Here you will find out:

- Disadvantages of other devices

- Infrared heaters - principle of operation

- Advantages and disadvantages

- Varieties of infrared industrial heaters

- Scope of application

- Popular models of IR heaters

Heating industrial and industrial premises is a problem - not every heating device will be able to efficiently heat large volumes, including those with high ceilings. The way out of the situation is industrial infrared heaters, which are optimal for use in large rooms. Let's see what these heaters are, how they work and what are their advantages.

Disadvantages of other devices

Heating in industrial buildings is often based on classic radiators and bulky registers made of large-diameter pipes. But if the room has a large area, then heating it will be somewhat difficult - high ceilings and too large a distance between the walls affect. Let's see in what other ways we can heat industrial premises:

The use of diesel heat guns requires a lot of space, and the high noise level and the need for ventilation make this method rather inconvenient in many rooms.

- Using gas heat guns is an excellent way out of the situation, allowing you to pump heat into large rooms. The downside is that these devices require a source of liquefied gas;

- With the help of diesel heat guns - these devices are often used for industrial premises, but they require good ventilation, which is necessary to remove combustion products;

- Using convectors is not the best option, it is only suitable for small workshops. The thing is that the height of the ceilings in this case should not exceed 3-3.5 meters. A different type of heater should be used in taller buildings.

Therefore, the best heater for industrial premises is an infrared device that works by means of infrared radiation.

Another disadvantage of the cannons is the increased noise level - they buzz perceptibly. Also, they are not environmentally friendly.

Principle of operation

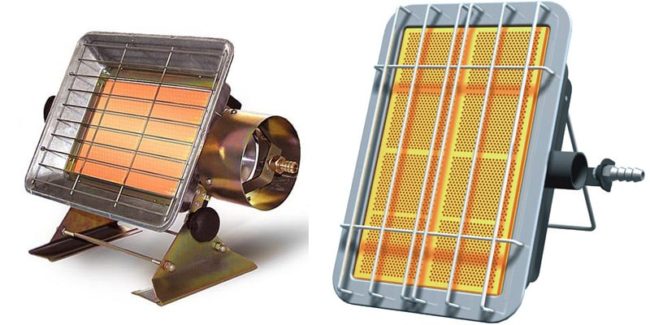

The convenience of using gas infrared heaters lies in their autonomy and mobility. Since the devices do not need to be connected to the mains for functioning, a small cylinder with liquefied gas will provide heat even in remote areas in the country, on a hike, fishing and other extreme situations.

The main features of the gas fired infrared heater are:

- in the rapid creation of a local thermal zone;

- in economical use of fuel.

Heater design:

- It is based on a metal body that contains a gas burner.

- In this area, there is a valve system for regulating the gas supply volume, as well as a control unit for the burner itself. These elements are responsible for the safety of the structure in the event of overturning or various failures.

- A heating element is supplied to the burner, which, depending on the manufacturer and model of the device, can be in the form of metal tubes, perforated sheets or metal mesh, etc.

- As a result of heating the radiating element by the reflector, the heat flux of infrared radiation is focused and directed to the desired area.

IMPORTANT: The specificity of heating with infrared rays is to receive energy from infrared waves, which heats only solid objects, and not the air around them.

Infrared heaters - principle of operation

Our natural luminary called the Sun does not warm the air at all, as it might seem at first glance - it warms up for completely different reasons. It delivers infrared radiation to the Earth's surface. This radiation, reaching the surface of the planet, landscape elements and artificial buildings, is absorbed by them and turns into heat.... In principle, we can call infrared rays thermal, although this is a bit different.

We go further - objects located on the surface of the planet (including the surface of the earth with landscape elements) begin to give off heat. It is this heat that heats the air and the objects around us, buildings and much more. With an increase in altitude, air cooling is observed, since it simply has nowhere to take heat from. Therefore, at the heights where planes fly, a terrible cold reigns, reaching marks of -50-60 degrees and even lower.

