Schott Robax® Heat Resistant Fireproof Glass

By purchasing heat-resistant, fire-resistant glass for the fireplace from us, you will receive high quality products at the most favorable prices, both retail and wholesale. brings to your attention glass for fireplace | fireproof screens | heat-resistant glass Schott Robax®

It is best to use special heat-resistant glass for protective screens and viewing panels of fireplaces. They are also actively used for glazing braziers, ovens, ovens and barbecues.

German-made glass-ceramics Schott Robax® has not only a beautiful and aesthetic appearance, but also the highest technical and consumer characteristics:

- the ability to withstand large thermal loads;

- optimal sheet thickness;

- high level of strength;

- the temperature coefficient of expansion is close to zero.

The main quality criterion when choosing glass for fireplaces is fire resistance. After all, its main function is to prevent sparks from entering the room, withstanding high temperatures. Protective glass for the fireplace from is a German quality and the lowest prices to date

... Delivery across Russia, Moscow and the Moscow region.

How to clean the glass of the fireplace from soot video

Not a big short video, which gives a video answer on how to clean the soot with the help of ash from the firebox. Perhaps someone still prefers "folk" methods.

P.S. Having watched this video again, I finally understood why this method is called folk. Not at all because the peasants of some Ryazan or Tula province liked to clean the glass doors of their fireplaces on long winter evenings, and only with ash. It's just that this method is free! And that means it is folk.

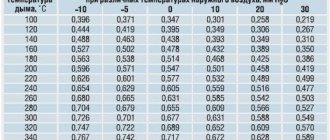

Rates

| Name | The cost |

| Fireproof glass for fireplace 4mm | wholesale price 10,500 rubles / sq.m |

| Fireproof glass for fireplace 5mm | wholesale price 11,500 rubles / sq.m |

| Refractory glass ceramics 4 mm | wholesale price 10,000 rubles / sq.m sale of glass sheets |

| Round fireproof glasses of any diameter. Thickness 4 mm Refractory glass of various diameters | Rub 450 / pc |

Tempered glass pre-furnace plate

| 5,000 rubles / sq.m |

Fireplace shield

| RUB 6,500 for 1 pc. |

The causes of contamination

If you want to know why glass is smoked in a fireplace, we recommend that you familiarize yourself with the following possible prerequisites:

- When using gas equipment, deposits and soot may indicate that burners are clogged or that the jets are not installed in the correct position. All this can subsequently lead not only to the occurrence of pollution, but also to improper air and gas supply;

- If the main component of the furnace unit is propane, various deposits and other contaminants appear on its surfaces very often and quickly. The reason for this can be either the wrong ratio of each component (air, gas) or the poor quality of the fuel. Also, the reason may lie in the fact that the regulator tank is faulty;

- The most problematic are the classic wood-burning installations. Soot and soot can form if you use softwood as a solid fuel. Also, the fuel itself may not completely burn out, or the reason may be hidden in a clogged chimney. You can find out how to clean the chimney from this article >>>

Regular care, in the future, allows you to quickly cope with emerging dirt

Regular care, in the future, allows you to quickly cope with emerging dirt

Important: if

fireplace glass turns blackor other contamination occurs more often than once every two weeks - this indicates the presence of internal malfunctions or violation of operating rules.

You can take a closer look at the different types of contamination by watching the video in this article.

Characteristics

| Manufacturer | Schott |

| Producing country | Germany |

| Glass type | Tinted, heat-resistant glass ceramics |

| Glass thickness | 4.0 or 5.0 mm |

| Glass width | 1100.0 mm |

| Glass length | 1954.0 mm |

About glass for the fireplace, protective screens for the fireplace

The fireplace combustion chamber poses a certain threat to the room due to the large number of sparks, coals emitted by cracking wood and hot ash. Closing the opening with a steel or cast-iron flap is inconvenient, in addition, all the beauty of the flame disappears and heat transfer decreases.

