Is it possible to use basalt insulation for a chimney

Basalt, used in the manufacture of chimneys, is one of the types of mineral insulation. Another name for the material is stone wool. Thermal insulation is made from gabbro-basalt rock waste. During the production process, the rock is crushed and melted, stretched into thin fiberglass.

The melting temperature in the furnace is 1500 ° C. The thickness of the pulled fibers is not more than 7 microns, the length is 5 cm. The resulting threads are passed twice through a press, preheated to 300 ° C. The resulting thermal insulation is distinguished by fire resistance, environmental friendliness, strength and other characteristics. It is not surprising that the largest manufacturers use fire retardant basalt insulation for chimneys.

Thermal insulation of the chimney with basalt wool, given the characteristics of the material, is quite justified. During the production process, the material acquires the following advantages:

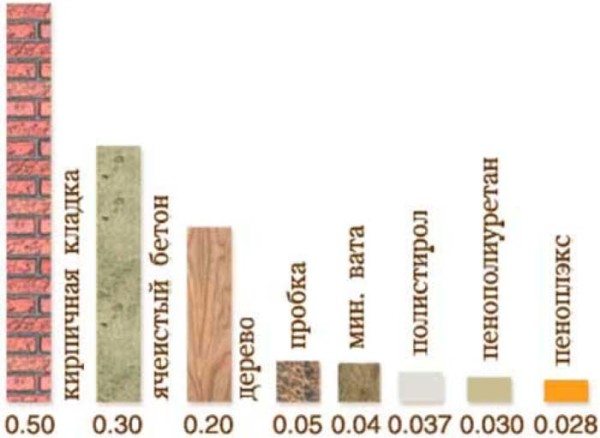

- Low thermal conductivity - depending on the brand, the thermal insulation value of the material ranges from 0.032 to 0.048 watts per meter per Kelvin. Foamed rubber, expanded polystyrene, cork have the same characteristics.

- Hydrophobic - moisture settles on the surface and cannot get inside. Even in damp rooms or under the influence of atmospheric precipitation, stone wool retains its operational and thermal insulation characteristics. Therefore, the choice of basalt wool for insulation of a chimney installed outdoors is a really good solution.

- Fire resistance - basalt wool, without loss of strength, heats up to a temperature of 1114 ° C. At a higher temperature, the material begins to melt. This ability allows you to withstand even direct exposure to open fire. The temperature of the chimney, even when soot is ignited, does not exceed 1000 ° C, therefore basalt is suitable for insulating any smoke evacuation systems, regardless of the principle of operation and the type of fuel used.

- Strength and resistance to subsidence - stone wool fibers are located both vertically and horizontally, which leads to the ability to withstand compressive loads from 5 to 80 kilopascals. During the entire service life, the material does not change its shape. Deformation is allowed no more than 10%.

Basalt wool for insulating chimney pipes is recommended for use in the manufacture of fire-prevention cuts, installation in wet rooms, as well as outdoor decoration.

The characteristics of basalt fiber made it possible to significantly expand the scope of application, in comparison with conventional mineral insulation. In chimney systems, stone wool is used for the following purposes:

- Sandwich pipes - insulation of a steel chimney with basalt wool is carried out at the factory, which ensures high thermal performance and the absence of cold bridges. The construction of a sandwich pipe is distinguished by its light weight, heat resistance and good thermal performance.

