Features of expanded polystyrene

Modern expanded polystyrene is a cheap material that is widely used both in country houses and city apartments. It is made by thermal swelling of polystyrene granules. As a result, the granules are sintered, forming a white material.

Section of the floor insulated with expanded polystyrene

Each of the expanded polystyrene granules consists of many microscopic cells with air. This can explain the extraordinary lightness of the material, because 97% of its composition is air voids.

Main varieties

Modern expanded polystyrene is represented by the widest range of brands that differ in thickness and performance properties. However, they are grouped into five groups:

- non-pressed expanded polystyrene (in particular, PSB-S, ЕРS, etc.);

- autoclave (Stirofoam);

- extruded (Penoplex, XPS, etc.);

- extruded autoclave;

- pressed (PS (from 1 to 4), other foreign brands).

Expanded polystyrene of the PSB-S-35 brand.

If you need to insulate the floor on the first floor of the house, then it is better to use the material of the PSB-S-35 brand. Such boards are characterized by low thermal conductivity (0.4 W / m²) and moisture absorption (maximum 2%).

With a heavy load, it is recommended to opt for the PSB-S-50 brand. This is the ideal solution for garage and other utility buildings.

Video - Production of extruded polystyrene foam

Material advantages

- Low thermal expansion + low thermal conductivity. Due to this, 10 cm of expanded polystyrene is comparable in properties to 40 cm of wood and 2 m of bricks.

- Environmental friendliness - the material does not harm health at all.

- The material is durable.

- Styrofoam has excellent sound insulation properties.

- It is also very durable, capable of withstanding significant loads.

- Its structure does not change with temperature changes.

- The material is resistant to moisture, that is, it does not swell or dissolve in it.

- It is resistant to aggressive environments of chemical and biological nature - to soap, bleach, salt solutions, bacteria, etc.

That is why expanded polystyrene is the best option for thermal insulation of the floor. The only negative is that it dissolves under the influence of organic resins.

Note! Recently, they began to produce slabs of different colors - green, red, blue. But this does not affect the properties and even more the cost of the material.

Description and features of floor insulation in a wooden house with penoplex

Penoplex is a collective name for a heat-insulating material. In general, strictly speaking, Penoplex is the name of a company that produces construction and finishing materials - by the way, ours, Russian. Thanks to the popularity of their extruded polystyrene foam, this material, even from other manufacturers, is now called penoplex.

Penoplex is made from the same raw materials as the familiar white foam. By the way, the latter can also be used for insulation. However, if the foam is always white, then the penoplex can be gray, red, and even colored. Penoplex took all its advantages from the foam, leaving the disadvantages.

Extruded polystyrene foam is produced by foaming the raw material. As a result of this processing, the output is a light but hard material, penetrated by many tiny air bubbles.Thanks to this air gap, the material has really high thermal insulation performance.

In addition to insulating the floor in a wooden house, penoplex can be successfully used for thermal insulation of ceilings, attics, interfloor ceilings, walls.

You will learn about the technology of insulating a wooden house outside with mineral wool for siding here.

Advantages of polystyrene foam material, comparison with foam

Let's find out what are the advantages of floor insulation in a wooden house with penoplex.

This insulation provides reliable protection of the room from the cold. The material has really high and reliable thermal insulation performance. In addition to the fact that the material retains heat well in the house, it also has high sound insulating properties.

Compared to polystyrene foam, penoplex is more durable. Many people know how easy it is to break a fragile foam sheet. This will not happen with modern penoplex.

Due to the fact that it is a solid material, it will not sag over time, exposing areas of the floor. By the way, a similar incident often happens when insulating with soft materials, for example, mineral wool. Penoplex is resistant to deformation, easily resists compression.

In addition, you may be interested in material about the features of the insulation of a log house from the outside.

Penoplex is resistant to moisture. This is a really important nuance, since the house can be located in a swampy area or on a flooded area. Mineral wool, for example, will not withstand moisture.

Penoplex is convenient and easy to install. No need to wear respirators or protective clothing. Slabs of this material are light, if necessary, you can achieve the desired size by simply cutting the slab with a knife. Penoplex easily "stands" on the glue, while fixing securely.

Penoplex is not gnawed by mice, bugs and other insects do not start in it. For an environmentally friendly wooden house, such a problem sometimes becomes a direct threat to the preservation of heat and the integrity of surfaces. For example, mice are very fond of settling in soft mineral wool. But with penoplex this, fortunately, will not happen.

We also advise you to familiarize yourself with the features of the house insulation from the outside from a bar 150x150 at this link.

Due to its artificial origin and insensitivity to moisture, penoplex does not rot at all, does not deteriorate or decompose. The material is environmentally friendly, completely safe for those living in the house.

The safety of this insulation is also manifested in the fact that the penoplex does not emit any toxic substances. When working, it, unlike mineral wool, does not "get dusty", does not cause allergic reactions. In addition, the extruded polystyrene foam is odorless.

It will also be interesting to read about the insulation of the house from the outside from foam blocks.

Penoplex is of different types. You can choose a non-combustible variety, which is important for a wooden house.

Penoplex insulation characteristics.

The material is laid in a rather thin layer, but due to its high heat-insulating characteristics and density, this is quite enough. Therefore, penoplex can also be considered a rather economical type of insulation.

If you correctly carry out the installation and choose a high-quality penoplex from a trusted manufacturer, the material can serve for a very long time without any loss of its technical characteristics. With careful operation, manufacturers guarantee uninterrupted service of the penoplex for at least 55 years.

How and how to insulate a brick house from the outside, this article will tell you.

Minuses

For balance, it is necessary to find out the disadvantages of floor insulation with the help of penoplex.

The material has a fairly high price. This stops some homeowners. However, we must not forget that styling foam does not require a thick layer.

The material is completely artificial. But thanks to this, mice and bugs do not start in the penoplex. So it is quite possible to consider this disadvantage as an advantage.

Penoplex does not withstand too high temperatures, while deforming. But these temperatures are from plus 80 degrees on the one hand and minus 90 degrees on the other. Such changes are rarely found in life, therefore, we can say that this drawback does not greatly affect the quality characteristics of the material.

The material does not tolerate strong mechanical stress. Do not forget that, in fact, these are balloons inflated with air or gas, so the penoplex is quite fragile. Do not jump or run on a laid surface that has not yet been protected by a floor covering.

Summary: compared to the list of pluses, the material flaws look completely invisible, so you can safely go to buy this high-quality and durable insulation.

Fire safety. Modified and unmodified polystyrene foam

Untreated material is highly flammable from a lit match or sparks from a welding machine. At the same time, it cannot catch fire from a cigarette or a red-hot metal object.

Modified polystyrene foam (self-extinguishing)

Expanded polystyrene can ignite at temperatures from 200 ° C to 450 ° C, in this case it all depends on the additives used in the production.