Industrial heaters, which are based on sources of infrared radiation, work in a similar way. Here's how they work step by step:

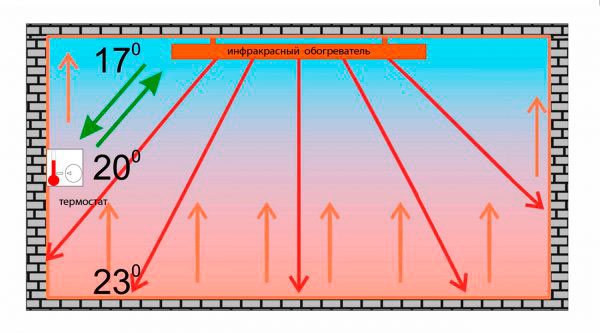

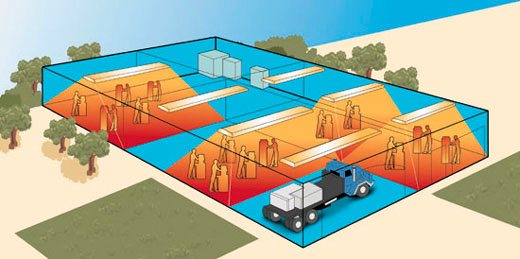

IR heaters concentrate heat in the floor area, which allows people to be in the most comfortable environment.

- Infrared emitters are connected to the mains and begin to generate infrared radiation (or generate it due to the combustion of natural or liquefied gas), and in very large quantities - you need to remember about the volume of industrial premises;

- Infrared rays penetrate the surrounding objects (ceilings, walls, floors, machines, furniture, etc.), as a result of which they begin to give off heat. In other words, they become noticeably warm;

- Heat is removed from heated objects into the air - as a result, the industrial premises become warm and comfortable.

While standard batteries heat the air near the walls, industrial heaters based on IR emitters actively heat almost all surfaces and objects. Even if the distance between the walls is 50 meters, the rooms will be heated practically throughout the entire volume.

The principle of operation of the IR heater and design features

From convectors and standard batteries, infrared heaters do not warm the air, but household items, as well as wall surfaces and floors. It is a sun-like glow that passes through the air masses, but does not warm them. Only objects in the path of infrared rays begin to heat up. Drafts and winds do not interfere with such infrared waves.

Convectors heat up the room gradually, and people have to freeze and feel discomfort for some time. Air flows move up and down. As for the infrared unit, the principle of operation is different. Households feel warmth immediately after turning on the device.

The steel body is painted with durable paint and an aluminum reflective screen. There is a heating element on it. It can be tubular (tenon), made of durable ceramics, carbon or halogen.

To regulate the temperature regime, each infrared heater is equipped with a thermostat, and there is also a sensor that is necessary to turn off the device if overheating occurs. The floor-standing models are equipped with a mandatory rollover alarm to prevent a fire.

How to clean and humidify the air in the room to improve the microclimate, read the article: washing air for home

Advantages and disadvantages

Industrial air heaters are ideal for large spaces. They warm them up throughout the entire volume and do not interfere with anyone, since in most cases they hang from the ceiling or are located on tripods (on stands). Infrared radiation spreads over fairly long distances, so it easily reaches surrounding objects, floors and even partially reflects towards ceilings. Let's see why infrared industrial heaters are so good. First of all, we note the fact that they are absolutely harmless to human health - provided they are correctly installed. Some experts point out that they are even useful. In any case, they do not harm at all and give a pleasant sensation of warmth - standing under them, you begin to feel how life-giving warmth penetrates literally into every cell of the skin and into its inner layers.

Absolutely silent operation is a very important advantage. It is one thing when it is noticeably loud in production facilities (machines, pumps, various technological equipment are working). And it's another matter when the production is quiet - in this case, industrial heaters with fans will add a few extra decibels. Therefore, the noiselessness of infrared devices is a solid plus.

