Inverter heater

Operating principle

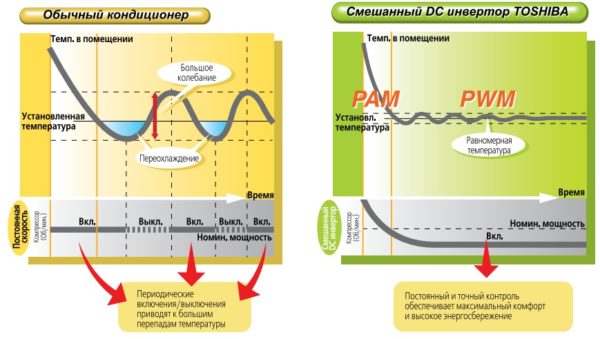

The inverter, which this type of device is equipped with, converts alternating current into direct current, while changing the voltage and frequency. This physical process is called inversion. The inverter looks like a periodic voltage generator. It is similar in shape to a discrete signal. Inverting has a profound effect on the power of the device, and all electrical appliances with it become less noisy and more economical.

Advantages and disadvantages

This type of device has enough advantages:

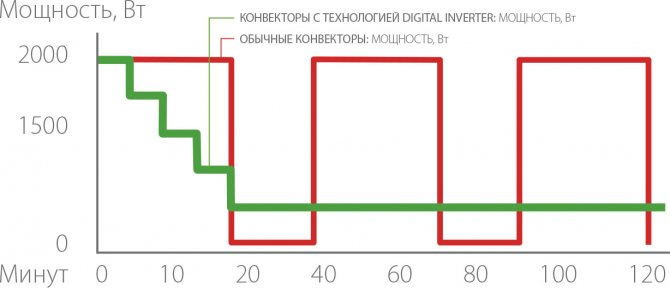

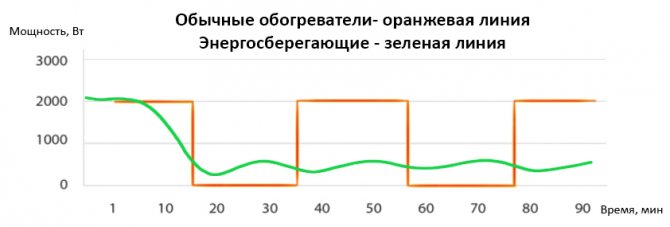

- Economical. When the inverter system of the device reaches the desired temperature level, the mechanism of the device does not turn off, but continues to work at low speeds. This leads to the maintenance of a favorable climate in the room. The heater does not need energy consumption for on and off functions. During the use of the inverter, there is no such thing as "high current" for starting. When the device is started, the current is not more than the rated one, which has a positive effect on the service life of the entire device. The device does not need to be constantly on and off. After all, these cycles significantly reduce the service life of the device. Compared to conventional appliances, energy savings are around 40%.

- Practical and efficient. This device is capable of heating even at very low temperature conditions, while the beneficial effect is expressed by a high coefficient. The heater during operation shows the ratio of the released heat to the consumed energy, denoted as EER. This indicator for the device is equal to four. For example, at a consumption of 250 W, you get more than 1 kW of heat. This is a good indicator.

- During operation, the heater has high safety and environmental characteristics.

- Operation is carried out with a low noise level, this is due to a decrease in rotational speed at partial load. Without a doubt, this indicator has a positive effect on the life of the consumer.

A large number of advantages of the device does not deprive it of its disadvantages, but it is only one. This is a considerable cost of the heater in comparison with other similar devices.

Use in heating systems

Today, the inverter device is successfully used in heating systems, the power source of which is electricity. This innovation has earned a lot of positive reviews. It is installed wherever there is an electrical connection. It is possible to use inverter heating without permits, in particular, you do not need to obtain permission to install a heating system. A pleasant moment for consumers is the cost of equipment, which turned out to be much less than other heating systems.

A conventional gas boiler these days is easily replaced by an inverter heater. Then the operation of the heating system with the implemented inverter device will be as follows: passing through the heater, electricity enters the boiler. In this case, the inverter boiler constantly produces an induction current. If a power outage occurs, the boiler will continue to operate on battery power. The heater includes a magnetic part and a heat exchanger.