Note! The ignition temperature must be indicated in the certificate supplied with the plates.

If ordinary unmodified polystyrene foam is burning, then the temperature around it can exceed 1200 ° C (although not for long). During combustion, toxic substances such as cyano- and hydrogen bromide, phosgene are released. If special additives were used, then the combustion temperature is reduced to that which is normalized for each specific grade of material.

In the manufacture of modified polystyrene foam, fire retardants (substances that prevent combustion) are used. In this case, the material is already considered self-extinguishing and is designated by the letter "C" at the end of the abbreviation (for example, PSB-S).

There is another way to reduce the flammability - when the granules swell, the flammable inert gas is replaced by non-flammable carbon dioxide.

Floor insulation with expanded polystyrene

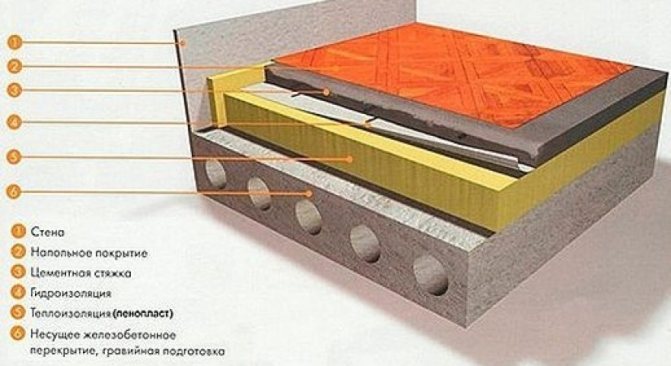

There are several floor insulation technologies that differ in the material of the topcoat:

- insulation on the ground;

- wood insulation;

- insulation of the concrete floor.

But it is worth noting that the installation procedure for floor insulation is the same for all coatings. There are, of course, some nuances, but we will get acquainted with them a little later.

Sequence of work

Below is the technology of insulation under the screed, but it is almost completely applicable for other methods.

Floor insulated under screed

Step one. Prepare the base. If there is no concrete or wood, then preparation consists in compacting the earth and preliminary (or rough) leveling of its surface.

Step two. Fill in a 10-centimeter cushion of rubble, tamp and flatten it too.

Step three. Fill in the next layer of fine grained sand to hide the sharp edges of the rubble and fill the voids in it.

Step four. Lay the polystyrene foam plates with an overlap (modern products allow you to do this - the end parts in them have special cutouts).

Laying slabs on a prepared pillow

Step five. Lay the waterproofing membrane, also overlapping. Seal the joints with assembly tape.

Step six. Next, install a reinforcing mesh to give strength to the future structure and evenly distribute the loads (instead of a mesh, you can install wooden logs, but more on that later).

Step seven. Pour the concrete screed. The concrete layer must be at least 5 cm to withstand the loads.

Step eight.The final part of the work. After the concrete has dried, finish its surface, lay additional materials as desired (parquet, linoleum, etc.).

Note! Leave a two-centimeter technical gap between the walls and the floor along the entire perimeter of contact (for waterproofing or possible thermal expansion). Fill the gap with polyethylene foam.

Video - Expanded polystyrene

Floor insulation technology with expanded polystyrene

How to insulate the floor with expanded polystyrene

Almost everyone who lives on the ground floor is familiar with the feeling of an ice floor when the heating system is operating at full capacity. In this case, the optimal solution would be a "warm floor", which, in addition to a feeling of comfort, will avoid heat loss. 20% of the total heat loss is due to losses through the floor, the design of which is not made correctly. But only heating the floor surface will not completely solve the problem - the heating area is larger, but the heat evaporates somewhere. To achieve the desired result, the insulation material must have not only low thermal conductivity and hygroscopicity, as well as withstand heavy loads, but also have an adequate price. Currently, floor insulation with expanded polystyrene is a reliable and easy way to save heat both in a city apartment and in a private house.

Content Styrofoam - what is it?

For the first time, expanded polystyrene in the USSR for construction purposes was produced by the Stroyplastmass plant in Mytishchi. Since then, the technology for the production of polystyrene foam has developed and improved.

The raw materials for obtaining this material are styrene granules and its derivatives, which are filled with a gas dissolved in the polymer. After that, with the help of steam, the mass is heated, in the process the volume of the granules increases more than 50 times until they occupy the entire space of the block-form and stick together.

According to the production method, this material can be divided into two groups. The first is produced by technology sintering under the influence of high temperature of the expanded polystyrene foam balls in the form. In the second method, the blowing agent and granules at elevated temperatures mingle... and then the resulting mass is forced through an extruder orifice.

Expanded polystyrene has various physical and mechanical properties and is subdivided into:

- expanded polystyrene, PS grade... made from polystyrene granules by pressing them. This type has high strength characteristics due to the tight adhesion of granules, but its production is quite expensive. Therefore, this type is currently used only for military needs.

- suspension pressless polystyrene grade PSB due to the lower cost, it has become more widespread. The quality of this material is very easy to check: on the fracture of the plate, well-adhered balls of the same size are clearly visible. A fracture can pass, so to speak, "living". Low-quality balls of various sizes and the break occurs only in the places of their contact. Plates PSB produced density 15-50 kg / m3... which is reflected in its strength properties and determines the field of application. For example, expanded polystyrene with a density of 15 kg / m3 is used as packaging for household appliances, and a denser one for insulating facades.

- suspension pressless self-extinguishing expanded polystyrene grade PSB-S is an improved modification of the previous type. The advantage of this modification lies in the absolute incombustibility, which is achieved by introducing fire-fighting additives into the raw materials - fire retardants.

- extruded or extruded polystyrene foam grade EPS belongs to the best type of polystyrene foam, which is due to the production technology, which makes it possible to obtain a dense, absolutely waterproof material with high resistance to mechanical stress at the output. This species fully meets the requirements of fire safety.

High-quality expanded polystyrene of the PSB and PSB-S brands will serve up to 40 years old, without changing its qualities at all, extruded polystyrene foam can be operated practically unchanged for 80 years.

Characteristics of expanded polystyrene as insulation

Regardless of the brand, expanded polystyrene has the following characteristics :

- low thermal conductivity and thermal expansion. For comparison, 12 cm of expanded polystyrene gives the same effect as 45 cm of wood or 200 cm of brickwork;

- high rate soundproofing ;

- durability ;

- long-term operation without loss of properties, both at high or low temperatures, and with a sharp drop;

- since the basis of the material is plastic, polystyrene foam is completely not hygroscopic... that is, it is not exposed to steam or moisture, does not swell or dissolve in water. Therefore, it prevents the penetration of moisture into the room;

- steady to biological and chemical effects;

- expanded polystyrene is well combined with water and electrical equipment of the "warm floor" system;

- ease of installation. Expanded polystyrene plates are easy to cut, which allows you to insulate the floor of any configuration;

- low cost.

