Many people call the insulated container the home of the future. The idea of using all-welded metal structures was adopted due to their ease of transportation over long distances and the possibility of quick installation. Due to their convenient size, they are well suited for a garage, basement, summer cottage, and even for the construction of a residential building.

You can stack modules together, stack on top of each other, connect. To build a home from shipping containers with your own hands on a tight budget, you need to know how you can do it and where you can save money to get the best results. The main job is to insulate the containers inside and outside.

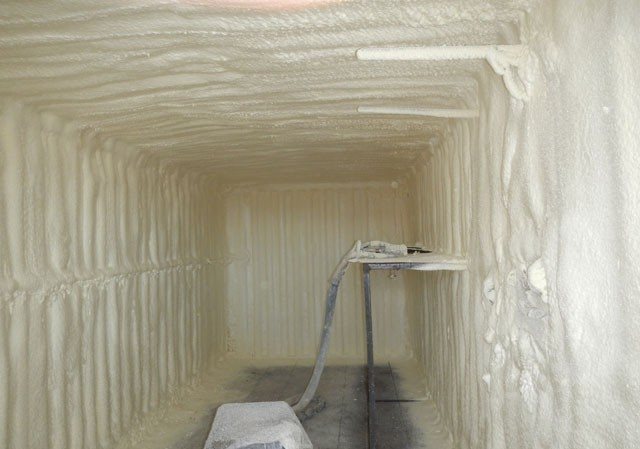

View of a non-insulated container inside

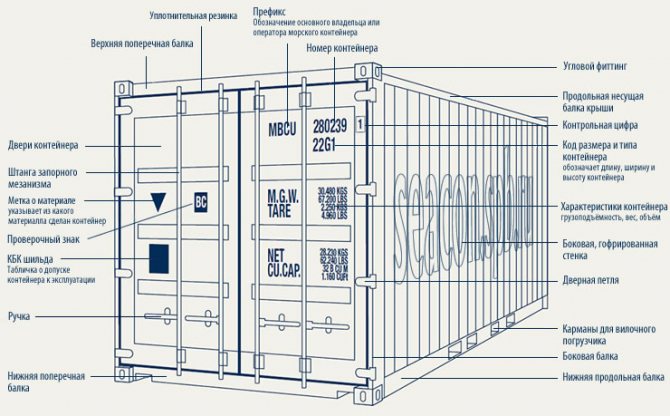

The device of the sea container

Universal large-capacity containers are designed for the transport of goods. Their base consists of a strong and rigid metal frame. The metal thickness ranges from 1.5 - 2.0 mm. On the inside, the metal structure is sheathed with steel anti-corrosion sheets with a corrugated profile, which gives it strength and good rigidity. Such modules can withstand various external influences.

How the sea container works

The container is equipped with hermetically sealed swing doors with handles that open with locking mechanisms. On the outside doors are marked with symbols: weight, volume, carrying capacity and others. If the labels are missing, the container has been repainted. There may be rust underneath the paint.

The weight of a 20-foot container is 2.1 tons, a 40-ton container weighs 3.6 tons.

The containers are not meant to be sheltered. Bare metal conducts heat well, so in order to live in such an iron box, you first need to insulate the sea container for housing, equip ventilation, make windows and doors, sort out floors, and erect a roof. Architects transform ordinary iron boxes into amazing homes and offices. They create custom designs and continually come up with new and improved ideas.