Pros and cons of the device

Inverter Heater Advantages:

- When the desired temperature is reached, the unit does not turn off, but switches to operation at low speeds.

- It doesn’t waste a lot of energy because you don’t have to turn the device on and off all the time. Energy saving in comparison with other heating devices is 30-50%.

- The set air temperature is maintained due to the smooth control of the compressor motor speed.

- The device has a high performance. It is capable of heating even at very low temperatures.

- Safe and environmentally friendly.

- Works almost silently thanks to the built-in fan.

Benefits of inverter devices

The disadvantages include:

- High cost compared to other heating appliances.

- Sensitivity to voltage surges.

- Parts are not standardized, so repairs can take several weeks.

Frequently asked questions about electric convectors

Which convectors are more efficient - high or low?

The efficiency of the device does not depend on its size, but on the power. All kinds of "form factors" of equipment are created, first of all, for the convenience of its fitting into various interiors.

Is it dangerous to leave the convector unattended?

Definitely not. As long as your home's electrical wiring is capable of handling the combined power of concurrent appliances, you have nothing to worry about.

Can the convector be used as the main source of heating?

As a rule, yes. It all depends on the specific equipment model and manufacturer's recommendations.

Is an electric convector a suitable choice for a children's room?

Quite. Among the products of most popular manufacturers there are units designed specifically for children's rooms - with a solid body, with streamlined shapes, without sharp corners. The holes in them are as small as it is, in principle, possible - all so that the child could not shove anything inside.

Many modern manufacturers of electric heating convectors offer heating equipment models adapted specifically for children's rooms - well-designed and as safe as possible.

How to install the convector correctly

Installation regulations, requirements and restrictions are detailed in the instruction manual. In particular, it states:

- Installation of a gas convector in a wooden house. During operation, the case heats up to 50-55 ° C. It is necessary to insulate wooden surfaces in contact with heating parts of the structure. Installation rules in a wooden house prescribe the manufacture of fireproof roof gaps. If a coaxial pipe is used, insulation is not required at the place of passage through a wooden wall. The surface of the coaxial chimney heats up slightly due to the special design of the burner and pipe.

- Location from the floor. Air heating of a country or residential building has certain features that affect the efficiency of heating. For maximum performance, install the convector as close to the floor as possible. As a result of this solution, the intensity of circulation of convection flows increases and the efficiency of the equipment increases.

- The gas pipe is supplied to the heater exclusively along the street. A shut-off valve must be installed at the connection point.

A test run is carried out in the presence of a gas service representative. A corresponding note is made in the documentation of the convector.

Which is better, a gas convector or a boiler

It all depends on the technical characteristics of the building and the features of its operation. The assembly of the convector requires less time and money.

Air heating is recommended for use in country houses that are not heated during the winter season.During installation, there is no need to use a water circuit, you can heat the building only from time to time. Even at a negative temperature in the room, you can warm up the room in 20-30 minutes.

A gas convector for a house on bottled gas is inferior to a boiler connected to a main pipeline in terms of efficiency, but superior in functionality. The choice of an air heater is justified in the absence of gasification. With a fully filled cylinder, the heater will work for approximately 10 days.

The convector heats the room better and faster and uses less fuel for this, but its efficiency is limited by the properties of convection flows. Heating intensity decreases as obstacles arise: walls, furniture, etc.

For heating a country house or small rooms, a convector-type heater is optimal. But for residential heated houses with large rooms, it is better to install a traditional gas boiler.

