Wall this is the main structural part of the building. Its main purpose is to carry weight from overlying structures and transfer it to the foundation. Therefore, it must have the necessary strength (which is calculated according to special methods) and stability, as well as successfully withstand the emerging vertical and horizontal loads.

Considering also that the walls are also enclosing structures that divide buildings into separate rooms and separate them from the external environment, they must have the required design coefficient of resistance to heat transfer. That is, to maintain the required parameters of temperature and humidity in the premises.

The walls also have a decorative function, since with the help of various solutions in terms of architecture, they form the overall compositional appearance of a building or structure.

Modern building technologies offer a wide variety of building materials from which walls are made. But the most popular of the materials is still brick. It can be used for both external walls and internal walls and partitions.

Bricks and masonry

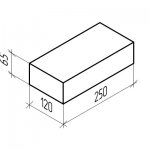

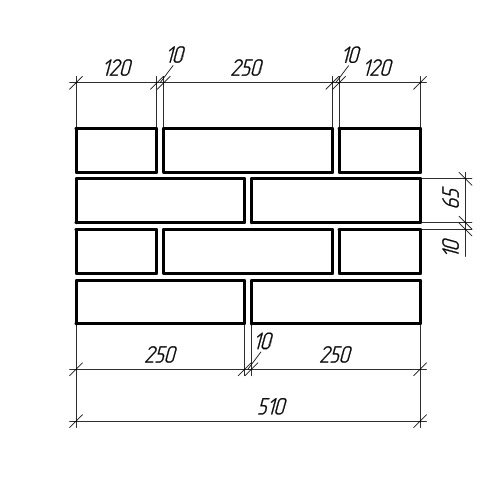

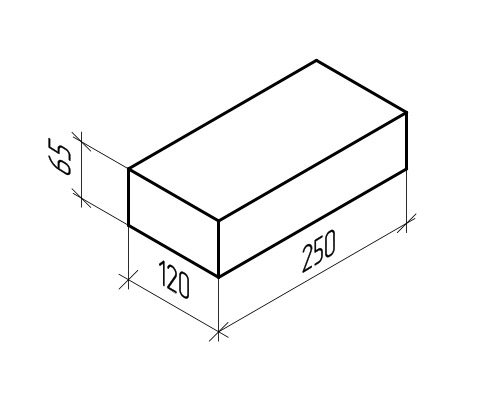

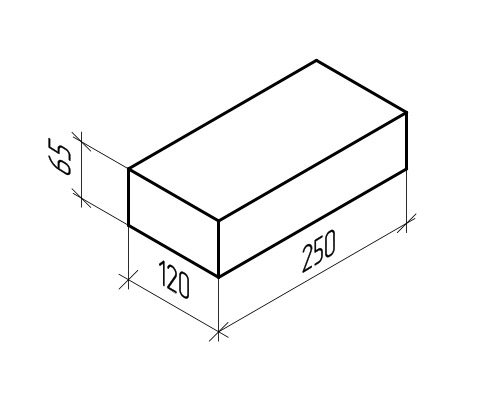

The standard size of ceramic bricks is 250 × 120 × 65mm. When performing brickwork, the bricks are laid on a 1 cm thick mortar. In order for the masonry to be strong and stable, the bricks are laid in the masonry, with the so-called bandaging of the seams.

Dimensions of standard brick masonry

The thickness of the walls is taken as a multiple of the size of half of the brick. For example, 120 mm is half a brick, 250 mm is a whole brick, 380 mm is equal to one and a half bricks, 510 mm is two bricks, and so on. Ceramic bricks are made hollow and solid, that is, with or without voids.

Dimensions of brickwork

Solid bricks are used in places where there is a need to withstand distributed loads. For example, in foundations, plinths and elsewhere. Although, external walls can be laid out of solid bricks. But this should be advisable, since the thickness of the wall can grow significantly in order to ensure the standard thermal conductivity.

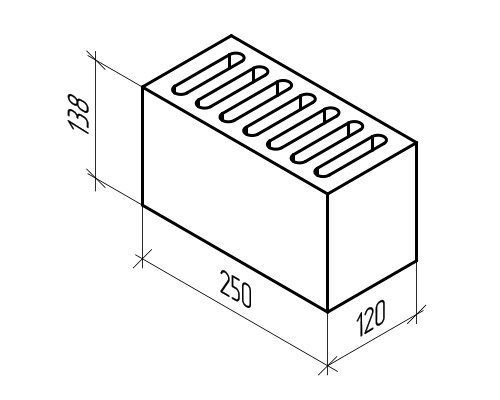

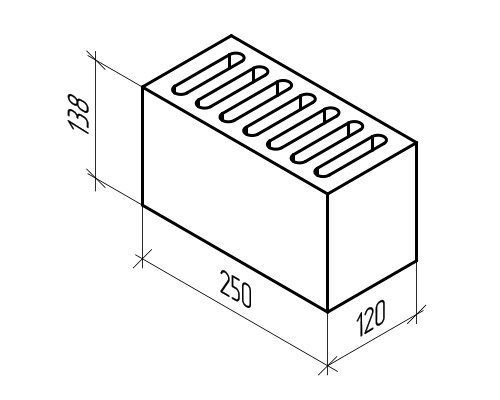

Hollow bricks, due to the presence of voids inside them, are less heat-conducting, that is, the walls of them can be thinner in size compared to solid ones. And due to their lower dead weight, they load less on the foundation of the building.

