In multi-storey panel-type buildings, there is one problem that any owner faced - the noise coming from the sewer. There are many reasons for the unpleasant sound, as well as methods for solving this problem. Correct sound insulation of a sewer riser can not only protect against noise, but also add zest to the interior design. In this material, we will try to consider all aspects of high-quality soundproofing of the riser, how to wrap it and what can be done.

@Shumka_Trub

What is the soundproofing of the sewer riser for?

The issue of soundproofing sewer pipelines is quite relevant today, since many use plastic components. Plastic pipe, unlike cast iron, is exposed to the passage of various types of noise. When sewer drains from cast-iron structures were installed, there was practically no noise, and if something murmured somewhere, then literally in a few days everything calmed down. Modern building materials differ in their cost and characteristics. The only drawback of plastic products is the low level of sound insulation, which leads to discomfort for household members. Noise insulation of sewer pipes in an apartment must be carried out in the correct sequence.

@Shumka_Trub

Some developers, when building new houses, install soundproofing of sewer pipes, but there are very few of them. The only solution to the issue is to independently make the soundproofing of the riser in your apartment. To carry out insulation work, you do not need special education, large financial costs or tools. Anyone with the ability to work with scissors will be able to do all the installation work with their own hands.

Despite the ease of the processes, there are a number of difficulties that the master may face. First, you need to figure out why and where the noise starts, after that you need to figure out the choice of components. Of course, a specialist can quickly and efficiently solve the issue of soundproofing the sewage system, but you will have to pay money for such work.

How to make noise insulation of a sewer riser

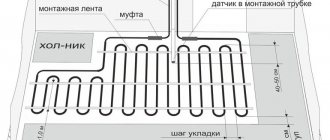

If a person has a question of how to make noise insulation of a sewer riser, then in this case it is better to give preference to winding labor with special soundproof materials.

An example of soundproofing a sewer riser

Such sound insulation is easier to perform than to sew up pipes with a box, but, despite this, it is also important to follow the exact sequence of actions:

- choose a suitable soundproofing material, as already mentioned, there are several options for such a material;

- degrease the pipe surface with special agents;

- apply vibration damping material to the pipes, which will remove structure-borne noise;

- roll the vibration damping material with a roller, at this stage it is important to remove all air bubbles from under the material;

- wrap the pipes with noise-insulating material and fix it to the pipe using clamps or construction tape.

Do-it-yourself noise insulation of a sewer riser

Previous articles Next articles

Similar posts

- 25.06.2016.

Sewer pipes from Politek: choose yourself

- 23.06.2016.

Sewer pipes Polytron: features, price, installation

- 14.05.2016.

Causes of the appearance of sounds from the sewer riser

Riser sounds can occur due to various factors.Depending on what reason, you can solve the problem as quickly and efficiently as possible. There are enough reasons for the noise of plastic pipes, they can be:

@Shumka_Trub

- Impact, if inside the riser some object beats against the walls;

- Atmospheric, resulting from the passage of the wind through a ventilated riser;

- Resonant when the trumpet transmits extraneous sound;

- Vibration, arising during the vibrations of the building structure.

The trumpet itself is an acoustic object and bears some resemblance to a speaker from a musical center. Even if something hits the pipeline on the top floor, the whole house will hear it well. It is problematic to protect the drainage system from the ingress of objects or contaminants, and only soundproofing the sewer drain remains.

There is another type of sound that is absolutely harmful in comparison with the others - this is infrasound. The main difference between this sound is that it is heard at 7 Hz. Such noise can not only infuriate or madden, but even kill a person. When choosing sound insulation for sewers, this aspect needs to be given special attention.

@Shumka_Trub

There can be a lot of reasons for the appearance of noises in risers, and it is pointless to find out their appearance. If there is a problem, then it must be solved immediately and for this the market offers a large abundance of goods. Correctly performed soundproofing of sewer pipes in the toilet will allow you not to listen to unpleasant noises while visiting the bathroom.

Why do not cast iron pipes make noise

If we compare the noise from plastic and cast iron pipelines, then the second material emits them much less. The whole secret is hidden in the composition of cast iron. It consists of microscopic grains, thereby reducing vibrational vibrations. In addition, the porous structure of the product contributes to the rapid growth of plaque, as a result of which the mass increases, and the resonant vibration decreases.

