What products can be made from a bent profile pipe

Quite often, for the construction of numerous structures, it is necessary to use bent shaped pipes as a decoration or to create a certain shape of the building.

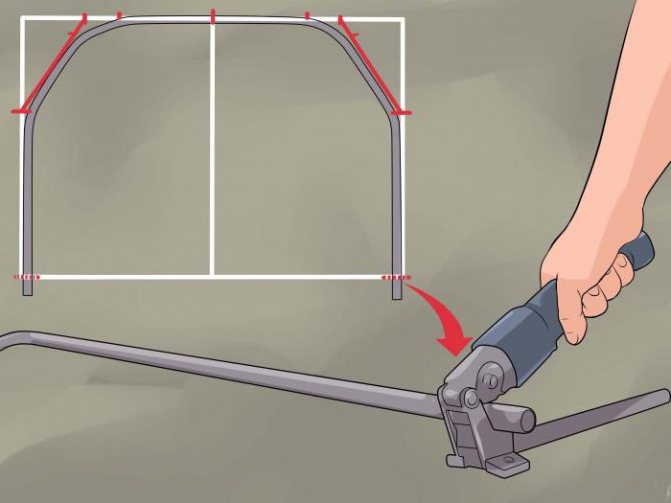

Before starting any work, you need to calculate the material and sketch the future structure schematically.

Any outdoor structures and some elements of the interior of the room can be made from shaped pipes.

What can be created using a bent professional pipe:

- Greenhouses - arched, gable structures for growing vegetables and seedlings;

- Stepladders;

- Entrance gate;

- Gazebos;

- Benches;

- Forged fences;

- Decorative arches.

Quite often, a bent profile pipe is used to create a canopy over the entrance to a house or a railing for steps to the second floor. Making furniture from a professional pipe will take more time and effort, but as a result, you can get an exclusive and beautiful decor.

Polypropylene pipe bending methods

If it is necessary to change the direction of bending of a polypropylene pipe, one of two possible methods can be used. The first involves heating the fold. For this, a construction hairdryer is usually used. The optimum heating temperature is 150 ° C. Hands should be protected with gloves that are resistant to high temperatures.

At the final stage, the product is bent to the required shape. The thickened wall should be located on the outside of the bend. Once the material has cooled, it will need to be checked for cracks and dents. Another way to bend such a pipe is cold. However, the bending radius should not be more than 8 diameters, otherwise the product may break.

Curved shaped tube for greenhouse frame

One of the most common applications of bent pipes is the frame of greenhouse structures. This frame is considered the most robust and durable when operating greenhouses at any time of the year.

When assembling the frame, metal professional pipes are connected to each other with a welding seam, and galvanized pipes can be bolted together.

Before starting work with the greenhouse frame, it is most reasonable to prepare a drawing indicating all the dimensions of the structure. For a more durable frame, a metal profile with a section of 4x4 cm with a metal thickness of 2 mm is used.

When working with shaped pipes, it is important to take into account not only the width and length of the future greenhouse, but also its height. It is these characteristics that affect the cutting of the professional pipe. It is also important to take into account the shape of the greenhouse - arched, gable or single-pitched. When calculating the material, it is recommended to take about 40 cm of stock in case of unforeseen events.

Hot bending

This method allows you to give the professional pipe the required shape without the risk of cracking and flattening. Bend lines are smooth. This method cannot be used only for zinc pipes, since during the glowing process the galvanized layer burns out, which performs the function of protecting the structure from corrosion.

Required tools and materials:

- quartz sand;

- wooden plugs - 2 pcs;

- gas welding (torch);

- drill.

Instructions:

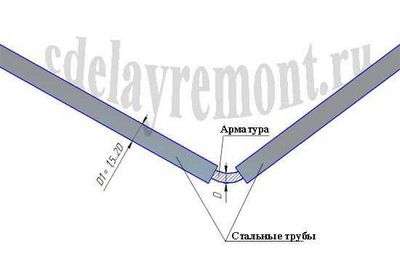

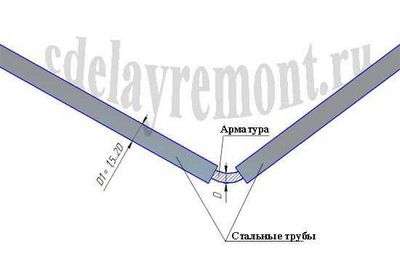

- Protruba is plugged wooden peg on the one hand, then quartz sand is poured and the opposite side is hammered in the same way. This is necessary in order to avoid deformation during the pipe bending process. Without the use of sand, the material of construction will be damaged.

- At one of the ends of the pipes, a hole is made through which air will escape during the heating process.