Recently, the building materials market has been filled with expanded polystyrene plates of various colors, which does not affect either the quality or the characteristics, but only indicates the belonging of this type of product to a certain brand. Also produced are polystyrene foam plates with milled edges, which allows you to lay the plates according to the scheme "Thorn-groove".

Floor insulation with expanded polystyrene

As a heater for the floor with the laying of foam plates between the logs, the brand is quite suitable PSB-S with a density of 15 kg / m3... since the main part of the load will fall on the lags. It should be borne in mind that to insulate the first floor, the minimum layer of insulation should be at least 10 cm, for interfloor floors - 5 cm.Gaps between expanded polystyrene plates and logs, as well as along the perimeter along the walls, are necessary for thermal expansion of the material. They are filled with polyurethane foam or fiberglass.

The density of polystyrene foam for insulation of a concrete floor must be equal to or higher than 35 kg / m3, for example, PSB-S 35. Before insulating the floor, a screed is made. Then a waterproofing film, foam plastic (foam) plates are laid and a reinforcing mesh is placed on the solution layer. Next, a finishing screed with a thickness of 5-8 cm is performed and the technological gaps are filled with fiberglass or foam around the perimeter. After that, the floor covering is laid.

Arrangement of floors on the ground differs from floor insulation on a rough concrete base additional soil preparation:

- soil by mechanical action rammed... thus, the surface is leveled;

- crushed stone is filled... the layer thickness of which is 10 cm, it is also leveled and compacted;

- filled with small-fraction river, quarry or sea sand... to fill the voids between the crushed stone particles;

- fits insulation .

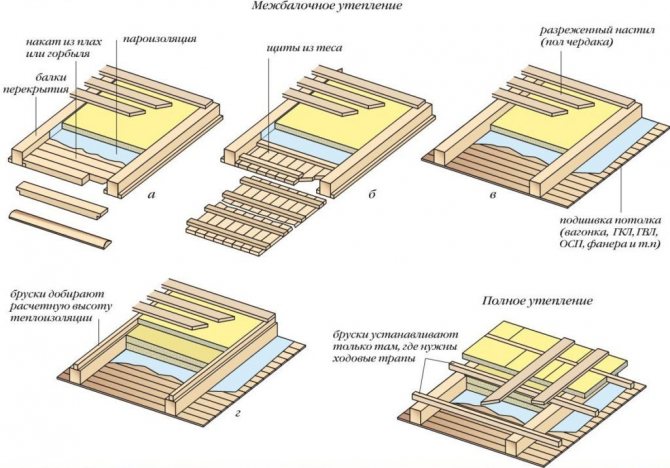

In the event that floor insulation is carried out in the attic or attic, instead of hydro-fit vapor barrier layer. This is due to the fact that the floor of the attic or attic is at the same time the ceiling of the rooms on the upper floor. The insulation is laid on a vapor barrier material and covered on top with exactly the same layer of material. Next, either a crate for the subfloor is made, or a concrete screed, on top of which the floor covering is mounted.

Insulation of the floor with expanded polystyrene allows not only to save heat, but also increase the sound insulation of the room. It should also be noted that the use of this material as a heater can significantly reduce the load on the building structure. At the same time, a person who has no experience in construction or decoration can cope with floor insulation.

Video of floor insulation with expanded polystyrene How to properly insulate the floor with expanded polystyrene?

A modern house is a structure that has rather stringent thermal protection requirements. A large number of highly efficient thermal insulation materials are now on the market. They allow you to provide a comfortable temperature and humidity conditions in the premises. The most effective and reliable way to increase heat-shielding characteristics will be floor insulation with expanded polystyrene.

The need for thermal protection and requirements for insulation

If a person is told that something needs to be done, he has every right to know why it is needed. If the house has insufficient thermal insulation of structures, serious problems arise during operation.

Insulation performs the following functions:

- prevention of freezing of the floor of the first floor and the penetration of cold into the premises;

- protection against the appearance of condensation, which leads to the formation of mold, mildew and rotting of the structures of a wooden house;

- the house will require less heating costs during the cold season;

- improving sound insulation characteristics.

The following requirements are imposed on the insulation used in the floor cake:

- good strength characteristics;

- resistance to moisture;

- not susceptible to decay and mold;

- safety for humans;

- incombustibility;

- ease of installation.

All these requirements are met by extruded polystyrene foam, which can be used to insulate structures of concrete, wood, brick and frame buildings.

What is expanded polystyrene

Expanded polystyrene consists of gas-filled styrene granules. Air is the most effective insulation, therefore, a large number of cavities allows the material to have good heat-shielding performance. Currently, two types of polystyrene foam are widely used in construction: foam plastic and extruded material. The second is preferred for use.

These two materials look similar in appearance, but differ in their characteristics and manufacturing method. Polyfoam is produced from expanded polystyrene balls by sintering. In the production of extruded polystyrene foam, the granules are mixed with a foamed reagent and forced through an extruder.

What's better? Styrofoam or extruded polystyrene foam?

Option 1. Styrofoam

Option 2. Extruded polystyrene foam

Polyfoam in comparison with extruded material has only one advantage: low cost.

If the house is being built without strong financial constraints, it is better to choose the second option.

If we carry out a comparative analysis, then we can come to the following conclusions:

- extruded polystyrene foam has high strength and works better in floor construction;

- foam is characterized by a higher water absorption (approximately two times);

- in the presence of moisture and exposure to low temperatures, the foam can crumble into separate balls;

- polystyrene refers to medium and low-combustible materials and, when exposed to high temperatures, emits substances hazardous to humans;

- extruded polystyrene foam, thanks to special additives, becomes resistant to fire.

For insulation of the floor of a wooden house, it is better suited extruded polystyrene foam... To reduce construction costs, floor insulation with polystyrene foam of two types can be applied at the same time.The lower thicker layer of greater thickness is made of foam, and the upper one is made of a more durable material with a thickness of 3-5 cm. This method allows you to achieve a compromise between price and quality.