Other advantages:

When using infrared heaters, it is not at all necessary to cover the entire area of the heated room with them. It will be enough to concentrate them directly on the jobs of people.

- High efficiency - heating industrial premises with infrared heaters allows you to deliver heat directly to consumers. They are located above equipment and workstations, creating a comfortable environment. Their high speed of work is also noted - if the room has not been completely frozen before, then it will warm up rather quickly;

- The ability to work in rooms with high ceilings - industrial infrared heaters heat from top to bottom. Suspended from the ceiling or by cables, they send infrared radiation down to the consumers;

- Maintenance-free - industrial electric heaters don't require any attention. We hang them at the required height and use them;

- Economical - the use of industrial infrared heaters can reduce heating and energy costs by 10-15%;

- Even distribution of heat - only infrared devices can boast of this.

There are also some disadvantages:

- If the location of industrial infrared heaters is incorrect, people may have headaches - be sure to observe the correct installation height of the equipment;

- Electric models are quite voracious - but there is no getting around it. Gas infrared heaters for industrial premises are becoming an alternative to them;

- Risk of burns - the emitting plates of infrared industrial heaters are heated to a high temperature, so accidental contact (for example, when placed on a wall) can cause burns.

Some of the disadvantages are quite serious.

Gas infrared industrial heaters still need periodic maintenance - they need to be cleaned and checked for leaks. In addition, gas equipment is more dangerous than electrical equipment.

Industrial dark gas heaters and emitters Systema S.p.A

TC Group Energia LLC is the official distributor of SYSTEMA S.p.A. (Italy)

Industrial gas heaters SYSTEMA S.p.A. (Italy) is offered for delivery by the Russian company TC Group Energia LLC - we carry out a study of the object for the correct selection of equipment, supply equipment, perform installation and commissioning. Benefits of SYSTEMA products for the customer:

- the ability to select any configuration and power of the heating system;

- work on natural / balloon gas or liquid (diesel) fuel;

- modular principle of forming the active part, due to which it is possible to create directional heating lines of various lengths and shapes;

- the minimum number of burners and chimneys due to the perfect design of thermal insulation of all parts of the system.

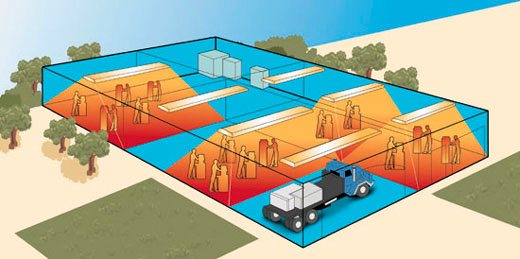

The high efficiency of the SYSTEMA cycle is ensured by the combination of thermal insulation with hot gas recirculation devices in the radiator pipes. The use of such equipment is relevant in rooms with high ceilings and large undivided spaces - depots, hangars, production workshops, poultry houses to create local zones with the required temperature under infrared radiation.

Examples of installation and use of SYSTEMA dark emitters:

Gas infrared radiators Systema INFRA

INFRA infrared gas heaters in lengths of 6, 9 and 12 meters create a downward flow of thermal energy. In its zone can be located the railway tracks of the depot, places for placing animals and birds, jobs for the repair of rolling stock in auto enterprises, machine tools in factory shops.

The heaters are mounted on a modular basis with the possibility of creating long heating lines with different suspension heights and radiation intensities.

The Infra BAF system with an adjustable cable suspension has been developed especially for poultry houses. The height of the suspension of the INFRA BAF gas heaters is controlled by a computer, depending on the height of the bird, which makes the design indispensable for increasing the efficiency of the poultry house.

The ability to adjust the distance to the birds creates a “brooding effect” where the chicks can choose their own comfort zone. Such controlled heating significantly accelerates their growth.

