Share this

In order not to be afraid of water leaks and the possibility of flooding the neighbors from below, the walls and floor in the bathroom must be protected from moisture by waterproofing. There are several types of waterproofing materials that differ in the method of application: gluing, coating and penetrating. Separately, paint waterproofing can be distinguished, but its differences from the coating are minimal, it differs only in a smaller layer thickness.

Let's consider what types of roll waterproofing are and how to properly install roll waterproofing materials for the floor using the example of roll waterproofing floor "Technonikol".

What is waterproofing for?

The role of waterproofing in building a house is difficult to overestimate:

- Durability. High-quality building materials do not guarantee the safety of the elements of the house. To do this, it is necessary to protect the walls, foundation and roof from the harmful effects of water.

- Keeping warm in the house. Waterproofing is used in situations where multi-layer installation using thermal insulation materials is applied. If you do not create a barrier to groundwater or rainwater, the thermal insulation layer loses its properties and becomes useless.

Roofing material - cheap and short-lived

A typical representative of roll materials is roofing material. The low cost of such waterproofing, unfortunately, does not provide durable protection. Usually the shelf life of roofing material does not exceed 10 years.

The main components of roofing material:

- cardboard, which plays the role of the basis for the main waterproofing agent;

- bitumen layer applied to cardboard and providing water resistance of the material;

- a sprinkling of stone chips that protects roofing material from mechanical stress and increases its strength.

The main problem in waterproofing with roofing material is the softening of the cardboard base with prolonged exposure to moisture. A loose structure quickly deteriorates, which is why all the material crumbles over time. Against the background of more expensive types of protection, roofing material is losing its popularity, but is still used for waterproofing technical structures such as sheds, temporary buildings and sheds.

Membrane (polymer) waterproofing

Polymeric waterproofing materials are a type of roll-on pasting materials created using modern advanced technologies. They are thermoplastic or vulcanized rubber membranes, reinforced polyethylene straps and other materials. In contrast to the above materials, membranes and films have a very small thickness, which ensures almost complete absence of compression shrinkage. Polymeric waterproofing materials are one of the most modern, but at the same time expensive waterproofing materials. They are distinguished by their strength, durability, and elongation. Available in soft sheets or rolls.

The disadvantages of this type of waterproofing materials include the need to pre-treat the base with a primer, or the presence of an air gap for ventilation. This is explained by the fact that polymer materials have a very low vapor permeability, and can simply come off under the pressure of water vapor.

High quality bitumen roll materials

More technological types of roll waterproofing using durable materials as a basis have become a worthy alternative to the outdated roofing material:

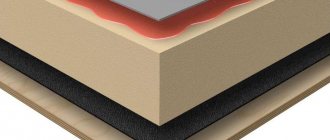

- Fiberglass. The water resistance of the coating is provided by bitumen spraying, which is applied to a layer of fiberglass or fiberglass. To give the bituminous layer flexibility and strength, manufacturers add special modifiers.

Benefits:

- durability due to the resistance of fiberglass to decay after prolonged exposure to water, acids and alkalis.

- the ability to select material of different density and purpose;

- soundproofing;

- higher fire safety class;

- thermal stability due to the inclusion of various stabilizers in the bitumen layer, which ensure the softness of the layer during temperature fluctuations.

When choosing a fiberglass-based material, it is better to choose a denser material. In styling, it is more comfortable and smoother.

- Polyester.

Fiberglass is also used for the base of these materials, but with the addition of synthetic resins. This combination provides high elasticity and strength of the material in the event of deformation or tension. Such waterproofing is especially recommended for structures with complex shapes.Benefits:

- high elasticity and preservation of integrity under tension;

- durability, since the material is not subject to destruction in the aquatic environment;

- high resistance to temperature fluctuations, UV rays.

safety and environmental friendliness;

The use of polymers in production technology

Roll-type waterproofing materials using polymer modifiers have a high degree of thermal stability. Due to this property, they are recommended to be used for roof protection in hot climates. Some types of rolled waterproofing materials retain their elasticity and integrity when heated above 100 ° C and reduced to -40 ° C. For use in the middle zone, the more affordable euroruberoid, bikrost, uniflex, bipole are most often used. In the production of these materials, a technology is used, due to which bitumen is combined with polymer components and acquires flexibility, resistance to decay and elasticity.