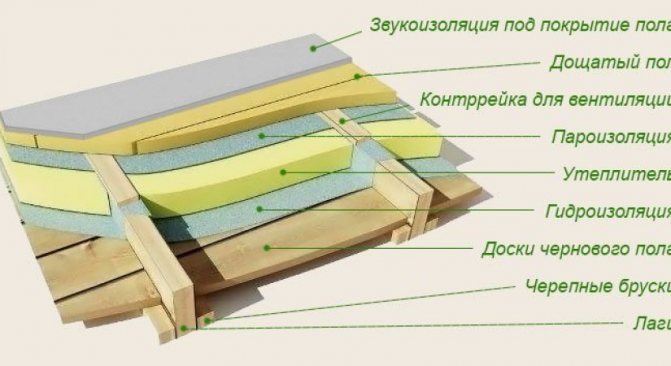

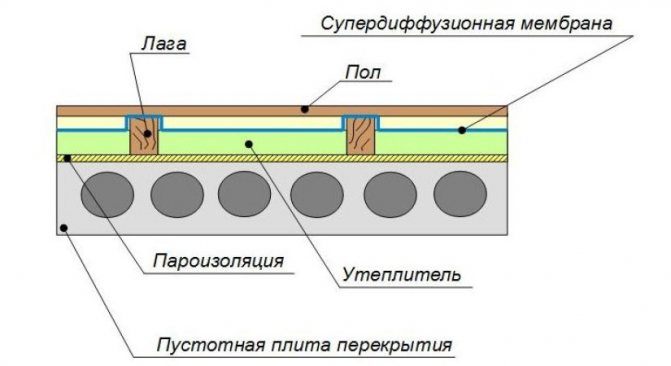

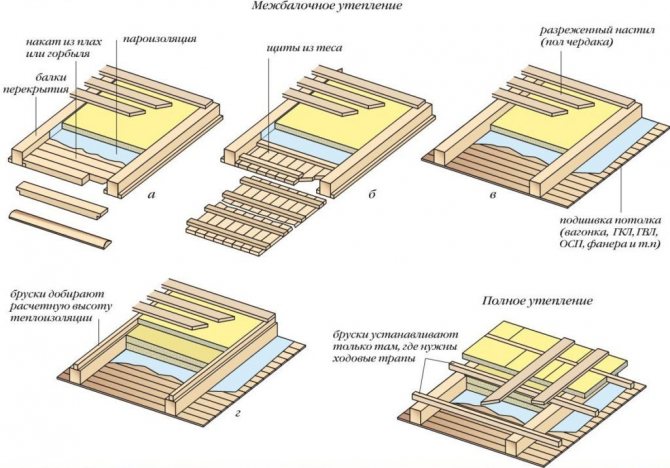

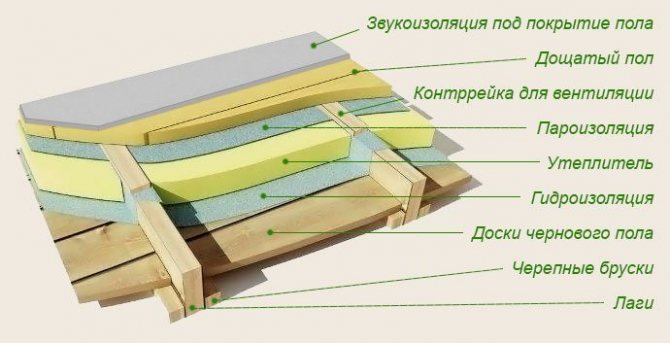

Wooden house overlap pie

Depending on the strength, the material can be laid in two ways: without logs and with their help. In the first case, the weight of the entire structure of the clean floor falls on the insulation, therefore, a cement-sand screed is performed on top of it. Earlier, we have already examined in detail the technology of floor insulation under the screed. Most often, this method is used for floors of brick and concrete buildings.

For a wooden house, insulation is carried out between wooden logs. It is important to take into account the location of the insulation in the building - the thermal protection of the attic floor differs from the insulation of the floor over a cold basement or underground.

Please note that the process of floor insulation in a house on screw piles is slightly different from the above method.

In the first case, the layers are stacked in the following order:

- wooden floor;

- vapor barrier;

- insulation.

- wooden floor;

- waterproofing;

- insulation;

- vapor barrier.

- Features of work

- Advantages and disadvantages

- Insulation technology The choice of expanded polystyrene

- Selection of glue

- Warming on the ground

- Insulation on a concrete base

- Thermal insulation of a floor with logs

When used in construction ground floor floor the stacking order is as follows:

When using extruded polystyrene foam, the vapor barrier does not need to be installed.

For polystyrene, it is important to remember that protection from steam is located on the side of warm air, and protection against moisture is on the side of cold air. Only in this case the house will be reliably protected from the penetration of cold air. As a vapor barrier and waterproofing, you can use ordinary durable plastic wrap.

Installation process

Depending on the method of installation, the work can be carried out in different ways.

The minimum layer of insulation depends on the climate in which the house is located, but on average it is 10 cm.

Laying insulation without lag (under the screed)

The working process begins with cleaning the base from dirt and dust. Further, if necessary, perform alignment. After preparing the base, the plates are laid out, taking into account the gap for thermal expansion. These gaps are filled with fiberglass or polyurethane foam. With this method of installation, a cement-sand screed is performed on top of the insulation. For fragile foam, it must be additionally reinforced.

Laying between lags

The process starts with installation lag... the step of which is selected depending on the size of the insulation plates.

This method does not require high strength, so you can safely use foam.

Between the lags, depending on the structure to be protected, places vapor barrier or waterproofing... Plates are mounted, as in the previous case, with a small gap. After the installation of the insulation, they begin to erect the structure clean floor .

The floor pie arrangements are given in this article above ↑.

Thermal insulation of the floor with expanded polystyrene can significantly reduce the load on the building structure. This is especially important if the house is being built on unstable soils with poor characteristics, since it allows you not to overload the foundations.

If you follow all the rules for laying polystyrene foam, then it is able to protect the house from the cold for 40-50 years. The correct choice of materials and quality control of the production of work allows you to reduce the cost of operating and repairing a home.

This video clearly tells about the insulation by this method:

Floor insulation with expanded polystyrene

Insulation of the floor with expanded polystyrene Variants of using expanded polystyrene for insulating floors of different types, the advantages and disadvantages of this method of thermal insulation, the choice of consumables.

The content of the article:

Thermal insulation of the floor with expanded polystyrene is an affordable and simple option for keeping heat indoors at any stage of building construction. The use of this material brings other benefits: it absorbs noise on interfloor ceilings and serves as a good vapor barrier. Where insulation is used and how to install it, we'll talk in this article.

Features of work on floor insulation with expanded polystyrene

Extruded polystyrene foam is a granular heat insulator obtained from polystyrene and styrene copolymers with the addition of natural or carbon dioxide. It is made by extrusion from an extruder, hence the name. The result is a high-quality porous substance with a uniform distribution of cells, the dimensions of which do not exceed 0.1-0.2 mm.

The material is marked with XPS and other letter and number designations, each manufacturer has its own. For example, Styrofoam extruded polystyrene foam is marked 1B-AXPS-EN13164-Tl-C5 (10 / y) 250DS (TH) -TR100. In encrypted form, there is information about thickness, density, weight and other important characteristics.

Due to the increased resistance to steam movement, the product is used in such cases:

- For insulation of a concrete floor above a high basement, for which it is mounted to floor slabs from the outside. In high humidity conditions, the coating will serve as additional waterproofing.

