How to properly place stones in the sauna stove

What function does a stone perform in a bath? Most see him steam generator, and already in the second place heat accumulator... But these are things that are directly related to each other: vaporization occurs at a certain temperature, to which it must still have time to reach before starting the procedures.

It is logical to assume that the heating rate of the stone will depend on the way it is placed in the sauna oven, but the design of the furnace itself plays a role here. there is convection ovens - they were purposefully created in order to reduce the amount of fuel and the time for heating the premises. As a result, we get a short heating, after which the bath is ready, but the stones are not yet. No matter how you put them, they simply do not have time to heat up in a short time, so they will give weak steam. That's why economical convection ovens are much more often used in saunas, rather than Russian baths.

If you heat an ordinary, for example, a brick stove for a long time, then everything will heat up evenly - both the air and the stove. In this case, the return will also be long, because the heater starts "working" after the stove is no longer heated. Our task is to use some tricks in order to achieve the shortest time to bring the stove to the desired state.

The stone has two important characteristics: heat capacity and thermal conductivity... And if we want to at least slightly accelerate their heating, then closer to the fire, it is better to put those with a higher thermal conductivity and a lower heat capacity. So the heat will be transferred faster to those that lie higher, up to the very top. See the heat capacity table and other details in the article What stones for a bath to choose.

This condition is easy to fulfill if use layers of different rocks. Because there is another rule that practically cancels the first one:

Judge for yourself: the larger the stone, the more heat is needed to heat it up. However, the smallest ones are also not easy to heat - they have a smaller contact surface required for heat transfer. All this can only be solved by choosing the correct size of fractions, which will be discussed below.

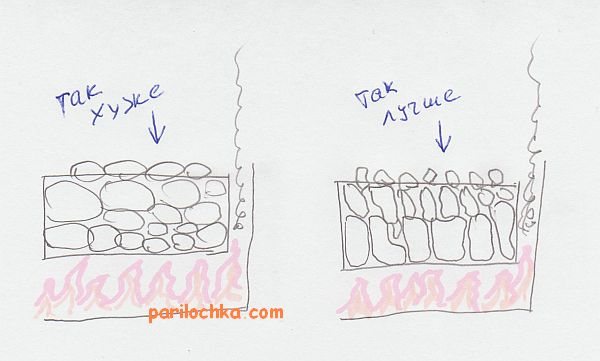

So, you have selected the largest copies in the batch and are going to put them on the bottom. How to do it correctly, given that their shape is arbitrary, often extended to one side.

This rule is empirical, but it can also be due to the higher rate of propagation of thermal energy along the layers, and not across them. Another reason for this choice is the need for free passage of hot air between the stones. End masonry increases the amount of gaps between stones.

After laying the first row, lay the next fraction as the next row. Laying tightly is still not worth it. After all, in addition to the fact that we must ensure air circulation, we also need to leave a little space for the future. thermal expansion of stones. It is, of course, different for different breeds, but it happens in all cases. The stone increases in size, and dense packing leads to the emergence of compressive forces that destroy the stone.

Physical parameters of stones

Select stones for the bath - business is simple and complex at the same time. Should be considered:

- density, that is, the greater the weight of the stone, the better;

- heat resistance, the ability of a stone to undergo a repeated heating / cooling process without significant losses (at least for a sufficiently long time) of its qualities and properties;

- heat capacity, the property of a stone to accumulate and retain heat, for the purpose of subsequent return to the bathhouse. The higher the heat capacity of the material, the longer it retains the ability to maintain the required temperature after stopping the heating process of the furnace.

Peridotite stones in the sauna heater of the steam bath complex in Aprelevka

Is it possible to mix stones for a bath

The answer to this question is definitely yes. You can mix. Moreover, you are free to lay them out in layers or mix different ones within one layer.

Many of those who have an open fire in the stove or have no opportunity to fill the entire volume with expensive rocks use cheaper for lower layers... Or they do the same for other reasons, for example, as mentioned at the beginning, so that accelerate heating due to different thermal conductivity and heat capacity of rocks. The third reason is purely aesthetic... You can choose the colors so that they look beautiful when wet. For example, mixing green and red specimens. Or red and gray.

