Plasterboard finishing is highly popular and in demand. Plasterboard sheets are used to hide the imperfections of the walls, irregularities. And also, to translate design solutions into reality. Installing the gypsum board with your own hands is not difficult. Not everyone can handle the finish. But if you wish, you can master this complex science. Drywall is not only easy to install, it is also popular because it can be used for any type of finish. For example, paint, wallpaper or tile, you can simply decorate with any other decorative mixture.

Variety of fastening the lathing

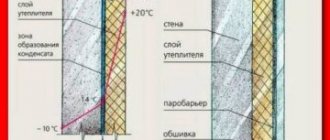

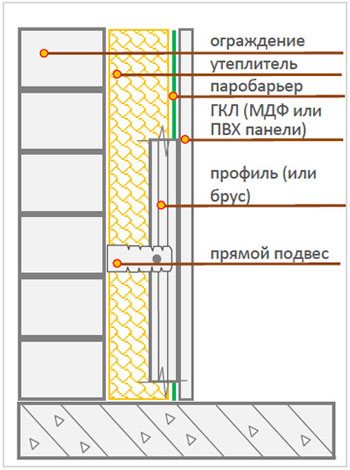

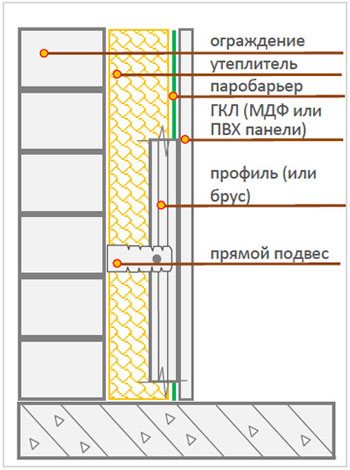

Installation of the battens to the walls is the main difference when working with drywall in a wooden house. The traditional method of fastening, when the lathing is attached to the walls using suspensions and the CD 60 profile or directly the CW profile to the wall, is used for walls made of laminated veneer lumber, which is not subject to shrinkage. These structures are designed for small deformations and are compensated by a suspension system.

For movable walls of a log house and walls made of timber with natural moisture, the structure is complicated by "sliding" suspensions that prevent shrinkage processes. It is impossible to rigidly fasten the crate to the ceiling, as with the traditional method. The vertical shrinkage of the walls can be about 2 cm, and this deforms the drywall, provoking the appearance of cracks and internal stress. In order to prevent this from happening, the lathing should end 2-3 cm from the rough ceiling. The resulting gap will be hidden by a clean ceiling and will not be noticeable.

The ceiling lathing is attached to the rough ceiling if there is no rigid attachment around the perimeter. It is necessary that the crate adjoins the drywall on the walls as tightly as possible, but at the same time is not rigidly attached to it. When shrinking, the sliding "false wall" will remain unchanged, and the ceiling with overlap is deformed. A gap is inevitable along the perimeter of the abutment to the ceiling, but it is easily masked with a decorative cornice or baguette.

Having created such an independent structure using high-quality materials and adhering to the puttying technology, there is no need to fear cracks.

Back to the table of contents

The essence of the frameless method of fastening the GKL sheet

Installation of drywall on walls without a frame is carried out using a special compound. They glue the sheet to the base surface. The joints are putty and reinforced with tape. After priming, the wall is ready for finishing - wallpaper, decorative plates are glued to it, or painted at your discretion.

Since the sheets themselves are of small thickness, the total area of the room hardly suffers. They are convenient to use when leveling the walls of small rooms: a bathroom, a pantry, a loggia, and in other places where every centimeter of space is important.

Wooden base for fixing drywall

In wooden houses, drywall installation can be carried out in one layer to a metal profile or in two layers to a wooden surface. In this case, the thickness of the structure must comply with the rules of operation: the walls for wall cabinets and bookshelves must be fixed in a more reliable way.

To create a frame from metal profiles, they make a skip of the planes. On the ceiling along the walls, draw a straight line parallel to the wall.Then a plumb line is lowered from this line at the corners of the ceiling, the line is transferred to the floor. With the help of U-shaped and CD profiles, a frame is made. In addition to metal profiles, you can take a wooden profile (slats, beams). It turns out a wooden crate, which serves as a frame. It is an economical and environmentally friendly option.