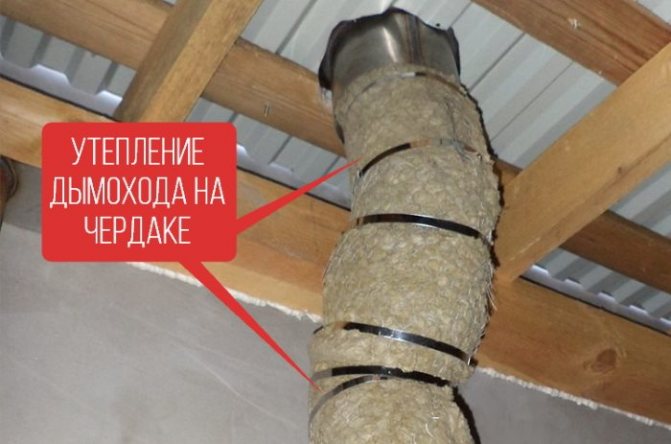

- Ceramic pipes with an outer casing made of stainless steel - cylinders of basalt wool, 3-4 mm thick, are inserted into the structure. The absence of seams increases the already high thermal insulation characteristics. Ceramics installed in expanded clay concrete blocks are insulated during installation. You can wrap the chimney pipe with insulation with a thickness of 30/40/50 mm. Fix the cotton wool with clamps.

- Insulation of pipes of a single-wall steel chimney with basalt wool.For these purposes, it is recommended to use foil-clad basalt for the chimney. Foil stone wool reduces heat loss and protects the pipe from external influences of atmospheric precipitation.

- Insulation in penetrations - roof cutting for the chimney, as well as the passage in the floor slabs, in accordance with the requirements of PB and SNiP, is insulated with a non-combustible material. The gaps between pipes and structures are filled with stone wool. Fireproof foil-clad basalt insulation for chimneys is also used for the manufacture of fire-prevention cutting, protecting wooden elements of the building with it, located in the immediate vicinity of heating surfaces.

- Insulation of the chimney box - in order to prevent the appearance of oxides on brick channels, it is required to insulate the walls. For this purpose, rigid basalt slabs are optimal, allowing you to subsequently finish under plastering, laying ceramic tiles, etc.

Basalt is intended for thermal insulation of chimney pipes located inside and outside the building, for the manufacture of fire breaks and chimney passage nodes through structures.

The main mistakes in insulation

| Benefits | Description |

| No condensation

| The walls are reliably protected from the ingress of condensate on the surface, which does not allow moisture to accumulate. All combustion products come out together with the smoke. |

| Stability

| As a result of thermal insulation, hot air and cooled walls do not create sudden changes. |

| Energy saving

| Insulated pipes retain and retain heat for a long time, which allows you to profitably save consumer resources. |

| Strength

| The design becomes more robust and reliable. The likelihood of various destruction and damage caused by environmental influences is excluded. |

You can find out how to properly carry out insulation by watching the video in this article.

When performing chimney insulation, the following mistakes can be made:

- insulating material of insufficient thickness was laid, due to which the dew point was inside the chimney;

- leaks in the casing or insulation, which led to the appearance of condensation;

- non-compliance with the technology of laying the heat insulator;

- installation of insulation on an adhesive base that does not withstand high temperatures;

- the thermal expansion of materials was not taken into account, as a result of which the connecting seams were depressurized;

- a low-quality refractory insulation for the chimney was used, which does not meet the declared characteristics;

- the hardening time of putties, sealants or other materials has not been observed;

- installation is carried out in conditions of low temperatures or in case of precipitation;

- the base of the steel chimney for installation was not properly prepared, as a result of which it rusted and became unsuitable for further operation.

To avoid mistakes, it is necessary to strictly observe the insulation technology, control all stages of work and use exclusively high-quality materials. Quality control can be carried out in the following ways:

- Heat the oven up to 60% of its power and check the appearance of seam disconnections.

- Use a thermal imager to detect heat leaks.

Thermal insulation of chimneys is a relatively simple, but very profitable procedure, thanks to which the operating modes of the furnace will improve, heat loss will decrease, and fuel consumption will be reduced. The service life of the chimney will increase several times, while the need for frequent cleaning from ash will also cease to be a problem. The main thing is that the choice of material and installation method is correct.