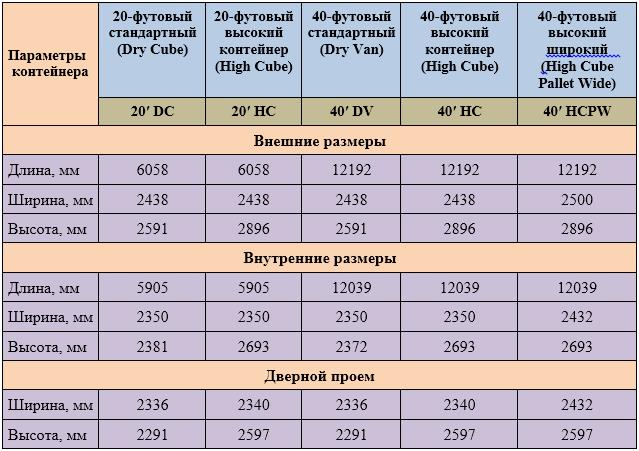

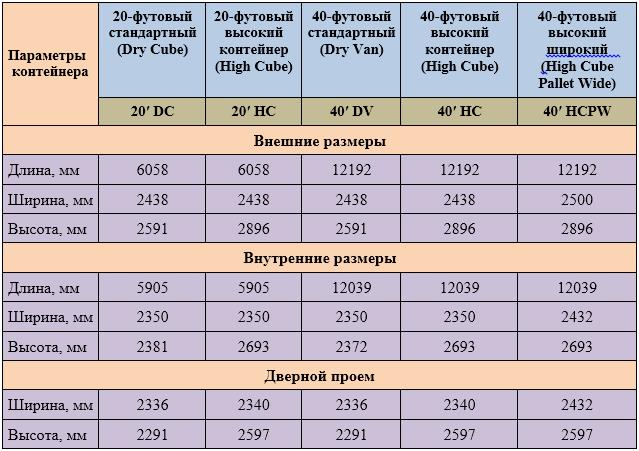

Shipping container size chart

What else does the price of a container house depend on?

- the number of containers used - a building from one container unit will cost less, but when buying several at once, you can get a good discount;

- condition - the price varies greatly depending on whether you are purchasing a new container or already used;

- the need for additional services - whether you will insulate the container with your own hands, as well as carry out all the necessary communications (electricity, water supply and sewerage, heating) or contact a specialized company, its final cost will also depend.

The disadvantages of the container structure can be attributed only to the fact that it is impossible to build a high (more than three floors) house from the container and its urbanity - it is difficult to beat the rectangular shape. Although such a strict geometric appearance just attracts those who decide to build a house from containers.

How to equip a container for housing

If you purchased a container and decided to make a garage, cellar, living quarters out of it, conduct a thorough inspection before insulating it. If you find any damage, repair it.

The sequence of works on insulation:

- clean rust with sandpaper or grinder;

- weld the holes;

- prime and paint the walls;

- make a crate from a wooden bar 5 cm thick or a metal profile;

- fix it around the perimeter of the walls and ceiling using fasteners for the drywall profile and self-tapping screws;

- Insulate the sea container from the inside by placing the insulation in the grooves between the bars;

- stretch the vapor barrier.

Before insulation, preparatory work is carried out

Do not forget about the support of the house. The container is placed on a timber frame.

Where else can insulated containers be used?

The scope of application of sea containers is very wide - from a seasonal summer-summer cottage shed for storing garden tools to capital housing. In Europe, it is used to build budget hotels, fast food establishments and even public transport stops. And as cabins at construction sites, staff and residential trailers on watch, etc. they are simply irreplaceable. This is due to the fact that corrugated steel is a very durable material that is not subject to weathering. A container, even without additional external finishing, can serve for decades.

How and how to insulate walls and ceilings

If the container is not insulated, it will be stuffy in the house in the heat, and very cold in the cold. In addition, condensation forms on the steel walls, leading to other problems such as corrosion or mold. When deciding which side to insulate, preference is often given to internal thermal insulation, since the appearance of corrugated steel walls in the interior of the house does not look at all.

Retrofitting the containers inside allows for a more traditional interior. When it comes to what type of insulation to use, the following materials are commonly chosen:

- polyurethane foam (PPU);

- mineral wool;

- expanded polystyrene.

The type of insulation and thickness are selected based on the climatic zone and the purpose of the building. How to insulate a container for housing?

Polyurethane foam

PPU spraying protects the metal from corrosion and external noise. For work, cylinders with polyurethane foam are used. There is a cheaper option - two-component foam spraying using special equipment. This material costs less, but the equipment to work with it is very expensive. Therefore, it is better to use the services of builders or rent a tool.

Insulation with polyurethane foam.

Insulation works using PPU are carried out in the following sequence:

- clean the walls and ceiling from dust;

- moisten the surface;

- shake the foam canister for at least one minute;

- turn the can over and spray the foam in a thin layer as it expands after being applied to the surface.