INFRA B

- Top model in the INFRA series

- Heat insulated reflector

- Burner BAF

- 1st heating element made of fire-resistant stainless steel

- Non-burnt aluminum alloy swivel element

- Heavy-duty extractor fan with die-cast aluminum housing.

| Length, m | power, kWt |

| 6 | 28 |

| 9 | 45 |

| 12 | 45 |

More details ...

INFRA +

- High power models

- Waste gas turbulator

- Robust stainless steel swivel and fan

- Recirculation of gases for increased power (Plus R model)

- 2 types of reflectors for different suspension heights

- The perfect combination of price and quality

| Length, m | power, kWt |

| 3 | 15 |

| 6 | 35 |

| 9 | 53 |

| 12 | 60 |

More details ...

INFRA BL

- Ideal price for the Russian and CIS market

- Economical slow ignition burner

- Flame and vacuum monitoring

- Waste gas turbulator

- Reliable swivel and fan

- Recirculation of gases for increased power (Plus R model)

- 2 types of reflectors for different suspension heights

| Length, m | power, kWt |

| 3 | 15 |

| 6 | 35 |

| 9 | 53 |

| 12 | 60 |

More details ...

Technical data of INFRA series heaters

| Model | INFRA 6B | INFRA 9B | INFRA 12B | ||

| Rated power, kW | 28 | 45 | 45 | ||

| Thermal power, kW | 24,1 | 38,9 | 39 | ||

| Combustion efficiency, min.,% | 86,1 | 86,5 | 86,7 | ||

| Combustion efficiency, nominal,% | 90,1 | 90,3 | 90,6 | ||

| Nominal fuel consumption at 15 ° C and 1013.25 mbar | Methane (natural), m3 / h | 2,96 | 4,76 | 4,76 | |

| Methane grade L, m3 / h | 3,45 | 5,54 | 5,54 | ||

| Butane (liquefied), kg / h | 2,21 | 3,55 | 3,55 | ||

| Propane (liquefied), kg / h | 2,18 | 3,50 | 3,50 | ||

| Power supply, V / Hz | 230/50 | ||||

| Max. electricity consumption, kW | 0,16 | 0,16 | 0,16 | ||

| Gas connection, inch | 3/4” | 3/4” | 3/4” | ||

| Air duct fitting, mm | 100 | 100 | 100 | ||

| Chimney fitting, mm | 100 | 100 | 100 | ||

| Set weight, kg | 94,2 | 144 | 209,3 | ||

Technical data of INFRA + heaters

| Model | INFRA 3 PLUS | INFRA 6 PLUS | INFRA 9 PLUS | INFRA 12 PLUS R | ||

| Rated power, kW | 15 | 35 | 53 | 60 | ||

| Thermal power, kW | 13,9 | 32,3 | 47,7 | 54,3 | ||

| Combustion efficiency,% | 92,5 | 92,3 | 90 | 90,5 | ||

| Nominal fuel consumption at 15 ° C and 1013.25 mbar | Methane (natural), m3 / h | 1,59 | 3,7 | 5,6 | 6,34 | |

| Butane (liquefied), kg / h | 1,18 | 2,76 | 4,18 | 4,73 | ||

| Propane (liquefied), kg / h | 1,16 | 2,72 | 4,11 | 4,66 | ||

| Power supply, V / Hz | 230/50 | |||||

| Max. power consumption, W | 70 | 70 | 120 | 200 | ||

| Gas connection, inch | 3/4” | 3/4” | 3/4” | 3/4” | ||

| Air duct fitting, mm | 100 | 100 | 100 | 100 | ||

| Chimney fitting, mm | 100 | 100 | 100 | 100 | ||

| Set weight, kg | 65 | 116 | 173,5 | 230 | ||

For a consultation with a specialist, call:

8

Main office

We can call you back:

SYSTEMA gas heaters Infra BAF series

The Infra BAF series has been specially developed for use in agriculture - greenhouses, poultry houses and farms.