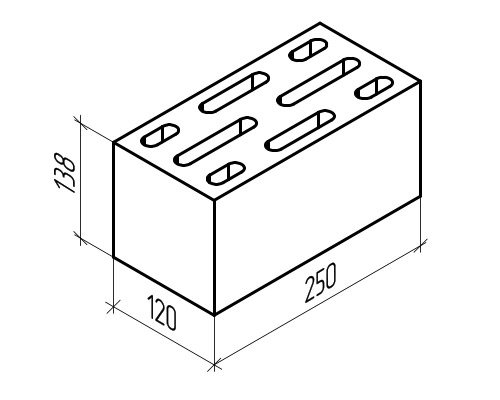

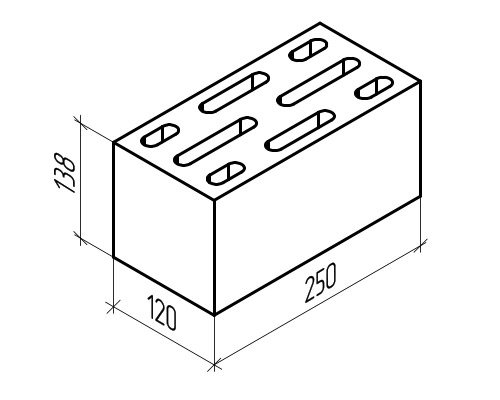

Dimensions of a standard brick

Brick with seven slotted voids

Lightweight concrete stone with slotted voids

Brick is an excellent material that has been used in construction for a long time. But its successful use largely depends on the quality of the masonry. To make the brickwork even, use a special device - order.

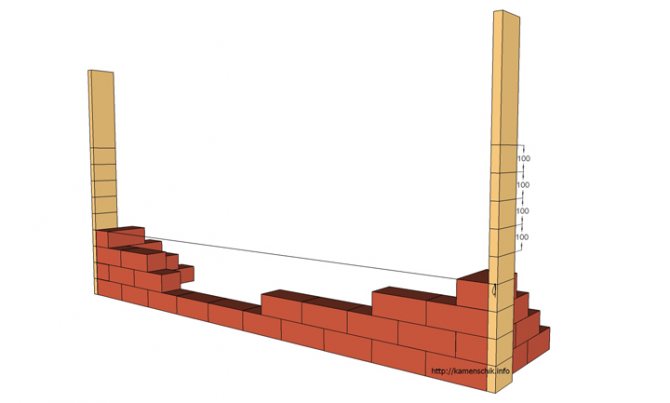

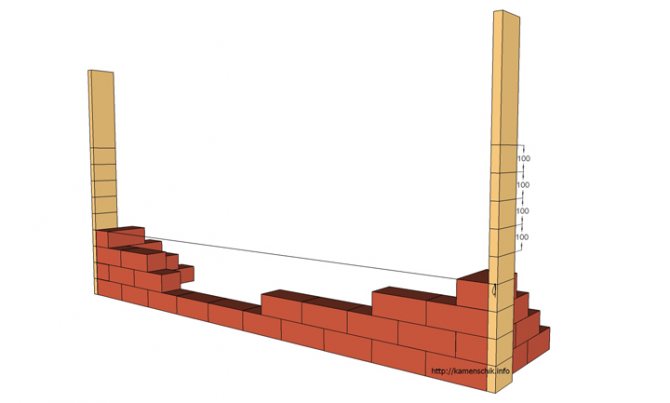

Ordering is a bar with divisions, which serves as a template for even, high-quality masonry.

The order can be made at the factory, but you can also assemble it yourself, observing the basic design principles. It helps to control the vertical and horizon level when laying bricks, speeds up the work, since it takes less time to check.

As a rule, the order is made from a metal corner or wood. The corner is taken with a size of 60x60 millimeters, and the wooden slats - with a section of 5x5 centimeters. The divisions are applied to the vertical ordering posts, according to the thickness of the brick, taking into account the width of the seams, this is approximately 77 millimeters for ordinary bricks (65 millimeters is the thickness of the brick, plus 12 millimeters for the seams) and 100 millimeters for thickened bricks (88 + 12). If a brick of a different size is used, then the distance between the divisions will be different.

The divisions can be indicated by marks in the form of serifs or slots, which are also used to stretch the mooring cord. It will indicate the horizon of the masonry and the line for vertical correction. The mooring cord is located at the level of the top of the brick in the row, each row of the masonry is equal to it.The order can be from 1 to 5 meters long. It is used in the construction of various objects: walls, fences, stoves, etc.

For the convenience of work, the order is established from the outside, by divisions inward, so that the mason can navigate along them during the masonry process.

The order from a metal profile is placed on the corners of a building or structure and attached to clamps. The end of the clamp is hammered into the seam, the screw is clamped. The second clamp is installed in the same way several rows higher. After laying the tier, the order is rearranged into the upper clamp, and the lower one is moved to the height of the next tier. It is better to clean the order from the mortar before each movement.

Intermediate orders are mounted on straight walls with a difference of 10-12 meters. They are attached to U-shaped metal brackets equipped with a transverse bar. The part is placed in the seam horizontally after 5-7 rows of masonry. The staples are placed one above the other, deepening with the ends and the transverse bar into the seam. When installing, it is important to check the verticality of the order using a plumb line. The location of the marks (notches or holes) is checked with a level. When all the parameters are verified, you can finally fix the order and pull on the mooring cord. To prevent the cord from sagging on the longest sections of the wall, an intermediate beacon is placed under it, on which the cord rests.

