Positive characteristics of PP pipes

Pipe products made from polypropylene have a number of advantages:

- long service life, which is at least 25 years;

- resistance to aggressive environmental influences;

- a wide range of connecting fittings and other accessories;

- absence of condensate and various deposits on the inner and outer surfaces;

- insignificant weight of products;

- resistance to corrosive processes;

- ease of installation work;

- sufficient strength;

- low noise level.

The maximum permissible operating temperature of a liquid moving through polypropylene pipelines is considered to be 90ᵒC (the limitation applies to products of brands 20 and 21). In the case of arranging a line for supplying cold liquid, the temperature of which most often does not exceed 20 degrees, pipes of grades 11 to 16 are laid.

The main features of installation work

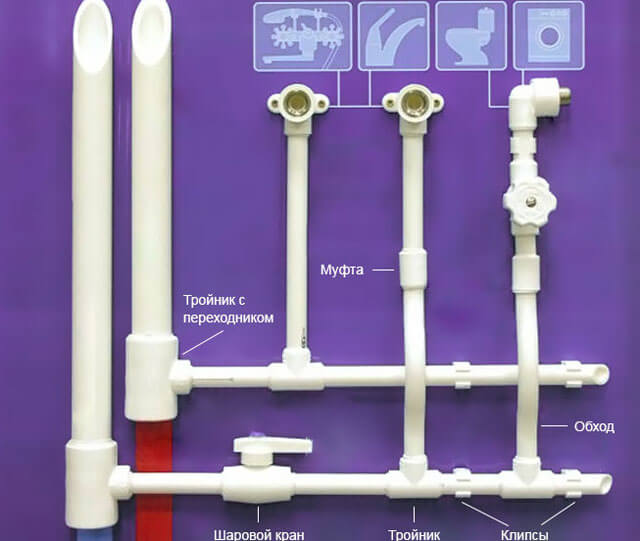

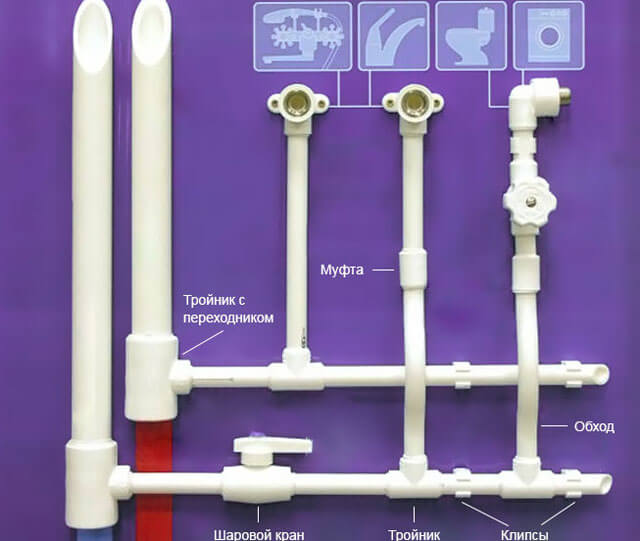

Polypropylene pipes are laid using fittings, both threaded and non-threaded. Products with thread are:

- detachable;

- one-piece.

The choice of the method of installation work is primarily influenced by the conditions in which the pipeline will be operated. All components made of polypropylene must be protected from fire.

When you need to embed a water meter or storage tank into the system, use split-type threaded products. In addition, the one-piece connection is used only when working with flexible hoses. It is forbidden to use dirty or deformed elements. It is also not allowed to self-thread.

If you have to connect flat sections or equip the transition of a pipeline segment to a diameter of a different size, use couplings. For turns, special elbows are used, and tees are used to create branches in the system. Bending of pipes is not allowed.

After all the necessary information has been studied, they proceed to the installation of polypropylene pipes, which is carried out in several stages (in more detail: "Types, properties, installation of propylene pipes with your own hands").

Heating system installation with steel pipes

Installation of a heating system with steel pipes can be done in the following ways:

- welding;

- twisting with threading.

From the technological point of view, the process of installing a heating system is very complex. Therefore, this kind of work should be entrusted to the masters.