The meaning of the procedure

Unfortunately, it will not be possible to completely get rid of annoying noise. The creation of sound insulation for sewer pipes is carried out in order to reduce them to the lowest possible level. Taking into account the reasons for the occurrence of noise in the apartment and the essence of the work performed, the goals can be divided into three main areas:

- Reducing the vibration of plastic pipes.

- Prevention of the transmission of vibrations from the sewer riser to the structural elements of the building.

- Creates a barrier to the sound generated when the water is drained.

Noise insulation methods for the riser

If it is not possible to replace a regular pipeline with sound-insulating products, then a number of measures can be taken to reduce noise in the sewer. Cast iron pipes were installed in old houses, and there are those who are just thinking about replacing them with modern plastic products. When the question arises: how to soundproof a sewer pipe, then there is no definite answer, only an integrated approach will help to do everything quickly and efficiently. If such thoughts are in the future tense, then the old metal structures can still serve, the only thing they need to do is a good cleaning. Today there are tons of descaling products. It is necessary to carefully treat the internal parts of the structure with a chemical solution. Of course, it is impossible to completely clean everything, however, chemistry will destroy the structure of the plaque and literally in a few days it will be washed off with water. The advantage of such cleaning is simplicity and low cost.

@Shumka_Trub

The appearance of cast iron pipes is completely unattractive, so they often replace the pipeline throughout the house. Plastic pipes are the best value for money. Such a sewage system will be prettier, but it additionally needs to be soundproofed with special soundproofing products.If the riser in the apartment is made of a solid pipe without connections, then using special clamps, dampers can not only be securely fixed, but also soundproof the material. The cage glass has a rubber insert in its design, which is a vibration-insulating layer. It is this layer that helps to minimize vibration and structural noise in the structure. To protect the room from noise, it is also important to treat the top and bottom of the riser with a soundproofing sealant.

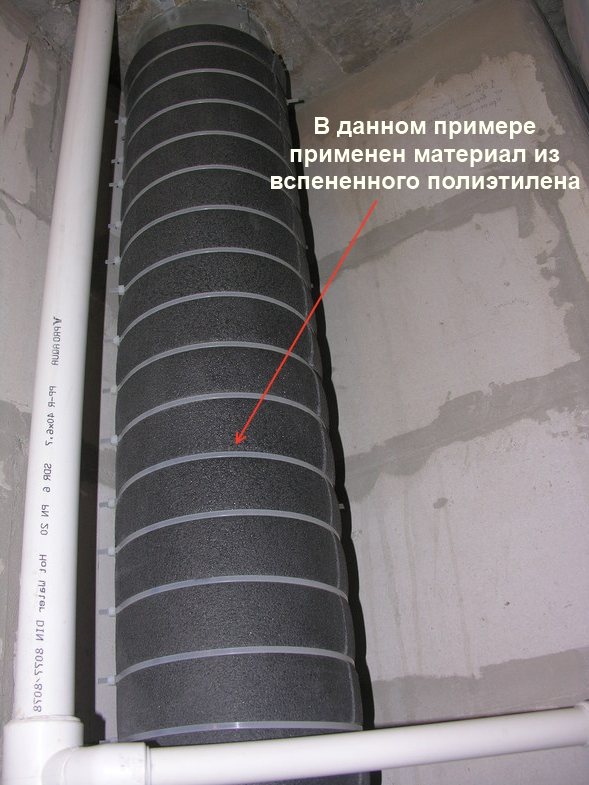

Also, foam polypropylene can be used as an option for sound insulation. The principle of soundproofing the riser is similar to the previous one, but the difference lies in the cost of the components. The second option is cheaper. Regarding the working process, the insulating tube has one seam, and due to the softness of the product, you can easily wrap it around the noise generator and fix it with tape. All types of installation work can be done by hand, thereby saving on calling the masters.

Important! If sound insulation of a plastic sewer pipe is used, then you should choose products with a diameter that fully correspond to the size of the product, the quality of the insulating layer depends on this.

Some "masters" argue that soundproofing of water supply pipes can be carried out with construction foam. In fact, the effectiveness of such a method is minimal, and there will be a lot of garbage, and the appearance will suffer greatly.

@Shumka_Trub

There are people who use mineral wool as a soundproof building material. It is not advisable to use such an insulator open. Microparticles of fibers can enter the respiratory system and cause a lot of problems. In addition, the effectiveness of mineral wool extends to airborne noise, but it cannot cope with infrasound, so it is better to protect yourself and your family from negative effects.