The following can act as a basis for fastening:

- walls made of wood;

- wooden slats;

- wooden bars;

- wooden beams;

- wooden crate;

- wooden frame;

- wooden wall.

Installation on wooden slats is suitable for walls with communications, which it is desirable to hide or create additional sound or heat insulation from the inside. For this you will need:

- slats (soft wood; section 75x50 mm and 100x50 mm);

- self-tapping screws;

- dowels;

- drill;

- screwdriver;

- saw;

- drywall.

Sheathe a house from a bar with plasterboard is a pretty practical solution. The use of this type of material allows you to reduce the time of interior decoration and costs. But, an acceptable quality of repair can only be obtained by observing the technology, taking into account the peculiarities of the construction from a wooden bar. Otherwise, the end result will not meet expectations.

Finishing and interior of a house from a bar with plasterboard

Wood is one of the first building materials used by mankind. It has not lost its relevance today. And the use of modern processing and construction technology allows you to quickly build a house according to all quality requirements. However, the interior decoration has its own nuances, without which, all the advantages of the building will simply turn into disadvantages:

- Firstly, it is worth remembering that it is worth starting internal work in a house made of wood after at least 6 months. During this time, the house will "sit down", and the movements of the load-bearing walls and ceilings will not spoil the interior decoration.

Fireplace decoration with plasterboard in a log house - Secondly, despite the natural finish of wood, in any case, additional finishing of the external surfaces of the premises will be required: a bathroom, a bathroom and a kitchen. The walls of these rooms will be exposed to higher humidity, which will deteriorate the material.

- And thirdly, it is difficult to lay communications in the walls and ceilings of a wooden house.

What are the advantages of decorating a house from a bar with plasterboard, taking into account these nuances of construction?

Fastening the gypsum board by the frame method

A more common way of attaching gypsum boards is to install sheets on a frame made of metal profiles, installed along the wall.

Work order:

- Stage 1. First of all, measurements and markings are carried out for the installation of profiles and suspensions. The markup for the guides starts from the upper profile, the required distance recedes from the wall, a line is drawn, and is transferred to the floor with the help of a plumb line. Vertical bearing profiles should be spaced 60 cm from each other, and so that each sheet of drywall fixed to the wall rests on three racks. The hangers should be installed at a distance of 60–80 cm.

- Stage 2. Installation is in progress. It is necessary to install along the perimeter: using a puncher, dowels and screws, the upper one must be screwed to the ceiling, the lower one - to the floor. At the marked points, suspensions are attached, bearing profiles are inserted into the guide profiles. They must be fixed with hangers.

Installation of drywall can be carried out on walls and ceilings in two main ways: on the frame and directly on the wall.

Frameless installation involves fixing drywall sheets directly to the surface, without first creating a frame. The choice of method depends on the unevenness of the wall or ceiling.

It can be done in three ways:

- On plaster putty.

It is acceptable when the irregularities are not more than 4 millimeters.The bonding material is applied along the edge and in the middle of the gypsum board in a thin layer. - The glue method is used

when the amount of unevenness is up to 20 millimeters. The glue is applied to the gypsum board in thin lines over the entire surface, the distance between the adhesive layers is 30-35 centimeters. - If the irregularities are large

(up to 40 millimeters), then two layers of gypsum board are created: the first is strip (strips of 10 centimeters), the second is solid, undivided sheets of drywall are used.

For this method, gypsum boards with a thickness of no more than 12 millimeters are used. The height of such a structure can be 3 meters.

Facing the walls of the gypsum board in a frameless way is used:

- In loggias, terraces, bathrooms and toilets, in showers and pools, in basements and on, for decorating the slopes of door and window openings.

- In niches where communications pass, in corridors and halls of non-residential premises, lobbies, foyers.

The frameless method of fastening can be used when the unevenness of the wall does not exceed 2 centimeters in some places. It is used on various surfaces: concrete, brick, block, and under certain conditions, timber walls can be sheathed with plasterboard.

The advantages of this method are:

- Economy.

You don't have to buy metal profiles, guides, fasteners. - It takes less time to create the skin.

Since no wireframe creation is required. - During operation, it is much less likely that cracks will appear at the joints

, the wall is smoother and more reliable. - Possibility to perform installation

do it yourself.

The disadvantages include the fact that this option can only be used on flat surfaces. If the irregularities are large, then you will have to first prepare the wall: align with beacons. This is a rather laborious process that not everyone can do on their own.