Before installation, it is necessary to arrange risers and lay pipes. When choosing a welding method, self-shielded wire should be used. In some cases, electrodes up to 3 mm in diameter can be used. If the pipes are not galvanized, then the welding can be done with an overlap. The welding process is painstaking work, since the seams must be even without any pores or sagging. In the process of welding, pipes that are under pressure can cause difficulties. Therefore, welding must be carried out from the center at the lowest section of the pipe. When using an electrode, you need to position it perpendicular to the welding site. To make vertical seams, you need to change the position of the electrode. The method involving twisting with threading is equally effective. In this case, the pipes are connected using elbows, couplings and other elements.

Mainline project development

Always before starting the installation, a project of the future system is drawn up. Ergonomics is considered the main criterion - for this reason, it is necessary that the number of turns of pipelines and connecting elements in the line be minimized.

If you plan to arrange a heat supply system, it is important to correctly draw up a project in which the location of the following elements should be accurately indicated:

- heating equipment;

- fasteners;

- various adapters and couplings;

- corners.

The heat supply line is connected to the batteries from the side or bottom in one of two ways - one-pipe or two-pipe.

When developing a project, it is necessary to take into account the likelihood of thermal expansion of the pipe material, which in this case is polypropylene.

If necessary, the laying of water distribution, the pipeline is connected to centralized communications. When designing a water supply, it is taken into account that such plumbing fixtures as toilets, heating units, sinks, etc. are to be connected.

In practice, one of two ways of arranging the wiring is used:

- Open option... Pipes installed horizontally are placed above the level of the floor covering, and vertical products - only in the corners. Thanks to this installation, it is possible to make the pipeline less visible.

- Closed option... This installation method is difficult to implement, since it will require preliminary accurate calculations. Pipes embedded in walls must be solid, and unhindered access must be provided to each joint.

The distribution of the water supply network is of three types:

- consistent. This budget approach is easy to implement;

- collector - water supply is organized using special equipment - collector;

- with pass-through sockets - it is rarely used.

Welding PP pipes

To start this stage, you must have at your disposal an electric jigsaw for cutting polyethylene and equipment designed for welding.

Before starting work on the device, you need to put on nozzles (sleeves) of a certain diameter. Then, using the thermostat, set the desired temperature, which should be about 260 - 265 degrees, and wait until the device warms up. There is a step-by-step instruction from the manufacturer of the welding equipment that describes in detail all the nuances, including the warm-up time.

Soldering and installation of heating pipelines

Before starting installation work, the design of the distribution of heating pipes in the house is carried out, which should be done exclusively by a professional, since the further operation of the heating depends on this.

Polyethylene and PVC pipes are fixed using electrofusion soldering or compression joints, they can be glued with special glue with PVC fittings.

Reinforced-plastic pipes are connected using fittings using a wrench.

Polypropylene is connected without the use of couplings and fittings with a soldering iron.

How to make a welding machine yourself

Since a good welding device is not cheap, it would be better to rent it or make it yourself.

When the choice is made in favor of the second option, then you need to prepare in advance:

- electric drill;

- nozzle (sleeve) of the required diameter;

- outdated iron;

- washer and bolt for it;

- thermal paste for computers.

The sequence of actions will be as follows:

- To increase the degree of heat transfer, the sole of the old iron is treated with paste, after which you need to fix the Teflon sleeve. Its position is determined in advance - they have a wide part towards the bottom or towards the top.

- They cut the nose off the iron so that it is more convenient to work with it in the immediate vicinity of the walls.

- Heat the ironing unit until it switches off again.

- The presence of a thermal sensor at the iron allows you to more accurately determine to what temperature the unit has heated up. There is also an easier method to find out the degree of heating of the device using lead. The fact is that this metal begins to melt at 230 degrees, which almost coincides with the temperature required to perform welding.

The subsequent steps for soldering are similar to the assembly described above.

Installation of a polypropylene pipeline

To create a highway, you will need:

- PP pipes;

- plastic clamps;

- threaded fittings;

- couplings and tees;

- detachable connecting elements;

- bends and adapters;

- ball valves; stubs.

First, the main elements of the system are installed, which include plumbing fixtures, radiators, heating units, etc. On the basis of the project, the places for laying the highway are marked. Installation of polypropylene pipes is carried out using couplings. If necessary, collect hard-to-reach sections of the highway - this is done separately.