Decorative insulating box

For audible noises in the sewer, you can use special polyurethane foam pads, which are made to the appropriate size and diameter. This is a kind of decorative and insulating boxes, which, in addition to insulating properties, complement the overall appearance of the structure. Insulation consists of two halves; when assembling the structure, it is fastened with grooves. The main advantage of such a soundproofing of the riser is the speed of work. In just a few minutes, you can put on a cover, and additionally wrap it with construction tape. Such products can be used if there is a space between the main wall and the riser for connecting the casing. If the pipeline fits snugly to the surface, then such sound insulation will be ineffective, but it will be able to keep a certain level of noise.

@Shumka_Trub

Communication connections are often located in the corner of the room. This arrangement is beneficial and convenient in its own way. If you install a box in the corner of the room, then you can completely hide all communications, and give the room a more aesthetic look. It is convenient to make a box from two walls in the corner. Not only will it take a minimum of work, but such a change will have a good effect on the overall look.

To make such a box, you need to install two supports on the wall at the top and bottom. It is necessary to install the mount in such a way that the canvas completely overlaps the corner. Any type of building material can be used as a panel, from plywood to acoustic drywall.

Even if the pipe runner itself is not neatly noiseless, the panel will hide all the flaws. You can make sure that access to the corner remains. The panel can be fixed using decorative fasteners. Thus, if necessary, the structure can be dismantled for carrying out repair and technical processes.

Silent pipes

The best is considered to be the soundproofing of the drain pipe in the toilet, it is its content and design. Products with sound-absorbing characteristics are offered on the market today. In terms of sound retention, such products are comparable to cast iron. The composition of the material contains various additives, making the product immune to all kinds of noise. Such tubular products are capable of neutralizing even infrasound. The plastic contains a special powder made on a mineral basis. In appearance, such products differ in the thickness of the pipe walls. Basically, such designs are made in white with red and green stripes applied. The manufacturer's logo is applied to high-quality products. Sound-absorbing pipes, as well as cast iron pipes, are capable of dampening various types of noise, including infrasound. The only drawback of such components is the high cost and relatively short service life, which is equal to twenty years.

@Shumka_Trub

If we consider silent pipelines for the sewer system, then they are considered the best option. Despite the rather expensive product, there will be no communication problems for two decades. The installation method of such communications does not include anything complicated, the main thing is to correctly assemble and make additional waterproofing in advance. Having completed the installation of noiseless pipes correctly, you can ensure comfortable conditions, and if, in addition, you perform soundproofing of the entire apartment, then the level of comfort will be maximum.

Use of sound-absorbing films and coatings

Due to the abundance of soundproofing materials on the market, it is possible to find relatively inexpensive and simple options. For an economical option for soundproofing the sewage system, you can use a film coating or soundproof tape. The cost of such goods is low, and with properly carried out sound insulation, the noise level will significantly decrease. The only drawback of this method is that it is not very attractive, but this issue can be dealt with much easier than effectively and inexpensively protecting the sewer pipe.

How to choose a soundproof material

Of course, the offered assortment of building materials gives some difficulties with its choice. How to soundproof a sewer riser at minimal cost. First, when you come to the store, you need to initially understand what his budget is designed for these purchases. It is important to choose in such a way that the insulating material is sufficient. It makes no sense to purchase expensive products if there is only enough money for part of the structure. Also, the selection criterion is the installation method and the location of the riser relative to the walls. If the communications are in a separate niche in the wall, then in this case it is not necessary to insulate the riser itself, but the entire place allocated for the pipeline. In this case, it is necessary to create a false wall with accessibility. Quite often, such niches are laid with bricks, leaving a small revision window. By installing soundproofed inspection doors, you can hit two birds with one stone at the same time. Get rid of noise and add neatness to the interior.

@Shumka_Trub

Of course, the main selection criterion is the cost of the material, and only after that they look at the characteristics. With the use of modern sound insulation, good results can be achieved even with a minimum thickness. Everything entirely depends on the owner of the apartment and his financial capabilities.

Work on soundproofing the sewer riser

- The circumference of the pipe is measured first. This is required in order to know exactly how much material should be cut to obtain a perfect joint.

- If the material was purchased with a margin, then you need to cut off a small strip from it, about 1-3 centimeters, and wrap the pipe with it. In the case when it fits perfectly, then you can measure the entire remaining segment along it.

- As soon as the material is cut, you need to pull off the joints from above and then wrap the pipe with construction tape for several turns. This work should be done along the entire length of the riser.