- The place to be bent is heated with a gas welding or torch, and then give the pipe the desired shape... When working with gas welding, all fire safety measures must be observed. It is necessary to avoid overheating of the metal, which can lead to the appearance of scale and deterioration of the performance of the product.

- Once the tubular product has acquired the desired bend, it is necessary to remove the wooden wedges and pour out the sand. The plugs can be easily pulled out by heating the ends of the professional pipe with a burner.

How to bend a square pipe at home

Very often, when arranging a site, a cottage or a summer house, it becomes necessary to use a profile pipe with a bend. In order not to go to the workshop to complete this task, many craftsmen have found ways to bend the pipe on their own using the materials at hand.

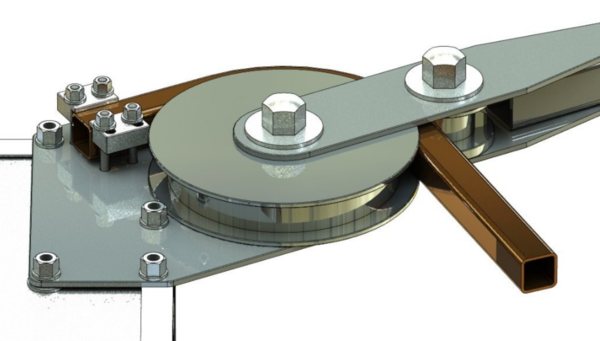

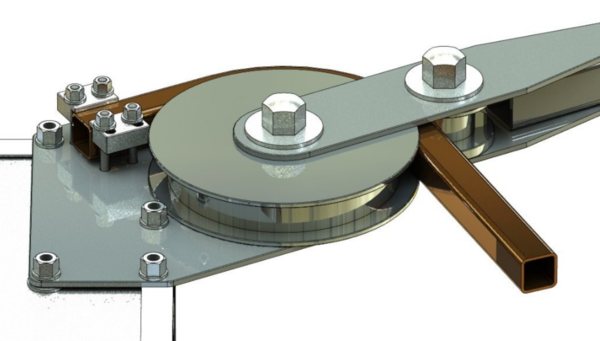

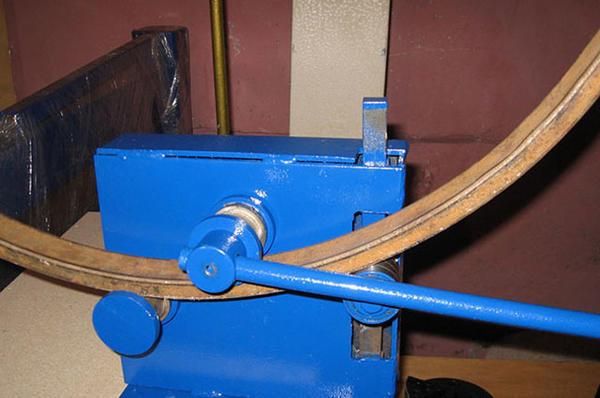

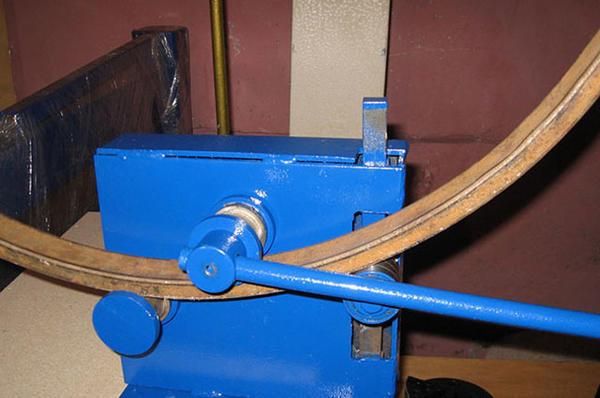

For frequent use, it is recommended to use profile bending devices that are suitable for square cross-section pipes.

It is impractical to buy this machine if the owner periodically needs to bend the profile pipes. For infrequent use, manual methods are fine.

How to bend the pipe yourself:

- Use a pipe bender. When working, you need to apply a lot of effort to bend the pipe. The device is suitable for both round and square pipes.

- Cold method. Bending consists in pre-cooling the pipe filled with water. After the liquid inside freezes, the pipe is easier to bend.

- Hot method. River sand is poured into the professional pipe, on one side with a closed cork. In the area that needs a bend, you need to make two holes. Then heat the selected area to a certain temperature and you can begin to form a bend. To do this, most often use a blank with a suitable diameter.

- Bending consists in using a grinder and a welding machine. In places of the future bend, 3 transverse cuts are made around the metal, then the pipe is bent at the desired angle. After bending, all seams must be carefully welded and cleaned.