With this finish, the walls are quite difficult to hold inside the communication. In addition, there are few options for insulation with this design. Most often, foam is used, which not everyone loves for its environmental friendliness.

Methods for fixing the material against the wall can be as follows:

- With glue.

- Using gypsum plaster.

The advantages of plasterboard finishing in a house from a bar

In addition to the simplicity, speed and low cost of assembling structures, interior plasterboard finishing in this way gives an advantage precisely taking into account the specifics of the building.

Option for finishing a wooden attic with drywall sheets

Pros of using drywall:

And, most importantly, the finishing material will not load the supporting structures. With a large margin of safety, drywall has a low weight in comparison with other materials. Yes, and it is difficult to use the classic methods of construction and decoration in a house from a bar.

Insulation by means of polyurethane plates

At the initial stage, the insulation process differs little from the previous method. Preparation involves cleaning the walls from the previous coating, with the exception of stuffing the lathing. Before fixing the plates, the cleaned surface must be treated with a primer.

After the preparation process, you can proceed to the direct installation of the slabs on the wall:

- work begins from the bottom row, gradually rising up;

- adhesive glue is applied to the first sheet of material along the diagonal of the board and along its edges;

- after that, the sheet is fastened to the wall, with the obligatory alignment of the horizontal;

- so that in the process of further finishing the slabs do not fall off, they must be additionally fixed on the wall using plastic dowels. Do not overdo it with the depth of immersion of the dowels in the polyurethane sheet in order to avoid deformation;

- after finishing the entire surface of the walls, the joints must be treated with polyurethane foam to prevent the appearance of cold bridges;

- after the sealant has dried, you can proceed to further work on wall decoration, plastering, fixing lining, drywall sheets, etc.

Wall insulation

How to choose the right materials

When choosing materials for decorating a house from a bar with plasterboard, several fair questions arise:

Frame or frameless ways

To the surface of the walls is easier and faster, but many factors are required.

GKL can be mounted directly on the walls if the planes do not have significant differences. Perfectly flat walls in a wooden house are very rare, even in a new building. After all, the wood dries up and shrinks along with the movement.

And the laying of communications in this case is much more difficult. For example, under the wiring, you will have to cut directly the supporting structures.

Scheme for frameless drywall installation

The frame, on the other hand, makes it possible to align any differences and unevenness of the walls to the ideal value, and it will not be difficult at all to lay engineering lines under the plasterboard sheets. In addition, if planned, structures on a solid foundation can withstand the load much better.

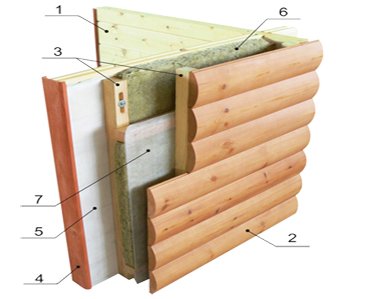

Metal or wood

In houses from a bar, both wooden slats and metal profiles can be used as a frame material. Moreover, in the first option, it is permissible to build a simpler structure by attaching the bars under the gypsum board directly to the walls (again, taking into account the differences). But, the quality of lumber must be at a high level. Only wood that has been well dried and treated with protective compounds is used. The cross-section of the racks of such a frame should be exactly maintained 50 × 25, the same criterion for the crossbars, but the guide bars - 75 × 25 at least!

Mounted wooden frame for drywall in a house made of timber The process of fastening wooden frame racks

Metal types of profiles are also suitable for use in timber construction. With their help, you can build a solid foundation that does not lend itself to such influences as humidity and temperature drops.

An example of fastening a metal frame in a house from a bar Metal frame on the ceiling

To do this, you need ready-made elements and. In terms of cost, metal "parts" of the frame will be cheaper in comparison with high-quality wooden slats. The video shows how to mount a metal frame on timber walls.

Which drywall to choose

The type of drywall for finishing a wooden house is selected depending on the purpose of the room. In the bathroom, bathroom and kitchen, there must be a moisture-resistant sheet, in living rooms the wall version is quite suitable, and the fire-resistant one is used for finishing structures that may be exposed to temperatures. In addition to the above features of the selection of material in a house from a bar, it is imperative to use a vapor barrier.