Calculation of power and temperature of a warm water floor

Heater device and principle of operation

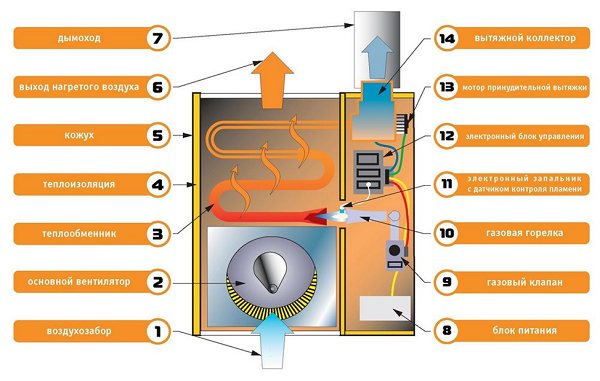

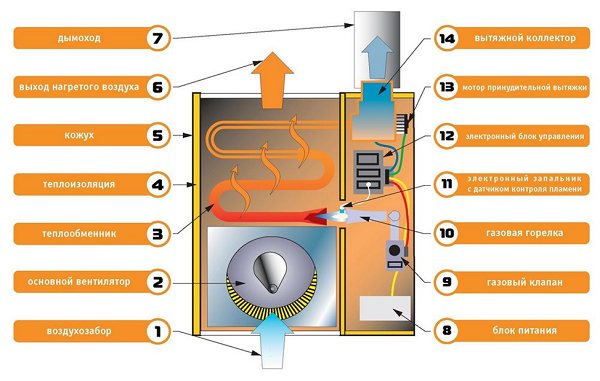

A gas heat convector is a device that is capable of generating heat through the combustion of gas. The design of the unit is quite simple.

- Burner. An igniter is connected to it.

- A heat exchanger, the task of which is to give off heat to the air passing through it. To heat more air, the heat exchanger is made finned (to increase the area).

- System for the removal of combustion products.

- The automation system is installed for safety purposes and shuts down the unit in case of problems in operation.

- The thermostat ensures the maintenance of the set temperature in the room.

- The housing is used to protect the device and is made of metal coated with heat-resistant paint.

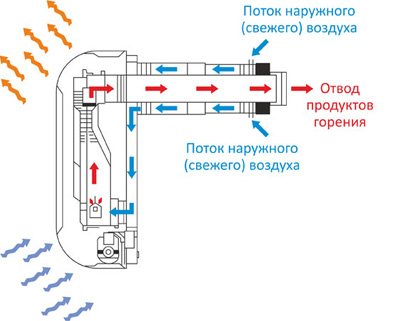

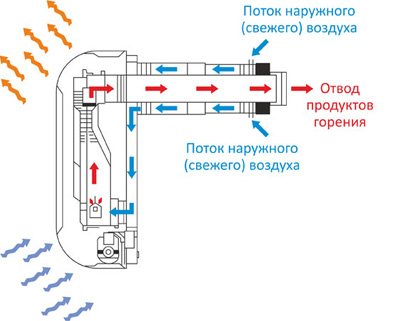

The figure below shows the construction of a gas convector.

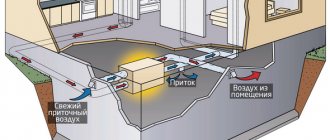

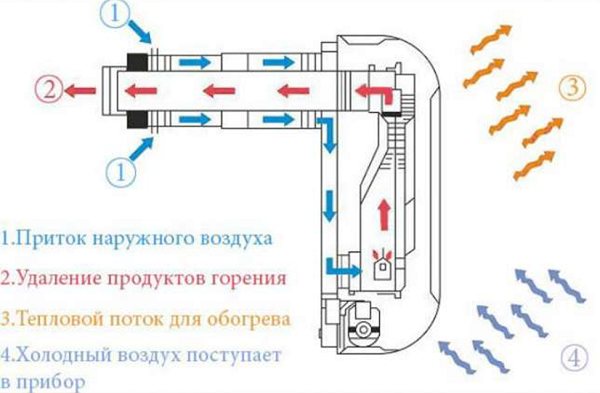

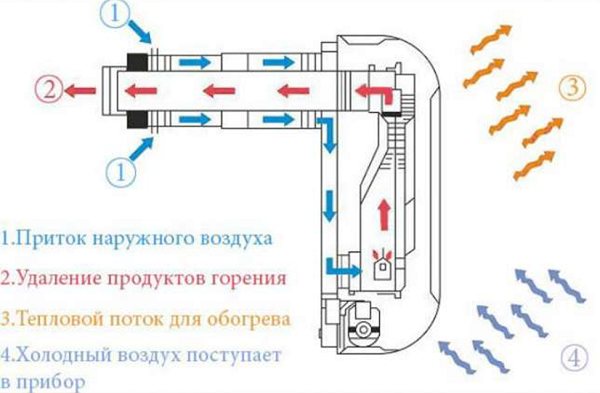

The principle of operation of the apparatus is that the gas, when burned in the chamber, heats the heat exchanger. The air flow, passing through the lower openings of the unit, moves through the heat exchanger, takes heat and exits heated into the room through the upper openings. Meanwhile, the combustion products of the gas are removed from the chamber through a double-walled (coaxial) pipe. Through it, fresh air enters the apparatus from the street to maintain the combustion process.