What stones cannot be placed?

Minerals such as are contraindicated for use:

- Granite.

- Quartz.

- Spar.

- Mica.

- Pyrite.

- Electro porcelain.

- Marble.

- Limestone.

- Flint.

Such minerals contain harmful elements such as sulfur, iron, decay products of radionuclides that emit radioactive gases.

Which shape is the best?

We have already considered this issue in the article on the choice of stones. Recall that the choice most often lies between stabbed and tumbling varieties. Sanded are less common and we will not advise taking them, because they do not hold water at all on their surface. The stone must be at least slightly rough.

As for the advantages of the chipped version, they are all enclosed in a larger surface area of the uneven stone. It has much more disadvantages - where it is thin, there it will break off, chipped samples often have cracks (when tumbled, the most durable remain), in general, the tumbling option is better, and its only drawback is the higher price.

Material preparation

Not all cobblestones are suitable for a bath. The easiest way to find the right materials is to head to a specialist store, which has a ton of options to choose from. They differ significantly from stones of natural origin, which not only will not bring benefits, but also harm health. The main characteristics for which you need to make a choice are:

- Heat resistance - the ability of a material to withstand high temperatures.

- Heat capacity - the ability of cobblestones to keep warm.

- Environmental friendliness. Many materials are capable of emitting harmful substances during the heating process.

- Thermal expansion capacity. The less stones increase in volume when heated, the better.

The size of the material is very important. It depends on the type of heating device. Small-sized specimens are suitable for electric stoves, but for wood-burning stoves with an open stove, a filler of various sizes is suitable - from 6 to 20 cm in diameter.

The installation work is started after the electrical supply, when all the other necessary communications have already been laid.

Hidden electrical wiring in the bath

Installation of sockets on a log

Ceiling wiring

For finishing, you will need the following materials and tools:

- building level,

- binding device,

- puncher,

- screwdriver,

- a hammer,

- lining under the crate,

- kleimers. and self-tapping screws.

Cooking the tool

Before installation, the lining is adapted to the microclimate of the steam room. To do this, they bring the wood into the room and carefully lay it out, they start work only after a few days.

The lining needs to be adapted to the microclimate of the bath

The surface of the walls should be treated with antifungal antiseptics.

Antiseptic protection of wood structures

To prevent heat loss, even the smallest gaps are closed.

Sequence of internal work on filling cracks

The slope of the wall is determined by the level. If the walls in the steam room have drops, then they must be leveled with wooden spacers so that the mounting rails do not subsequently appear at different heights.

Checking the evenness of the walls

Rough wall marking scheme

How to prepare a stone?

Preparation includes testing. You need to do the following:

- just soak the batch in water without anything for several hours (you can skip this, but this is also a test: watch out for gas bubbles - this is a sign of cracks, specimens with bubbles must be removed);

- then go over each well with a stiff brush and rinse under running water.

The washed batch can be ignited and thrown into water. If any of them break, they will be rejected.

In the future, the stones will need to be sorted out with a certain regularity. You can do this once a year, every six months, every season. Deterioration in the quality of heating can be a signal for an unscheduled revision.

Possible mistakes

Inexperienced bath lovers can make the following mistakes when laying and choosing material:

- Incorrect amount of cobblestones. An insufficient number of elements in the heater will not produce enough steam. And if there is more material than is needed for this type of oven, it will not be able to warm up well.

- Incorrectly selected filler and its size. Vaporization depends on the properties of the components, and the circulation of gases in the space between the cobblestones depends on the size.

You should consult a professional before placing stones in the heater. And if you are unsure of your abilities, then it is better to invite a master. After all, the correct styling affects the pleasure obtained from taking bath procedures.

How much stone should be used?

There can be no definite answer here, because the breeds are different. However, no breed will last forever. With time stones are coked, covered with carbon deposits, some of them change their structure, become porous, crumble into dust, others burst into pieces. Only a check can show how many of them are out of order and need to be replaced.