Cured gypsum is hard and brittle. In the gypsum board, it is reinforced with cardboard located outside. The smooth surface of the sheet is ideal for quick and budget leveling of walls. Drywall in a wooden house has recently been used. It used to be thought that movable wood and durable gypsum were incompatible. Thanks to the metal profile and suspension systems, plasterboard is now widely used by builders and amateurs to make repairs on their own.

Wall lathing for installation with plasterboard

The metal profile allows you to sheathe a wooden house from the inside with plasterboard

Self-contained wall lathing

Given the ability of gypsum to absorb moisture even from the air, it is possible to sheathe walls from the inside with plasterboard only in houses with heating and year-round living. Otherwise, after 3 - 4 winters, repairs will have to be done again and fight against mold.

Wood is an ideal building material for your home. It retains heat well, absorbs noise, and purifies the air.The complexity of finishing consists in the peculiarity of the tree constantly changing its size - to breathe. This must be taken into account when installing drywall in a wooden house. GKL are attached only to the crate. Even on walls made of laminated veneer lumber, drywall is not glued directly to the surface.

It is possible to sheathe the ceiling and walls with plasterboard inside if they are even and do not sit down. This is a clutch of:

- aerated concrete;

- foam concrete;

- bricks;

- cinder block.

Artificial stone should have even corners without chips. The surface should be flat, the seams are thin, without excess mortar.

Immediately after the completion of construction, it is impossible to sheathe a wooden house inside with drywall. It should settle, shrink. A year is enough for brick buildings. The tree takes more time. Small deformations will occur constantly. It is enough to cover the stone and plaster with a primer so as not to sprinkle, then sheathe it. The tree goes through several stages of treatment with antipyrine and antifungal compounds.

Sheathing the house with plasterboard from the outside is not cost-effective. Special moisture resistant sheets are required. They are much more expensive than conventional ones. The facade of the house is treated with special compounds that protect the wood from moisture, mold, insects and fire. At the end, the entire facade must be putty and primed and painted.

First, we plaster the ceiling with plasterboard using suspensions

We sheathe the ceiling with plasterboard

Plasterboard alignment starts from the ceiling of the house. It is necessary to sheathe it so that there is a gap between the sheets and the walls. The metal profile frame is mounted on the floor beams. The sequence of works is standard.

- Make markings all over the ceiling.

- Fasten the PP guide profile along the perimeter. It cannot be rigidly fixed to the ceiling. You need to use suspensions. If the house was built more than 5 years ago and there are no living quarters at the top, you can get by with black self-tapping screws for wood and not tighten them tightly, leave a gap under the hat. The hole in the profile must be larger so that the bolt shank can move. The best option is to use special spring plates.

- Planks are inserted into the guides on which the sheets will be attached. They are fixed to the ceiling using hangers or perforated strips.

- Inside, wires are laid and communications are carried out, the places of installation of the lamps are marked, fastening is made for them.

- It remains to sheathe the ceiling. The holes for the lamps should be 2 to 3 mm larger. The same gap is also around the entire perimeter of the ceiling and between the sheets of drywall. Sheets are attached to the profile with self-tapping screws.

Attention! For a frame made of wooden slats, a 50x50 bar and spring brackets should be used. In the hole in the center of the arc, the screw is screwed into the bar, the edges are fixed to the ceiling.

Sealing and filling is done after all surfaces inside the room and even at home have been sheathed.

Plasterboard cladding of log walls inside the house

Lathing on wooden walls

Sanded and varnished or waxed wood has its own unique pattern. It goes well with most modern styles. Some harmoniously complements, others emphasize with its contrast of smooth lines and shapes. Sheathe the house from the inside should be in several cases:

- there is no way to regularly care for the tree;

- the wood darkened over time and lost its attractive appearance;

- wall insulation;

- additional sound insulation;

- the need to hide communications;

- you need a solid, even base for tiles and other finishes.

There may be other reasons for plastering a wooden house inside with plasterboard. This mainly concerns interior decoration and furnishing changes. Partitions are made of gypsum plasterboard in houses during redevelopment.

When making a crate for drywall in a wooden house, several rules should be followed:

- it is necessary to clearly maintain the horizontal and vertical position of the frame and cladding elements;

- when screwing the suspensions, a gap should be left;

- the distance between the vertical struts of the structure is equal to half the width of the drywall sheet - 60 cm;

- the length profile is fixed to the wall at a distance of no more than 50 cm;

- when joining sheets along the length, horizontal crossbeams from the profile are placed at the joints;

- covered, black self-tapping screws are used for wood;

- leave a gap of 2 - 3 mm between the sheets.