- A box is installed on top of the pipe, which outwardly has an attractive appearance. It is desirable that he be filmed.

There is a misconception that heat insulators can be used instead of noise absorbers. It is impossible that the sound insulation of the sewer riser was made of heat insulators - they are not able to protect against sounds.

Also, when arranging the soundproofing of the sewer, it is impossible to use foam, since it does not have elasticity, and this enhances the mutual sound transmission between the riser and the walls.

Installation

When you have figured out the choice, you can proceed to the installation work. Before doing anything, it is imperative to prepare tools and accessories. Everything should be at hand, but, in no case, interfere during the work process. It is also important to know that preparation is done before any installation work. The surface of pipes, riser must be cleaned of dirt and dust. Such a procedure is necessary, since almost all dust, cobwebs and other defects that negatively affect the fixation of components accumulate on it. To begin with, you can wipe it off with a rag, and then degrease it with a special solution, the main thing is that the product does not collapse from direct exposure.

@Shumka_Trub

The required size of the web is measured and cut in accordance with the design of the drain. If the material has an adhesive base, then wrap it with the soft side outward, and with glue to the pipeline. The soundproofing qualities of the entire structure depend on the correct cut. If the product is used without an adhesive base, then glue or silicone is applied to the surface of the pipeline. The wrapped insulation sheet can be overlapped to improve the insulation performance. On top of the sound insulation, you can stick an adhesive tape for additional fixation of the insulating layer. The tight-fitting insulation will effectively and reliably protect not only the pipe, but also the bathroom itself from extraneous noise.

Silent pipe laying

Silent pipes are quite popular today and they are being installed to replace the old cast iron or even plastic ones. Despite the slightly high cost of products, its popularization is not diminishing, but all thanks to its performance.

@Shumka_Trub

To lay a silent pipe line, certain recommendations must be followed:

- When measuring length, it is important to consider product tolerances. The plastic structure is cut to the required size, and the cut edge should be filed to remove the burr, as this can affect its tightness.

- At the connection points, it is necessary to install the O-rings in accordance with the grooves intended for them.

- Pipes are connected by inserting a socket into the fittings. Before inserting the joint, it is treated with a sealant for better sealing and sound insulation. The fittings are inserted all the way to the stop, but during installation it is necessary to move the pieces in such a way that a small gap is formed if there is thermal expansion.

By the nature of the work, it is not difficult and any owner can perform it, the main thing is to correctly measure and install. If necessary, the product can be fixed using special holders with rubber tabs. In addition to fixing, such fasteners minimize vibration noise in the riser. By using noise-insulating pipes, it is possible to minimize the noise arising from the sewer system.

@Shumka_Trub

The use of such a sewage system will save you from noise and repair problems for at least twenty years, so it is not a pity to spend money on communications, it is much more profitable than to repair individual sections in the future.

Soundproofing works

Noise insulation of plumbing pipes should be carried out in a comprehensive manner. In addition to the riser, there are also other communications and thin walls. As for the walls of the bathroom, depending on the area of the room, the optimal sound insulation is selected. The pipeline must be prepared before starting the insulation work. All dust and dirt is removed from the surface. It is also possible to additionally degrease the surface for maximum adhesion to the adhesive backing. The material is selected in accordance with the requirements for sound insulation.

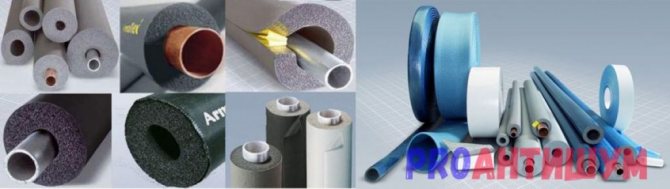

If a sheet canvas is selected, then it must be marked and cut to size. Correct measurements guarantee a reliable sound insulation effect and an exact match. For an economical method of insulation, you can use: expanded polyethylene, polyurethane foam, plastic scarlop, soundproofing tapes and roll insulation.

Insulation such as mineral wool is not suitable for open sound insulation, small particles of fibers can be deposited in the lungs or on the skin, which will lead to a deterioration in well-being and health in general. Also, do not use construction foam, which is helpless for soundproofing the fan pipe.

@Shumka_Trub

Roll-up will be a good soundproofing of a budget type. The drain is wrapped in a dense overlapping layer of insulation. For better fixation, several layers of construction tape or crimping clamps can be wound over the insulation. It should be noted that an increase in the mass of the structure helps to reduce resonant sound.