As you move up, the mooring cord moves to the upper level of each new row with an indent from the wall plane by approximately 3 millimeters. On the borders and at the corners of the walls, a lighthouse is laid out - a refuge shtraba. It will not only simplify further work, but also allow you to take a break.

The bendings are made 6 rows high and are used to attach the mooring cord. Ubezhnaya shtraba is a laying method in which bricks are stacked in a "ladder" with a difference of half a brick. It helps to make the dressing more secure. It is used to secure the mooring cord and connect the masonry sections. This shtraba is especially useful when you need to build a flat partition between the walls. The mooring at the lighthouses is fixed with staples every 5 meters or fastened to a nail inserted into the seam.

When all the orders are installed and the cords are taut, you need to check them again with a level and a plumb line. Further adjustments can be made using staples and beacons. When working indoors, instead of ordering, as a rule, mooring brackets are used. The lower end of the bracket is inserted into the seam of the masonry, and the other must rest on the lighthouse brick. It is to this part that the mooring cord is attached. The second end is attached to the lighthouse brick on the other side of the masonry. The mooring cord must pass from the bracket to the upper plane of the lighthouse brick.

These structures are placed with a frequency of several rows. She is allowed to work in places where it is impossible to establish order. Masonry bricks can be full or hollow. A different mortar is used for each type of brick. But in any case, it should not be too liquid, otherwise its consumption will increase dramatically. For laying bricks, you will need an ordering with a mooring cord, a plumb line, a trowel, a pick, a level, and a jointing.

The ordering allows not only to simplify the work on the masonry, but also guarantees the construction of a smooth wall along the entire length. Although erect more than six rows at a time, only a bricklayer with extensive experience can.

Ordering drawings

When making drawings of sections of buildings, with a drawing scale of 1:50 or less, the masonry on them is shaded with thin lines with an angle of inclination of 45 degrees. It is also possible to trace them along the contour with a solid main line.