Advice! Don't use nails. They do not stick well in the tree and soon begin to fall out. The screw connection is much stronger.

A starting profile is attached around the perimeter of the room, and vertical posts are inserted into it. The sheet is screwed on at the edges and in the center at a distance of 15 - 20 cm. The screw heads are recessed. They are hidden when leveling with putty.

After fixing the casing, the corners of the sheets should be slightly cut They can fluff up and protrude beyond the plane. It is advisable to immediately cover the entire wall with a primer. Then a reinforcing paint net is glued to the joints and the gaps are leveled with putty. The bolt heads are spattered crosswise with a narrow trowel.

Under the wallpaper, it is enough to clean the irregularities and cover everything with a primer again. Painting requires a smoother surface. The entire wall is treated with a finishing putty, sanded and, if necessary, applied several layers.

The tile is heavy. A base is made under it from a thick waterproof sheet of drywall. After sealing the joints, they are primed twice with a deep penetration compound. Then an adhesive solution is applied and the tiles are laid. The starting profile for the first row does not touch the floor and is attached to the wall.

Installing the frame

It does not matter at all how the frame will be installed, vertically or horizontally, because each master chooses convenience for himself, but takes into account for the future what exactly will be located on the wall. Vertical installation is considered classic, but if you need to hang a shelf on the wall, you can always make the frame horizontal and reinforce the metal profile with a wooden bar.

Before installing the profile on the wall, it is advisable to clean it of serious irregularities and old construction debris, that is, to prepare it.

Then you can proceed directly to the installation. Having marked out the profile installation lines every 50-60 cm (along the width of the insulation), marking the ceiling and floor for the depth of the frame and beating off clear lines, we fix the metal profile. First, we install the guide profile on the floor and ceiling. to which we will attach the vertical posts. Also, along the edges of the wall on the right and left, a carrier is installed, from which the external finish will begin after the insulation itself is laid.

Vertical racks are installed on the wall strictly in compliance with the level and correct markings, fastened to dowels and screws. Above and below, where the rack profile is connected to the guide, you can use special screws or work with a cutter.

Depending on the method of insulation and the selected material, the installation technology may vary

If, in the course of work, all the rack profiles are installed through, say, 50 or 60 cm, and the latter is placed at a distance of 20 or 30 cm, it's okay. Our walls are of different sizes in length, and therefore you do not need to adjust to them. The main thing is that all cells for insulation are strictly in size, and the latter can be of any width. Here, only one thing is important - you can reduce the width, increase it - no.

Lathing made of wooden beams for the inner lining of the house with plasterboard

Wooden lathing

Sheathing the house from the inside with plasterboard can also be done on a wooden crate. It should be chosen for racks and a beam of 50x50 mm is transverse. Use a 70 mm wide plank as a starting point. The screws are fitted with washers and are not tightened.

Lack of timber frame in complex timber preparation. It is necessary to treat with fire retardants, soak in antistatic agents. The service life of such a sheathing is much shorter than that of a metal one, and soon you will have to sheathe the house inside again. Even well-dried wood can lead to processing. The beams should be carefully checked for curvature.

Frameless plasterboard cladding inside the house

We sheathe the walls with plasterboard without lathing

A frameless method of installing gypsum plasterboards inside the house is possible on stable, even surfaces. This is mainly plaster. The masonry must have irregularities within 5 mm. If the wall does not need to be aligned vertically, then the house can be sheathed from the inside with drywall without lathing.

The surface of the walls of the house must be cleaned of dust and other contaminants. Cover in 2 coats with deep penetration primer. The starting profile is installed below. It serves as a support and helps to align the sheets horizontally. The adhesive is applied with a notched trowel. The advantage of this mounting method:

- sheathing is done faster;

- the useful area of the room is preserved along the entire perimeter;

- the cost of finishing is much lower.

The disadvantages include the inability to hide communications under the cladding, and to make the internal insulation of the house.