Therefore, in modern fireboxes, glass is used for the fireplace, which is strong enough not to scatter when closed, and heat-resistant to withstand the thermal head of the flame.

GLASS FIREPLACE DOOR DEVICE

The idea of using glass as a material for fencing a fireplace insert has been around for a couple of hundred years. In those days, quartz glass was used for fireplaces in the form of separate mosaic fragments on a bronze or copper fireplace screen. The glasses had to be changed periodically, as the screen moved too close to the fireplace got hot and the mosaic cracked.

Today there is no alternative to the use of a glass valve:

- Fireplace doors made of heat-resistant glass do not expand or deform from heat, like cast iron or steel, thanks to this, it is possible to obtain minimal gaps and high quality sealing between the frame and the edge of the door;

- Fire-resistant glass for a fireplace does not burn and does not oxidize, retains its original appearance throughout the entire period of operation;

- The main thing is that a fireplace door with glass allows you not only to enjoy the play of fire, it is the only possible way to control the combustion process so that the flame does not turn into decay with the formation of carbon monoxide.

Today, rarely any fireplace insert is made with a black metal shutter, most often these are high-temperature fireplaces designed to use universal fuels, including those with a high content of tar and tar. But even in such structures, the manufacturer tries to use fire-resistant glass for the fireplace, since it is easier to see with your own eyes what is happening in the firebox than to guess from the sound or the thermometer readings. True, the owners have to regularly look for a means and a way than to clean the glass of the fireplace from soot.

For a small country house and summer cottage, a cast-iron fireplace with glass is most often chosen. In addition to the beautiful appearance, this choice has a purely practical advantage - heat-resistant glass for the fireplace provides faster and more uniform heating of the room. The champion in terms of heating efficiency is a round fireplace with glass, which is able to heat and illuminate the room at the same time.

Glass selection

Before proceeding with the installation or manufacture of a door for a furnace with glass, you must familiarize yourself with the requirements that it must meet. It should be said right away that the production process and raw materials for this part will depend on how you plan to use the fireplace or stove. If, for example, an object will be used as a heating medium, then at least two-layer, and preferably three-layer material is required. In addition to this requirement, there are several more that must be met by furnace doors with glass for a stove, fireplace:

- First, it is highly resistant to high temperatures.

- Secondly, the service life. Most often, this parameter is specified in hours.That is, the time that the glass can withstand under the temperature load is indicated.

- Thirdly, it is necessary to attend to the overall strength of the door with glass. Most often, this parameter is indicated in millimeters and is up to 3 mm.

- Fourth, the noise isolation effect. Of course, for some time the noise and hum of the stove or fireplace will delight, but over time, a person will get used to it and constant noise will start to interfere a lot, therefore, providing sound insulation is also an important parameter for the door.

Fireplace maintenance

Over time, in any fireplace, glass elements will lose their former transparency. You don't have to worry about the integrity of the surface. Durable glass is reliably protected from minor scratches and chips. The only thing the owner will have to worry about is cleaning the soot from the inside. It can be produced with any detergent, since refractory glass is resistant to aggressive chemicals.

Good to know: How to make a metal fireplace with your own hands, tips from experts

Manufacturers are trying to increase the service life between general cleaning of the fireplace body. For this, systems of recirculation and afterburning of gases at high temperatures are used. However, the maintenance process cannot be completely avoided.

When choosing a fireplace with glass elements, you can always count on a full overview of what is happening in its firebox. Such a device will certainly give you the pleasure of contemplating the combustion process.

Choosing a cleaning agent

If you do not know how to clean the glass of the fireplace, you can use both ready-made compounds, which you can buy at any specialized store, and alternative methods of cleaning.

Important: when choosing a commercial compound, pay attention to the fact that it is suitable for use and contact with the surfaces of your fireplace insert and hearth. Do not use compounds for metal surfaces if you need to clean the glass door or shutter!

We use ammonia

The easiest way to clean fireplace glass is ammonia. With its help, you can quickly, simply and as safely as possible remove shallow formations, darkening and soot from the surface.