Types of basalt insulation for thermal insulation of chimneys

The choice of a brand of basalt wool depends on the desired thermal performance. The material is selected depending on the features of operation, the type of chimney design.You will also have to decide on the appropriate insulation for the manufacture of roofing cuts and nodes of passage through the wall, and floor slabs.

Heat-insulating basalt chimney shells are used in industrial and domestic smoke evacuation systems. By wall thickness, they are subdivided into several grades: 55, 75, 90, 110, 150, 200. The shells are supplied in lengths of 1 meter each.

We suggest that you familiarize yourself with: Installation of chimneys from sandwich pipes instructions

When installing pressed basalt cylindrical insulation, they are guided by the requirements set out in SNiP 2.04.14-88, and specifically, by the following instructions:

- The cylinders have a longitudinal seam for easy installation on pipes. The insulation is fixed with bands made of thin sheet galvanized or stainless steel, with a thickness of at least 0.8 mm. Alternatively, stainless steel or black steel knitting wires are used, with diameters of 1.2 and 2 mm, respectively.

- Non-combustible basalt heat-insulating elements of the cylinders are installed at intervals along the seams. The joints are insulated with aluminum tape.

- Installation work starts from the flange. Foil insulation does not need a protective coating. In other cases, a casing or metal casing is made for insulation.

The use of basalt insulation in the chimneys of a sandwich system, in the form of heat-insulating cylinders, is limited to pipes with a flue gas temperature of no more than 300 ° C.

Basalt mats are used to insulate heated surfaces at temperatures from 450-700 ° C. Operation methods are regulated by GOST-16381. Insulation is selected according to the following parameters:

- Density.

- The type of cladding.

- One or two-sided material stitching.

- Operating temperature limit.

First of all, you need to pay attention to the declared density of basalt wool. For connection to solid fuel units, stone wool with a coefficient of 30-125 kg / m³ is suitable. The material does not have a covering layer and is able to withstand a constant working temperature of 700 ° C.

Non-combustible basalt insulation of high density, used in the manufacture of nodes of passage, as well as insulation of chimneys of any design.

For external and internal insulation of single-wall pipes, a basalt mat with foil is used. When installed inside a building, there is no need for a protective sheathing. The foil layer is connected to the insulation by means of stitching.

It is not recommended to use stitched mats for the wall duct of the chimney. It is possible to install mats for insulating ceilings at the place of passage of chimneys, making fire-fighting cuts.

One of the novelties on the market of heat-insulating materials is basalt fiber board. The main characteristics of basalt cardboard:

- With a small thickness, it has a high density and is able to withstand temperatures up to 900 ° C.

- It is used as refractory coatings during the installation of wood and solid fuel stoves, boilers.

- Resistant to vibration and moisture.

- Service life is not less than 50 years.

- Basalt cardboard thickness: 5/10/14/19 mm.

- The creation of multilayer structures is allowed to increase the thermal insulation properties.

It is quite simple to insulate a metal chimney by wrapping it in basalt foil cardboard. The material bends well around the circumference. After wrapping the pipe, the insulation is fixed with clamps.

It is allowed to insulate the chimney with foil-clad basalt cardboard for all types of flue systems. After installation, there is no need to make an additional protective structure.

A basalt shield is installed as a fire cut, protecting the wooden walls adjacent to the heating pipe.

Installation process of thermal insulation materials

- Mineral wool.

Before installing the heat-insulating layer, the metal chimney is cleaned of dirt and dust, then galvanized iron rings are applied to it, which will act as a holder.

We strongly advise against using ordinary metal rings, since ferrous metal is a material that rusts quickly and does not tolerate high temperatures.

The insulation is rammed sequentially: from bottom to top.

To make the tamping process not complicated, disassemble the asbestos pipe into elements of 0.5 meters each. After tamping, reassemble the pipe and secure the seams with rings. Formed seams at the joints must be sealed with construction sealant.