After spraying, a finely porous structure is created, which perfectly insulates the walls and ceiling. Cylinder foam is almost impossible to apply to the ceiling and tops of the walls. Therefore, for their finishing it is better to spray with two-component foam. It provides very high strength and hardens quickly and evenly.

Expanded polystyrene

Expanded polystyrene in slabs is a new generation of foam. It has a higher structure density. Two layers of this material create a seamless vapor barrier, which in turn prevents condensation from forming on the metal walls.

Warming with modern foam

How to insulate a container house with expanded polystyrene plates? For this, during the construction of the lathing, cells are made equal to the width of the foam plate, which is laid in the cells.

Mineral wool

The "cake" of mineral wool insulation is durable and fireproof. Cotton wool has biological and chemical resistance. Metal elements in contact with mineral wool do not corrode. When installing thermal insulation inside the room, a mineral wool insulation is covered with a membrane film.

Mineral wool insulation

This insulation has a low vapor permeability, so all condensate will concentrate in the layers of mineral wool. The film is attached using a construction stapler or expansion anchors.

Advice! If you buy foil mineral wool, you can do without a vapor barrier film.

If you have no experience in insulating living quarters, be sure to watch the video on how to properly insulate a container before starting work. After insulation, the house is ready for sheathing with plasterboard or other materials.

Table of characteristics of materials for thermal insulation of metal containers.

| Name | Properties | Features of insulation |

| Mineral wool | Fungus and mold are not formed in the fibers. | You can hide the wiring in mineral wool. The laying of these materials begins from the walls, and only then the ceiling is insulated. Be sure to make holes for the condensate outlet. |

| Expanded polystyrene | Has a low thermal conductivity. Has the best ratio: price - quality. | |

| Sprayed polyurethane foam | Durable and resistant to wear and tear; | The insulation layer should be solid. |

Which side to do the insulation

The metal walls of the container have high thermal conductivity. This means that it is hot in summer and cold in winter. It is important to correctly make the correct thermal insulation of the future home.

From within

In order for the building of container blocks to be suitable for life, it is necessary to insulate it from the inside. To do this, you can use the services of companies that are engaged in the insulation of premises with expanded polystyrene.

A layer of foam of 5 cm in terms of thermal insulation competes with a brick wall 1.5 meters thick. With such insulation, the effect of a thermos is created - the heat does not leave the room, and one heater can heat rooms in 30 - 40 minutes. You can also insulate the container with a 12 cm layer of mineral wool.

Possible problems

During the insulation of the room from the inside, problems may arise. They can be avoided with the following guidelines:

- With internal thermal insulation, it is very important to lay the materials in a continuous layer, avoiding any gaps. It is easier to achieve this effect when using polyurethane foam.

- It is important to exclude contact of materials with high thermal conductivity with the interior of the room. If isolated rooms are planned in the house, and a metal partition is needed, it is forbidden to weld it to the walls of the container.

If you consider these two points and do everything right, heat will not escape from the room through the walls. Constant temperature containers are called insulated containers.

Outside

External insulation implies a complete decoration of the walls of the trailer with penoplex, aka expanded polystyrene, or mineral wool. First, the lathing frame is installed, the facing material is fixed on it.

The thermal insulation is protected by waterproofing or a special membrane that protects from the wind, under which a vapor barrier is placed.

How to insulate a floor for a living space

Before insulating the floor, a thick film for vapor barrier is first laid in the container. After its arrangement, logs are installed with a step of at least 0.9 m.Then foam or other high-quality insulating material from the above is laid. If there are gaps, they are filled with polyurethane foam so as not to leave cold bridges. Then the floor is covered with moisture resistant material. It can be plywood, chipboard or fiberboard.

Note! Do not choose cheap mineral wool of dubious quality and from an unverified manufacturer. Usually the reason for the reduction in price is a deviation from the manufacturing technology. Therefore, such a material can quickly lose its thermal insulation properties.