Infra BAF has a modular design, i.e. there is one fan for several burners and radiant tubes. This makes it easier to install the system in greenhouses and poultry houses.

The emitter works under discharge, preventing the penetration of flue gases into the room.

The maximum temperature of the radiant tube is 400 ° C for the U-tube and 300 ° C for the M-tube and for the MC tube (animal husbandry).

|

|

The BAF series emitters can be suspended on a computer-controlled cable suspension that changes the height from the heaters to the bird as it grows.

In this way, the mother-chicken effect can be realized in the house, which promotes the fastest growth of the chicks.

Ask us your question:

Radiant gas heaters - ONA tapes

The ONA radiant tape system generates effective infrared radiation from pipes located under the ceiling, into which a stream of hot air from outdoor combustion of gas is directed. The burners and blowers installed outside in a single block provide uniform heat supply to production or sports premises, warehouses, hangars, regardless of whether they are separated by partitions.

With the length of the ONA tape up to 300 meters, its power can be in the range of 30-400 kilowatts.

The price of a gas infrared heater is such that its purchase pays off within a short period of time, provided that the equipment is correctly selected and installed correctly. The sealed installation of the burner nozzle allows the manufacturer Systema S.p.A to practically reduce to zero heat loss during the transition to the OHA radiant tape. Combined with the precisely calculated fan thrust, this results in high efficiency and fuel savings when heating large enclosed spaces.

|

|

| OHA band heaters installed above the depot tracks | OHA emitter burner blocks are installed above the depot gate |

For a more complete acquaintance with the capabilities of the Systema infrared dark gas emitters, you can download the corporate catalog in .pdf format

Order us a free selection of equipment:

Varieties of infrared industrial heaters

Let's take a look at what infrared industrial heaters are for industrial premises. To begin with, they are divided by the type of fasteners - there are wall, ceiling and floor. Wall mounted models are designed for small spaces. They are mounted on walls at a height of 2.5-3 meters and are most suitable for buildings of limited volume and small area.

For uniform heating, infrared heaters should be placed at an equal distance from each other.

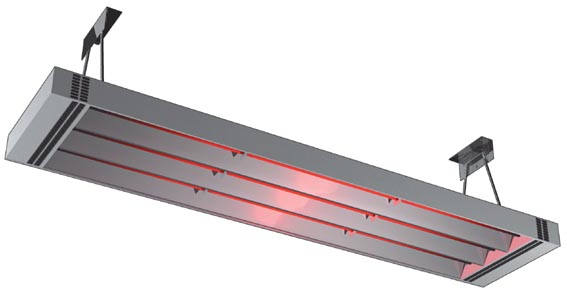

Ceiling industrial air heaters are designed for large areas. They are distinguished by their high power, therefore they are mounted at high heights, on suspensions or cables. Such devices are quite popular and the most convenient - they have great power, they do not interfere with anyone, the danger of getting burns is excluded.

Floor standing industrial infrared heater is the rarest type of heating equipment. A device of this type is a tripod or a single stand with emitters fixed on them. Scope of destination - spot heating.

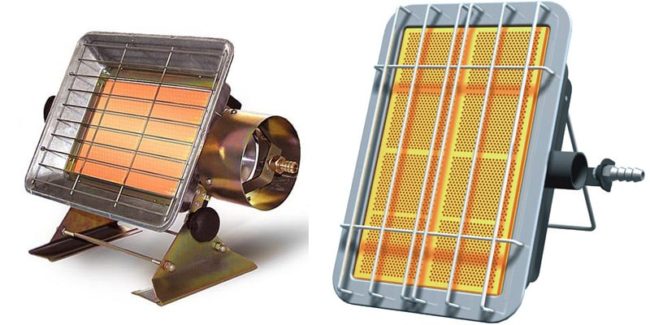

The next division of industrial infrared heaters is by the type of power supply. Industrial gas heaters run on liquefied or natural gas. They are equipped with miniature burners with automatic ignition. They heat metal or ceramic emitters, causing them to generate infrared radiation that is sent to rooms.