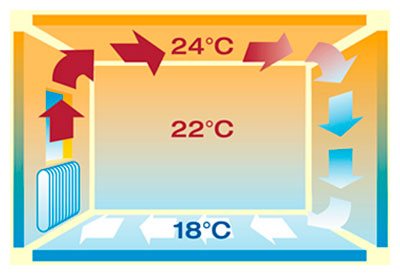

The principle of operation of the convector

Characteristics and working principle

New models of electric heaters work in automatic mode. This means that when the device reaches the set temperature, it does not turn off, but reduces the power. Thanks to this, the set temperature is constantly maintained in the room. Since there are no recloses, the equipment consumes less energy compared to oil heaters. The principle of operation of the inverter is similar to that of household air conditioners. The device has a heat pump with indoor and outdoor units. A heat exchanger is located in one block, where freon is compressed, heating up to 80 degrees. After that, the freon goes to the external unit, where it is converted into gas. Due to this, heat is released, which is directed into the room.

Types of electric convectors heating

When choosing climatic technology, it is important to take into account that electric convectors may differ from each other in the following characteristics:

- Mounting type.

- The heating element used.

You should also pay attention to the manufacturer of the product and the cost of electricity.

Types of electric convectors, according to installation features

Air convection heaters can be divided into three categories.

Wall mounted. Wall-mounted convectors are the most efficient.The location on the wall facilitates the convection process and increases the efficiency and heat transfer of the heaters.

Floor-standing version - used as an additional source of heat. Models with a built-in fan differ in performance. The convector with forced air circulation cannot boast of quiet operation, but it warms up the air well. Universal models - can be installed on the floor and mounted on the wall using special mounts. When choosing, you should pay attention to the presence of wheels in the kit. By installing the wheels on the body, you can easily move the heater anywhere in the room.

The main advantage of the convector is the low heating of the device body. This allows you to install a heater for heating a wooden house.

Classification of convectors according to the heating element used

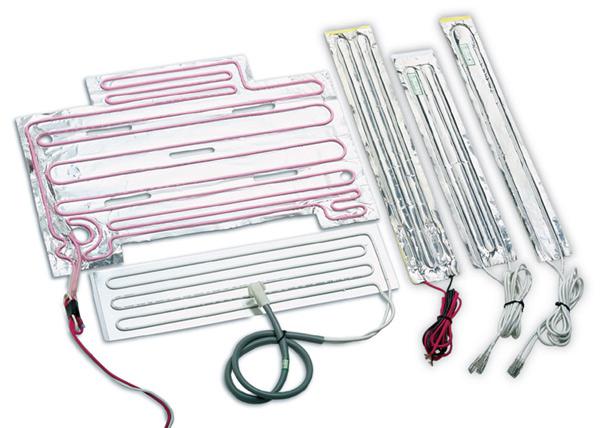

In total, three types of heating elements are used. The design of the heating element affects the operation of the heater.

- Needle heating element is a simple design, it is a chromium-nickel heating thread located in a dielectric plate. The top is covered with a special insulating varnish. A heater with a needle heating element is not suitable for wet rooms, since the heating element has absolutely no protection against the ingress of water, steam, condensation and other liquids. As a rule, budget models are equipped with a needle heating element.

- Tubular heating element - manufactured in a waterproof design. The structure consists of a steel tube filled with a heat-conducting backfill, which is also an insulator. To increase heat transfer, heat-distributing fins are fixed on the sides of the heating element, increasing convection. The heaters are equipped with protection against overheating. As a disadvantage of the tubular heating element, one can single out the fact that the electric convector heats up for a long time. The operation of the appliance may be accompanied by sounds resembling the crackling of burning wood.