When laying communications for the construction of heat supply or hot water supply, the coefficient of thermal expansion is taken into account. In order to compensate for it, it is recommended to use movable type fittings.

When the installation of PP pipes for laying a closed pipeline is carried out, the walls are first grooved, for which a groove is made in certain places, the width of which is equal to two pipe diameters. It is possible to fill the line with liquid only one hour after the completion of installation work, and hydraulic tests are carried out after a day.

Low pressure polyethylene or PVC

The water temperature in such pipes should not exceed 60 ° C. Pipes made of such material find their main application in the laying of sewage systems, while they cannot be used without insulation materials, since at low temperatures they lose their mechanical strength.

Reinforced plastic

Excellent characteristics (maximum water temperature 95 ° C) allow these plastic pipes to be used for heating with constant pressure. Such pipes are often used when installing underfloor heating.

Polypropylene

This type of pipes can be used both as heating pipes and in the water supply system. In this case, the system can be defrosted and the pipe itself weighs 9 times lighter than steel.

The water supply system made of polypropylene pipes allows you to keep hot water with a temperature of 95 ° C and easily tolerates pressure fluctuations. The cost of installing heating pipes in a private house made of polypropylene is usually low.

Arrangement of a sewerage system made of polypropylene pipes

When creating a sewage system, sewer PP pipes are often used. The process of laying them has features that should be taken into account.

A careful study of the rules and instructions for installing polypropylene pipes will help to equip a sewer system in your own home with your own hands:

- The pipeline is laid under a slight, approximately 3 cm, slope towards the location of the drain.

- When the pipes are in a cold room, they should be additionally insulated with mineral wool.

- It is not allowed to make sharp turns of communications, or rather, at right angles. Instead of them, half-taps are used.

- An obligatory element of the sewage system is a fan ventilation structure, which prevents the penetration of unpleasant odors into the premises.

- The toilet must be connected after installing the sink, otherwise the breakdown of the water seal cannot be avoided.

The external sewage line is laid in a certain sequence, taking into account some of the nuances:

- The diameter of PP pipes is determined, which depends on the number of people who live in the household.

- From the sewer runoff, they dig a trench in the direction of a septic tank or a cesspool, observing a slope, the size of which depends on the depth of soil freezing, or the pipeline is insulated.

- A sandy "pillow" is laid on the bottom, its minimum thickness should be 20 centimeters.

- A pipeline is laid, preventing sagging of its sections - otherwise, the joints will soon collapse.

During the installation of the system, the seams do not need to be sealed, since there are rubber seals in the polypropylene pipes for outdoor installation.

Self-installation of the sewer main will help significantly save money, but only on condition that it is correctly executed.