Among the manual methods, pipe benders win, since only they make a perfect bend of the pipe with minimal effort.

How to bend rebar, sheet metal, etc. without a special tool

If you have already started a major overhaul with your own hands, regardless of where it is being carried out: at home or in an apartment, then you need to be prepared for many tests.

Including a number of questions may arise, which are very difficult to solve without proper experience and special equipment. For example, not everyone knows how to bend a sheet of metal, reinforcement, profile, corner, etc. while getting a decent result. In this article, we will try to answer the "diehard" questions, using the minimum amount of tools.

How to bend a sheet of metal, galvanized, profile

Very often, when installing metal structures, it is necessary not only to cut steel sheets, but also to give them a curved shape.

This can be done at home without spending money on the services of third parties. For example, how to bend a sheet of metal? To do this, we need a wooden or rubber hammer, pliers, a table.

If a 90-degree curvature is expected, then this set of tools should be sufficient. The sheet is simply hung from the edge of the table, after which the desired curvature is achieved by uniform tapping in the bending area.

How to make a machine for bending a profile pipe with your own hands

With the growing popularity of products from bent shaped pipes, the demand for equipment such as a pipe bender has grown. With this device, you can bend pipes of various diameters from 0 to 180 degrees.

There are 3 types of roll forming equipment:

- Hydraulic - used mainly in production;

- Electromechanical - thanks to electronics, you can accurately calculate the bend angle;

- Manual - used for bending small diameter metal profiles.

Several methods are used to create your own manual tube bender. The easiest one is to make a fixture from a wooden semicircular template.

This version of the manual tube bender is suitable for small sections of steel and aluminum.

For manufacturing you need: a piece of thick durable wood, several screws and a screwdriver.

Progress:

- We take a block of wood and cut out a hemisphere of the required diameter. Several different blanks can be made.

- The thickness of the tree should be greater than the pipe to be bent.

- We fasten the hemisphere with a screw to any base on which it will be convenient to work with a profile pipe.

- At one of the ends of the template, we fix the stop so that the pipe fits between it and the semicircular template without problems.

- Checking the pipe bender. We insert the pipe exactly between the template and the stop and bend until the desired bend angle is formed.

This method of creating a device for bending a professional pipe is the simplest and cheapest, since you can make as many templates of different diameters as you like. More serious models of pipe benders provide for the use of rollers and shafts of different sizes.

How to bend a metal pipe

To produce such a deformation, simple machines are often used in the country - pipe benders:

- Manual pipe benders. Such machines are used for bending small diameters and most often for non-ferrous metals. The process itself is quite simple - you need to install the tube into the machine, fix it, and then, using a special lever, make a fold. You can change the diameter by advancing the product in the machine and sequentially making additional folds, if, of course, your machine allows it;

- Hydraulic benders work in much the same way, but they don't require much physical force. The main action falls on the hydraulic cylinders;

- Electromechanical pipe benders are even more serious and, naturally, expensive equipment. They differ in multitasking and precision in work.

It is necessary to consider the types of pipe benders, depending on the requirements for bends and materials for the manufacture of pipes:

- Dornovy pipe bender - for products with a thin wall and small diameter;

- Spring - for manual bending using a spring (for small tubes);

- Crossbow - a machine with a finished shape for bending;

- Segment pipe bender - a machine that works by drawing a pipe around a special segment.

You can bend a metal product on a plane-parallel plate. So, having installed the workpiece in the clamps, a force is applied, due to which the pipe takes the shape of a plate. It's pretty simple and the fold is good. But in the case of working with a plate, you will receive products of exactly the same shape, with an identical bend. This is the whole low practicality of the method, since in order to obtain other forms, you will need to have several plates in the country.

There is a way that uses a metal spring. But he works with non-ferrous metals, which are soft.

The object of work is installed inside the spring, clamped with one edge in a vice and bent to the desired diameter. Thus, compressive and tensile forces are transferred from the pipe walls to the spring, and the chance that colored thin-walled material will burst is seriously reduced.

Specialist recommendations

If you are faced with the question of how to bend an aluminum pipe without a pipe bender, then you can use a grinder to carry out the work, with which several thin cuts must be made at the place of the intended bend. The product is preliminarily clamped in a vice. As soon as the cuts are made, they should be cleaned of chips, only after that you can begin to bend the pipe.

Sometimes the product needs to be bent in a circle. As soon as the ring closes, the holes are welded, and some craftsmen even use a soldering iron for this. In order to make the place of the fold neat, it is additionally sanded and covered with a protective agent. This eliminates corrosion and premature destruction of the joint.