Advantages and disadvantages of floor insulation with expanded polystyrene

The material has become popular due to its unique qualities that distinguish it from other types of sheet heat insulators:

- Insulation does not absorb ground water. Under the influence of moisture, it does not change its size and does not deform.

The negative properties include deformation of sheets at a temperature of + 80 + 90 degrees and the ability to ignite. Therefore, it is not used in fire hazardous areas. The product costs significantly more than other samples.

Technology of floor insulation with extruded polystyrene foam

Floor insulation with expanded polystyrene is carried out in two stages. First, there is a process of preparation for the main operations, during which the base is cleaned and leveled. At this stage, consumables are purchased - glue and other components of the insulating layer. Next, the heat insulator is laid in accordance with the selected installation technology, which depends on the type of flooring, the design of the "pie" and the requirements for it. Let's take a closer look at all the stages of installation work.

Features of the choice of expanded polystyrene

Expanded polystyrene for floor insulation

Before buying, it is necessary to determine the main characteristics of polystyrene foam for floor insulation in each case. These include the density and thickness of the material.

Features of the choice of expanded polystyrene, depending on its density:

It is recommended to calculate the thickness of expanded polystyrene foam for floor insulation according to SNiPs or, simplified, according to our recommendations:

Only high-quality insulation is capable of reliably insulating the warp. At home, it is difficult to check its characteristics, but a fake can be determined by indirect signs:

Rules for the selection of glue for expanded polystyrene

To create an insulating layer, you may need special adhesives such as Kliberit, Knauf, Ceresit on a polyurethane basis. They are sold dry, packaged in 25 kg bags. For cooking, it is enough to dilute them with water in the proportions indicated in the instructions.

Inexperienced users are advised to buy solutions with a long cure time, so that there is time to adjust the position of the sheets.

The insulation can be glued with universal means that do not contain gasoline, kerosene, formalin, acetone or toluene. They destroy expanded polystyrene.

The instructions for the tool always indicate its consumption per 1 m 2. but it is necessary to buy it with a margin on an uneven base.

More recently, Penosil iFix Go Montage foam in cylinders has appeared on the market, designed to fix the product to any surface. It is applied with a mounting gun.

Warming of floors with expanded polystyrene on the ground

For decks that are erected on a subgrade, thermal insulation with extruded polystyrene foam is essential.

The technology of floor insulation with polystyrene foam on the ground looks like this:

- Level the area under the base. If the soil is loose, compact it and let it sit for a month. During this time, the soil will shrink.

Warming of floors on the ground in the presence of lags is found in private houses that have already been in operation for a long time. In this case, the use of extruded insulation is justified if high-quality vapor barrier of the base is required.

The work is carried out as follows:

To quickly cut extruded polystyrene foam, you will need the following tools:

- Sharp clerical or wallpaper knife. It is in every home.

Floor insulation with expanded polystyrene on a concrete base

Extruded polystyrene sheets can be attached to the concrete base from the outside (eg from the cellar). This option has its advantages, since allows you to keep warm not only of the floor slabs, but also of the walls in contact with it. Also, the ceiling height in the room does not decrease.

The work on insulation of the floor from the basement side is carried out as follows:

- Clean the concrete slab and rinse with water.

Insulation on concrete from the inside of the room is used to protect floors in high-rise buildings with expanded polystyrene plates, including above basements.

The work is performed in the following sequence:

In the case of thermal insulation of attic and attic floors, the construction of the "pie" is somewhat different from that used on the middle floors. On the floor, not a waterproofing, but a vapor-permeable film is placed. This is due to the fact that the attic flooring serves as the ceiling of the upper floor, which must "breathe".

Put insulation on it and cover with the same vapor barrier. Sheets can be stacked in several layers with offset vertical joints. They can be glued with special solutions. Then you can fill in the screed or assemble the crate and nail the boards of the finished floor.

Thermal insulation of the floor with expanded polystyrene with lags

Thermal insulation of floors of a similar structure is performed in the following sequence:

- Clean and level the concrete base as previously described.

To protect concrete floors with extruded crumbs, you will need expanded polystyrene granules, which can be found in hardware stores. The solution is prepared in the following sequence: pour a little water into the concrete mixer and add dry cement, mix the mixture until a homogeneous consistency, add granules in a ratio of 1: 3, 1: 4 or with other values. The larger the insulator, the better it will hold heat, but the strength of the coating will deteriorate. It can crumble during operation. Fill the overlap with this solution.

How to insulate the floor with expanded polystyrene - watch the video:

The method of thermal insulation of the base with this sheet material is so effective and simple that it is deservedly considered the best of all possible options. The main thing when insulating the floor with polystyrene foam with your own hands is to follow the work technology exactly, since negligence can easily negate what has been done.

Similar news

- Epoxy Concrete Floor Paint Acrylic, rubber, epoxy and polyurethane concrete floor paint - which is better? Elakor polyurethane enamel ...

- Porcelain stoneware for laminate flooring What is better than porcelain stoneware or laminate? Step 12. Check again the quality of the tiles, if you find ...

- Thermal insulation of the floor with extruded polystyrene foam Thermal insulation of the floor with expanded polystyrene Thermal insulation of the floor with expanded polystyrene Variants of using expanded polystyrene for thermal insulation of floors of different types, advantages ...

- Installation of concrete floor screed Reinforced concrete floor screed Remove large bumps with an angle grinder. Thereafter…

Features of floor insulation in the loggia

Loggias differ in that the floor level in them is almost always lower than in the apartment. Therefore, in this case, insulation must also be carried out using wooden logs. Fill the steam-line membrane on the expanded polystyrene plates, and then mount the board covering.

Note! It is advisable to insulate the floor even before entering the apartment, while there is no furniture, or at the stage of building a house. And if you use extruded polystyrene foam, you can further improve sound insulation.

Why is floor insulation necessary?

The floor is the only surface in the house that cannot be avoided. Therefore, it is important to keep it at a comfortable temperature. Warm air heated by radiator heating batteries rises, and if the floor is not insulated enough, it is unpleasant to walk on it.

When using a floor heating system, insulation is also necessary. In its absence, the coolant will not give energy rationally, heating not only the floor covering, but also the underlying cooled layers.

The lack of full-fledged floor insulation leads not only to overspending on heating, but also to damage to structures by mold and fungus. Condensation falls on the warm air side, and a humid environment is beneficial for the development of dangerous microorganisms.

Advantages of using foam in floor construction

Thermal insulation of the floor with foam is a fairly common option, which has gained popularity due to the following qualities:

- ease of installation: there is no need to provide workers with overalls and protective equipment, as is the case with mineral wool or polyurethane foam;

- ease of cutting allows you to insulate the floor in a room of any geometric shape;

- the cheapness of the material in comparison with other effective insulation materials in many cases becomes a decisive factor;

- can be used to insulate the underfloor heating system;

- resistance to the appearance of mold, fungus and other microorganisms harmful to humans allows us to call the material safe, not causing allergic reactions.