Builders are not advised to wrap the chimney with mineral wool outside. This technology of laying heat-insulating material will lead to the fact that the mineral wool is saturated with moisture (it does not tolerate it well) and quickly deteriorate.

- Insulated metal pipes.

Insulated chimney

Such pipes entered the construction market recently, however, they quickly gained adherents. Insulation of a chimney with an already built-in metal pipe is possible. To do this, you need another metal pipe with a smaller diameter, which is inserted into the chimney. So that the pipes do not come into contact with each other and keep at the same level, they must be secured with stainless steel rings: one ring is placed from below, and the other from above.

The securely fixed structure is filled with a glass wool heat-insulating layer. Building materials must be well tamped, otherwise all efforts will go down the drain. You can tamp them with an ordinary long stick or other improvised means. After tamping, the chimney must be sealed with cladding. It can be sheets of corrugated board or ordinary plaster.

- Brick chimney.

A brick chimney is the most common construction that is insulated with plastering. On the one hand, plastering gives a certain result, but on the other hand, such insulation of the chimney does not have a long service life.

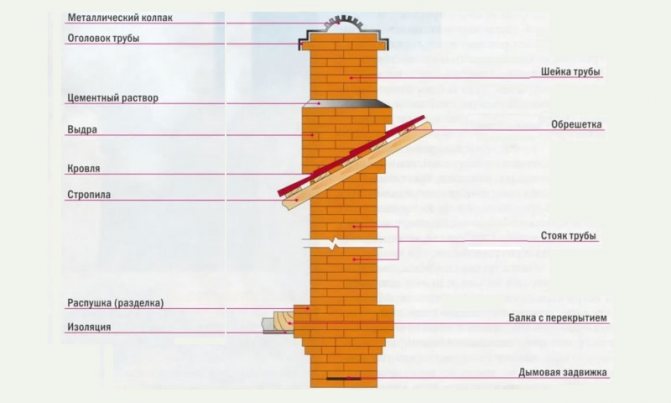

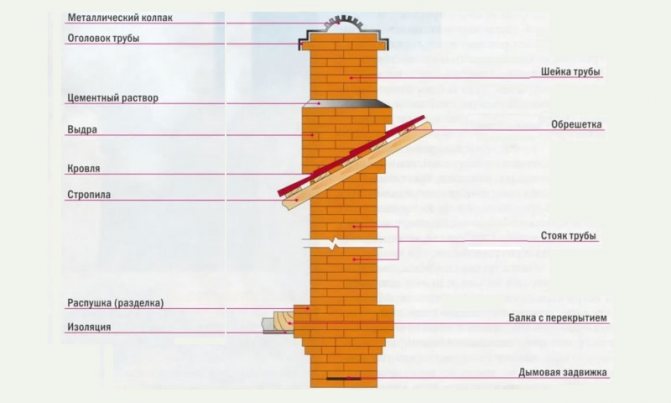

Brick chimney insulation scheme

The technology for applying thermal insulation plaster is no different from the usual scheme for working with a solution. Add lime and slag instead of sand. These materials increase the thermal insulation properties of cement several times. In addition, they protect it from stratification and crumbling.

The plastering process consists of two stages: first, a liquid layer is applied; the second layer is applied only after the first has completely dried. It is worth noting that the second layer is applied with a thick solution and smoothed out with grout.

Basalt (stone) wool

Basalt wool is the second, more reliable way of insulation. Of the tools we need: a construction knife, a grinder and several attachments for a power tool. The first step is to grind the pipe and clean it from dust and dirt.

After removing all the deposits of dirt and cement, the sheathing frame is assembled. Use a hammer drill and drill with a diameter of 8 mm to drill holes in the profile at the joints. Conventional dowels are used as connecting elements.

The finished structure must be fixed outside the chimney and securely fixed with dowels. Basalt wool is stuffed into places with a gap. Tamp down the insulation thoroughly. Remember, the smaller the gaps, the longer your chimney will last.

