High-quality and well-assembled insulation is one of the main components of home comfort. In addition to performing the main function of keeping warm, some of the heat insulators provide protection of walls and floors from external sounds and evaporation.

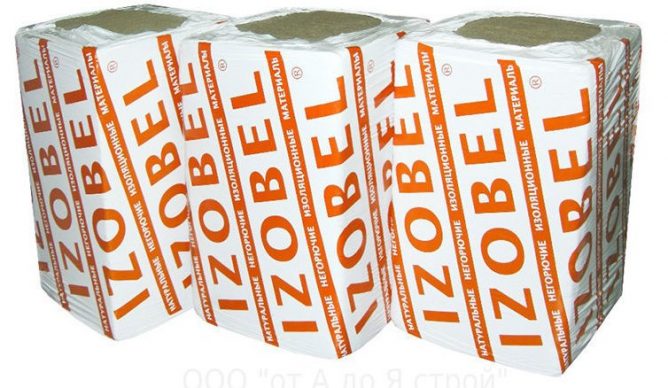

Domestic specialists have launched on the market the latest development in this industry - heat-insulating plates of Izobel mineral wool. The growth of their popularity in the market is stable. Why do buyers appreciate them and why do craftsmen recommend them? Let's figure it out.

Insulation features

The area of use of isobel is to reduce the thermal conductivity of buildings for various purposes. In the production of insulation, EcoSafe technology is used, which reduces the amount of moisture absorbed by the material. Izobel slabs are a type of basalt wool (material with the lowest thermal conductivity) and are manufactured without the use of blast furnace slags. Typically, the insulation has a standard size (1000 × 600 mm, 1000 × 1000 mm, etc.).

Isobel can be produced not only from heavy basalt rocks, but also lighter ones like limestone or quartzite.

The resulting slabs weigh less and do not hold heat so well, but their density is higher, which affects the durability. A similar izobel is used for cladding places in a house, where thermal insulation does not play a special role, and fire resistance and noise absorption are much more important (non-residential attics, ceilings, pitched roofs).

Features of the manufacture of Isobel L-25

When developing a new product, specialists put the quality indicators of Izobel L-25 insulation in the first place. The technological process of EkoSafe products, first of all, is based on the quality and stability of the raw material indicators.

Often, in the production of heat-insulating materials from mineral wool, blast-furnace slags are added to the raw materials, which directly affect the value of the acidity modulus. On the one hand, these additives increase the percentage of iron and improve the physical characteristics of the product, as well as reduce the cost of the product, but on the other hand, they significantly reduce the life of the insulation.

Since slags are blast furnace waste, each batch is characterized by its own chemical composition. Consequently, after their addition to the basalt raw materials, the properties of the Isobel L-25 slabs will also change. Therefore, it is very difficult, and sometimes even impossible, to ensure the constancy of thermal insulation and noise suppression performance.

For the production of Isobel L-25 plates, blast-furnace slags are not used at all. The balanced composition of the melt with a minimum modulus of acidity makes it possible to achieve an accurate design viscosity and fluidity of the material. Holding the Isobel L-25 semi-finished product at a constant temperature makes it possible to obtain a finished product with pre-planned characteristics. The certified laboratory constantly inspects the quality of each batch of insulation Isobel L-25.

Features of installation isobel

Due to its ease of use, insulation is used almost everywhere. Thermal insulation with its help will be justified in such places:

- partitions between floors;

- floor;

- sloped roofs;

- attic;

- walls.

The only place that is undesirable to insulate with isobel is the foundation, since the slabs can get wet from interaction with the soil and fail.

Like any other mineral wool, insulation requires two additional layers - hydro and vapor barrier. The first protects the plates from getting wet from the outside, the second - from the inside. When installing Isobel on a sloping roof, it is recommended to make an air gap, the purpose of which is to drain the accumulating condensate.

The key difference between isobel like mineral wool and foam is that it is not mounted directly to the wall with glue, but is placed inside the cells formed by a wooden crate. Plus such a need - additional strengthening of the building frame, minus - financial investments.

IZOBEL® LIGHT

Due to its ease of use, insulation is used almost everywhere. Thermal insulation with its help will be justified in such places: The only place that is undesirable to insulate with isobel is the foundation, since the slabs can get wet from interaction with the soil and fail.