- Monolithic heating element - the most economical electric convectors for heating a private house use a monolithic type heating element. The body of the heating element has no seams, the work does not accompany extraneous noise. If it is planned to make the electric heating of the apartment with convectors the main one, then the models with a monolithic heating element are the best solution. During operation, minimal heat loss is observed. The heater efficiently and quickly heats the room. The only noticed drawback of a monolithic heating element is the high cost of the device.

For space heating using an electric convector, it is better to choose devices that have a tubular or monolithic heating element and are equipped with a built-in electronic or programmable thermostat.

Heat exchanger material

The operation of the convector is based on the combustion of gas in the heat chamber of the unit, while the heat exchanger from the inside is exposed to a powerful thermal effect, its burnout quickly disables the convector. Therefore, it is natural that the material of manufacture should be as strong and stable as possible.

Here the undoubted leader is cast iron. The cast iron heat exchanger is thermally stable, the service life of such convectors is up to 50 years. Another plis of a cast-iron heat exchanger is a more even distribution of heat and slower cooling. The downside is the large mass and high price indicator.

Convectors with a steel heat exchanger are lighter and cheaper than cast iron

When buying, you should pay attention to the quality of the steel, such a gas convector serves for at least 20 years

Heating convector, what it is and how it works a detailed overview

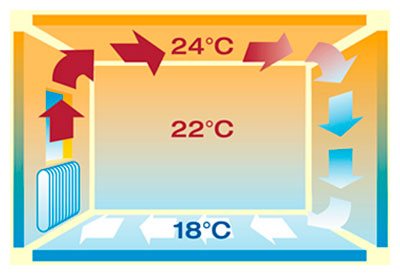

A little has already been said about the principle of work, now let's take a closer look. Any electric convector is based on the principle of movement of air masses in a room.We all know that cold masses go down, and warm ones are a little higher. The developers of the heaters took advantage of this by placing openings for cold air in the lower part of the device. The air-type heating element heats up quickly, which is its main feature. The most important thing is that the heated air is lighter and does not have any harmful impurities. Warm masses are discharged through the center and top vents in the enclosure. This solution allows you to increase the room temperature in the shortest possible time. It often takes just a few minutes to heat a small room with a medium-power convector.

How convector heaters work and how they work

Before we talk about all the pros and cons of convector heaters, you need to properly study their device. They consist of the following parts:

- Heating element - it is equipped with a large area ribbing, providing heating of air masses;

- Control system - it can be electronic or mechanical, providing operation in certain modes and controlling the temperature;

- Case - protects all insides.

The design of the equipment is extremely simple, and this is more a plus than a minus.

Warm air tends upward, and cold air fills its place - this is the principle of convection.

Let's see how a convector heater works. When you turn it on, the heating element starts working. It heats up the air, as a result of which its density decreases - becoming lighter, it rises to the ceiling and takes out cold air masses from there. Cold air goes down and is sucked into the convector. Some time after turning on the technology, a stable air circulation is created in the room.providing a comfortable atmosphere.

Automation monitors the temperature regime - it turns off the convector heater when the set temperature is reached, and turns it on as soon as it becomes colder in the premises. Automation can be electronic or mechanical. The electronics are more accurate, provide energy savings and add many additional functions to the machine. As for the "mechanics", it is simpler, but less economical.

An electronically controlled convector heater will cost more than its counterpart with a mechanical thermostat - but the presence of electronics is considered a plus.

How to choose a gas convector

Attention should be paid to the technical characteristics of the heaters. The best option is to choose a convector with a closed-type cast-iron heat exchanger and a programmable control unit.

When choosing equipment, you will need to consider the following:

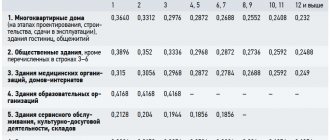

- Power calculation. Air convection is used to heat the room. Consequently, heaters are only effective in confined spaces. For each room you will need to install a separate convector. The power is calculated according to the formula 100 W per 1 m².

- Housing type. Heaters with a closed combustion chamber and exhaust of combustion products through a coaxial chimney are suitable for an apartment. You can put any type of equipment in your home. But when installing a heater with a closed chamber, it is necessary to take care of a constant and intensive supply of fresh air.