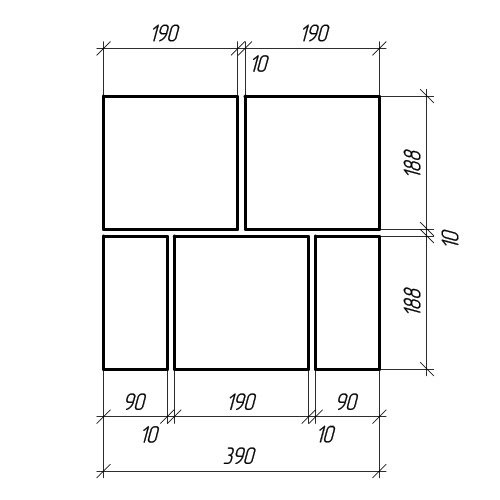

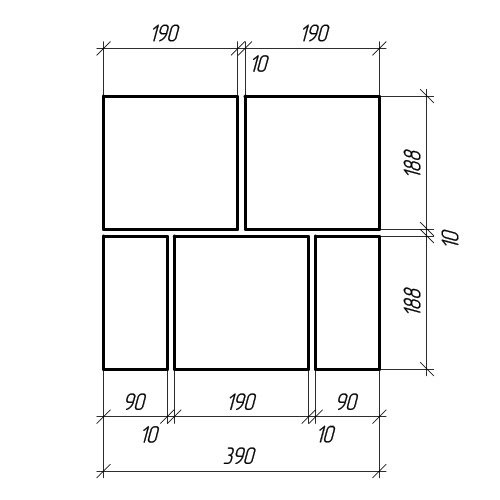

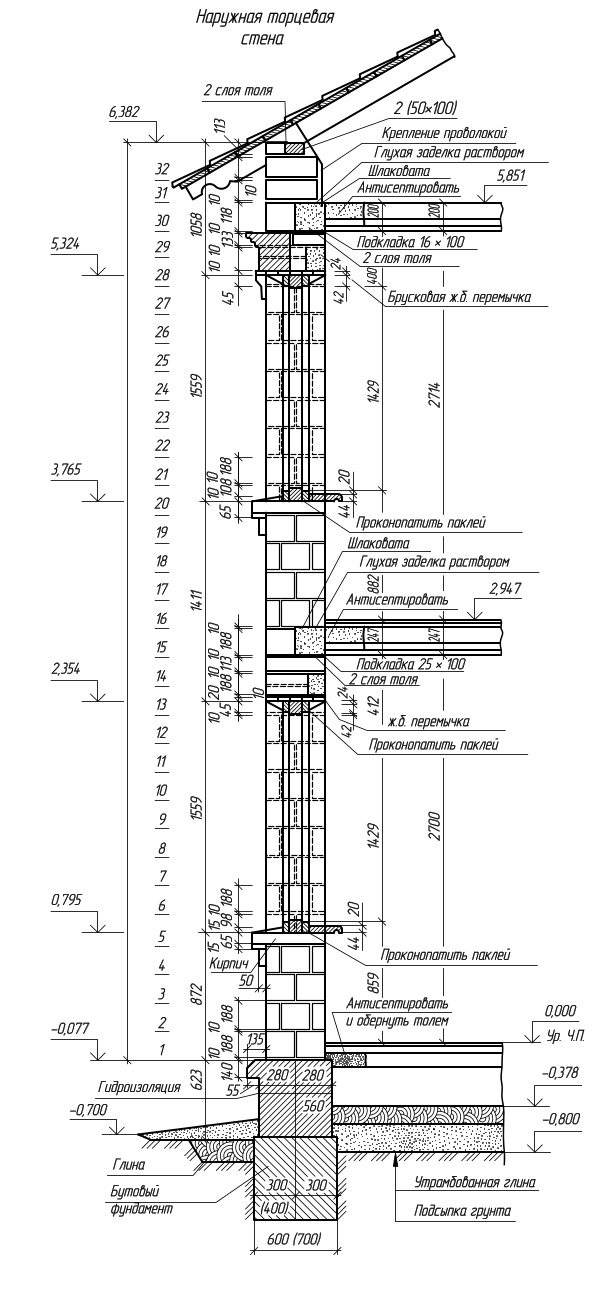

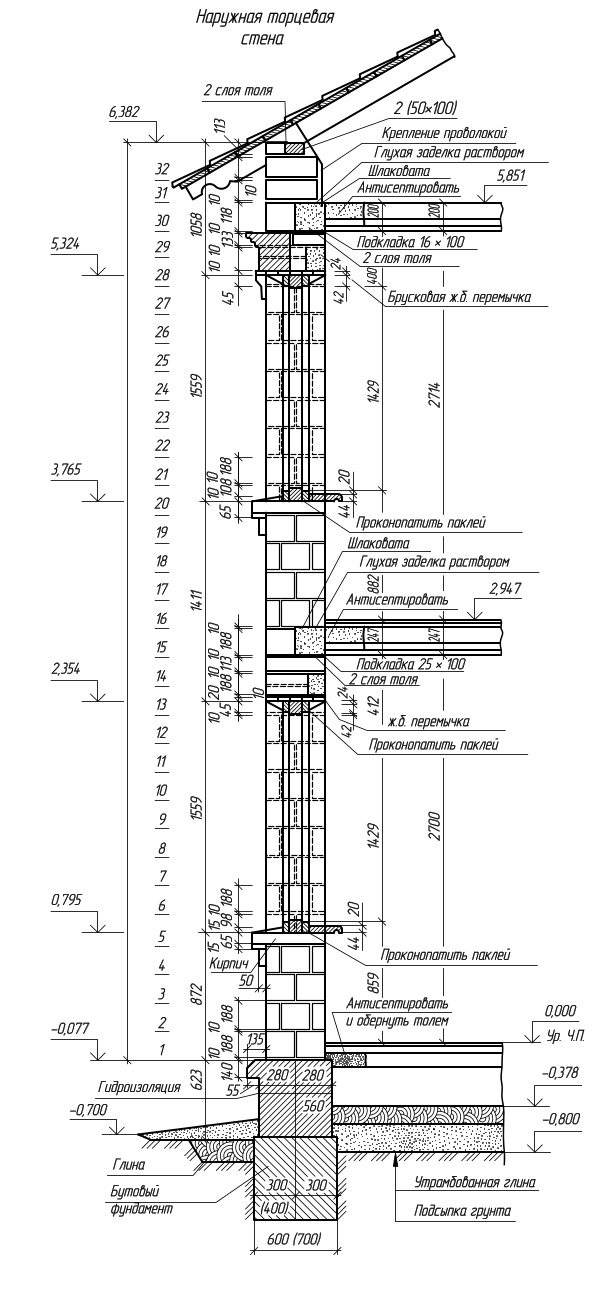

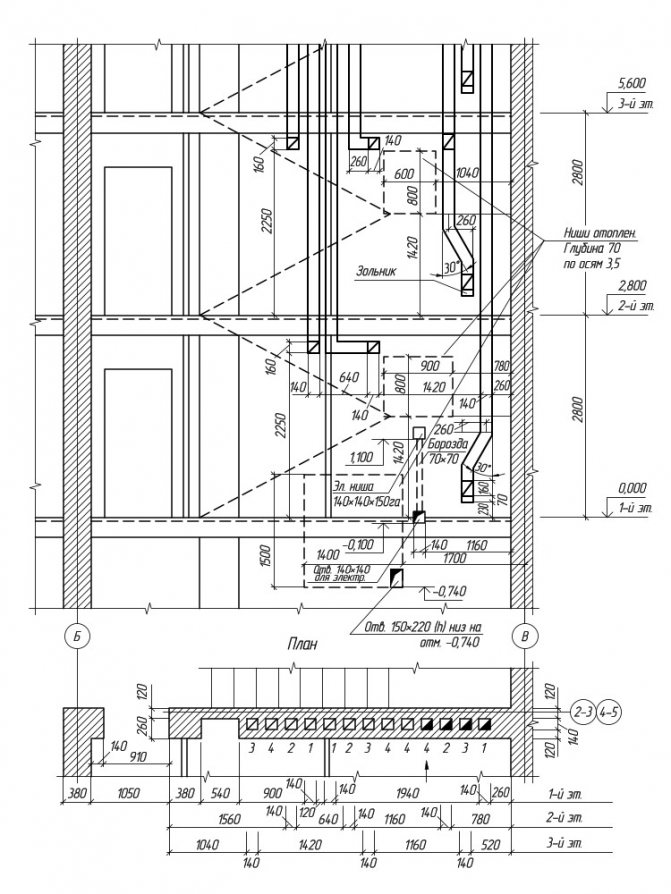

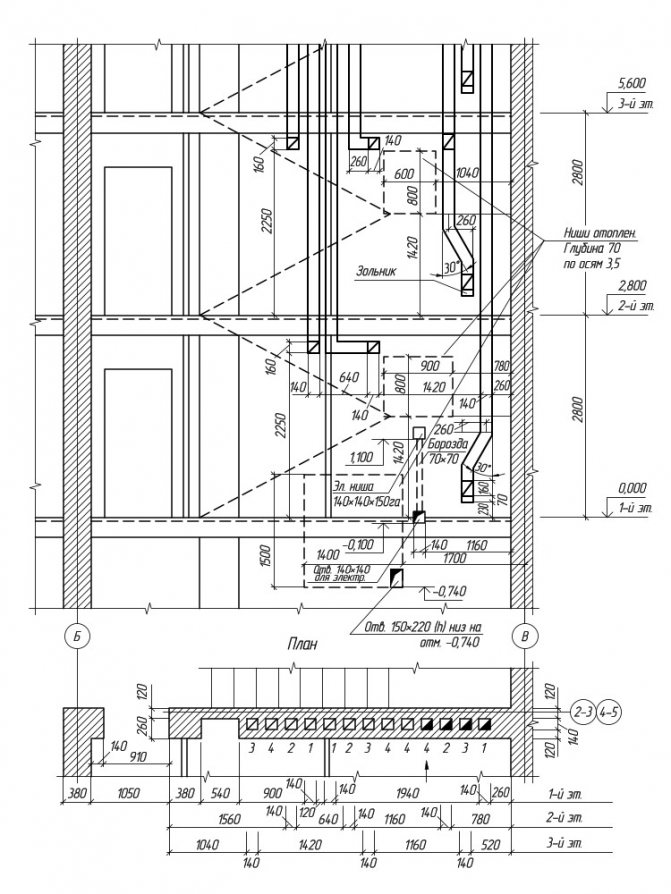

Vertical ordering from lightweight concrete stones

To depict masonry, special drawings are used, which are called orders... They are usually manufactured on a scale of 1:10 to 1:20. The illustration on the right shows the vertical arrangement.Namely, a cut in the area of the outer wall window in a two-story house. As can be seen from the drawing, its walls are lined with two types of bricks: 390 × 90 × 188 mm in size and longitudinal halves 390 × 90 × 188 mm with a mortar joint of 10 mm. In the drawing, the rows are numbered, all the dimensions necessary for reading are set, height marks are set and the necessary inscriptions are made for explanation.