Like any other mineral wool, insulation requires two additional layers - hydro and vapor barrier.

Varieties

The first protects the plates from getting wet from the outside, the second - from the inside. When installing Isobel on a sloping roof, it is recommended to make an air gap, the purpose of which is to drain the accumulating condensate.

The key difference between isobel like mineral wool and foam is that it is not mounted directly to the wall with glue, but is placed inside the cells formed by a wooden crate. The material is new, no one really could advise the sellers of nothing, since the persons are interested.

But for 3 years now our bathhouse has been heated and everything is in order! It turned out that for less money we bought ourselves and the quality is excellent! Types, application Isobel brand slabs differ in some technical parameters: 1. Technical characteristics Since Izovol refers to basalt heaters made without the use of iron-smelting waste, it has all the advantages of this rock: strength, heat resistance, durability, environmental friendliness. Its unconditional advantages are: Low water absorption.

Low thermal conductivity. Stone wool mineral Izovol consists of the thinnest, elastic basalt fibers, which have a low coefficient of heat conductivity. High vapor permeability. The internal structure allows excess moisture to easily pass through, which can accumulate inside the building, which has a beneficial effect on the condition of the building. This is especially important when insulating industrial premises, baths or saunas. Excellent soundproofing.

Reviews about the insulation made of Izovol mineral wool boards confirm that the products of this company almost completely neutralize noise, maintaining a comfortable environment in the room. It has excellent resistance to various organic substances, does not corrode and form fungi. The technical description of the insulation company Isobel classifies it as non-combustible materials.

Environmental Safety.

The service life in the temperate continental climate zone is 50 years. A clever meter that conserves electricity. Pays off in 2 months! Everyone needs to know this in order to save money!

U-shaped cut

Description and reviews Order at a discount. Author: Roman Medvedev. Overview of mineral wool insulation Thermal insulation of a house in the harsh Russian winters is an overview of the characteristics of insulation in rolls For large areas, pipes, ventilation shafts, mineral wool in production technology allows you to get material of different thicknesses and densities.

The purpose of the insulation and its price depend on this value.

Material specifications

Izobel heaters have approximately the same physical characteristics. For example, a plate with a size of 1000 × 600 mm is considered below. Its characteristics will be:

- density - 25 kg / cu. m;

- thickness - from 40 to 250 mm;

- vapor permeability - from 0.3 mg / m * h * Pa;

- flammability class - IV (best);

- thermal conductivity coefficient - 0.03-0.04 W / m * K;

- absorption of liquid at full immersion in water - up to 1.5%;

- moisture content by weight - up to 0.5%.

The key advantage is obvious - the low degree of water absorption makes it possible to use isobel even when external walls are insulated.

Features of the national product

Insulation Izovol is produced at the Belgorod plant of non-standard equipment (CFO) from gabbro-basalt fibers. But unlike foreign analogues, the melt of rocks for the formation of thin threads is carried out in gas furnaces. This allows you to reduce energy consumption for production, and hence the cost of the product itself. The technology was named Ecosafe, since the presence of coke or blast furnace slag in the insulation fibers is completely excluded. As a result, it was possible to achieve constant properties of stone threads, a stable acidity modulus (2.0-2.2) and record efficiency indicators for mineral wool.

The scope of Izovol insulation is the same as that of other stone wool, and also depends on the density of the material. Basically, Izovol insulation is used in construction to protect:

- Indoor premises (walls, lagged floor).

- Roofs and attics.

- Unloaded floors.

- Facades for cladding or subsequent plastering.

- Flammable objects such as steam rooms in saunas and baths.

So far, the Belgorod mineral wool Izovol is not very well known to a wide range of buyers. However, the relatively low cost of the insulation with decent characteristics arouses interest in it. So some have already tried out the new material at work and shared their impressions in their reviews. The only thing that is too early to talk about is the actual service life of the mineral insulation. It entered the market only 10 years ago, but from 50 to 80.

Insulation specifications:

- The density is 20-175 kg / m3 (depending on the Izovol series), respectively, the compressive strength varies within 35-80 kPa.

- Thermal conductivity - 0.033-0.041 W / mK.

- Fire resistance - + 800 ... + 1100 ° С. In fact, stone wool does not burn, but when this temperature is reached, it begins to deform.