- Fuel type. It is forbidden to install a gas heating convector on liquefied gas in an apartment of a multi-storey building, due to the high explosion hazard of cylinders.

All convectors are initially manufactured with the ability to connect to the main gas pipeline. If you plan to connect the gas convector to the cylinder in the future, you need to purchase a special reducer (in some modifications it is included in the kit).

Types of gas convectors

To choose a suitable convector, you should learn about the main differences of existing equipment, the pros and cons of modifications.

What are the criteria for classifying heaters?

- Installation method - there are wall and floor models. The former take up less space, are lightweight and efficient, and are limited in performance (maximum power 10 kW). For heating a garage, rooms with a large area, it is better to choose a floor model. The heaters are heavy due to the enlarged heat exchanger. The performance of floor convectors reaches several mW (industrial versions).

- Exhaust gas removal. An open gas combustion chamber is installed in a conventional convector. The principle of operation of the device is somewhat reminiscent of a simple wood-burning stove. The design has several disadvantages - it burns oxygen, requires good ventilation of the room, as well as the manufacture of a complex smoke exhaust system. New generation convectors use a closed combustion chamber. A coaxial pipe is used instead of a chimney. Air intake is carried out from the street, therefore, during operation, oxygen is not burned in the room. Systems with a closed combustion chamber have only one drawback - the cost is more than that of classic models by 30-50%.

- Heat exchanger material. The principle of operation of the convector is associated with constant thermal exposure. One of the most common reasons for a heater failure is the burnout of the chamber walls. The heat exchanger is made of steel or cast iron. The crystal structure of the latter metal provides a long service life (about 50 years) and high heat transfer. The steel chamber will work for about 10-15 years.

- Fan. High power convectors are equipped with a forced air circulation system. Budget household models may not have a fan.

- Gas type. The models are designed to operate on any kind of "blue" fuel. The natural gas convector can also be operated with propane. A special adapter kit is required for conversion.

- Control automation. Budget models are equipped with conventional thermostats. The programmable control unit allows you to control the room temperature and set the required heating mode.

The cost of a gas convector depends on the material of the heat exchanger, the availability of an adapter kit, and the characteristics of the control unit.

Electrolux ECH / AG2-1500 T - economy, long service life

The efficiency of the Electrolux heater is provided by a powerful heating element, the length of which is increased by 10; due to the updated design.

The device is characterized by high heat dissipation as well as an impressive service life. The service life of the heating element alone is at least 25 years. This is more than other manufacturers' inverter heaters with similar prices.

Uninterrupted operation of equipment is ensured by built-in thermal protection. Because of this, the possibility of overheating is excluded. And when the maximum temperature is reached, the convector switches off automatically.

Another feature is the front panel that does not heat up during operation. While the Air Gate BIO filtration system effectively purifies the air. Its set of filters includes elements for removing tobacco smoke, as well as protecting against viruses.

| Heating element type | monolithic |

| Weight | 3.2 kg |

Reasons for buying equipment:

- profitability of work;

- build quality;

- noiseless operation - during operation, the sound of the relay is almost inaudible;

- filtration in the form of a plastic mesh;

- wheels on legs, providing convenient movement of the device.

Cons of technology:

- heating rate;

- bulky legs - although this feature provides the device with stability;

- lack of a handle with which you could carry the heater.

| Room heating speed | 9,8 |

| Safety | 9,8 |

| Build quality | 9,6 |

| Design | 9,8 |

| Efficiency | 9,6 |

Appointment

A natural gas-fired convector is intended for heating premises for various purposes. In this case, combustion occurs in a closed chamber, air is supplied from the street and combustion products are discharged there. The heat released during fuel combustion is transferred to the combustion chamber housing and heat exchanger, and then to the indoor air. Due to the rapid heating, the air rises up, making room for the colder one, maintaining an active convection process throughout the room.

A gas convector warms up the air faster and more actively than its electric counterparts or, even more so, converter-type radiators for a water heating system. This is due to the higher surface temperature of the heat exchanger and the increased rate of heat transfer from the combustion chamber.

The gas convector is an excellent solution in the following situations:

- The main heating of a small room or a house with one or two adjoining rooms.