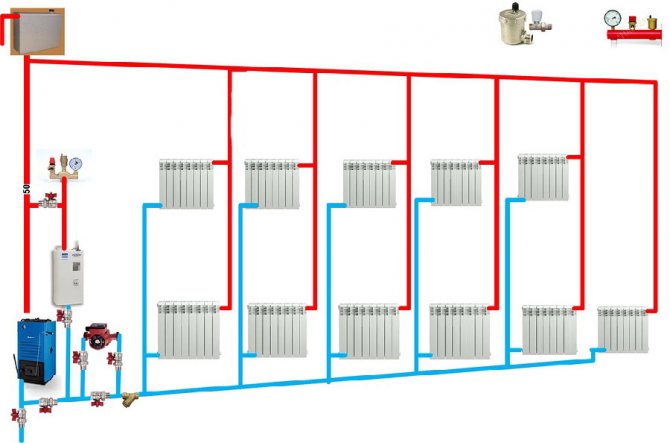

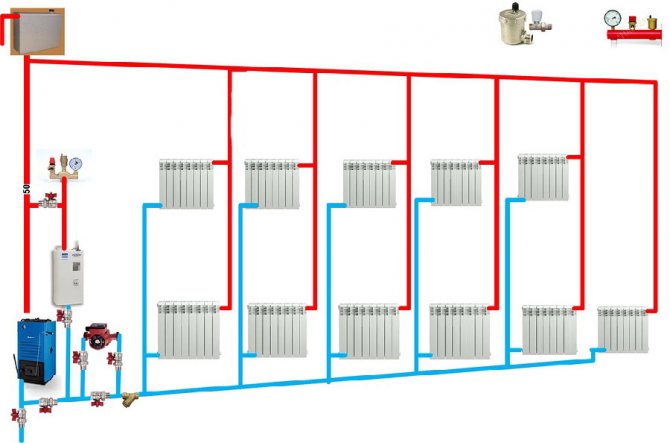

Types of wiring

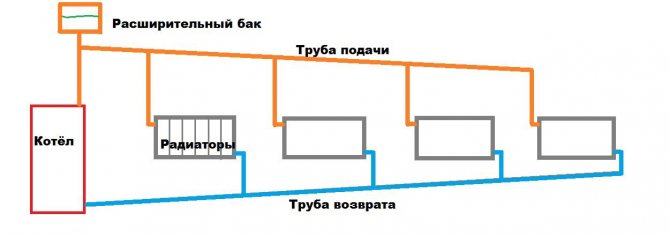

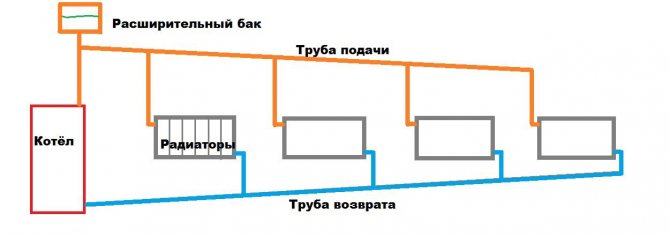

After choosing the pipe material, it is necessary to think over the wiring diagram of the heating system. Depending on the area of the heated premises, the layout of the building, the type of coolant and the energy source, the engineer must select one or another pipe layout. Experts distinguish between several ways to install pipes in the house.

We recommend that you familiarize yourself with: How to hide the ventilation pipe from the hood in the kitchen?

Top water filling system (gravity)

In such a system, the heating boiler is located at the lowest point of the object, and the circulation of water is based on natural physical laws (expansion during heating, contraction during cooling). As it heats up, the water increases in volume and flows from the boiler through the pipes upward, filling the risers and heating radiators. Circulating in a closed loop, the cooled liquid returns to the boiler, where it heats up again.

The top water filling system is the simplest and most economical in terms of installation and operation. The advantages of this layout include:

- independence from electricity;

- no need to install a circulation pump.

Overhead water distribution system is suitable for a relatively small area of heated premises. The disadvantages of a gravity system include low efficiency and the need to increase the power of boiler equipment. In top filling systems, abnormal situations often occur - airing, boiling water - which further reduces the efficiency of heating. When operating the system in rooms farther from the boiler, the temperature of the riser and radiators is usually lower than in other areas.

Bottom water filling system (forced)

In such systems, the circulation of the coolant is carried out due to the operation of a special pump, which is installed at the outlet of the collector connected to the boiler. Thanks to the circulation pump, the performance of the system is significantly higher compared to gravity heating. Other advantages of this type of wiring are the ability to use thinner plastic pipes and install the pipeline under the floor.

The only downside to bottom wiring is the dependence on electricity. In the event of an unscheduled power outage in the house, the circulation pump stops and the system stops functioning.

There is another classification of heating system wiring:

- one-pipe - the installation of the riser is carried out on the basis of one pipe, which leaves the boiler and is connected to one radiator, and from it to the next, and so on;

- tee - several radiators are connected to a common riser;

- collector - based on the supply and return pipelines, which are connected to the collectors, and radiators are connected to them using separate pipes.

Important! One-pipe wiring is suitable for small (up to 150 m2) residential buildings. Collector wiring is most often installed in residential buildings and cottages on two or more floors with several rooms, a kitchen, a bathroom, and technical rooms.

Before planning the installation of heating pipes, you must also take care of the purchase of small engineering equipment.It includes all kinds of valves and plugs, steam traps, control and metering devices (manometers, thermometers).

We recommend that you familiarize yourself with: How and how to make a hole in a pipe made of different materials