One layer of vapor barrier film is placed on top of the insulation. It is fixed with a construction stapler. The seams between the foil are sealed with construction tape. At this stage, the insulation of the chimney is over, it remains only to make the cladding. As a facing material, you can use corrugated board.Sheets of corrugated board are mounted to the frame using ordinary dowels that come with the product. After finishing work, the sheets of corrugated board must be washed with a damp cloth.

Basalt insulation brands for chimney insulation

Various manufacturers, the consumer are offered more than several dozen names of basalt heaters. Some are manufactured abroad, others at domestic enterprises.

Judging by customer reviews, the products of the following companies are popular:

- Basalt wool Rockwool is produced at the enterprises of the company of the same name, located in Denmark. In terms of its characteristics: hydrophobicity, sound and thermal insulation, as well as mechanical strength, Rockwool significantly outstrips analogues of other manufacturers. Basalt wool Rockwool is used by manufacturing companies for insulating finished ceramic chimneys Schiedel, Effe2 and others.

- Basalt wool URSA - originally made in Italy. Today the company has 14 large production centers located in Europe, the Middle East and Asia, which, as a result, could not but affect the quality of the products. The URSA company specializes in the insulation of industrial and domestic premises, and is popular due to the good price-quality ratio of its products.

- Izovat basalt wool is a heater made in the near abroad, in Ukraine. The product range includes mineral slabs with a density of 30 to 200 kg / m³. It is worth paying attention to a brand intended for insulating brick chimney ducts with subsequent plastering of the surface. The thickness of Izovat boards is from 30 to 200 mm.

- Paroc basalt wool is a Swedish company specializing in the production of stone wool since the 30s of the last century. Paroc production workshops are located exclusively in the EU countries, which allows maintaining a high level of quality and full compliance with safety standards in force in Europe. Paroc basalt cylinders can be used to insulate iron chimney pipes. To this end, the company has developed the Paroc Pro Section and Paroc Pro Bend cover layers, which provide maximum thermal insulation and protection for steel structures.

We suggest that you familiarize yourself with: How to impose a brick on a metal stove in a house: how to overlay a heating boiler, an iron stove, which brick is better to make

When choosing basalt for pipe insulation, it is mainly necessary to focus on the heat engineering characteristics specified by the manufacturer. On the basis of large concerns, modifications have been developed specifically for smoke extraction systems.

The best and proven heaters

If you do not know how to insulate the chimney, we suggest that you familiarize yourself with the basic materials and the features of their use.

- Choose a material that can tolerate well not only the effects of high temperatures - up to 300 degrees, but also their sharp drops;

- The best option would be special fiber-based insulation;

- Also perfect - glass wool, mineral wool, slabs of cinder-concrete origin;

- Additionally, when carrying out this procedure, it is necessary to use a fixing mixture - plaster;

- For sandwich pipes, you can opt for sleeves made of stainless steel.

Non-combustible winding for sealing the chimney

Non-combustible winding for sealing the chimney

Mineral wool for pipe insulation

Mineral wool for pipe insulation

Insulation for chimneys can be cylindrical. This variety is sold with special foil. That allows you to quickly and efficiently perform insulation.

Tip: when choosing a finished product, pay attention to its thickness. The material should not cover the entire interior of the chimney or most of it.This will not allow the traction to work at full power (How to make a traction amplifier with your own hands), and combustion products will accumulate inside or remain indoors, which is very dangerous to health.

How to insulate a chimney - a diagram of work and manipulations:

Features of chimney insulation with basalt wool

In addition to the correct choice of basalt insulation, you need to worry about observing the installation rules. As practice shows, the following norms are especially often violated:

- The thickness of the layer of basalt wool in penetrations through wooden structures is at least 5 cm.The distance from the supporting beams is at least 1 m.

- If you need to lay the material in several layers, correctly lay out the fire-resistant basalt slab with an offset to overlap the joints of the lower sheet with the upper one. The same rule applies to the installation of a cylindrical insulation. The longitudinal seam of each subsequent shell is shifted 180 °.