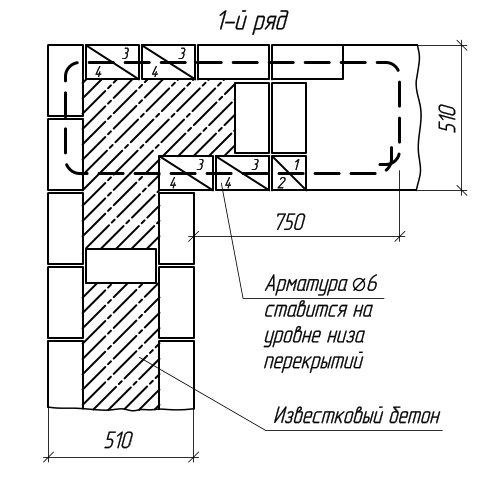

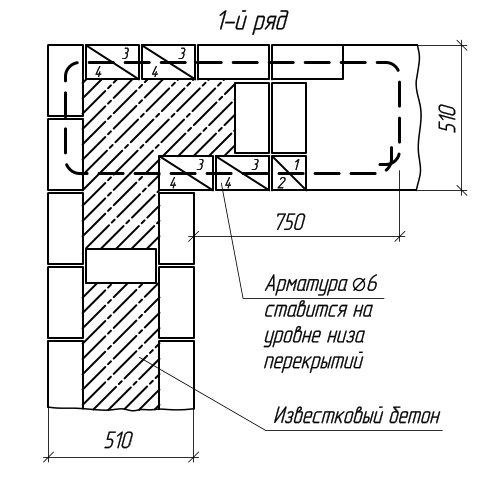

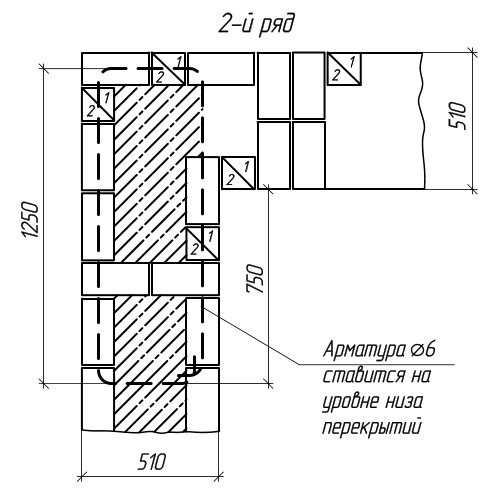

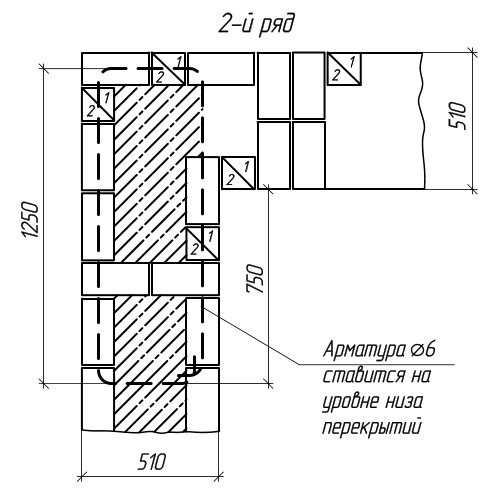

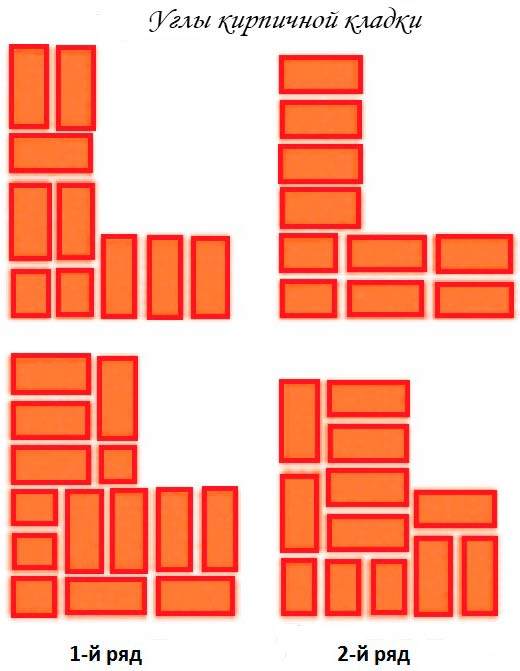

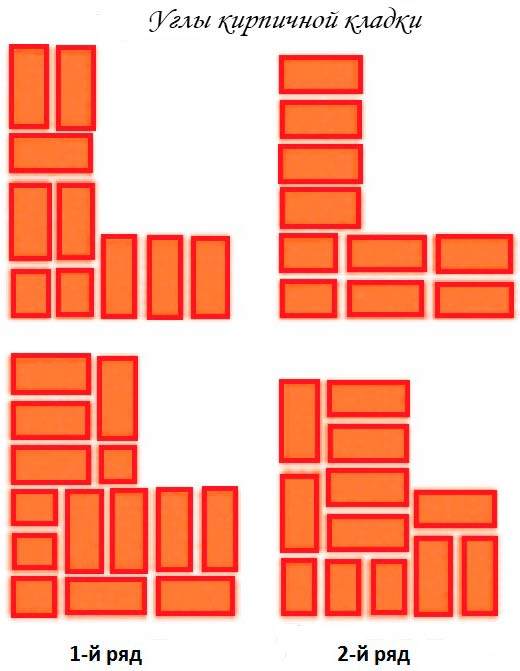

If it is required to clarify the type and type of individual structural elements, then a drawing of individual masonry units is performed. The explanatory figures below show a horizontal order of two adjacent rows for the corner of the outer wall, made of ceramic bricks. The reinforcement used in the masonry is marked with a dashed line.

Horizontal ordering of the first row

Horizontal ordering of the second row

Brick BBQ masonry

Below is a master class on laying a brick barbecue with a step-by-step photo report.

For example, an extension of a barbecue to a blank wall of a brick gazebo will be carried out.

The barbecue is laid on a concrete base (reinforced slab, 30 cm thick). Please note that a waterproofing layer is first made under the barbecue oven (2 sheets of roofing material are cut to size).

A cement-based refractory mixture "Hercules" is used as a mortar for laying bricks.

Expert advice: if you use a clay solution, then 200-250 gr can be added to a bucket of clay-sand mixture. cement M400.

Refractory fireclay bricks are used for construction. Specifically, for this design, a barbecue will need about 1200 pieces.

Masonry joint thickness:

- for the heat-resistant mixture "Hercules" - 5-7 mm;

- for oven mixture "Martel" - 3-5 mm.

Brick cutting:

- Chamfering from a brick (cutting the edge, done to give the brick a decorative effect) - a tile cutter with a 180 mm diamond disc is used

- Brick cutting - done with a grinder with a 230 mm diamond blade

Before a sharp fireclay brick is soaked for 5-10 minutes, a red brick - from 20 minutes (the lower the grade, the shorter the soaking time). For chamfering (edge), the brick is only wetted.

Flat pattern of walls with channels

If channels are provided in the wall for ventilation or chimneys, then special drawings of the wall sweep with channels are made.

The figure shows a flat pattern for walls with channels, as well as a wall plan. For the convenience of reading the drawing, the channels are highlighted with a solid main line. The openings in the ventilation ducts are shown diagonally, and in the chimney ducts, half darkened. Exactly where these channels are located is indicated by binding to the floor of the floor and to the outer wall.

For each channel, a numerical value is indicated separately, indicating on which floor the channel begins. As you can see in the figure above, on each floor of the building there are two ventilation ducts located in the bathroom and toilet rooms and one for the chimney starting in the kitchen.