These positive qualities make the material suitable for use in house building from any material.

Advantages and disadvantages of expanded polystyrene

TO positive

the qualities of the material include the following points:

The advantages of the material include such qualities as sound insulation, moisture resistance, low price and durability of the material (more than 50 years).

Negative

the qualities of this insulation are much less:

- Deformation

... Low heat resistance allows the development of thermal deformation at a temperature of + 80-90 degrees. - Flammability

... Gas-filled expanded polystyrene granules are capable of igniting at very high temperatures. - The need for protection

from mechanical damage

Having familiarized yourself with the basic properties of the material and opting for polystyrene foam, you can use the options below. Warm floors are an integral part of an energy-efficient home. Floor insulation with expanded polystyrene under the screed will help reduce heat loss

and will make the temperature in the room comfortable and cozy.

Insulation with expanded polystyrene is an affordable and simple way of thermal insulation.

Installation technology

Before insulating the floor with foam, you need to understand the features of its use for various structures. The laying process itself is as simple as possible, but the material requires an additional protection device against moisture and steam.

Insulation of the floor of the first floor

There are no big differences when working in a brick, concrete or wooden building. Insulation of the floor with foam is carried out both from the top of the floor and from the bottom. The method from below is more competent from the point of view of heat engineering, but it is very laborious. In the overwhelming majority of cases, insulation is performed over the floor.

Styrofoam can be laid on logs or under a concrete screed. In a wooden house, it is appropriate to use insulation between the logs.

If desired, you can lay the material along the logs and with concrete floors, if you are planning wooden floors.

Installation on lags is carried out in the following order:

- preparation and cleaning of the base;

- laying waterproofing material;

- lag layout and their fixing;

- styling foam;

- laying vapor barrier;

- installation of a clean floor.

For polystyrene, installation on logs compensates for its low strength. When laying under a screed, it must be additionally reinforced, which leads to an increase in the cost of construction or repair. Read more about floor insulation under the screed.

In a wooden building, it is not recommended to use polyethylene film as a waterproofing and vapor barrier. Better to choose a more expensive breathable material.

Use as soundproofing

To prevent noise penetration, a layer with a thickness of 30-50 mm can be used. The overlap cake should look like this:

- overlap;

- vapor barrier;

- Styrofoam;

- waterproofing;

- clean floor.

Calculation of the thickness of insulation

In a private house, it is allowed to take the thickness of the insulation layer "by eye", but if you wish, you can master the program to perform calculations. It is called "Teremok" and is freely available. Working with this software is simple. Even a person who is far from construction can deal with this. The calculation will help to provide the necessary thermal protection with minimal costs.

The floors in a private house are a place of great heat loss, especially if they are made of wood without insulation. And in our time, when the heating of the home eats up a large part of the family budget, this is simply unacceptable.

Therefore, the insulation of a wooden floor is an important point in home improvement. You need to pay special attention to this question and do not spare money for insulation.

There are several ways to warm your floor, in this article we will look at several options.

Floor insulation material

The construction market offers a wide range of materials for floor insulation. They differ in cost, installation technology, optimal operating conditions, etc.

Mineral wool for floor insulation

Materials used for floor insulation in a wooden house from below:

- mineral wool;

- ceramisite;

- penofol;

- polystyrene or expanded polystyrene;

- sawdust;

- penoplex;

- ecowool.

Each of the materials has its own advantages and disadvantages. The choice of it as a heater depends on the characteristics of the house, the financial capabilities of the owner and the type of flooring.

Penoplex is a common foamed polymer. It is distinguished by high strength, ability to keep its shape well. For the production of foam, the extrusion method is used. This allows for a strong structure with a large number of small cells inside for better heat transfer. Moisture does not penetrate inside the holes, so the material does not need additional waterproofing.

Penoplex does not need additional waterproofing

Mineral wool

Mineral wool is used most often as a heater. It is lightweight, does not burn, and has a high degree of protection against extraneous sounds.

There are three types of this material:

- glass;

- slag;

- stone.

You can use rolled mineral wool for floor insulation

This material is produced in the form of a dense plate or flexible mat. For ease of installation, the plates are marked with a blue stripe. This allows the sheets to be positioned in the desired direction.

The big disadvantage of this material is the ability to absorb moisture. Therefore, when insulating the floor in a private house with your own hands, it is necessary to conduct a good vapor barrier.

Additional insulation of pipes with mineral wool insulation

Expanded clay is small round porous balls of shale or clay. They are obtained by firing materials in a furnace at a high temperature. Expanded clay is considered a safe and environmentally friendly material. Among its advantages should be highlighted:

- high sound insulation;

- resistance to low temperatures;

- environmental safety for humans.

A noticeable disadvantage of this material is its own weight seal. Expanded clay balls are pressed together. This leads to an increase in the weight of the substance and a decrease in thermal insulation properties.

Expanded clay is often used to insulate a wooden floor

Sawdust is a waste product of the woodworking industry. They have good steam and sound insulation characteristics, retain heat, and are environmentally friendly for humans. Sawdust is of low cost. The resulting thermal effect is not worse than that of expensive materials. Thanks to the cement component, they are also well suited for floor insulation in a ground floor apartment. Subsequently, such a screed can be used for laying laminate, linoleum, tiles, etc.

Sawdust is subjected to special processing before use. This prevents the appearance of rodents and beetles in them. After that, they are mixed with cement and water and evenly applied over the entire area of the flooring.

Sawdust is a very cheap material for floor insulation.

Sawdust is ideal for insulating floors on the ground, especially if the building does not have a solid and solid foundation.

Floor insulation with expanded polystyrene is popular. Most often, this material is called foam. The advantages of this insulation:

- low vapor and sound permeability;

- low thermal conductivity;

- resistant to external factors and chemicals;

- does not lose its properties for a long time;

- easy to install.

Polyfoam is not afraid of fire and exposure to high temperatures

A significant drawback of foam is its susceptibility to moisture. He can absorb it into himself. This negatively affects the basic performance characteristics. He is also afraid of the effects of fire and high temperatures. But a simple and inexpensive technology for insulating floors with polystyrene is its significant advantage. This is what, in most cases, the owner of the house is guided by.

Ecowool

Polyurethane foam (ecowool) is a great way to solve the problem of floor insulation in an apartment on the ground floor and in a private house (dacha). This material is blown into the free space using a compressor. In this way, he evenly fills all the voids. Small particles that make up ecowool provide excellent vapor barrier.

After hardening, a solid, even layer is obtained. It can withstand the load perfectly. Light weight does not increase the weight of the structure. The service life of this insulation is more than 20 years.

Thermal insulation of a wooden floor with ecowool

A significant disadvantage of ecowool is the need to use special industrial equipment.