Gas industrial infrared heaters are divided into dark and light. In the dark, the combustion process is hidden; it takes place in a sealed pipe through which air is supplied. Infrared radiation is emitted using ribbed emitters. The combustion temperature in the system does not exceed +400 degrees.

Light infrared industrial heaters operate at higher temperatures - high-temperature burners are installed in them, giving a flame with a temperature of up to +1000 degrees. Compared to dark appliances, they are lighter, so they can be used in prefabricated buildings where various restrictions apply.

Pros and cons of equipment

Gas highly efficient IR industrial heaters have a number of advantages

- The possibility of using in open areas, since the emitter acts on objects.

- Independence from electricity. In the conditions of its unstable supply, this moment is very important.

- Profitability. Due to the low cost of gas compared to other types of energy.

- The ability to function from natural fuel supplied through a centralized line, or liquefied, supplied in cylinders.

- Simple installation and maintenance.

When choosing gas infrared emitters for heating industrial premises, it is important to pay attention to the disadvantages

- the need to organize supply and exhaust ventilation in the workshop, in the warehouse, since the burner burns oxygen

- strict adherence to safety requirements, since the presence of an open flame in the combustion chamber of the device may cause a fire

- connection of a chimney for the removal of combustion products, which is associated with additional costs and time costs

Scope of application

Industrial gas heaters and their electrical counterparts can be used in various premises. First of all, these are factories, factories, furniture shops, technological buildings and much more. They are also in demand in warehouses. An infrared warehouse heater will create excellent conditions for storing any goods, including food.

Industrial infrared heaters are also used in agriculture. Here they are needed to heat large greenhouses. For greater savings, gas models are used in greenhouses - they are economical and emit carbon dioxide consumed by plants and converted into oxygen through photosynthesis. And the infrared radiation itself has a beneficial effect on crops.

Advantages and disadvantages of electric heaters

Many people cannot get enough of infrared heaters due to their striking advantages:

- ideal for work in dusty and dirty rooms, as well as for buildings with an increased level of fire hazard;

- the possibility of using not only as a general and partial heating system, but also as special equipment for drying;

- a spot heater is used in paint and varnish industries, for heating steel before processing, for arranging an anti-icing floor system;

- electric heaters are actively used in educational and medical institutions.

Recommended: Is there any health hazard from infrared heating at home?

The downside is the high price for electricity. You can slightly reduce heating costs by installing industrial temperature sensors.

Popular models of IR heaters

If there is a need to buy infrared industrial heaters, pay attention to the following models:

Ballu BIH-T-6.0

This is an excellent device from a trusted manufacturer. Its power is 6 kW, which allows it to heat an area of up to 60 sq. m. and even a little more (depending on the ambient temperature).

MO-EL Hathor 793

Wall mounted shortwave infrared industrial heaters with three heating elements. Suitable for small spaces and open areas.

Neoclima UK-05

Gas appliance for small rooms. Endowed with a ceramic emitter.

Do IR heaters harm the industry?

Air heating of workshops and factories of infrared gas and electric types, under the conditions of the correct choice of the system and adherence to the recommendations, is completely safe for people and the environment. Human beings can be harmed by shortwave emitters. You also need to strictly observe the correct installation of IR systems in the production area. Usually the manufacturer marks the dangerous installation location. Subject to all safety requirements, ICs are considered safe and have a positive effect on humans.In terms of their technical parameters, IR emitters have no analogues.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- Is there any health hazard from infrared heating at home?

- How to install an infrared ceiling heating?

- How is infrared film heating installed?

- How to organize infrared heating at home?

- How to calculate infrared heating?

- Installation rules for infrared floor heating

How to choose the best infrared heater

Before buying, it is important to decide on the characteristics and parameters of the device. It is better to choose devices that are not cheap and from a well-known company. It is more economical than replacing cheap heaters monthly. The power of the device is also selected for the size of the room. For good heating, 1 infrared lamp with a power of 1 kW for 7-10 square meters is enough.