The owners of wooden log cabins are rightfully proud of their purchases (or the results of the construction undertaken). The house turns out to be cozy, beautiful and ecologically sound - complete order! But when it comes to the interior decoration of a wooden house, and even with their own hands, people sometimes get lost. In some areas of the building, there is simply no way to leave the tree intact. For example, in the kitchen, it will quickly smoke up, and possibly begin to crack. And in the bathroom it will swell from moisture, threatening the tenants with mold. You just can't put the same tile on a bar or log: either it won't hold on at all, or very soon it will start to "walk" because of the breath of the tree. And here drywall can come to the rescue: in a wooden house, it will perform the functions of a supporting base for finishing.

Wooden lathing

It is especially appropriate if you are installing drywall in an old wooden house. Its shrinkage is complete, and the walls are probably not too even. But the main thing is that they are just breathing and will not change much in size.

- A bar with dimensions of 75x25 mm is taken under the support posts. More is possible, less - in no case. Naturally, the lathing is made of lumber treated with fire retardants and antiseptics, followed by drying.

- For guides and crossbars, 50x25 mm strips are sufficient.

- The support posts are attached with a step of 1.2 meters, that is, in the width of the gypsum board sheet. At least one guide is mounted between them. If you want more structural strength, fill them more often. The main thing is that there is a support stand at the center of the sheet, and a guide at the junction of the plates.

- The crossbars are packed in such an order that they are at the place where the narrow sides of the gypsum board meet. Do not forget that horizontal seams should not line up: drywall is mounted in a checkerboard pattern, or at least with a noticeable displacement.

All slats are level-checked. The largest protrusion of the wall is taken as the reference point. In the places of the depressions, wedges are placed, hewn to the required thickness. When decorating your home with plasterboard on a wooden frame, the slats are attached to the lumber with screws and a washer at a distance of 20-30 cm. Do not tighten them too much so that the cladding does not deform with natural movements of the walls.

To the concrete wall

Since the concrete wall is usually fairly flat, drywall is accepted on it. Before starting work, you should dust and degrease the surfaces, and to improve the adhesion of the gypsum mixture, make notches on the concrete with a jigsaw or an ax.

Then materials and tools are prepared:

- drywall for walls;

- dry gypsum mixture;

- container for diluting the mixture;

- cutting tool - jigsaw and painting knife;

- notched trowel and trowel;

- a board with a length of 30 cm less than the height of the walls;

- roulette;

- level.

Advice.

Before starting work on installing the gypsum board to the wall, all engineering work on the electrical wiring must be completed.

Use a level to evaluate the curvature of the walls and mark the deepest and most prominent spots with chalk or pencil. From the latter, they begin gluing the sheets, and the first gypsum board, fixed at the highest point of the surface, will become a reference point for the level of installation of the rest. If there is a large difference between the existing irregularities, it is recommended to knead a little dry mixture and seal it with holes.

Algorithm for attaching the gypsum board to glue:

- Plasterboard along its length should correspond to the height of the wall. It is recommended to cut sheets only after accurate measurements. Keep in mind that the gypsum board is glued with a small gap in relation to the floor - the distance from it to the lower edge of the sheet should be about 1.5 cm.

- The glue is mixed from a dry mixture in small portions in accordance with the instructions on the package.

The composition retains its consistency for no more than half an hour, and then begins to harden and loses the necessary adhesion. - Apply the adhesive with a notched trowel along the contour to the edges of the sheet in a continuous strip, and along the surface, make fixing points with a trowel, staggered at a distance of about 40 cm from each other. The diameter of the glue spot should be about 15 cm.

- While the glue is not frozen, the sheet is lifted and pressed against the wall. A prepared board with careful pressure is carried out along the gypsum board, thereby distributing the glue under it. If necessary, the rule can be additionally tapped with a rubber mallet.

- The plasterboard sheet is pressed against the wall with spacers at several points for 40 minutes until it is fully adhered.

- Adjacent sheets are fastened with a gap of 5-7 mm. To maintain the required gap, you can use wooden wedges.

If the curvature of concrete is strongly pronounced, you can get out of the situation by installing beacons from drywall strips on the surface. They are set on glue along the perimeter of the wall, the vertical extreme lines are connected at different levels with fishing line. Focusing on it, you should glue vertical strips of drywall in increments of 40-50 cm, if necessary, raising them above the wall surface with a plaster composition. On the installed beacons made of gypsum plasterboard strips, the main wall sheets of drywall are attached with glue or self-tapping screws.

Upon completion of the work, the seams between the sheets and the ceiling gap are laid with putty. After that, you can start using finishing materials.