The combination of polyethylene foam and a thin layer of aluminum foil is called penofol. It is sold as a rolled roll. The thickness of the seal is from 3 to 10 mm. Penofol retains heat well, is environmentally friendly, and has high sound insulation.

Penofol retains heat well

The big disadvantage of this material is exposure to moisture due to the presence of aluminum foil in the composition. Another disadvantage is that penofol does not differ in long-term operation. After five years, it is necessary to re-insulate.

The modern market offers a wide range of materials suitable for insulating a wooden floor on logs. You can find the properties of the most commonly used heaters in the following table.

Table. Popular heaters

| Heat insulating material | Basic properties |

| Sawdust | One of the most budgetary, and sometimes completely free thermal insulation material. It is characterized by good thermal insulation properties, helps to normalize the level of humidity inside the floor structure.The main disadvantage of sawdust is its poor resistance to the effects of various kinds of insects, fungi and other harmful microorganisms. In addition to this, the material supports combustion, which is also a big disadvantage. |

| Mineral wool insulation | Materials based on mineral wool are characterized by high thermal insulation properties and do not support combustion. Along with this, the material does not tolerate contact with moisture poorly - it swells under the influence of water and loses its original performance characteristics. If mineral wool is used for insulation, waterproofing will need to be equipped on both sides of the material. |

| Expanded clay | A relatively inexpensive and easy-to-equip material with good thermal insulation characteristics. For insulation, it is recommended to use granules of different sizes - so the backfill will turn out to be denser. |

| Styrofoam | One of the most popular heaters. It is sold at a relatively affordable cost, provides highly effective insulation, is not afraid of contact with moisture, but supports combustion, while releasing substances that are unsafe for human health. In addition, the foam attracts rodents, "encounters" with which do not in the best way affect the service life of the material. |

- Bulk;

- Bulk;

- Roll;

- Tiled (block);

- Sprayable.

Various types and types of heaters for a wooden floor (bulk, spray, roll, block)

For insulation, you can choose:

- Styrofoam;

- Penoplex;

- Expanded clay;

- Glass wool;

- Cork material;

- Reflective insulation (penofol);

- Cellulose;

- Gypsum fiber;

- Fiberglass;

- Foam glass;

- Polyurethane foam.

- Drill with various drills;

- Screwdriver;

- Saw;

- Plane;

- Electric jigsaw;

- Construction mixer.

Read next: How to remove old wallpaper effortlessly

Thermal insulation of a wooden floor with expanded clay

Expanded clay is a fairly well-known material that is used to insulate houses. It has been in use for several decades and has not diminished in popularity due to its high performance data.

It is made of special types of clay, which is processed at high temperatures. As a result, balls of a certain size and a certain density are formed.

Before work, the surface must be cleaned of debris. A broom and a scoop will be a good helper in this matter.

If there are gaps between the floor and the walls, they must be sealed with sand-cement mortar or polyurethane foam.

Now, so that when the dry screed expands, the floor does not bend, you need to leave a gap between the floor and the wall. To do this, you can lay a tape of polyethylene foam along the entire perimeter of the wall. Its thickness must be sufficient so that the floor can expand freely.

It will not be superfluous to lay a plastic film on the base, it will serve as a steam and hydro insulator for us. The film should rise along the edges of the walls just above the level of our future floor. It is best to secure the edges of the film to the wall with masking tape or tape.

Now that the preliminary work has been completed, we can lay a layer of expanded clay.

It should be borne in mind that for insulation it is better to buy expanded clay in which the granules are of different sizes, then the material will be distributed more evenly. The expanded clay layer should be at least 3 cm and no more than 7. Considering this, you can pick up beacons, it can be wooden slats or a metal profile of the required size. It can be fixed to the floor with both cement-sand mortar and self-tapping screws. Beacons must be perfectly level and securely attached.

Now you can scatter expanded clay and level its layer with a rule made from scrap materials.

You may not use beacons, but then you will need to align the layer with a rule that has a level indicator. It is much more difficult and not everyone can do it.

It is best to cover such insulation with sheet material. Particleboard, OSB, GVL and even plywood sheets are suitable for this. But it is most practical to use (GVL) - gypsum fiber sheets.

Some, so that expanded clay is not free-flowing, but turns into a solid surface, fill it with cement diluted with water. Such a solution is prepared using a construction mixer.

By pouring expanded clay with it, you will strengthen the surface with a depth of more than three centimeters.

After the plates are laid, the topcoat is already mounted on top. It can be boards, parquet, linoleum and much more, even ceramic tiles.

You can read how to paint the park here, all the detailed instructions that will surely help you in this laborious task.

The use of expanded clay for insulation has a number of advantages, it is not flammable, it is lightweight, keeps heat well and does not conduct sound. It is convenient to work with it, because it gives minimal shrinkage.

Thermal insulation of a wooden floor along the logs

Whatever the material for insulation, the technology remains the same. The main thing before installation is to determine the conditions in the house in which the wooden floor will be used. The level of humidity and temperature, the degree of load and the purpose of the room are important here.

To insulate a wooden floor with your own hands, you need to know a clear procedure:

- Installation of wooden logs;

- Fastening of rough boards from the bottom of the lag and waterproofing flooring;

- Placement of insulation between the lags. Experts recommend laying the insulation as tightly as possible. All gaps are sealed with sealant or foam;

Wood floor insulation device

- Vapor barrier flooring for insulation. It is fixed on the logs, and if gaps or joints are formed, then they must be glued with tape;

- Laying boards on an insulated structure, finishing.

Thermal insulation of a wooden floor with mineral wool

The easiest and most reliable way to insulate a wooden floor is to use mineral wool. Usually, the floor structure contains logs, and it is between them that this insulation material is laid.

- Before starting work, you must install the plastic wrap. It is advisable to do this before installing the lag. If this is not possible, you can try to push the vapor barrier under the lags, or cut into strips wider a little more than the width of the lag. (Although not the best option).

- When the foil is installed you can place the mineral wool between the logs. There are several nuances here, firstly you need to buy insulation so that its width is slightly wider between the lags, then you do not have to adjust the material in width. You can buy insulation, and then install the logs at the right distance. Further, the height of the installed insulation should be slightly less than the height of the log.

- On top you need to lay a plastic wrap that will protect your mineral wool from moisture penetration. If you do not have such a large film, you can cover everything from several parts, the film should be overlapped with an overlap of at least 10 cm.

- On top of the film, sheet material is laid on the logs, the so-called subfloor. In the role of which the chipboard sheets should act.

Insulation technology

Spraying is a fast and high-quality, but expensive way of insulating a wooden floor. It is applied to absolutely any surface, it is used in private houses, and in apartments, and in industrial premises. Polyurethane foam is sprayed after removing the old coating. At the same time, there must be appropriate equipment; without it, the process is impossible.