The advantages of such a tool include its low consumption and affordable price.

Step-by-step instruction:

- At the first stage, the fireplace must cool completely;

- In a plate or any other container, you need to mix together a little alcohol, water and lemon juice or vinegar. This mass must be mixed well and poured into a special container for spraying;

- To remove soot and soot, it is necessary to apply a small amount of the solution to the surface and remove it with a paper towel or napkin. If the dirt has strongly eaten into the surface, leave the sprayed agent on the surface for 10-15 minutes, and then remove in the same way. In the presence of strong and ingrained formations, to achieve the desired effect, you may have to do this procedure several times.

Mandatory use of gloves, since any composition is potent and includes various chemical components

Application of the resulting acetic-ammonia suspension

Perfectly clean, streak-free surface

Fast removal with ammonia or alcohol based formulation

Advice:

cleaning the glass of the fireplaceusing undiluted ammonia may not be effective, since this component evaporates quickly enough and, in order to preserve its properties, it must be diluted with plain water. For the fastest cleaning possible, you can soak a paper towel in ammonia and then dip it in the ash. This will make the surface of the napkin harder and will allow for a better effect in the fight against stubborn dirt.

Fuel types

By its technological properties, tempered glass allows it to be used in fireplaces of different types of fuel. But transparent elements have one significant drawback - the inevitable coating with combustion products (soot). Wood-burning fireplaces emit it in large quantities, so it is irrational to make them out of glass.

Good to know: What kind of fireplace can be installed in the apartment and how to do it

Gas leaves much less products after combustion. The flame of fire looks quite attractive, so they try to demonstrate it as much as possible. There are options in which gas fuel creates the illusion of burning wood, for which dummies of logs are used.

Biofuels are alcohol-based and have high environmental performance. This fireplace usually contains a large number of glass surfaces.

Electric counterparts are certainly supplied with glass parts that give a full view of the simulated fire.

Massive construction in the middle of the living room

Characteristics of heat-resistant glasses

Fireproof fireplace glasses have some characteristics that must be taken into account when choosing your model:

- First of all, this is the maximum heating temperature, which it is undesirable to exceed.

- Secondly, the strength of the fireplace glass.

- Next, you need to take into account the thickness of the heat-resistant glass. In some designs of the firebox, glass for the fireplace is provided with a thickness of up to 4 mm.

- The most important indicator for the consumer is the service life of the glass, which depends on the highest temperature during the operation of the fireplace. If it does not exceed 600 ° C, then the glass retains its properties for several thousand hours. If the limit is exceeded, the service life is significantly reduced. for these reasons, it is not recommended to use coal for the fireplace or overload the firebox with wood, while creating increased traction.

The traditional idea of a fireplace is an open version, modern models are more often closed. Such a fireplace looks more aesthetically pleasing and safer ─ it can be easily left without constant attention.

The externally closed type of fireplace is similar to the traditional model, but it gives more heat, here you can even control the combustion process without worrying about the fire safety of the room.

The list of characteristics of heat-resistant glasses will be incomplete if not mention some inconveniences... The main enemy of these glasses is soot. In a closed fireplace, the glass inevitably becomes covered with soot over time, which significantly reduces its decorative effect. To avoid such a problem, the glass is equipped with protection against soot, for which a system of air recirculation in the firebox is incorporated into the design of the firebox, ─ this protects the glass from soot settling.

A pyrolysis cleaning system for fireplace glass has been developed, when, under the influence of high temperature, soot burns out from the glass surface by self-cleaning. For this, the glass is treated with metal oxide. This protective layer is invisible to the human eye and does not affect the appearance of the glass. Because of this shell, infrared heat radiation is largely reflected into the interior of the fireplace, increasing the temperature of the inner glass by 25% compared to standard heat-resistant glass. The soot deposited on the glass burns out instantly, the result is clear glass with a beautiful view of the fire.