- As a replacement for the solid fuel stove, which was previously used to heat the house.

- For quick warming up and maintaining a comfortable temperature in a garage, utility room, small country house.

- As a supplement to the central heating system in rooms where the installation of a water radiator is difficult (basement and basement, attic, veranda, etc.).

- For heating greenhouse facilities.

As a replacement for the main heating, a gas convector is suitable only for small houses or individual rooms. The efficiently heated area is easily calculated based on the models of gas convectors available in terms of power. On sale, devices with a power of 2.5-6 kW are more common, less often up to 12 kW. In the first case, the convector is enough to heat a room up to 50 m2. The most powerful models are in demand only for industrial and public premises up to 100 m2.

general description

This type of device has a built-in inverter that converts alternating current into direct current, while changing the voltage and frequency. In physics, this process is called inversion. The described devices are alternators with periodic voltage. They are close in shape to a discrete signal or sinusoid. This process significantly affects the power of the unit. Due to this, electrical devices during operation show noiselessness and efficiency.

Gas convector

A wide variety of devices and heat sources are now used to heat premises for any purpose. All possible versions and operating principles are involved, from electric heaters, gas boilers to the use of geothermal energy. Among this variety, there is also a heating gas convector. This device outwardly resembles a conventional radiator, only slightly larger and runs on mainline natural or liquefied gas. The water is not heated in it, followed by distribution to the radiators, the heat from the combustion of gas through the heat exchanger immediately enters the room.

It is interesting to understand the features of this type of heaters and determine the scope of its application based on the advantages and disadvantages of a gas convector.

Advantages and disadvantages of the device

The electric inverter heater has the following advantages:

- When the required temperature is reached, the product does not turn off, but starts operating at low power.

- A large amount of electrical energy is not wasted, because there is no need to constantly turn on and off the device. When compared with other types of heaters, the savings can be up to 50 percent.

- The product maintains the required ambient temperature by automatically controlling the compressor motor speed.

- The device has a high level of performance. In other words, it can heat air at a negative temperature.

- The device is safe to use and does not pollute the environment.

- The heater is very quiet due to the built-in fan.

The disadvantages include the following factors:

- The high price of the device compared to other types of heaters.

- Strong sensitivity to frequent power line voltage surges.

- Spare parts are not standardized and in the event of a breakdown, the repair will be quite long.

About the advantages of electric convectors

It is impossible not to highlight this aspect, since it is necessary to clearly understand what the pros and cons of such equipment. The main advantage is that the efficiency reaches 95%. This means that the consumed electricity is almost completely converted into heat. Quiet operation is another important point. For many, this factor is decisive, for obvious reasons. If you come from work to a cold apartment, then you need to heat it up as quickly as possible. The convector will best of all cope with the solution of this issue. The device does not need to waste time heating the media. It is enough to wait just one minute, and the unit will operate at the set temperature. One cannot but mention the cost of equipment, which is much less than that of gas boilers, oil heaters, etc.

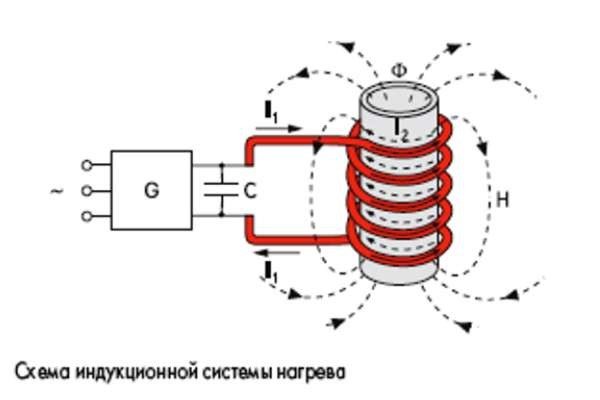

The principle of operation of the inverter boiler

Traditional electrical equipment works on the principle of transferring energy directly to the coolant through heating elements. Moreover, if the device is equipped with heating elements, then, therefore, it is necessary to prepare a place for heating water.

Heating elements are also highly susceptible to corrosion, so they must be protected from irreversible processes.