Bonded waterproofing TechnoNIKOL

The brands of TechnoNikol are very well known to Russians by the names "Solo", "Vent", "Technoelast", and "Bikrost". With their help, you can make high-quality insulation for any flat roof. All insulation of the series is made of oxidized modified bitumen with glass fiber reinforcement or polymer bases. In production, the technological parameters are constantly monitored, therefore the products of the TechnoNikol company have proven themselves from a very good side, therefore, construction companies prefer to purchase materials only of this brand.

For large-scale developments, it is worth purchasing a "Business" or "Premium" class water protection. Polymer-bitumen materials of this class are of high quality, as they are made on the latest equipment. Waterproofing is designed for a service life of 15-30 years. That is why large developers give their preference only to those brands that use modern technologies in production.

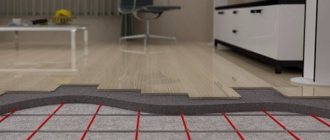

Features of laying bitumen roll waterproofing

Laying of the coating is carried out taking into account the peculiarities of the type of roll waterproofing. But there are general requirements that must be followed without fail.

- Surface preparation consists of thorough cleaning of dirt, debris and dust. This helps to create good adhesion of the protective layer to the structure. If there are any irregularities, cracks and protrusions, they are pre-sealed with a special plaster and treated with a primer.

- Measure the length of the pasting area and cut the required length from the roll.

- At the stage of laying the roll waterproofing, depending on the manufacturer's recommendations, use bituminous mastic for gluing the canvas or use other adhesives. Fused bitumen materials may require some skill from the craftsman. The rolled-up web is laid at the beginning of the surface to be treated, the adhesive side is heated with a gas burner and the web is leveled. To create high-quality protection and good adhesion over the entire plane, you should evenly heat the adhesive side of the material and press the web against the surface. Close attention should be paid to the joints of the canvases, a poor-quality connection can cause problems with wetting the walls or roof.

Roof waterproofing

If the roof is insulated with expanded polystyrene, you can use a film as a waterproofing material, or you can not install waterproofing at all, since expanded polystyrene itself resists moisture well if the seams are properly processed.

When it is necessary to insulate and waterproof a flat roof, then it will be relevant to use various membranes along with thermal insulation. One of the simplest options for a flat roof is to use mastics (bulk waterproofing). This method can be used both for a new roof and for filling and sealing joints of an already in use structure. However, if you have opted for roll waterproofing materials and are planning to do their installation yourself, we advise you to pay attention to ordinary roofing material, as well as new materials - rubemast and euroruberoid.