- Water vapor permeability - 0.03-0.035 mg / m · h · Pa.

- The maximum length of the insulation fibers is 50 mm, the thickness is 5-15 microns.

- High resistance to aggressive environments, fuels and lubricants, alcohols.

Judging by customer reviews, there were also some drawbacks, but they turned out to be uncritical. Most of all complaints are about bulky packaging and thin film, which makes it difficult to transport mineral wool.

Insulation advantages

Minvata would not have become so popular among consumers if it did not have a number of advantages. With regard to insulation of the Izobel brand, the qualities listed below are considered as such.

- Excellent thermal conductivity - coefficient from 0.03 to 0.04 - one of the smallest among heaters. If you add to this the thinness and elasticity of basalt fibers, you get an almost ideal material that allows you to significantly save on heating the room.

- Fire resistance - isobel belongs to the IV group of fire safety materials. In the presence of a nearby fire site, its physicochemical properties will remain unchanged; also the plates will become an obstacle in the path of the spreading fire.

- Long service life - insulation made of basalt stone lasts for at least 50 years, subject to storage conditions. Excess liquid will in no way affect the material - the fibrous structure will easily let steam through and evaporate condensate.

- Weak water absorption - basalt is non-hygroscopic; only 1.5% of its volume can be filled with moisture. If water-repellent additives are used in the production, the value is reduced to 1%.

- Good vapor permeability - achieved by the fibrous structure of the material and promotes the use of isobel in baths, saunas or industrial premises.

- Sound insulation - depending on the thickness of the slab, they completely or partially neutralize extraneous noise.

- Resistant to corrosion, fungi, rodents, unattractive to birds.

- Affordable price - isobel is on average 15% cheaper than mineral wool analogues; for a slab with an area of 1 sq.m and a thickness of 50 mm, the consumer will give from 100 to 300 rubles.

- Environmental safety - achieved by a minimum amount of chemical components used to increase water repellency, and even then not always.

The above is only a part of the positive aspects of the izobel insulation. Other benefits are easier to perceive in operation rather than describe.

Life time

Isobel is considered one of the most durable insulation materials produced from basalt stone due to the successful combination of its unique properties.

During the experiments, which included 2360 cycles, based on the stability of the main technical characteristics of stone wool, the preservation of the structure of its fibers and binder, a long service life in a moderately cold climate was determined - more than 50 years.

Excessive moisture in the room will not affect the quality of the heat-insulating material in any way. The fibrous structure of the Isobel slabs easily allows steam to pass through, and the condensate that accumulates on the surface evaporates without affecting the quality of the slabs themselves.

Related article: My experience of using liquid sealant in construction

Disadvantages of thermal insulation material

Alas, even Isobel is not devoid of disadvantages, although there are not so many of them. These include:

- the possibility of loss of thermal insulation properties at the joints of the slabs or in the area of contact with the crate (the joint is not sealed with a sealant or foam, like polystyrene);

- an additional waterproofing layer is required, since with a direct hit of water, the plate will swell and cease to be useful;

- a crate of certain sizes is required (according to the dimensions of the izobel insulation slabs);

- the process is complicated by the use of a mask, gloves and clothing that covers the skin; otherwise, small particles that come off the stove will get on the skin, causing allergies or scabies.

Despite the slight disadvantages of isobel, the material is still recommended for use in almost any room. It is accessible, it is easy for them to sheathe a section of the house, and the next replacement of insulation, subject to the installation technology, will not have to be done earlier than 50 years later. When buying material, the consumer will save a good amount, and during operation he will be convinced of the right choice.

The main advantages of using ISOBEL insulation material

The advantages of using heaters of the IZOBEL series are as follows:

- obtaining high thermal insulation indicators, which opens up the possibility of using the material in a variety of situations (due to the saving of heat in the room, the cost of heating the building is significantly reduced);

- due to excellent soundproofing performance, the maximum possible silence is achieved (the structure of the material does not allow sound waves to pass through the insulation);

- during the development of the material, a high-tech production method is used, due to which a high-quality environmentally friendly product is obtained from mountain basalt rocks;

- when working with insulation, you do not need to have any special technical knowledge or skills (due to its high compressive strength or any other mechanical impact, the insulation quickly takes on its original shape).