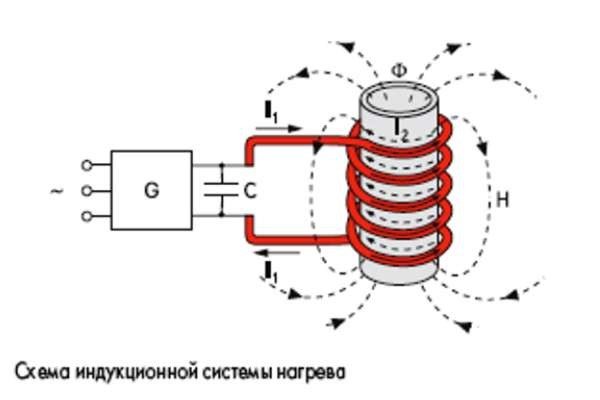

Inverter equipment works on the basis of electromagnetic induction. The generation of the current itself occurs due to an alternating magnetic field. For this purpose, it is necessary to convert the DC mains current into AC. The inverter perfectly copes with this task, the operation of which is possible both from the mains and from the batteries.

There are two type of contours in an inverter boiler:

- Magnetic, allowing you to generate a magnetic field of an alternating type.

- Heat exchanger that helps to heat the coolant.

With an appropriate supply of alternating electricity, the coil begins to form a magnetic field. This contributes to the heating of the liquid in the system and its further transfer through the pipes.

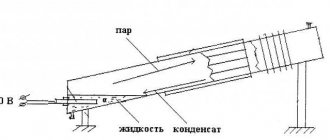

Induction heating system diagram

Some general information about the device

In Europe, many have been using electric heating for quite some time. In our country, due to high electricity prices, this is problematic. Nevertheless, you need to somehow warm up, and therefore buying a convector is one of the best solutions. The principle of operation of the device is quite simple. The essence lies in the natural convection of air passing through the heating element. Heating equipment of this type has a small shape, which allows it to be placed where it is convenient. Today there are both floor-standing and wall-mounted options. In most cases, the shape is rectangular, although there are also squares, etc. So what are convectors, you ask? This is a device that has many holes in its body. Cold air enters the side and bottom, then it heats up and exits through the holes on the front side.

How the convector works

The principle of operation of a gas convector is based on the change in the properties of the gas with an increase in its temperature.

Pre-assembled gas convector

Passing through the convector's heat exchanger, the air heats up, becomes lighter and rises higher, and new portions of cold air come in its place. This movement of air layers is called convection, hence the name of the device.

Internally, the device and the principle of operation of this heater uniquely determine the way of its placement: it is best to install the convector as low as possible, then its efficiency will be greatest.

The fact is that the coldest air, due to its density and greater weight, is always at the bottom, and it will heat up in this configuration in the first place. In practice, a gas heating unit is most often tried to be mounted under a window, where heat loss is usually maximum.

The principle of operation of a gas convector

Gas heaters are often equipped with a tangential fan. Its installation helps to increase the rate of supply of heated air and noticeably speed up the process of warming up the room. In addition, some expensive models have an increased thickness of the walls of the case and, therefore, are able to accumulate significant amounts of heat, and then transfer it to the surrounding space using thermal radiation. Such devices combine the advantages of conventional radiators and convectors and provide the highest heating quality.

Varieties

Inverter-type units are divided into several types. Devices that run on natural and liquefied gas are gaining popularity. These devices are used to heat summer cottages, cottages and open areas.

The first type is an electric inverter heater, it is powered from the mains, which is very convenient for a large number of people. There are also infrared varieties. Their difference from other heating devices is that they do not heat the air mass, but objects around them, which after a while transfer heat to the surrounding space. Only those objects that fall into the zone of action of infrared rays are heated (for more details, see the article on the principle of operation of a heater with infrared radiation). This type of heaters is used not only at home, but also on the street - for heating garages, verandas, utility rooms.

Infrared inverter heaters are leading in terms of sales, are considered the most economical and resistant to various adverse conditions, practical and durable.

The second type includes air conditioners in which heat pumps are installed. The scheme of its work is described above.

The third type includes gas heaters, which do an excellent job of heating any premises. Their main task is to maintain the required temperature in the building. Gas appliances are characterized by the fact that they give off a lot of heat with a minimum of fuel costs.