In rooms with high humidity, some heater models cannot be installed. It is more convenient to have units with heating sensors, a remote control panel, and malfunction fuses.

A good infrared heater will help you choose not only the advice of consultants from the store and specialists, but also positive reviews from real buyers. A suitable heater has a lot of positive feedback, so even the high price of such a device will quickly pay off. Have a qualified electrician install the appliance correctly in a suitable place and connect it to the mains.

Types of heaters

Gas

Infrared heaters with thermostat for summer cottages - your own sun in the house

Gas infrared heater is used for heating outdoors or in industrial buildings. It is unacceptable to use such a heater in a private house. Heat is released due to the combustion of the gas-air mixture.

The room where the gas infrared heaters are installed must have good ventilation.

The principle of operation of gas infrared equipment is as follows. Gas enters the isolated chamber and mixes with oxygen. Under pressure, the resulting mixture enters the radiant panel, where the process of its combustion takes place. As a result, the panel heats up and transfers heat in a radiation manner, i.e. in the form of thermal radiation.

Ceiling infrared gas heater

Advantages of gas infrared heater:

- Rapid heating of the room.

- Autonomy. Connection of main communications is not required.

- Working at very low temperatures.

- Convenient adjustment of the directivity of infrared rays.

- Heats the surface of objects and people quickly before the air heats up.

- Dust does not rise during operation.

- Fast and easy installation.

- Does not emit harmful substances.

Disadvantages:

- There is an additional risk associated with the combustion process.

- Dries the air.

- Burns oxygen.

- Gas is required. Although a connection to the main gas pipeline is not required, there must be charged gas cylinders.

Installation of a gas infrared heater:

- It is important to familiarize yourself with the connection technology and safety precautions before installation.

- Installation brackets must be strong and secured to a secure base.

- Gas is supplied to the heater through a flexible hose. It must be checked for cracks and holes.

- All connections must be reliable and gas-tight.

The ceiling heater is mounted on brackets or secure chains.

Electric

The electric infrared heater is powered by the mains. A tubular electric heater (TEN) or an open spiral is used as a heating element. With the help of mirror reflectors, the rays are directed to the desired heating place. Such equipment is used both for public buildings and for a private house.

Advantages of electric infrared equipment:

- The heating process starts in the first minutes.

- Does not burn oxygen.

- Does not dry the air.

- Leaves no unpleasant odor.

- No combustion product remains.

Disadvantages:

- Dependence on electricity and its uninterrupted supply.

- Limited heating area.

- High cost of equipment.

- High cost of ownership.

Electric ceiling heater

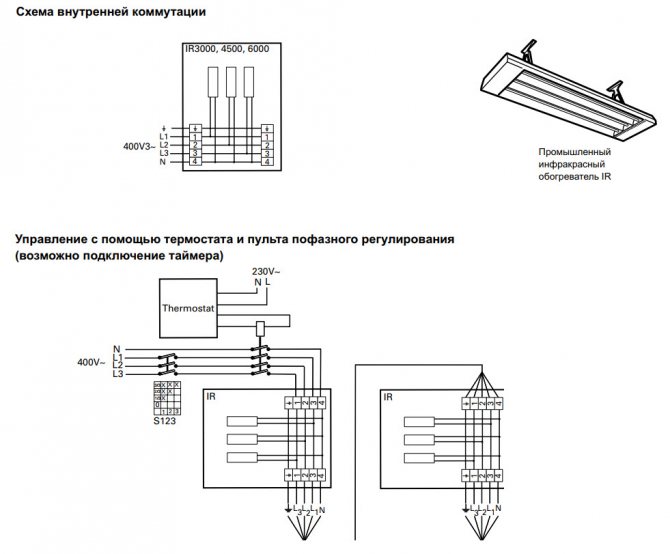

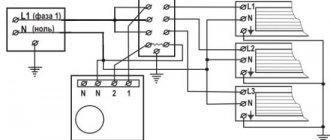

Installation of an infrared ceiling heater:

- Before installation, you must familiarize yourself with the wiring diagram and safety precautions.