The next stage of floor insulation is the laying of decorative flooring.After that, along the perimeter of the container, the floor is insulated with a sealant or polyurethane foam. At the end of the work, plinths are installed.

Required materials and tools

Penoplex does not allow moisture to pass through, therefore it is recommended for insulating metal structures

To organize and implement the insulation of the sea container from the inside, you will need to prepare:

- insulation material of the selected type (expanded polystyrene, for example);

- wooden bar 5x5 cm and dowels;

- scotch tape, primer and plastic wrap;

- polyurethane foam, paint and sealant.

In addition, it is necessary to purchase plasterboard sheets, as well as chipboard or fiberboard blanks.

From large tools, you will need a grinder, an electric drill and a screwdriver. In addition, you need to prepare the following toolkit:

- screwdrivers;

- yardstick;

- a device for applying polyurethane foam and sealant;

- dowels;

- brush, hammer, sharp knife and building level.

You will also need a pencil or colored marker for marking.

When working, you should use protective equipment for the skin of the hands and face - a respiratory mask, gloves and goggles.

Is a sea container suitable for arranging a cellar

Many people believe that a metal cellar is unprofitable, it will take a lot of costs to install it, and still iron, even strong, will soon begin to deteriorate due to moisture in the ground. Usually, the conversion of containers into a cellar is common in the southern regions of the country, where there is little rainfall.

For the equipment of the cellar, a pit is first dug out of the sea container. The bottom is covered with a 15 cm layer of gravel or a concrete cushion is created to prevent moisture increase. The insulation of the cellar is done in the same way as for the house. Leave a gap in the upper part and install ventilation.

The optimal result is guaranteed by a combination of external and internal insulation. A well-insulated container inside and out will serve you for a long time. In principle, such a modular building is no different from an ordinary house.

Pros and cons of houses

Sea containers are a reliable material for housing construction, especially after they have been insulated. For a better understanding of the situation, it is worth considering what are the advantages of such structures, and what are their disadvantages. The advantages of container houses include the following:

- Low price. A sea container is a budget material, construction from it is inexpensive.

- The house is not afraid of natural disasters.

- It will not take much time to make an apartment from a block - container.

- The ability to use different types of foundations - concrete, strip, piles. This moment depends on the location of the site on which the construction is planned.

- Unusual and modern look.

- Mobility. A small building, if desired, can always be moved to another place.

Like any building, these houses have their drawbacks. The original purpose of the source material is transportation by sea. A toxic chemical composition is applied to the walls of the container in order to protect the contents from external factors. Before you build a house or garage from a trailer, you must thoroughly clean it. Additionally, this material requires special anti-corrosion care.

Insulation of wagons and containers for transportation

Modern insulation helps to maintain the temperature inside the shipping container, which is optimal for storing and transporting food. Food products, cosmetics, perfumes, medicines, when transported in unsuitable temperature conditions, lose their consumer qualities, leading to losses. Therefore, such goods have to be transported in special refrigerated wagons, which have a high cost and a relatively small capacity.

If you insulate an ordinary carriage, creating the necessary temperature conditions there, you can save a large amount on the purchase of refrigerators and transport 30% more goods. This is the path taken by companies producing beer and other drinks, which are now transported in ordinary, but insulated wagons.

Typically, foam is used for this purpose, which has to be attached to the cars using complex structures and multi-stage technology:

- the carriage is listened to and warmed up to a temperature of 10-15 degrees;

- slots and holes are sealed with polyurethane foam;

- a wooden crate is attached to the floor, walls and roof, inside which a plastic film is laid;

- walls are reinforced with an additional film layer;

- in the resulting cells from the bars, sheets of foam plastic 50 mm thick are stacked in 4 layers, shifted by layers of film;

- on top of the insulation sheets of hardboard are attached.

After warming, boxes with drinks are placed inside, and warm air is supplied through a special opening inside until the temperature in the carriage reaches 20 degrees. After that, the hole is foamed with polyurethane foam. After such insulation, drinks can be transported at any distance without fear that the contents of the bottles will freeze and break the glass container.

Using polyurethane foam instead of multilayer foam for this purpose will make the process much easier, reduce the time for insulation and save more usable space inside the car.