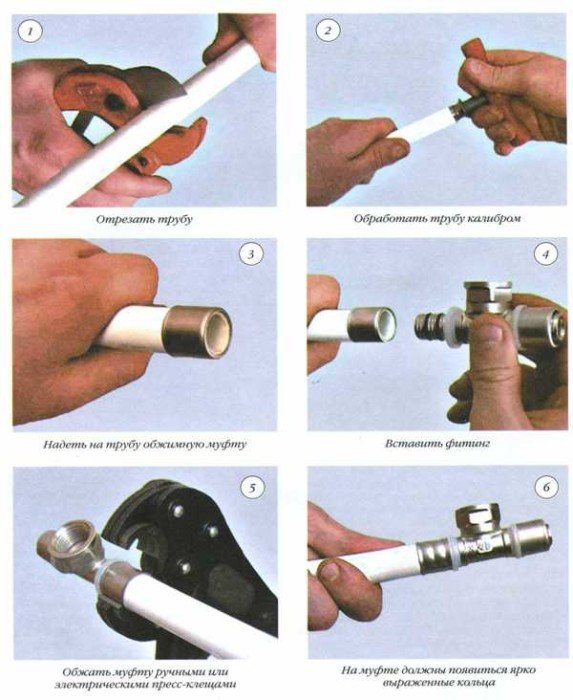

Heating system installation

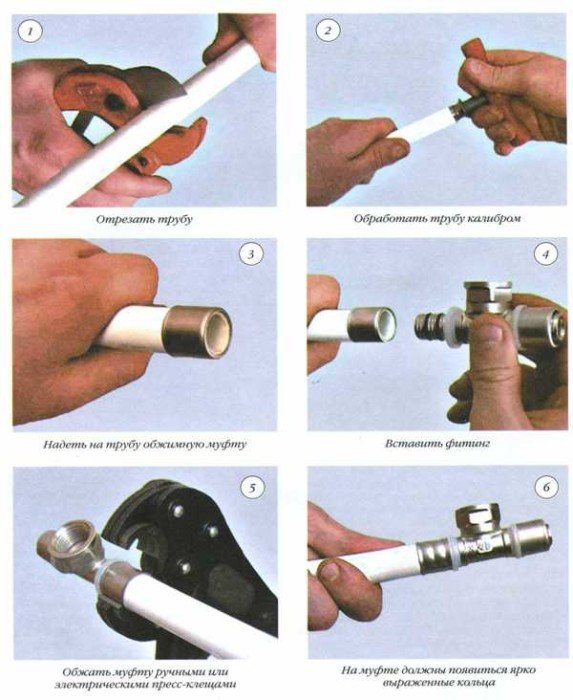

Do-it-yourself installation and routing of metal-plastic pipes does not require much effort and special tools. But still, it is worth immediately preparing a calibration device, an adjustable wrench and a knife.

Due to the high elasticity of polymer and aluminum, it is easy to bend the pipe with improvised means, but if you wish, you can use a special tool.

Requirements for fasteners

After drawing up a plan for the location of pipelines, their installation can go in any convenient sequence. Pipe fittings should be placed no further than 50 cm from each other, otherwise sagging and flow disturbances may occur during operation.

Improving efficiency

To reduce heat loss and protect against freezing, you can place each pipe section in a corrugation that retains heat. As a result, heating efficiency is increased by 10 - 20%. But it is not worth installing part of the system on the street, because the material may not withstand significant temperature changes.

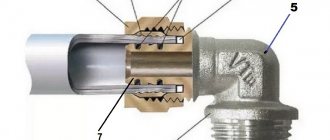

Connecting elements

The piping system is connected through special brass or metal fittings. They easily form the required joint. The simplest installation is considered to be where threaded compression fittings are used. Fastening and sealing is carried out with a nut together with a compression ring on the outside and compression rings on the inside.

What pipes to install for water supply?

Usually, for the device of the plumbing system, metal, plastic and metal-plastic pipes are used.

Internal plumbing is a wiring through which water flows to plumbing and other equipment in the house. For each type of pipe product, there is a value for the maximum water pressure that they can withstand. For example, in a house with a central water supply, the pressure is from 2.5 to 7.5 bar, and sometimes it can rise to 10 bar. To prevent the pipeline from bursting, it is necessary to focus on maximum performance.

When choosing water pipes for installation inside a house or apartment, it is necessary to take into account not only the maximum pressure, but also the temperature of the water. Copper, brass, bronze, steel pipes withstand high pressure - there are no restrictions when using them for water supply.

A metal-plastic plumbing is perhaps the best option for a private house. They do not corrode, do not sag under their own weight, and will last almost 30 years. Withstanding temperatures up to + 95 ° С at a pressure of 10 atmospheres, the structure does not deform with a short-term jump in temperature up to + 110 ° С and constant pressure.

The choice of diameter when installing heating

Most often, among the proposals, you can find pipes made of metal-plastic, for which the outer diameter varies from 16 to 63 millimeters. The wall thickness can be varied from 2 to 3.5 mm. Which pipes are best to use depends on the maximum pressure.

When marking, two values are often used - the outer diameter with an indication of the wall thickness or the inner diameter.

If we consider the main options for execution, then all pipelines for a private house can be divided into several groups:

- the outer diameter of 16 and 20 mm is most often used as a drain when supplying hot water to faucets in the bathroom and in the kitchen;

- a cross-section of 26 and 32 mm along the outer circumference of the pipe can be used for installing a "warm" floor system and organizing heating distribution when working with low pressure flows;

- external diameters of 40 and 50 mm are perfect for creating the basis for individual water supply and heating systems in a private house.

Service life of plastic (polypropylene) pipes

Manufacturers of plastic pipes assure that such products can serve up to 50 years. However, polypropylene products have appeared relatively recently and the reliability of such statements has not yet been proven.

In order for the plastic structure to last as long as possible, certain operating conditions must be observed, the main ones in which are the pressure and temperature of the water. The higher the load and the hotter the water, the shorter the service life of the polypropylene products. Moreover, it should be remembered that the temperature of the liquid in plastic structures should not exceed 95 ° C, otherwise the product will begin to deform and will not last even one year.

When arranging external pipelines, it is necessary to take into account the destructive effect of direct sunlight, as a result of which the plastic becomes fragile and extremely sensitive to deformation and mechanical shock.

Production of modern pipes

Reinforced-plastic pipes consist of a two-layer molecular cross-linked polypropylene called PE-X. A thin aluminum backing is laid between it. All three layers are connected using a specially developed adhesive. Each manufacturer strives to use its own individual adhesive composition.

Aluminum gives the pipes strength, and thanks to propylene, such plumbing fixtures can be bent at an angle without much effort. The minimum thickness aluminum strip is made of two semicircular pieces. They are connected end-to-end or overlapped with each other. For reliable adhesion, welding is used using ultrasound. After such a procedure, layers of polypropylene with an adhesive are applied from the outside and inside.

Once securely coupled, the pipes must be marked and reeled for ease of transportation. It is in this form that they go to stores.

View gallery