Metal carcass

It may well be used for such a cladding of log cabins. However, for new, not completely settled, buildings, it is better to use a mobile version.

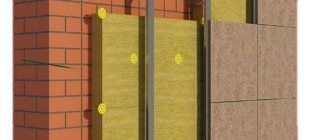

- Vertical posts from the profile are placed according to the general rules, with a calculated step and level check. However, they are mounted on a rigidly fixed wooden crate.

- Horizontal crossbars are fastened with self-tapping screws through oval grooves in the bearing profile. This will give them the ability to rise / fall as the tree moves.

Plasterboard wall cladding made in this way maintains independence from the walls, while having sufficient strength even for tiling. This method is somewhat more expensive than fastening on a wooden crate, since both it and a metal profile are required. But it gives more reliable results.

But finishing a wooden house with plasterboard from the inside, carried out directly on the lumber, honestly, is not the best option. Yes, if the walls are flat enough, you can glue the sheets directly to the surface. However, they will inevitably be led in the process of tree breathing, and compensation gaps will not save them either.Another option - the creation of a false wall - can be used only in large rooms, since it "eats away" a significant amount of space. In this case, the frame is mounted at some distance from the wall and sheathed with sheets. In fact, this creates a solid partition, as in a redevelopment.

Today, there is still no room that can compare with its environmental friendliness and originality with a wooden structure built of glued or profiled timber.

One of the ways to increase the service life of such an object is to carry out high-quality interior decoration.

What manufacturers of finishing materials offer us

It is unlikely that anyone will be interested in the interior decoration of a house made of laminated veneer lumber, since there is no need to cover such material with anything. Therefore, we will continue to talk about the interior of the house from ordinary and profiled material. In this case, it will be described in detail how it will help keep the house warm and strengthen its walls.

What options for interior decoration of a house from a bar can manufacturers offer us:

- fake diamond;

- lining made of plastic and wood;

- block house;

- panel siding;

- drywall.

If you look at the photos of various interiors of a wooden house, you will often find combined options here. Moreover, each finishing material complements the other, forming a complete project. There is an original and interesting interior decoration of a log house, striking in its practicality.

Fake diamond

The second name of the material is decorative stone. The correct interior decoration of the walls of a house from a bar with the placement of accents can transform a boring room and give exclusivity to a bright interior.

What we need to know about the material:

- it is analogous to natural stone;

- durable and moisture resistant;

- the components from which it is made are not harmful;

- it makes it possible to create original and even unique interiors in wooden buildings, this is especially noticeable in combination with wood;

- its surface does not absorb various dirt and is easy to clean, a damp cloth is enough.

Advice: it is forbidden to clean the surface of the artificial stone with abrasive products. They can damage it and spoil its appearance.

- Prepare the wooden base before placing the artificial stone on it.

- Close the gaps in the profiled timber walls resulting from the masonry. To do this, make caulking with linen-jute thread or use other materials suitable for these purposes. Do not rush, do everything carefully, since the finishing part of the finish cannot be started until even the slightest drafts are eliminated.

- Level the wall surface with plasterboard or plaster, you can also use OSB board or thin plywood sheet.

- When preparing dry plaster, refer to the instructions on the package, which will indicate the exact amount of water required.

- Do not confuse starting and finishing plaster, as they have different functions. The first evens out the surfaces, and the second is needed to hide the defects of the starting layer and for decorative functions.

Tip: when used for leveling drywall walls, a metal frame from a special profile is required. You should get a crate, on which the sheets of plasterboard are installed.

Prepare materials for the installation of artificial stone:

- cement-based mortar or special glue;

- two small spatulas;

- building level;

- grout if necessary.

Technology

Below is a suggested instruction:

- The installation process depends on the size of the finishing material. The cement or glue mortar is applied to the wall and to the smooth side of the stone with a trowel.

- Use a second spatula to remove excess mortar from the surface.With a seamless masonry method, the stone should be installed from the bottom up, pressing tightly against each other. When the laying is supposed to be with a seam, then from top to bottom.

- Traditionally, the installation of each element according to the level, although it all depends on their size. Sometimes it can be stacked in a chaotic manner. In this case, first measure the required area of the cladding and draw it on the surface.

- Rub all the seams after installation with a special grout on artificial stone, it will not work for tiles. You can add dyes to the solution and carry out installation and surface finishing at the same time.