The "dead" stone ceases to keep warm at all. It is easy to define him - it seems that he crusted... If the steam room starts to cool down quickly, check the heater, it may be time for a replacement.

Another thing that affects the service life: the temperature of the water that you supply for steam - it is better that it was hot, as well as contact of stones with an open fire - when he is not, they last longer.

*** So, to summarize what has been said: to put stones in the sauna stove correctly is to put them in descending order from the largest (10-12 cm) to the smallest (5-6 cm), and the lower layer must necessarily "breathe", that is, there you need to leave a little more free space between the stones.

We are confident that you will succeed with our recommendations. Light steam!

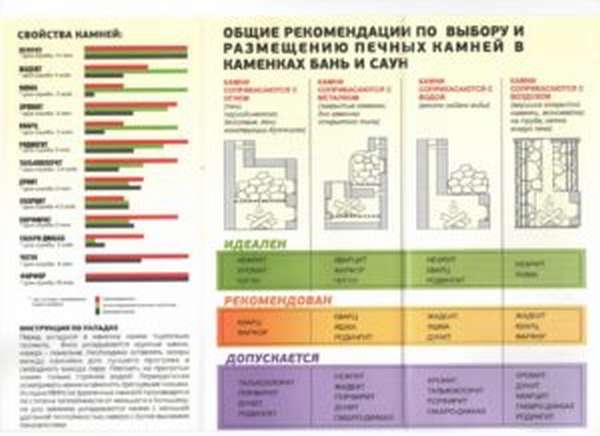

General recommendations for the selection and placement of stove stones in the heaters of baths and saunas

Properties of stones:

General recommendations for the selection and placement of stove stones in the heaters of baths and saunas

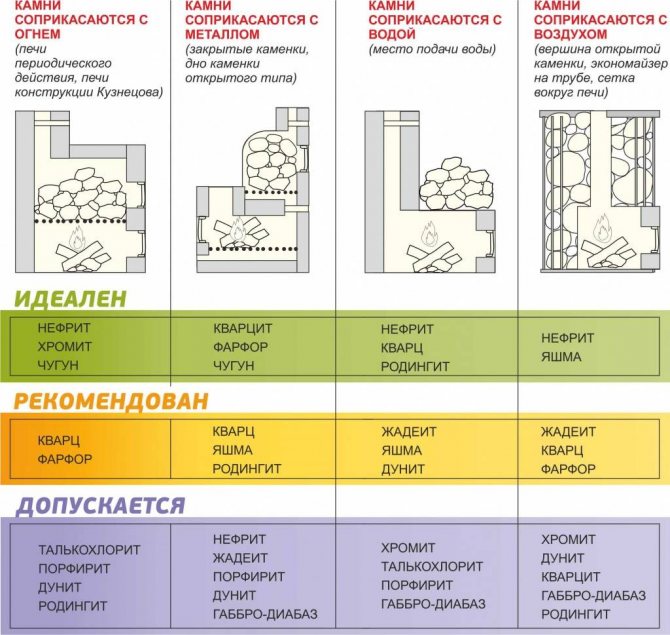

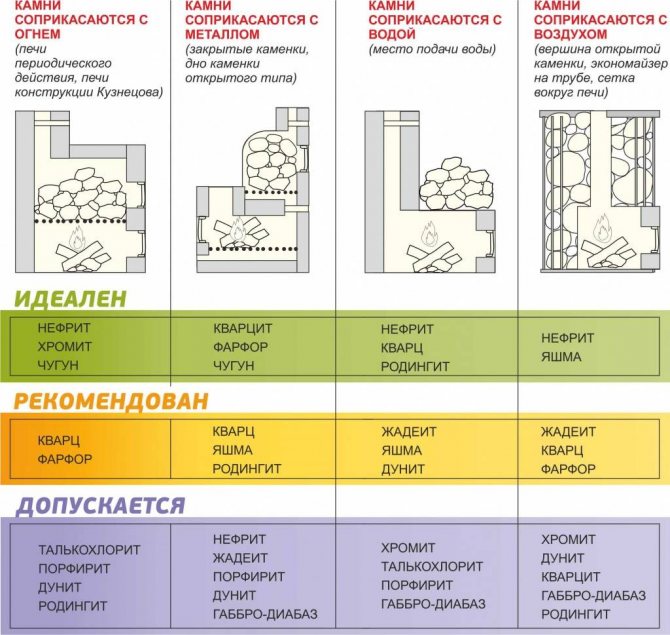

The stones placed in the heaters of baths and saunas must meet a number of general requirements:

1.For better adhesion (adhesion of water and stone surface), it is recommended to use chipped or bonded stones. Water from polished or polished stones will drain onto the metal, from where it will subsequently evaporate.

2. Absence of cracks.The stones should not have visible cracks and have a homogeneous structure, excluding their occurrence in the future.

3. Absence in the composition of carbonates. Bright signs of carbonates are white spots or cleavage chips that are easily scratched with a steel needle.

4. Absence in the composition of asbestos. Vivid signs of the presence of chrysotile asbestos (a mineral with fibrogenic properties) in the composition are the villi visible to the eye on the surface of the stone.

5.Lack of dust. The stones must be clean. To do this, immediately before laying, they must be thoroughly rinsed (this must be done even if the stones are visually clean).

In addition to the above requirements, there are also a number of highly specialized ones, depending on where the stones are used.

1. For intermittent furnaces, when the stone fill comes into contact with fire, it is important to select stones with the highest possible melting point.

2. For places where stones come into contact with metal (for example, the bottom of an open-type heater), a high coefficient of thermal conductivity is important.

3. In the places where water is supplied, it is necessary to choose stones that are resistant to sudden changes in temperature and have pronounced lithotherapeutic properties.

4.If stones are used as backfill in an economizer or a grid around the stove, it is preferable to use a backfill with high decorative qualities, as well as having lithotherapeutic properties.

5. Attention! When placing stones in electric heaters, it is prohibited to use chromite, jasper.

What else should you pay attention to?

It is important to be confident in every stone that you use as a furnace backfill and to give steam without thinking about possible troubles.

On the conscience of the manufacturer are indicators such as environmental friendliness, radiation safety, the absence of minerals harmful to health in the stone.

So that these invisible enemies of man do not spoil your pleasure from the bath, ask the sellers for a certificate of conformity and an expert opinion for a sanitary and epidemiological examination of stones. Remember, the stones must be certified SPECIALLY for use in bath and sauna heaters.

It is better if the stones that you buy will have a recognizable trademark from an understandable, real manufacturer.

Stones prohibited for use in the steam room

Minerals prohibited for use are, first of all, stones collected in places with a high radiation background. For example, in the dumps of former mines, in mining, in quarries. If you are not sure about the safety of purchased or collected stones, a dosimeter or a special examination will help to find out this indicator.

We also do not recommend using the following minerals for the heater:

- Collected on railway embankments. The impregnation for sleepers, which contains creosote, inevitably gets on the stones during processing. Upon subsequent heating, creosote is released into the atmosphere of the steam room, harming the people in it. Poisonous vapors are suffocating.

- Collected on the side of the freeway. In addition to the aforementioned creosote in the asphalt composition, there is a huge amount of dust on the stones nearby, which is difficult to remove even by dry cleaning. It clogs the cracks on the stones, and it becomes quite difficult to notice them at first glance.

- Soft rocks (limestone, sandstone). There is practically no sense from them: the steam is weak, the heating temperature is low. But damage from thermal effects cannot be avoided. Subsequently, crumbs of soft stones can clog the grate of the furnace, thereby interfering with the free passage of hot air and reducing the performance of the unit.

Important! Many bath attendants offer an alternative to the listed types of stones - cast iron cores. They motivate their advice by the allegedly excellent thermal characteristics of steel.This statement is highly doubtful, given the fragility of cast iron at the time of temperature drop. We do not recommend using this alloy as a stone for a steam room.