- The device for the passage of the chimney through a wooden floor using basalt wool provides for the use of fire cutting. To combustible material, from the heating surface must be from 50-100 mm. The gap is filled with stone wool.

- The thickness of the basalt fiber in the chimney should be no more than 40 mm, for external insulation, up to 100 mm. The density is selected depending on the operating conditions. For insulation of ceramic chimneys connected to solid fuel boilers, basalt wool with a density of 100 to 200 kg / m³ is used.

- It makes no sense to use high-temperature basalt wool for thermal insulation of a chimney connected to a gas or oil-fired boiler, since the temperature of the flue gases rarely exceeds 200-300 ° C. Installation of a cylindrical insulation will be optimal.

- Calculation of the required amount of basalt wool for insulating a steel chimney. The required material thickness is selected. On the packaging of the insulation, the approximate consumption of cotton wool is indicated for different layer thicknesses. It remains to calculate the dimensions of the circle in centimeters and the length of the pipe. After that, the number of packages is calculated.

- After insulating a single-layer pipe with non-foil-clad material, it is imperative to manufacture a protective structure.

In some hardware stores, I can cut packages with basalt insulation in two, or sell mats individually. This allows you to purchase the exact amount of material and avoid overpayments.

The main disadvantage of basalt insulation is its cost. Otherwise, in comparison with any other types of thermal insulation, basalt undoubtedly wins. The advantages of the material include:

- Low thermal conductivity - even at an exhaust gas temperature of over 500 ° C, basalt wool heats up no more than 30 ° C. During a short-term ignition of soot and a temperature jump up to 900 ° C, the outer circuit of the sandwich pipe will not heat up more than 45 ° C.

- Non-combustibility - the material can withstand direct fire from a gas burner without igniting. Wool begins to melt after exceeding 1100 ° C. Therefore, you can lay the basalt insulation close to the chimney and not worry about the safety of the room during the entire period of operation.

- Easy installation - mats and sheets can be easily cut with a regular painting knife. The material is fixed with clamps or knitting wire. If you lay basalt wool with your own hands when installing chimneys, you can significantly save on work.

- The specific weight of even basalt refractory wool is 30 kg / m³, respectively, after insulation, the mass of the chimney structure does not increase much.

Basalt wool has no analogues in its characteristics and is the optimal solution when choosing a heater for a chimney.The only thing that limits the popularity of the material is the high cost associated with the peculiarities of the production process.

Criteria for choosing a material for insulation

Insulation for the chimney pipe should be selected based on the following criteria:

- the temperature of the exhaust gases and the temperature difference between the chimney and the environment;

- the location of the chimney inside the building or along the outer wall;

- the material from which the chimney is made;

- maximum permissible roof loads.

Insulation for a chimney with foil is recommended for use in the following cases:

- the main part of the structure is laid outside the house;

- a large temperature difference between the external environment and the room, when it is required to heat the stove at extreme temperatures;

- there are no passages in the chimney, that is, the chimney is brought out directly, so that the temperature of the smoke hardly decreases compared to its value in the combustion chamber.

The main parameters of heaters

Thermal conductivity

When choosing a heater, the main attention is paid to its most important parameter - thermal conductivity, which does not at all depend on the density of the material, as many mistakenly believe. Heaters of the same density, but made using different technologies, may have different heat conductivity.

The lower the coefficient of thermal conductivity, the more efficiently and better the selected insulation material keeps heat in the house.

Coefficients of thermal conductivity of various materials (W / mK)

Water absorption

Another very important characteristic of an insulating material is the ability to absorb moisture. Water vapor is always present in the air. In a certain situation, it can turn into condensation inside the insulation, significantly reducing its thermal properties.

In this case, vapor barrier is required. This question becomes relevant if the loggia is also insulated.