In fact, do-it-yourself interior decoration of a house from a bar is not difficult for beginners, since the back of the stone is flat.

Block house or lining made of wood

What you need to know about materials:

- wood absorbs moisture, therefore, without processing, it is not used in points with high humidity;

- they are practical and environmentally friendly, the interior with their participation looks great in a wooden structure;

- to protect them from dirt and insects, they are varnished;

- they are strong and durable, most often used to decorate a bedroom or living room;

- interestingly combined with natural and artificial stone.

Prepare materials and tools for installation:

- screwdriver;

- wooden bars;

- wood screws;

- building level.

- Install a wooden starter strip on the wall. The material will then be installed on it.

- Make a wooden sheathing and place insulation in its cells. Thus, at the same time, insulation and interior decoration of houses from a bar will take place.

Siding and plastic lining

These materials for interior decoration of a house from a bar do not absorb moisture, therefore they are used in the sanitary and kitchen areas.

Features:

- the surface of materials does not absorb dirt, therefore it is easily cleaned of it;

- installation does not cause difficulties, and it is possible to do it yourself, without the involvement of a specialist. Thus, it will be possible to save the family budget;

- the price of finishing materials is affordable when compared with artificial stone or lining made of wood.

Prepare tools and materials:

- boards and wooden blocks;

- wood screws of various sizes;

- sealant;

- screwdriver;

- construction stapler.

Installation:

- Create a batten from wooden blocks in the first step. Attach them directly to the wall with self-tapping screws.

- Establish a starting strip around the perimeter. It sets the direction of installation of the material.

- Insert panels into it and connect to each other according to the “tongue-and-groove” system. Attach to the crate with a construction stapler.

Tip: Use a sealant for the strength of each joint.

Drywall

Interior decoration with plasterboard of a house from a bar is popular for decorating wooden houses, but it has some nuances. Typically, such walls shrink, and can also deform due to external factors.

This must be taken into account, otherwise cracks will appear at the joints of the drywall, which cannot be removed.

In this case, the installation of drywall in such a situation differs in the method of attaching the sheathing to the wall.

- In a house made of laminated veneer lumber, which practically does not shrink, the lathing is fixed in the usual way using the CD 60 profile, and the suspensions are mounted directly to the wall using the CW profile. The gypsum plasterboard structure is able to withstand minor changes to the base due to the suspension system.

- If it is required to finish with plasterboard movable walls made of timber of natural moisture, it is better to equip it with "sliding" suspensions that do not depend on shrinkage and impede the process.

- The crate must not be rigidly fixed to the ceiling. It is installed in such a way that it does not reach the rough ceiling by 20-30 mm.

Fastening drywall to a wall without a profile

Of course, the most reliable and correct method is a frame device with the subsequent fastening of drywall sheets.But in some cases, the construction of a structure from profiles or bars turns out to be impractical - for example, if necessary, close or level a wall in a small room. In this case, the frame device will take away the already scarce space.

The possibility of frameless fastening of the gypsum board to the wall can be carried out under the following conditions:

- Compliance with the height of the walls to the length of the gypsum board. The frameless method requires the absence of horizontal seams, therefore, for installation, sheets should be selected that match or exceed the height of the ceiling.

- Relatively flat surfaces. The curvature of the walls should not exceed 20 mm, otherwise the sheets will not be fixed securely and may repeat the configuration of the underlying surface. Pre-alignment may be required to fulfill this condition.

- Strength. Since in the frameless method there is no gap left between the sheets and the stationary wall and the surfaces are tightly glued to each other, it is important that the base is strong and reliable. Crumbling brickwork or concrete slab will lead to the rapid destruction of the constructed structure.

- Favorable conditions. Mold, dampness and walls freezing in winter will negatively affect the components of the gypsum board and destroy the sheets.

If with the frame method it is possible not to process stationary walls in any way, then when installing drywall sheets directly on the surface, it is required to first clean it of old finishing materials and dust. In addition, it will be necessary to protect the gypsum board from dampness by arranging waterproofing in those places where there is a possibility of moisture or fungus penetration.

You can fix gypsum board sheets to the wall in several frameless ways:

- with glue;

- using polyurethane foam;

- using self-tapping screws;

- using dowel nails.

The choice of method will depend on the nature of the walls: the optimal method is determined based on their curvature and the material from which they are built.