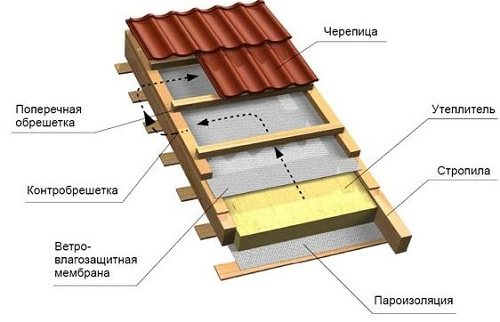

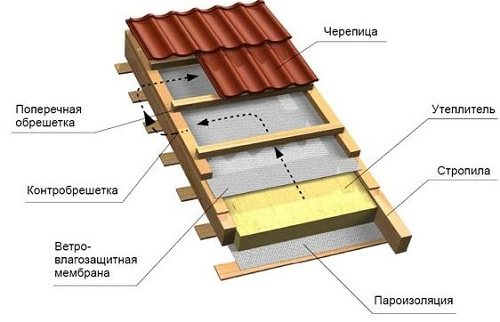

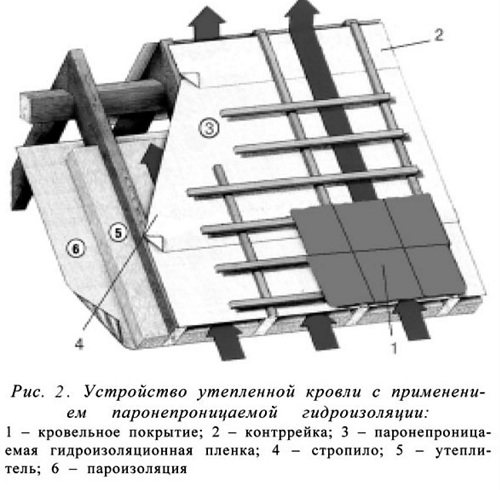

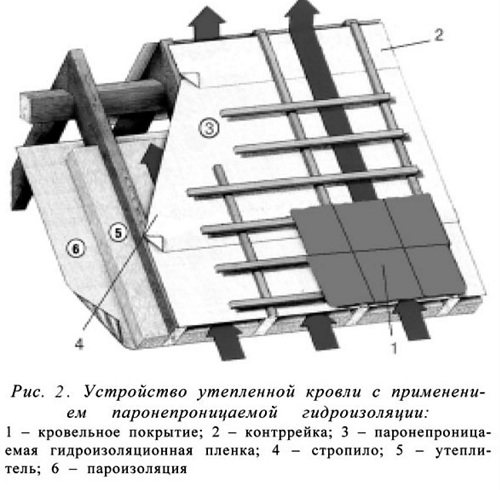

If the plans are to equip the attic in the attic, then together with insulation and vapor barrier materials, you can use a superdiffuse membrane.

This is the best option, but very expensive. However, if the roof has a complex configuration, it is best to use a membrane.

Some experts say that if the slate is laid according to all the rules, then there is no need for waterproofing. Let us disagree with them, and remind that earlier roofing material was laid under the slate. A hydro-barrier or perforated waterproofing film is now used. The same materials are laid under the metal tile.

The film is attached to the rafters on the pitched roof, or to the lags in the attic. Building fasteners are used to connect building elements. Fastening tools - stainless steel nails or staples. If the attic is not insulated, then such a film, and even in combination with insulation, is one of the most economical and high-quality options.

For metal roofs, it is recommended to use an anti-condensation film. When installing this waterproofing material, the upper and lower ventilation gap must be observed. For this, a crate is installed. If a diaphragm is used, there is no need for the bottom clearance.

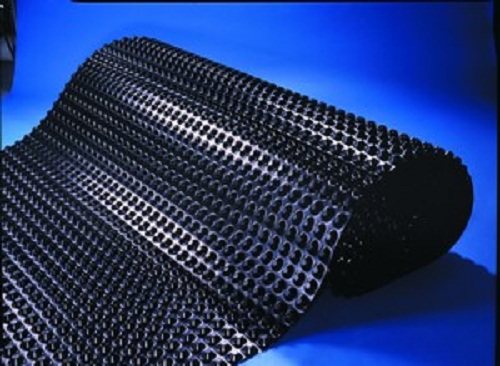

For flanged roofs, there are special volumetric separating membranes on sale. For slate roofs, membranes are used here and one ventilation gap is arranged.

Finally, I would like to note that there are a lot of important nuances when choosing waterproofing for a roof. But the most important ones depend on:

- Roof forms.

- The purpose of the roof (will it be used or not).

- Type of roofing material.

- Insulation type.

Advantages of roll waterproofing

Despite its requirements for surface preparation and the need for cutting out and measuring, roll waterproofing has many advantages.

Advantages of surfacing waterproofing

Bitumen-polymer roofing waterproof material is designed for high-quality insulation of flat roofs, foundations, underground structures, tunnels and bridges. Let's consider its advantages in more detail:

- frost resistance. Thanks to this quality, roofers are able to carry out work even at -20 ° C;

- quick installation;

- the reasonable price of welded waterproofing per m2 allows it to be used everywhere;

- good hydro and noise insulation;

- suitable for repeated repair;

- the ability to apply insulation over the old coating.

How to choose the type of roll material for waterproofing

The choice of material should be based on the following criteria:

- the degree of durability, which is determined by the shelf life on the package;

- the ability to maintain its properties under prolonged exposure to UV rays, which is important in case of direct contact with solar radiation;

- strength and ability to withstand the pressure of water in the case of pasting the foundation and walls of basements;

- cost is a rather conditional criterion, since a high price does not always guarantee quality;

- ease of installation (materials on an adhesive basis are convenient, which do not require the use of bituminous mastics).

The choice of a specific type of bituminous roll waterproofing depends on the room in which it will be performed. High-quality waterproofing assumes durable and effective protection of the premises from water ingress from the street.