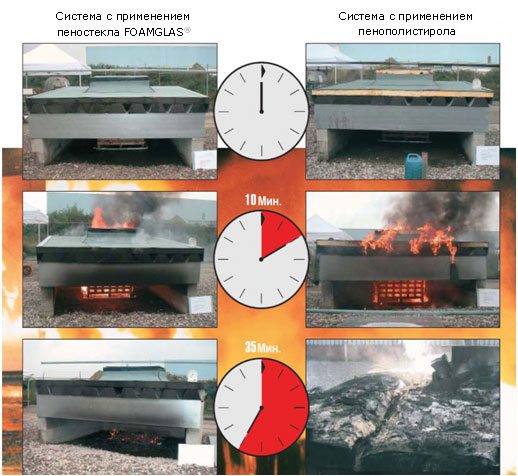

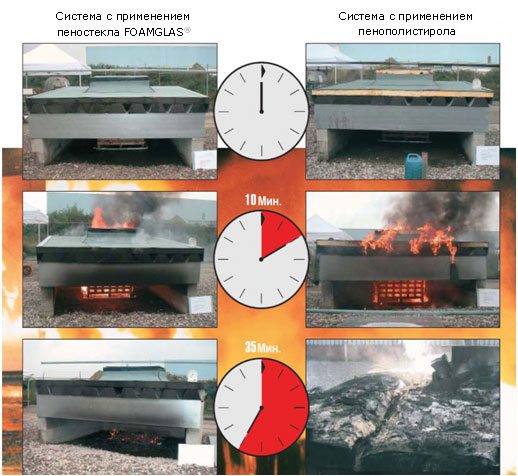

Fire resistance

Insulation, like the entire structure of a house, especially a wooden one, must also have a fire-fighting property. This is especially important for insulating chimneys, fireplaces and other elements of the house, which are directly exposed to strong heating or direct contact with fire.

Comparative fire tests

Requirements for a metal chimney

Before insulating the chimney, you must familiarize yourself with the basic rules and requirements for it:

- The pipe must be at least five meters high. Only in this way can you be sure that the traction will not function worse over time;

- The distance between the ceiling and the pipe must be at least 300 millimeters;

- If materials such as roofing material, slate, ondulin (combustible) were used as a finishing material for the roof, the pipe must be equipped with a special spark arrester.

Sealing metal pipes

Sealing metal pipes

Non-flammable heaters for the chimney

Non-flammable heaters for the chimney

Important: when carrying out insulation with your own hands, the optimal and safe distance between the ceiling and the stove should be at least 1-2 meters.

Types of fire insulation

Mineral wool

Photo of mineral wool

Mineral wool insulation is supplied in slabs or in rolls in the form of heat-insulating mats. Plates are more convenient and easier to use for insulation of roofs, floors and walls. Mats are more practical to use for pipes and various non-straight surfaces, as well as industrial equipment.

Cotton wool is made from sand, cullet, soda, and other components, which, after heating to a high temperature, turn into fiberglass. Then the material is impregnated with a special resin and pressed.

The most important advantage of mineral wool is its heat resistance. Cotton wool is a non-combustible insulation. Melting of the material begins when heated above 1000 ° C.

Therefore, such a fire-resistant insulation is effectively used by builders to insulate heat-resistant partitions, baths, chimneys and other structures.

Mineral wool insulation has also found application for the insulation of curtain facades and pitched roofs due to its excellent characteristics:

- low thermal conductivity;

- good sound absorption;

- high hydrophobicity (vapor permeability), which allows the building to breathe, thereby preventing the appearance of mold and mildew.

This refractory insulation consists of a layer of polyethylene foam, which is covered with polished aluminum foil on one side (or on both sides). It is a thin, very lightweight and completely environmentally friendly material with good flexibility.

Due to the low coefficient of thermal conductivity of foamed polyethylene, foil insulation is characterized by high resistance to heat transfer.