- The fasteners must be strong to keep the equipment securely in place. It is better if these are the brackets that come with the heater.

- Heating elements must be absolutely insulated from flammable material.

- The wiring must not be damaged, and the connections must be securely insulated with special tape and caps.

When installing the unit, embedded parts must be installed on the suspended ceiling under the fastening.

Film

Infrared film is also powered by electricity. Heating is carried out by heating the carbon elements in the film. IR films are best suited for heating specific areas.

Ceiling IR-film can be installed under any finish, except for a stretch ceiling, which is destroyed by high temperatures.

Advantages of Infrared Ceiling Film:

- Heats the surface quickly.

- Low material cost.

- Low power consumption.

- It is located at a height that children cannot reach.

- In case of accidental mechanical damage to the heater, it will not come out of working condition.

- Does not dry the air.

- Does not burn oxygen.

- Doesn't take up space.

- Can be used to heat a veranda or gazebo.

Installation of a "warm ceiling" in a private house

Disadvantages:

- If the house has high ceilings, then the IR film is ineffective.

- If it is installed in an apartment, then in case of flooding by neighbors from above, such equipment will burn out.

- Do not install the infrared heating film in a room with electrical household appliances.

Installation of infrared film on the ceiling:

- The surface of the ceiling is cleaned of debris and dust.

- Thermal insulation based on lavsan is mounted on the ceiling. The thermal insulation material should cover the entire ceiling area and slightly go over the walls. Thus, heat loss in the corners of the room is excluded.

- A heating film is laid on the surface of the insulation. In order not to damage it during installation, it is fixed at the joints.

- After the infrared heater is securely fixed, it is connected to the mains. For this, the contacts on one side are insulated, and an electrical wire is connected to the contacts on the other side, connecting in parallel the individual strips of the heating film.

- The electrical wire is connected to a thermostat mounted on the wall. With its help it will be possible to regulate the temperature in the room.

- After connection, the quality control of the work performed and the test connection are carried out. If the heater is working well, then a surface finish can be done on the ceiling.

- Plasterboard, suspended ceiling, wooden or plastic lining can be used as a finishing material.

Heat-reflecting material cannot be used for finishing.

The question of the cost of infrared ceiling heating needs to be divided into two parts: the cost of the equipment and the cost of operation.

The cost of the film is much lower than that of heavy equipment and amounts to about 300 rubles / m. Gas or heating element equipment is much more expensive. Their price range is wide enough.

As for the cost of operation, everything here depends on the price of gas and the tariff for electricity. More profitable infrared film in use. Carbon fiber floors consume relatively little electricity. Electric heating elements infrared heaters, especially of high power, are quite expensive to use, because electricity is consumed a lot, and the cost is rather big.

Questions and answers

Question: What is the purpose of the thermostat?

Answer: Thanks to the thermostat, a comfortable room temperature is established.

Question: Why is the thermostat not a component of the heater?

Answer: Because the thermostat and the heater have different purposes. If you follow this logic, then the bulbs should be sold with switches.

Question: How many heaters can be connected to one thermostat?

Answer: With a total load of up to 3.6 kW.

Question: Can the equipment be left unattended?

Answer: Yes, if the device is equipped with a thermostat.

Question: What wire is used for the connection?

Answer: Depending on the power of the equipment. For IR films, a wire with a cross section of 1.5 m² is allowed.

Question: If the heater heats from above, there will be no heat under the table?

Answer: The table creates a shade, so the heating will be less intense there.

Question: Is the infrared ray harmful to health?

Answer: Certified equipment is not only not harmful, but also useful.