Advice! If, at the end of the soundproofing, the maximum effect is not achieved, as an addition, it can be done using a plasterboard box. It is also possible to increase efficiency by using plastic structures. At the end of all work, an effective and reliable protection against sounds in the bathroom is obtained.

Sound insulation by infrasound

As you know, a person cannot hear ultrasound, since its range is 7 Hz. Such a sound is extremely dangerous to health and even human life, as it creates a negative impact. Even in the last century, weapons were developed at low frequencies. You can protect yourself and your household from such a sound using polyurethane foam or silent pipes. It should be noted that such soundproofing as mineral wool absolutely does not keep such sounds.

Partial riser replacement

For partial replacement, cast iron structures with crosses are used. Such elements are not dismantled, but cleaned from various growths and formations on the inner side of the surface. Cleaning is carried out using various chemicals that release scale and build-up, making them loose and porous. Over time and under the influence of waste water, the crosses will be cleaned, and they can be used for more than one year. The main advantage of partial riser replacement is that the pipe is divided into separate pieces, which means less acoustics. Also, one of the advantages of such work is that you do not have to dismantle the floor and ceiling in order to completely change your riser. Cast iron pipes are no longer installed today. If it turns out to find a suitable pipe, then many difficulties arise with its processing and installation.

Partial replacement of the riser, in contrast to complete dismantling and installation from scratch, does not require significant material costs, in addition, all the work can be done independently without seeking help from specialists. Modern materials are of high quality and can be used as a stand-alone structure or in combination with cast iron elements.Thanks to this feature, it is possible to save money and your own strength.

Riser damping

When a sewer system is installed, it will not work to use partial installation and everything must be done from scratch. In the place where the floor riser will be installed, it is necessary to make insulation. For such work, it is necessary to make a sleeve that has a larger diameter than that of the riser pipe, but at the same time it must pass into the hole between the ceilings. In the case of an uninstalled riser, the sleeve is inserted in its entirety, and when everything has already been delivered, it is necessary to cut the insert and put it on the main pipe. When the sleeve is in place, the void should be blown out with polyurethane foam. It is not recommended to use mineral wool as insulation. The slippery soundproofing option is the best solution for the initial preparation of the apartment.

There is another option for damping the riser; it involves the use of special clamps that attach the pipe directly to the wall. If there are no special damped mountings, then as an alternative, simple clamps with inserted pieces of foam rubber will do. Such a fixation will not only make the riser stronger, but also more reliable.

Insulation of pipes with polyurethane foam

PPU can have two types of insulation: cylinder and scarlop. Such insulation is used for soundproofing the main sewer routes. Due to the characteristics of the material, the products can be used at temperature extremes. Also, the product can have a foil surface. The term of use of such a material is about thirty years, while it does not lose its characteristics and properties.

The installation of the product on the pipe is very simple and does not require any special skills or knowledge. The two elements on the riser are connected into a single structure and fixed at the seams with glue. Scotch tape and clamps will also work as an alternative. Clamps are taken per linear meter of pipe, two plastic holders are installed. The connections are fastened with a special tape, which is installed in two pieces per running meter.

How to close a pipe with soundproofing material

As a rule, sewage and water supply pipes have a nondescript appearance and spoil the entire interior. Using the manufactured box, you can hide all the flaws in the room. It is worth noting that the pipe cover will not only serve as decoration, but also improve the quality of sound insulation. For the manufacture of a box, a structure made of plasterboard or plastic is suitable. Both of these materials have a flat surface, which will ultimately give the correct shape of the structure.

If drywall is used in the manufacture, then a frame is imperative. The frame can be made using an aluminum profile or a wooden bar. Dimensions are measured directly on site to minimize the chance of error. The box can have various shapes. If we consider the simplest options, then the square is the optimal solution.

Sometimes in apartments there are niches for communications and in this case it is possible to make a false wall as a solution. The opening of the niche is filled with bricks or a plasterboard partition is made. At the point of access to the taps and meters, an inspection window is made, into which the door is placed. Revision doors can be additionally soundproofed, thereby minimizing the penetration of noise. The finished structure will perfectly hide communications and protect the room from extraneous noise.

In most of the old-style apartments, the bathrooms are not quite right. As a rule, they are located near the kitchen or opposite the living room, and when the family is having dinner or guests come, it is problematic to go to the toilet due to the poor soundproofing of the room. If all the work is done correctly, then the next day the result will be noticeable and tangible.