Polished aluminum foil is highly reflective. The reflection effect is up to 97%. Having the above properties, this type of insulation has excellent ability to reflect infrared (thermal) radiation, preventing heat loss to the outside.

Thanks to the use of foil-clad insulation, energy costs for heating a building or room are significantly reduced. For this reason, it has found wide application for thermal insulation of hot (cold) water supply systems, heating systems, systems intended for air conditioning.

With its help, the interpanel seams and window openings are sealed. It is excellent for thermal insulation of floors and walls in both residential and public buildings.

Fireproof thermal insulation for walls

Application of liquid polyurethane foam to the walls.

Ideally, non-combustible wall insulation should always be used when it comes to insulating load-bearing structures. According to the rules of heat engineering, work should be carried out outside and only in extreme cases from the inside. For these purposes, the choice of materials is wide enough:

If earlier the most popular non-combustible insulation for walls was mineral wool, today it has greatly lost ground in favor of modern liquid thermal insulation. We are talking about polyurethane foam and penoizol, and although the paint-insulation is positioned as a non-combustible insulation for the facade, in fact it is only suitable for thermal insulation of communications.

Loose materials for horizontal structures are applicable not only during construction, when they can fill the inter-wall space. After the construction has been erected, it can be blown out through the holes made in the wall. Loose non-combustible thermal insulation for walls fills all the cracks, in principle, like liquid insulation, but the latter has its advantages:

- it is lighter; lower coefficient of thermal conductivity; reasonable price; the possibility of application on the wall, for example, on the facade.

Foamed glass is still the most expensive material among fireproof thermal insulation.

It comes in granules, stones (like crushed stone) and blocks. Granules and blocks are used for the walls. The former are poured into inter-wall cavities, and from the latter, protective structures are erected on the front side.

The blocks are strong enough, but still cannot act as load-bearing elements. Due to their high cost, such materials are used only at large facilities. For private houses, they are almost never used, since the insulation will turn out to be just golden.

After cleaning the heat exchangers, the liquid for heating radiators must be rendered harmless with a special solution and only then drained into the sewer. The non-freezing liquid for the heating system in a warm house, even at -60, only thickens. You can find its characteristics here.

The most popular insulation materials

The list below lists only those materials that meet the specified requirements for performance, properties, quality and reliability.

Such materials include:

- Glass wool / thermal fiber... It is used as a heater for metal-plastic products. The main advantage of the material is its low density, the disadvantage is the need to use additional external insulators (roofing material, fiberglass), which becomes the reason for the rise in the cost of insulation and an increase in the duration of work.

- Basalt insulation on the pipes. The starting material is “basalt fiber”. Manufactured in the form of cylinders. The raw material has good thermal insulation. The advantages of such insulation include simple and convenient installation, the disadvantages are the high price. As a rule, the following are used as a protective layer: foil insulation, glassine, roofing material. Installation does not require any special knowledge or skills.

- Styrofoam... Also called polystyrene foam insulation. For insulation of a water supply system in a suburban structure (cottage, house, cottage and others) is the best option. The shell of such insulation may or may not have an outer coating (in more detail: "What shell for pipes is used most often as insulation"). It is reusable and does not require trays to be installed. This type of insulation is an economical option that meets all the specified requirements for operational and technical characteristics. The versatility of foam allows it to be used as a material for insulating pipes indoors, outdoors, including underground.

Required tools

The following tools may be required to insulate chimneys:

- construction knife for cutting insulation;

- electric drill with drills;

- tape measure, level, marker;

- for applying the solution - a spatula, container, trowel, as a rule;

- for fastening a steel cap - rivets and riveting or self-tapping screws and a screwdriver;

- a syringe with a nozzle of the required diameter for applying mastic or sealant.

We suggest that you familiarize yourself with How to clean the chimney from soot at home

To insulate the chimney, you will need an electric drill