Thermal insulation of a wooden floor is a responsible process that requires certain knowledge. It is important to choose the right material, since not everything that is good for a private house is suitable for insulation in an apartment. It is also important to correctly divide the warming process, especially if the installation is done by hand.Any mistake can lead to the fact that you have to redo the work done earlier.

Let's look at several options for how you can make do-it-yourself thermal insulation of wooden floors.

It is much more convenient to insulate the floor in a private house at the construction stage. But quite often this moment is missed and it is necessary to produce thermal insulation already during the operation of the building. To do this, you must use the following technology of work:

- First of all, it is necessary to dismantle the old flooring. If you have linoleum, remove it carefully, it will still come in handy for waterproofing.

- After that, the floorboards are removed. If they are in good condition, they should be numbered to facilitate re-assembly.

- Then from below on the logs along the entire length cranial bars are stuffed, on which, in turn, the subfloor is laid. For its installation, you can use a non-edged board. Laying should be done as tightly as possible, and it is better to fill the remaining cracks with polyurethane foam.

- The next step is the installation of waterproofing material. Here you can use old linoleum or dense polyethylene.

- Heat-insulating material is laid on the waterproofing.

- The insulation must be covered with a layer of vapor barrier. Foamed polyethylene, which has a foil base, is best suited for this purpose.

- The final stage is the installation of old or new boards, you can also use plywood. Insulated linoleum can be placed on plywood sheets, which will increase the level of thermal insulation and reduce the noise level from steps.

In the apartment, wooden floors are insulated using a similar technology. It is a little easier to make thermal insulation here, since there is already a subfloor, which is played by a concrete floor slab. The technology for insulating wooden floors in an apartment is made in the following order:

- Just like in a private house, it is necessary to dismantle the flooring and boards.

- Wooden logs are installed on a concrete base. The remnants of the old insulation between the logs must be removed, sweep away other debris.

- After that, a layer of waterproofing is laid. In this capacity, you can use old linoleum, roofing felt or plastic wrap. It will be better if the beams are also covered with waterproofing so that they do not absorb moisture.

- Then the space between the lags is filled with heat-insulating material as tightly as possible. In this case, it is also necessary to provide a small gap so that the flooring boards do not lie directly on the insulation.

- The thermal insulation material is covered with a vapor barrier, the function of which is perfectly performed by inexpensive penofol.

- Now you can install the flooring. To do this, you can use old boards if they are in good condition, or lay new ones.

You can also install plywood sheets. It will subsequently need to be covered with a fine coating. To do this, you can use linoleum on an insulated basis, a laminate with a backing or carpet.

The timber frame structure is found not only in wooden houses, but also in many buildings built in the first half or mid-20th century. At that time, this was the most affordable way to quickly build a residential building. The characteristic features of such coatings are good thermal insulation properties.

In addition, the installation of logs is one of the effective options for creating a warm base in modern residential buildings, however, due to a decrease in the total height in the room, it is not always acceptable for standard apartments and houses.

- In most cases, the logs are installed on a rough wooden base, thereby forming several separate cells on the surface. Those. the insulation will not be evenly distributed over the entire surface, but will only fill these zones.The difference between the heat transfer coefficients of the beams and the heat insulator can cause uneven temperature distribution on the surface.

- The insulation material should not negatively affect the wooden structural elements. To a greater extent, this relates to its hydrophobicity - moisture absorption. Therefore, the technology of floor insulation along the logs provides for increased waterproofing measures.

- Mandatory air gap. It is necessary for the timely removal of water vapor emitted by wood. To do this, provide for the presence of ventilation slots between the insulation and the upper base of the floor.

Given this specificity, you can start choosing the optimal insulation scheme. To do this, consider various options for the design of the heat-insulating layer.

It is best to consider floor insulation along the logs visually, with options for installing various types of heat insulators. But first, you should carry out a number of preparatory work with a wooden structure.

Advice

If the thermal insulation layer will be installed in an old structure, a thorough revision of the wooden floor should be carried out.

During long-term use, wooden elements could be exposed to moisture or mold, which leads to a deterioration in their performance properties. Therefore, they are carefully checked and, as necessary, they carry out restoration work or a complete replacement. This procedure is not required when installing new floors.

After that, you can start installing the insulation. Regardless of its type, the subfloor is waterproofed first. Often it is also made of wooden planks, much less often you can find a subgrade. In the latter case, the beams are attached to the walls of the building and to the ground using special support structures.

At the end of the condition check, you can proceed with the installation of the thermal insulation layer. The general scheme is as follows.

- Formation of an internal waterproofing layer. For this it is necessary to use special mixtures. It is best to process the base before its installation - in this way, you can ensure maximum impregnation with a waterproofing compound. Most often, bituminous mastic with the addition of polymer components is used for this. It is necessary to process both the outer and inner surface of the flooring.

The use of roll materials is not recommended. During use, a condensation film may form between the boards and the film, which will be absorbed by the wood. The reason for this phenomenon lies in the temperature difference between the plane of the foundation and the inner surface of the board. Often the dew point is located here, which leads to the appearance of condensation in winter.

- Installing lag. If the supporting timber structures have not yet been installed, they must also be treated with a protective waterproofing material. During their installation, the optimal distance between the lags should be taken into account. It depends on the span width and the size of the beams to be installed.

If the installation takes place on a brick or concrete wall, you need to equip the place for connecting the lag and the supporting structures of the building. To do this, it is best to use a roll-up waterproofing material, such as roofing felt. Upon completion of the installation, you can proceed directly to the insulation.

- Installation of thermal insulation. The choice of technology for installing insulation directly depends on its type. For roll materials (basalt wool), it is enough to spread the material on the surface of the subfloor. During work, it is important to minimize the size of the gaps between the layers. Due to the fact that the height of the lag is often 250 mm, several layers can be installed. It is recommended to develop the scheme in such a way that the joints of each subsequent one do not coincide with the previous one.This is required to prevent the appearance of so-called cold bridges - zones where the temperature will be significantly lower than in the main heat-insulating layer.

Read more: Sand for plastering walls: DIY video instructions for installation, which is better for plastering, price, photo

Advice

For sheet material (polystyrene, extruded polystyrene foam), it is not recommended to fix it with mounting dowels. Since individual insulating elements will be located between the beams, it is important to draw up a plan for their cutting correctly. When tightly docked with each other, an optimal energy saving factor will be ensured. The absence of mechanical stress contributes to the preservation of the primary layout of the insulation sheets.

If loose heat-insulating materials are used - expanded clay, you must first prepare the composition. To do this, mix components of different fractions (from 10 to 20 mm), and then evenly fill the space between the lags.

- Ventilation gap. Before installing the main covering (boards or solid overlap), equip an air gap between it and the thermal insulation. It is better to install wooden slats on the surface of the beams for this. With their help, you can make ventilation voids necessary to remove moisture and level the finishing surface.

Insulated floor device