Wall sweep with ventilation ducts and chimneys

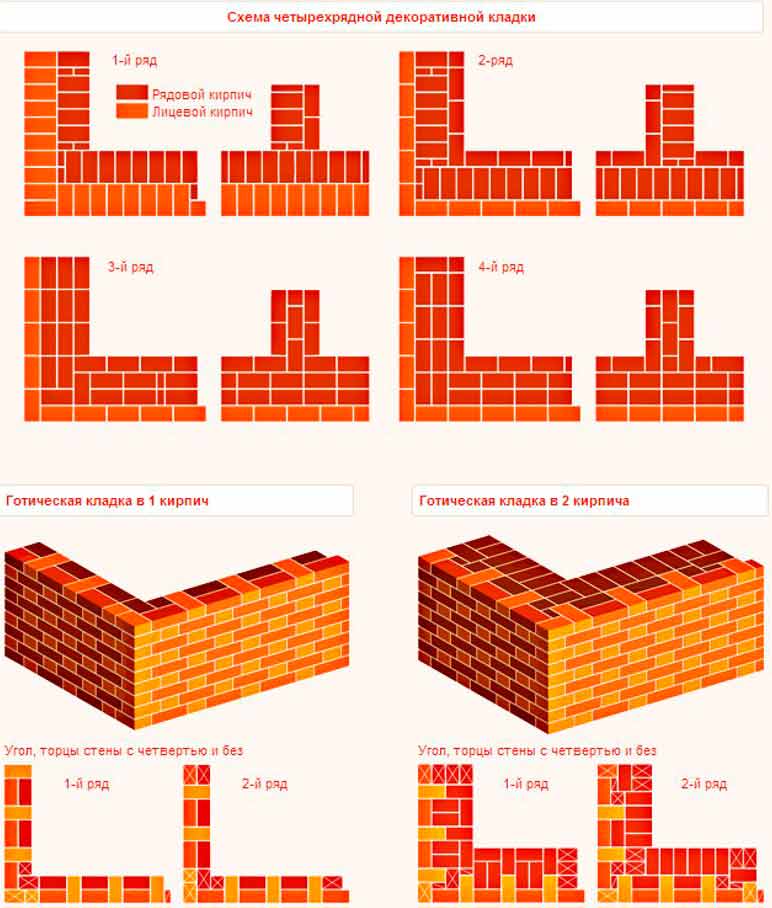

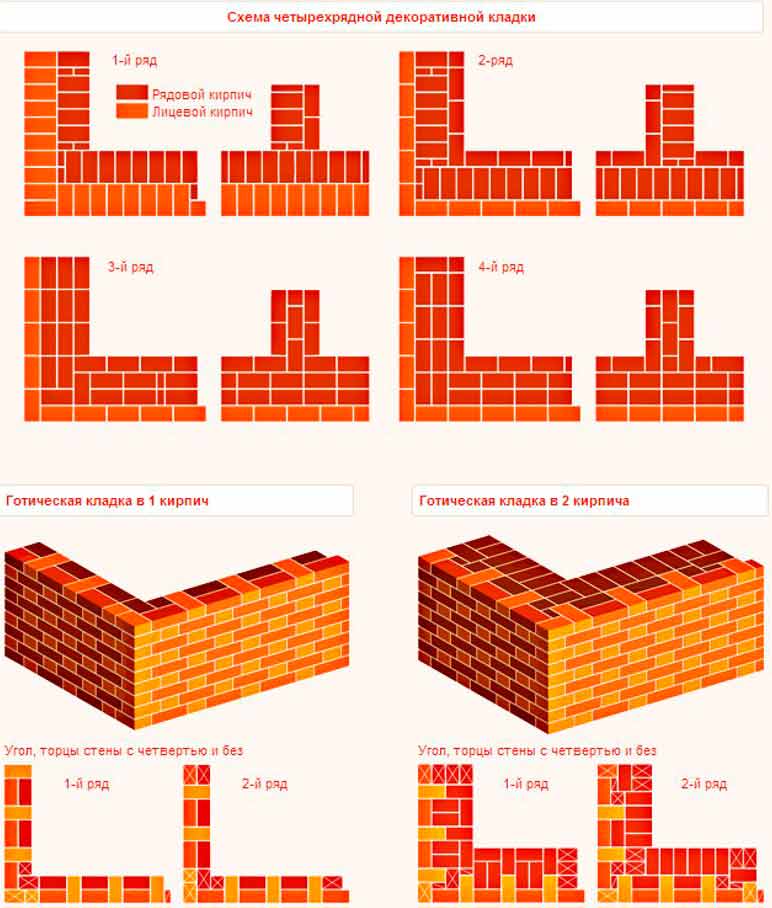

Ordering decorative masonry

In fact, there is an order twenty types of decorative masonry.

We will not touch all of them for now. But I would like to draw your attention to a couple of the main ones. Moreover, they are considered the most popular and, in my opinion, do not require large investments.

it gothic masonry, consisting of alternating rows, where spoon and butt bricks are arranged alternately. You will find this type of brickwork in seven cases out of ten. This is not surprising. Because, as I said, the ordering with Gothic masonry is considered the most popular and often used in the construction and cladding of a house. And of course, the ordering of the cross brickwork. In this masonry, there is also an alternation of spoon and poke rows of bricks.The only difference is that the alternation here goes like this: two spoon, one butt, etc.

Note: bonded masonry is when a brick with its narrow side (poke) faces the outside of the wall.

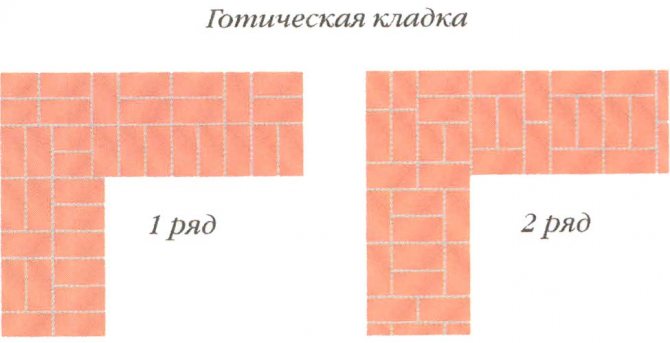

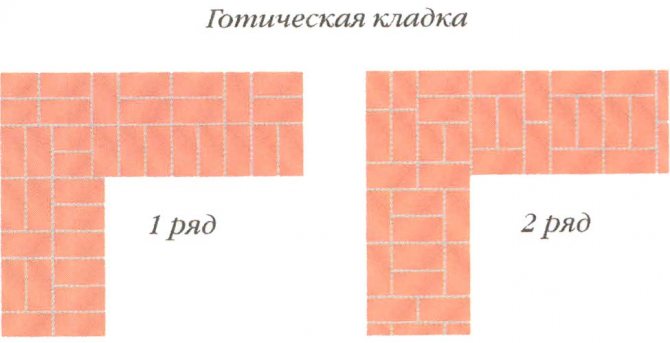

Gothic masonry

Scheme of gothic masonry in 1 and 2 bricks (click on the picture to enlarge)

The walls created with a thickness of two bricks with the order of the Gothic masonry are laid out in the following sequence. The initial row of the outer verst - alternating spoon and butt bricks, the inner verst - bricks laid with a poke, a backbone from spoon, the next row of the outer verst is the same as the first one, only with bandaging of vertical seams; the inner verst is laid out in the same way as the outer one, only the zabutka is done with pokes.

Note: a verst is the outermost rows of bricks that form the surface of the wall. ZABUTKA is a masonry located between the outer and outer verst (inner).

Right angles of brickwork with a Gothic pattern of seams on the facade begin to spread in the following order:

Gothic brickwork

Initial row:

- with three or four and a whole brick, we begin to lay out the outer verst. Further, on both sides of the corner, we alternate spoon and butt bricks;

- the inner verst is made up of two three or fours laid out with a spoon, and continues with poking;

- backing up is carried out with spoons, in the corner, fours and halves of bricks are laid out.

Laying corners

Next row:

- the outer verst begins with three or four and a whole brick, then we alternate spoons with pokes, made with bandaging of vertical seams on the facade;

- the inner verst copies the outer one;

- zabutka is carried out with pokes, and the corner is filled with a four and three or four.

During the laying of piers with Gothic patterns of seams on the facade, the initial row is laid in the same way as on sections of blank walls, only with quarters laid in the outer verst. In the second row, the inner and outer versts are identical - these are alternating pokes and spoons. To observe the dressing, the corners of the inner verst end with three or fours. Zabutka windows are made in fours.

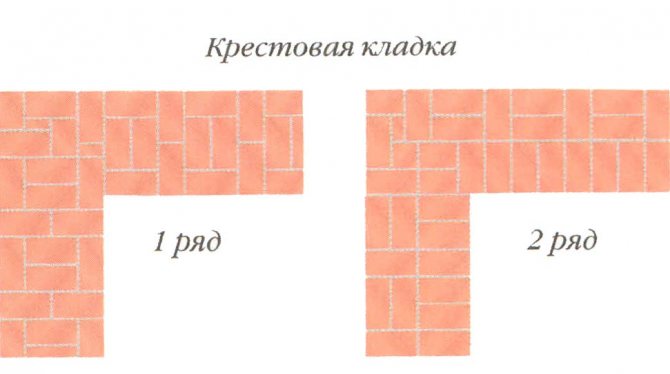

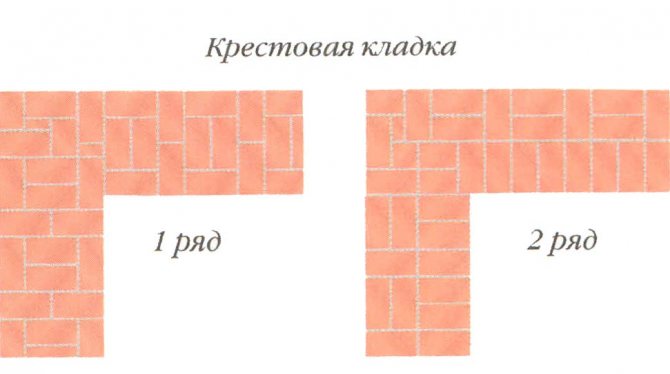

Cross brickwork

Cross masonry in 1 and 2 bricks

Walls with a thickness of two bricks with a pattern of seams of cross brickwork on the facade are lined up in the following sequence:

- the first row of the outer mile - alternating pokes with two spoons;

- inner verst - bricks lined with pokes;

- zabutka is laid out from spoon bricks.

Cross masonry

The next row of the outer mile imitates the first, but so that the vertical seam between the spoons is in the middle of the lower-lying butt;

- the inner verst copies the outer one; - the zabutka is made up of butts.

The right angles of the brickwork of the walls are laid out in the following sequence.

Initial row:

- the outer verst begins with two three or fours, laid with a spoon, then the butt and spoon bricks are laid out, then there is an alternation of a butt and two spoons, on the other side of the corner the outer verst is laid out from alternating butt and two spoons;

- the inner verst starts with two three-fours and continues with jabs on both sides of the corner;

- backing up is done with spoons.

Second row:

- the outer mile begins with two three or fours, laid with pokes, then one poke and two spoons alternate, on the other hand, a poke and spoons adjoin a three or four, and then an alternation of pokes, two spoons;

- the inner verst begins with two three-fours, tying up the bricks lying below. Laying bricks continues in the same order as in the front verst;

- zabutka is carried out with pokes, but two spoons are placed in the inner part of the corner.

Piers with cross stitch patterns on the facade are laid out in the same order:

- the initial row is the same as in the sections of blank walls, only with laying two three-fours in the outer verst;

- the next row - the inner and outer versts are the same, but to observe the dressing, halves and three-fours are used;

- the backbone is made up of bricks laid with a poke, filling the gaps with an incomplete brick.